- Privacy Policy

Buy Me a Coffee

Home » Case Study – Methods, Examples and Guide

Case Study – Methods, Examples and Guide

Table of Contents

A case study is a research method that involves an in-depth examination and analysis of a particular phenomenon or case, such as an individual, organization, community, event, or situation.

It is a qualitative research approach that aims to provide a detailed and comprehensive understanding of the case being studied. Case studies typically involve multiple sources of data, including interviews, observations, documents, and artifacts, which are analyzed using various techniques, such as content analysis, thematic analysis, and grounded theory. The findings of a case study are often used to develop theories, inform policy or practice, or generate new research questions.

Types of Case Study

Types and Methods of Case Study are as follows:

Single-Case Study

A single-case study is an in-depth analysis of a single case. This type of case study is useful when the researcher wants to understand a specific phenomenon in detail.

For Example , A researcher might conduct a single-case study on a particular individual to understand their experiences with a particular health condition or a specific organization to explore their management practices. The researcher collects data from multiple sources, such as interviews, observations, and documents, and uses various techniques to analyze the data, such as content analysis or thematic analysis. The findings of a single-case study are often used to generate new research questions, develop theories, or inform policy or practice.

Multiple-Case Study

A multiple-case study involves the analysis of several cases that are similar in nature. This type of case study is useful when the researcher wants to identify similarities and differences between the cases.

For Example, a researcher might conduct a multiple-case study on several companies to explore the factors that contribute to their success or failure. The researcher collects data from each case, compares and contrasts the findings, and uses various techniques to analyze the data, such as comparative analysis or pattern-matching. The findings of a multiple-case study can be used to develop theories, inform policy or practice, or generate new research questions.

Exploratory Case Study

An exploratory case study is used to explore a new or understudied phenomenon. This type of case study is useful when the researcher wants to generate hypotheses or theories about the phenomenon.

For Example, a researcher might conduct an exploratory case study on a new technology to understand its potential impact on society. The researcher collects data from multiple sources, such as interviews, observations, and documents, and uses various techniques to analyze the data, such as grounded theory or content analysis. The findings of an exploratory case study can be used to generate new research questions, develop theories, or inform policy or practice.

Descriptive Case Study

A descriptive case study is used to describe a particular phenomenon in detail. This type of case study is useful when the researcher wants to provide a comprehensive account of the phenomenon.

For Example, a researcher might conduct a descriptive case study on a particular community to understand its social and economic characteristics. The researcher collects data from multiple sources, such as interviews, observations, and documents, and uses various techniques to analyze the data, such as content analysis or thematic analysis. The findings of a descriptive case study can be used to inform policy or practice or generate new research questions.

Instrumental Case Study

An instrumental case study is used to understand a particular phenomenon that is instrumental in achieving a particular goal. This type of case study is useful when the researcher wants to understand the role of the phenomenon in achieving the goal.

For Example, a researcher might conduct an instrumental case study on a particular policy to understand its impact on achieving a particular goal, such as reducing poverty. The researcher collects data from multiple sources, such as interviews, observations, and documents, and uses various techniques to analyze the data, such as content analysis or thematic analysis. The findings of an instrumental case study can be used to inform policy or practice or generate new research questions.

Case Study Data Collection Methods

Here are some common data collection methods for case studies:

Interviews involve asking questions to individuals who have knowledge or experience relevant to the case study. Interviews can be structured (where the same questions are asked to all participants) or unstructured (where the interviewer follows up on the responses with further questions). Interviews can be conducted in person, over the phone, or through video conferencing.

Observations

Observations involve watching and recording the behavior and activities of individuals or groups relevant to the case study. Observations can be participant (where the researcher actively participates in the activities) or non-participant (where the researcher observes from a distance). Observations can be recorded using notes, audio or video recordings, or photographs.

Documents can be used as a source of information for case studies. Documents can include reports, memos, emails, letters, and other written materials related to the case study. Documents can be collected from the case study participants or from public sources.

Surveys involve asking a set of questions to a sample of individuals relevant to the case study. Surveys can be administered in person, over the phone, through mail or email, or online. Surveys can be used to gather information on attitudes, opinions, or behaviors related to the case study.

Artifacts are physical objects relevant to the case study. Artifacts can include tools, equipment, products, or other objects that provide insights into the case study phenomenon.

How to conduct Case Study Research

Conducting a case study research involves several steps that need to be followed to ensure the quality and rigor of the study. Here are the steps to conduct case study research:

- Define the research questions: The first step in conducting a case study research is to define the research questions. The research questions should be specific, measurable, and relevant to the case study phenomenon under investigation.

- Select the case: The next step is to select the case or cases to be studied. The case should be relevant to the research questions and should provide rich and diverse data that can be used to answer the research questions.

- Collect data: Data can be collected using various methods, such as interviews, observations, documents, surveys, and artifacts. The data collection method should be selected based on the research questions and the nature of the case study phenomenon.

- Analyze the data: The data collected from the case study should be analyzed using various techniques, such as content analysis, thematic analysis, or grounded theory. The analysis should be guided by the research questions and should aim to provide insights and conclusions relevant to the research questions.

- Draw conclusions: The conclusions drawn from the case study should be based on the data analysis and should be relevant to the research questions. The conclusions should be supported by evidence and should be clearly stated.

- Validate the findings: The findings of the case study should be validated by reviewing the data and the analysis with participants or other experts in the field. This helps to ensure the validity and reliability of the findings.

- Write the report: The final step is to write the report of the case study research. The report should provide a clear description of the case study phenomenon, the research questions, the data collection methods, the data analysis, the findings, and the conclusions. The report should be written in a clear and concise manner and should follow the guidelines for academic writing.

Examples of Case Study

Here are some examples of case study research:

- The Hawthorne Studies : Conducted between 1924 and 1932, the Hawthorne Studies were a series of case studies conducted by Elton Mayo and his colleagues to examine the impact of work environment on employee productivity. The studies were conducted at the Hawthorne Works plant of the Western Electric Company in Chicago and included interviews, observations, and experiments.

- The Stanford Prison Experiment: Conducted in 1971, the Stanford Prison Experiment was a case study conducted by Philip Zimbardo to examine the psychological effects of power and authority. The study involved simulating a prison environment and assigning participants to the role of guards or prisoners. The study was controversial due to the ethical issues it raised.

- The Challenger Disaster: The Challenger Disaster was a case study conducted to examine the causes of the Space Shuttle Challenger explosion in 1986. The study included interviews, observations, and analysis of data to identify the technical, organizational, and cultural factors that contributed to the disaster.

- The Enron Scandal: The Enron Scandal was a case study conducted to examine the causes of the Enron Corporation’s bankruptcy in 2001. The study included interviews, analysis of financial data, and review of documents to identify the accounting practices, corporate culture, and ethical issues that led to the company’s downfall.

- The Fukushima Nuclear Disaster : The Fukushima Nuclear Disaster was a case study conducted to examine the causes of the nuclear accident that occurred at the Fukushima Daiichi Nuclear Power Plant in Japan in 2011. The study included interviews, analysis of data, and review of documents to identify the technical, organizational, and cultural factors that contributed to the disaster.

Application of Case Study

Case studies have a wide range of applications across various fields and industries. Here are some examples:

Business and Management

Case studies are widely used in business and management to examine real-life situations and develop problem-solving skills. Case studies can help students and professionals to develop a deep understanding of business concepts, theories, and best practices.

Case studies are used in healthcare to examine patient care, treatment options, and outcomes. Case studies can help healthcare professionals to develop critical thinking skills, diagnose complex medical conditions, and develop effective treatment plans.

Case studies are used in education to examine teaching and learning practices. Case studies can help educators to develop effective teaching strategies, evaluate student progress, and identify areas for improvement.

Social Sciences

Case studies are widely used in social sciences to examine human behavior, social phenomena, and cultural practices. Case studies can help researchers to develop theories, test hypotheses, and gain insights into complex social issues.

Law and Ethics

Case studies are used in law and ethics to examine legal and ethical dilemmas. Case studies can help lawyers, policymakers, and ethical professionals to develop critical thinking skills, analyze complex cases, and make informed decisions.

Purpose of Case Study

The purpose of a case study is to provide a detailed analysis of a specific phenomenon, issue, or problem in its real-life context. A case study is a qualitative research method that involves the in-depth exploration and analysis of a particular case, which can be an individual, group, organization, event, or community.

The primary purpose of a case study is to generate a comprehensive and nuanced understanding of the case, including its history, context, and dynamics. Case studies can help researchers to identify and examine the underlying factors, processes, and mechanisms that contribute to the case and its outcomes. This can help to develop a more accurate and detailed understanding of the case, which can inform future research, practice, or policy.

Case studies can also serve other purposes, including:

- Illustrating a theory or concept: Case studies can be used to illustrate and explain theoretical concepts and frameworks, providing concrete examples of how they can be applied in real-life situations.

- Developing hypotheses: Case studies can help to generate hypotheses about the causal relationships between different factors and outcomes, which can be tested through further research.

- Providing insight into complex issues: Case studies can provide insights into complex and multifaceted issues, which may be difficult to understand through other research methods.

- Informing practice or policy: Case studies can be used to inform practice or policy by identifying best practices, lessons learned, or areas for improvement.

Advantages of Case Study Research

There are several advantages of case study research, including:

- In-depth exploration: Case study research allows for a detailed exploration and analysis of a specific phenomenon, issue, or problem in its real-life context. This can provide a comprehensive understanding of the case and its dynamics, which may not be possible through other research methods.

- Rich data: Case study research can generate rich and detailed data, including qualitative data such as interviews, observations, and documents. This can provide a nuanced understanding of the case and its complexity.

- Holistic perspective: Case study research allows for a holistic perspective of the case, taking into account the various factors, processes, and mechanisms that contribute to the case and its outcomes. This can help to develop a more accurate and comprehensive understanding of the case.

- Theory development: Case study research can help to develop and refine theories and concepts by providing empirical evidence and concrete examples of how they can be applied in real-life situations.

- Practical application: Case study research can inform practice or policy by identifying best practices, lessons learned, or areas for improvement.

- Contextualization: Case study research takes into account the specific context in which the case is situated, which can help to understand how the case is influenced by the social, cultural, and historical factors of its environment.

Limitations of Case Study Research

There are several limitations of case study research, including:

- Limited generalizability : Case studies are typically focused on a single case or a small number of cases, which limits the generalizability of the findings. The unique characteristics of the case may not be applicable to other contexts or populations, which may limit the external validity of the research.

- Biased sampling: Case studies may rely on purposive or convenience sampling, which can introduce bias into the sample selection process. This may limit the representativeness of the sample and the generalizability of the findings.

- Subjectivity: Case studies rely on the interpretation of the researcher, which can introduce subjectivity into the analysis. The researcher’s own biases, assumptions, and perspectives may influence the findings, which may limit the objectivity of the research.

- Limited control: Case studies are typically conducted in naturalistic settings, which limits the control that the researcher has over the environment and the variables being studied. This may limit the ability to establish causal relationships between variables.

- Time-consuming: Case studies can be time-consuming to conduct, as they typically involve a detailed exploration and analysis of a specific case. This may limit the feasibility of conducting multiple case studies or conducting case studies in a timely manner.

- Resource-intensive: Case studies may require significant resources, including time, funding, and expertise. This may limit the ability of researchers to conduct case studies in resource-constrained settings.

About the author

Muhammad Hassan

Researcher, Academic Writer, Web developer

You may also like

Questionnaire – Definition, Types, and Examples

Observational Research – Methods and Guide

Quantitative Research – Methods, Types and...

Qualitative Research Methods

Explanatory Research – Types, Methods, Guide

Survey Research – Types, Methods, Examples

To read this content please select one of the options below:

Please note you do not have access to teaching notes, integration in a mixed-method case study of construction phenomena: from data to theory.

Engineering, Construction and Architectural Management

ISSN : 0969-9988

Article publication date: 19 October 2021

Issue publication date: 27 February 2023

This study demonstrates integration within a mixed-methods case study of construction phenomena, whilst ensuring reliability and validity. This is in view of the established philosophical challenges in theory generation, whereby qualitative and quantitative methods are underpinned by divergent, almost incompatible, paradigmic assumptions.

Design/methodology/approach

The study uses a sample case study research on the phenomenon of cost overruns, supported by a coherent flow of well-articulated philosophical arguments to idealise the logic of integration. Issues of reliability and validity were resolved along these lines, by incorporating applicable criteria from both the qualitative and qualitative strands. A detailed outline and rationalisation of the stepwise approach to achieving integration are provided, from the point of design conceptualisation, data collection, analysis and further down to theory generation.

The study generated two level-1 theories by collecting numerical data on cost overruns, geotechnical index parameters and textual data on the geotechnical practices. Another level-1 theory was generated in reflexive adaptation to unanticipated social constructs emerging from the qualitative data. All level-1 theories from the quantitative and qualitative strands were triangulated to yield two “level-2 theories”: A log-regression model and a cognitive map. The approach to integration is thus explanatory sequential, and concurrent (at the second stage of transformation in the generation of level-2 theories).

Research limitations/implications

The study empirically reinforces that ontological flexibility, achievable through the use of thoughtfully designed integrated mixed-methods case studies, permits the investigation of multidimensional construction phenomena in innovative ways, relevant to provide holistic theoretical and practice-based contributions.

Originality/value

The study practically signposts a bespoke stepwise approach to integration, in a mixed-methods case study of construction phenomena, against the contextual backdrop of its relative novelty and lack of studies delving in-depth into the theoretical nitty-gritty.

- Construction

- Design conceptualisation

- Integration

- Mixed methods

- Qualitative

- Quantitative

- Reliability

Amadi, A. (2023), "Integration in a mixed-method case study of construction phenomena: from data to theory", Engineering, Construction and Architectural Management , Vol. 30 No. 1, pp. 210-237. https://doi.org/10.1108/ECAM-02-2021-0111

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

Have a language expert improve your writing

Run a free plagiarism check in 10 minutes, generate accurate citations for free.

- Knowledge Base

Methodology

- What Is a Case Study? | Definition, Examples & Methods

What Is a Case Study? | Definition, Examples & Methods

Published on May 8, 2019 by Shona McCombes . Revised on November 20, 2023.

A case study is a detailed study of a specific subject, such as a person, group, place, event, organization, or phenomenon. Case studies are commonly used in social, educational, clinical, and business research.

A case study research design usually involves qualitative methods , but quantitative methods are sometimes also used. Case studies are good for describing , comparing, evaluating and understanding different aspects of a research problem .

Table of contents

When to do a case study, step 1: select a case, step 2: build a theoretical framework, step 3: collect your data, step 4: describe and analyze the case, other interesting articles.

A case study is an appropriate research design when you want to gain concrete, contextual, in-depth knowledge about a specific real-world subject. It allows you to explore the key characteristics, meanings, and implications of the case.

Case studies are often a good choice in a thesis or dissertation . They keep your project focused and manageable when you don’t have the time or resources to do large-scale research.

You might use just one complex case study where you explore a single subject in depth, or conduct multiple case studies to compare and illuminate different aspects of your research problem.

Here's why students love Scribbr's proofreading services

Discover proofreading & editing

Once you have developed your problem statement and research questions , you should be ready to choose the specific case that you want to focus on. A good case study should have the potential to:

- Provide new or unexpected insights into the subject

- Challenge or complicate existing assumptions and theories

- Propose practical courses of action to resolve a problem

- Open up new directions for future research

TipIf your research is more practical in nature and aims to simultaneously investigate an issue as you solve it, consider conducting action research instead.

Unlike quantitative or experimental research , a strong case study does not require a random or representative sample. In fact, case studies often deliberately focus on unusual, neglected, or outlying cases which may shed new light on the research problem.

Example of an outlying case studyIn the 1960s the town of Roseto, Pennsylvania was discovered to have extremely low rates of heart disease compared to the US average. It became an important case study for understanding previously neglected causes of heart disease.

However, you can also choose a more common or representative case to exemplify a particular category, experience or phenomenon.

Example of a representative case studyIn the 1920s, two sociologists used Muncie, Indiana as a case study of a typical American city that supposedly exemplified the changing culture of the US at the time.

While case studies focus more on concrete details than general theories, they should usually have some connection with theory in the field. This way the case study is not just an isolated description, but is integrated into existing knowledge about the topic. It might aim to:

- Exemplify a theory by showing how it explains the case under investigation

- Expand on a theory by uncovering new concepts and ideas that need to be incorporated

- Challenge a theory by exploring an outlier case that doesn’t fit with established assumptions

To ensure that your analysis of the case has a solid academic grounding, you should conduct a literature review of sources related to the topic and develop a theoretical framework . This means identifying key concepts and theories to guide your analysis and interpretation.

There are many different research methods you can use to collect data on your subject. Case studies tend to focus on qualitative data using methods such as interviews , observations , and analysis of primary and secondary sources (e.g., newspaper articles, photographs, official records). Sometimes a case study will also collect quantitative data.

Example of a mixed methods case studyFor a case study of a wind farm development in a rural area, you could collect quantitative data on employment rates and business revenue, collect qualitative data on local people’s perceptions and experiences, and analyze local and national media coverage of the development.

The aim is to gain as thorough an understanding as possible of the case and its context.

Prevent plagiarism. Run a free check.

In writing up the case study, you need to bring together all the relevant aspects to give as complete a picture as possible of the subject.

How you report your findings depends on the type of research you are doing. Some case studies are structured like a standard scientific paper or thesis , with separate sections or chapters for the methods , results and discussion .

Others are written in a more narrative style, aiming to explore the case from various angles and analyze its meanings and implications (for example, by using textual analysis or discourse analysis ).

In all cases, though, make sure to give contextual details about the case, connect it back to the literature and theory, and discuss how it fits into wider patterns or debates.

If you want to know more about statistics , methodology , or research bias , make sure to check out some of our other articles with explanations and examples.

- Normal distribution

- Degrees of freedom

- Null hypothesis

- Discourse analysis

- Control groups

- Mixed methods research

- Non-probability sampling

- Quantitative research

- Ecological validity

Research bias

- Rosenthal effect

- Implicit bias

- Cognitive bias

- Selection bias

- Negativity bias

- Status quo bias

Cite this Scribbr article

If you want to cite this source, you can copy and paste the citation or click the “Cite this Scribbr article” button to automatically add the citation to our free Citation Generator.

McCombes, S. (2023, November 20). What Is a Case Study? | Definition, Examples & Methods. Scribbr. Retrieved March 25, 2024, from https://www.scribbr.com/methodology/case-study/

Is this article helpful?

Shona McCombes

Other students also liked, primary vs. secondary sources | difference & examples, what is a theoretical framework | guide to organizing, what is action research | definition & examples, what is your plagiarism score.

Improving Mid-Term, Intermediate, and Long-Range Cost Forecasting for State Transportation Agencies (2020)

Chapter: 3 case study methodology.

Below is the uncorrected machine-read text of this chapter, intended to provide our own search engines and external engines with highly rich, chapter-representative searchable text of each book. Because it is UNCORRECTED material, please consider the following text as a useful but insufficient proxy for the authoritative book pages.

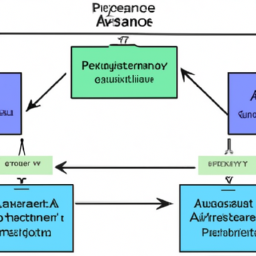

26 3 Case Study Methodology 3.1 Introduction Case studies are in-depth investigations of subjects, groups, or phenomena on their respective real- life contexts, providing researchers with a better view of the problem at hand and facilitating the detection of issues that could have passed unnoticed with other research instruments. The unique perspective of the research problem provided by a case study allows researchers to better fill intended and unintended knowledge gaps. Case studies in this research project were conducted with the state transportation agencies (STAs) of Minnesota (MnDOT), Colorado (CDOT), and Delaware (DelDOT). This chapter discusses the case study objectives and methodology, including a general description of the data collection, cleaning, and processing efforts undertaken by the research team. The chapter also introduces the different cost indexing approaches considered in the study, with a general description of the alternative Multilevel Construction Cost Index (MCCI) approach. The actual application of the case study methodology and its results are described in the following chapters. 3.2 Case Study Objective The case studies were mainly intended to contribute to the accomplishment of the second project objective stated in Section 1.1: conducting a qualitative and quantitative assessment of the current practices by comparing forecasted cost estimates with actual cost outcomes. Case study results were consolidated into the following outputs: ï· A protocol to perform a comparative suitability analysis of cost indexing alternatives (Chapter 4) ï· Guidelines to apply different cost forecasting approach (Chapter 5) ï· The Cost Forecasting Approach Selection Framework (Chapter 6) ï· Guidance to use the Cost Forecasting Toolkit (Chapter 6) ï· Other relevant findings and observations. 3.3 Case Study Methodology Figure 3.1 illustrates the methodology followed by the research team for each of the selected case study agencies. Each case study started with the collection and cleaning of 20 years of historical bid data, which was required to perform a long-range âforecasts vs. actual outcomesâ analysis. Data gathering efforts also included historical index values from five external construction cost indexes (CCIs). Those indexes are also available to the case study agencies (and to all STAs) as possible inputs to cost forecasting processes. In the case of MnDOT and CDOT, their case studies also involved in-house CCIs. The comparative analysis in Figure 3.1 was divided into two parts. The first part consisted of a comparative suitability analysis among various cost indexing alternatives (i.e., multiple MCCI versions, external and in-house indexes), while the second part

27 was intended for the assessment and comparison of different cost forecasting methods. After completion of the three case studies, the team proceeded to synthesize all results and observations into the outputs listed above in Section 3.2. Calculations for MnDOTâs case study were repeated, assuming that only the most recent 10 years of data were available in an attempt to assess the implications of using a smaller amount of historical bid data. Figure 3.1 Case Study Methodology The historical bid data was used to develop different MCCI versions for each agency, served as a reference to assess the suitability of various cost indexing alternatives (as explained in Chapter 4), and to assess the level of accuracy and reliability of the forecasting methods under consideration (as explained in Chapter 5). The application of both parts of the comparative analysis to the three case studies allowed the research team to refine the procedures for the suitability analysis of cost indexes (first part) and for the implementation of each cost forecasting approach (second part). The refined procedures correspond to the first two outputs listed in Section 3.2. The following sections are related to the initial steps in the case study methodology shown in Figure 3.1. Those are the collection and cleaning of historical bid data, the collection of data from existing CCIs, and a general description of the MCCI system developed with the collected historical bid data. 3.4 Historical Bid Data Collection and Cleaning Table 3.1 summarizes the amount of historical bid data collected from each case study agency in terms of the number of years of data and the number of projects that provided that data. Considerable data collection efforts were required to gather 20 years of bid data from each agency. That amount of data was required to effectively assess the performance of the cost forecasting practices over long periods of time. Data from MnDOT and DelDOT was collected directly from bid tabulations posted on their websites for all projects awarded between 1999 and 2018. CDOTâs data was provided directly by the agency and comprises project awarded between 1994 and 2013. Appendix A summarizes a number of attributes from the dataset collected from each agency. Table 3.1 Summary of Collected Historical Bid Data per Agency Agency Years of Bid Data Number of Projects Minnesota DOT 1999 â 2018 (20 years) 4,299 Colorado DOT 1994 â 2013 (20 years) 2,653 Delaware DOT 1999 â 2018 (20 years) 1,530

28 The original format of the collected data was not ideal for data analysis and processing, especially to handle the large amounts of data used in this study. Part of the data cleaning efforts undertaken by the research team aimed to reformat the data into a tidy format while merging the data from all projects into a single dataset. Figure 3.2 shows a screen capture of a small portion of the tidy dataset created for MnDOT. Figure 3.2 Example of Tidy Dataset â MnDOTâs Tidy Dataset âTidy datasets are easy to manipulate, model and visualize, and have a specific structure: each variable is a column, each observation is a row, and each type of observational unit is a tableâ (Wickham 2014). There is only one observational unit in this study: pay items included in the collected projects. Thus, there is only one table, with each row referring to a single pay item used in a given project. The columns correspond to all the available information associated with each pay item and its respective contract. Information provided for each pay item on each row includes, but is not limited to, item identification number, item description, awarded quantity, unit of measurement, contract identification number, project location (e.g., county, district), and unit price submitted by each bidder. 3.4.1 Outlier Detection and Removal Another critical part of the data cleaning process consisted of removing observations that do not belong with the rest of the data, generally called outliers. âUsually, the presence of an outlier indicates some sort of problem. This can be a case that does not fit the model under study, or an error in measurementâ (Cho et al. 2010). In this study, the authors used two different outlier identification methods that were strategically selected and applied to serve different purposes. The first outlier detection approach used was the modified Z-score method. It was applied following the guidelines provided by Iglewicz and Hoaglin (1993), and at the Pay Item Level (to each row) in order to identify outliers among the unit prices received for the same item under the same contract. While some of those errors could correspond to typographical mistakes, or the misinterpretation of the scope contained within the unit price, a number of them are the result of unbalanced bids (Rueda 2016). âA bid is considered unbalanced if the unit rates are substantially higher or lower, in relation to the estimate and the rates quoted by other biddersâ (JICA 2000). There are three main reasons that could lead a contractor to unbalance a bid: 1) to protect its intended profit or fixed cost which could be partially lost if actual quantities of work are less than the bid quantities; 2) to maximize profits by taking advantage of errors in the quantities of work

29 listed in the solicitation documents; or 3) to inflate prices for early activities to reduce financial costs (the cost of borrowing money) (FHWA 1988). Regardless of the possible ethical implications associated with unbalanced bids, this is a common practice among construction contractors, and could mislead STAs when tracking market changes over time. The second outlier detection approach was used as a secondary filter to remove outliers overlooked by the modified Z-score method. The missed outliers could have resulted from unusual project requirements that may have forced all contractors to bid outside the typical unit price ranges. Since the modified Z-score method compares unit prices for the same item under a given contract, it may find no outliers if all bidders are forced to submit unit prices substantially higher (or lower) than those typically paid by the agency for the same pay item in other projects. The second outlier detection approach used in this study was the Robust Regression and Outlier Removal method (ROUT). This method was developed by Motulsky and Brown in 2006 and combines robust regression and non-linear regression techniques to identify values that could be significantly apart from the regression equation. Detailed information about the application of the two outlier detection methods used in this study is provided in NCHRP Research Report 953: Improving Mid- Term, Intermediate, and Long-Range Cost Forecasting: Guidance for State Transportation Agencies. 3.5 Existing Cost Indexing Alternatives In addition to the different MCCI versions developed for each case study (see Section 3.6.4), the cost indexing alternatives considered by the research team included five external and two in-house CCIs. Three of those indexes, including the in-house CCIs, are classified as highway construction indexes, one is a building/vertical construction index, and two are macroeconomic indexes. Table 3.2 shows some general information about those indexes. It should be noted that MnDOTâs and CDOTâs in-house cost indexes were only used with their respective case studies. The five existing indexes include the national and the regional versions of the RSMeans CCI. Although RSMeans cost indexes are mainly intended for the vertical and commercial construction industry, this study found that RSMeans CCIs are an option considered by some STAs. Table 3.2 outlines the components (or inputs) used in the calculation of each index, as well as their applicability, which refers to their geographic scope (i.e., national, state, and regional). The final column in this table refers to the updating frequency of each index. This is how often a new index value is generated; on an annual, quarterly, or monthly basis.

30 Table 3.2 Existing Construction Cost Indexes Index Components Applicability Updating Frequency Highway Construction Federal Highway Administration: National Highway Construction Cost Index (NHCCI) ï· Bid data from highway construction contracts executed by STAs National Quarterly Minnesota Department of Transportation: Construction Composite Cost Index (CCI) ï· Excavation Index - Excavation ï· Structures Index - Reinforcing Steel - Structural Steel - Structural Concrete ï· Surfacing Index - Bituminous Pavement - Concrete Pavement Minnesota Quarterly &Annual Colorado Department of Transportation: Colorado Construction Cost Index (CCI) ï· Earthwork ï· Hot Mix Asphalt ï· Concrete Pavement ï· Structural Concrete ï· Reinforcing Steel Colorado Quarterly Building Construction RSMeans Construction Cost Index (CCI) ï· 9 types of buildings - 66 construction materials - Wage rates for 21 different trades - 6 types of construction equipment National & Regional Annual Macroeconomic Indexes Bureau of Labor Statistics (BLS): Consumer Price Index (CPI) ï· 80,000 items in a market basket of goods and services purchased by urban consumers National Monthly Bureau of Economic Analysis (BEA): Personal Consumption Expenditures (PCE) Price Index ï· Actual and imputed expenditures of households, including data pertaining to durable and non-durable goods and services National Quarterly 3.6 Multilevel Construction Cost Index This section presents a general description of the configuration and process to develop the different MCCI versions evaluated in this study. A more detailed and technical description of the MCCI development and updating process (i.e., mathematical and statistical procedures) is presented in the Transportation Cost Forecasting Guidebook. An MCCI consists of a group of indexes organized in a multilevel arrangement. Thus, each cost element in a program/project can be

31 individually represented by its closest matching MCCI index. After selecting the most relevant group of MCCI indexes for the scope of work under consideration, they are mathematically combined into a single scope-based CCI, which is then used to generate annual inflation rates. Costs for different programs/projects are forecasted with different sets of indexes, offering great flexibility to customize the forecasting process to the specifics of each program or project. MCCIs are built with a basket of relevant pay items selected according to the procedures described in the following section. 3.6.1 Defining Basket of Pay Items for MCCI The âbasket of pay itemsâ in the title of this section refers to the set of contract pay items used to create an MCCI. In an ideal world, an STA would be able to easily track the prices of all its contract pay items. However, most items are not frequently used, making it difficult to track their pricing variability over time. Likewise, some pay items with a low frequency of use and low impact on total project costs may not be worth monitoring. The research team performed the following steps to find the largest possible group of significant repetitive pay items to build the MCCIs for the case study agencies: 1. Discard those items whose units do not consistently refer to the same set of specifications or amounts work (e.g. each, lump sum), and keep those units that are comparable between projects (e.g. linear feet, cubic yards, tons). Pay items measured on an âeachâ or âlump sumâ basis are usually not comparable between projects. Therefore, it is not appropriate to track price fluctuations for those items using historical unit prices. 2. Identify those pay items frequently used by the agency, ideally but not necessarily, at least once in the first and second halves of each year. For this study, the calendar year is divided into two periods as follows: Period 1 (P1) from January 1 to June 30 and Period 2 (P2) from July 1 to December 31. Although items used on a semi-annual frequency are preferred, that is not a strict requirement since that could lead to the dismissal of relevant items whose frequency of use could skip a few periods. As explained later in this chapter, the structure of the MCCI system facilitates an effective handling of missing values. 3. Discard those items that show no apparent correlation between their unit prices and their respective quantities of work. As explained in the following section, an ideal cost indexing system takes into consideration the quantity-unit price relationship to effectively quantify price fluctuations over time. Appendix B shows the final basket of pay items developed for each agency. A total of 61, 40, and 37 representative pay items remained for MnDOT, CDOT, and DelDOT, respectively, after following the three steps listed above. The number of items is less than 1% of the entire list of pay items used by those agencies. However, they could represent over 25% of their annual construction budgets. 3.6.2 MCCI Configuration and Calculation The basket of pay items selected for each agency was then used to develop several cost indexes organized in a multilevel arrangement like the one shown in Figure 3.3. This figure illustrates the

32 five-level arrangement with the 96 cost indexes developed with CDOTâs 40 representative pay items. The lowest level is the Pay Item Level, which contains one cost index for each of the selected 40 pay items. This level has the most specific cost indexes. Each of the 40 cost indexes at this level is only intended to be used on its respective pay item. Figure 3.3 Example of MCCI Configuration â CDOT MCCI Following a bottom-up calculation approach, CDOTâs indexes at the Pay Item Level were used to calculate the 28 indexes at the Sub-Division Level 1, which are less specific. Similarly, the indexes at the Sub-Division Level 1 were used to calculate 22 broader indexes at the Sub-Division Level 2, and so on until reaching the top level where a single general index was calculated at the Agency Level. All indexes were developed with a semi-annual updating frequency, with index values updated twice every year, once on June 30, and again on December 31. A semi-annual recalculation approach was selected in this study because an exploratory data analysis anticipated an inconsistent quarterly supply of data for some of the chosen pay items. Likewise, a semi-annual updating frequency was preferred over annual updates because shorter periods can better reflect the volatility of the construction market (Molenaar et al. 2013). As explained in the previous section, there are a number of factors that would prevent STAs from developing Pay Item Level indexes for all their pay items. However, if that were possible, the agency would always be able to fully meet the matching principle (see Section 1.4.1) at the project level since each pay item could be paired with an index calculated with its own historical data. On the other side of the spectrum, the worst possible matching would correspond to a situation where the Agency Level index is equally applied to all pay items. This would be the equivalent to the traditional use of a one-size-fits-all cost index, with zero flexibility to adapt to the intended scope of work. The use of an MCCI to model the fluctuation of prices for a typical project would be expected to include cost indexes from various, or all, MCCI levels. This means that MCCI users would usually be somewhere in-between the ends of the matching principle spectrum. The greater the use of indexes at lower MCCI levels, the better the matching, as well as the proportionality. As explained

33 in Section 1.4.1, the degree at which the matching principle is met would affect the ability of the cost index to meet the proportionality principle. Perfect proportionality could only be achieved after ensuing perfect matching. An appropriate identification of the maximum number of suitable MCCI pay items with the process proposed in the previous section, as well as a sound MCCI configuration would contribute to the maximization of the matching degree between the resulting cost indexes and the intended scopes of work. A sound configuration would be achieved by ensuring that all MCCI cost indexes at each level are appropriately and thoughtfully grouped to create upper level indexes. It should be noted that the discussion about the matching and proportionality principles presented in this section occurs at the project level. However, as discussed in the next section, scope-based CCIs at the program level are developed by combining project level CCIs from a selected group of sample projects. Therefore, a greater use of lower level indexes would have a similar impact at the program level, improving the degree of matching. Even though STAs execute hundreds of contracts per year, it is not possible to ensure that every item in a representative group of cost items will be used during each index period, which could result in missing index values. Unlike traditional CCIs, the multilevel arrangement of MCCIs facilitates a mechanism to avoid missing index values due to lack of data by allowing the use of corresponding upper indexes to fill the gaps. Calculations to develop MCCIs are divided into two major steps: 1) calculation of indexes at the Pay Item Level and 2) bottom-up calculation of indexes at upper levels. Step 1: Calculation of Indexes at the Pay Item Level The first step is the calculation of all indexes at the Pay Item Level. Since those are single- component indexes (calculated with a single pay item), there is no need to deal with the challenges associated with the combination of different types of index inputs. Nevertheless, to effectively track unit price fluctuations at the Pay Item Level, it is necessary to consider the economies of scale principle. âEconomies of scale refers to a reduction in total cost per unit as output increasesâ (Betts 2007). The higher the quantities of work, the lower the unit price (Zhang and Sun 2007; Akintoye 2000). Figure 3.4 uses MnDOTâs Common Excavation pay item to illustrate the concept of economies of scale. This figure shows some awarded unit prices for that pay item (in dollars per cubic yard [CY]) paid by MnDOT during a 5-year period. As shown in this figure, the quantity-unit price relationship for this excavation activity can be modeled using a non-linear regression model. More specifically, Figure 3.4 shows a power regression curve, which is a regression approach commonly used to explain the reduction in unit prices as the quantities of work increase (Rueda 2016; Pakalapati 2018). Power regression functions were used to model unit prices for all items at the Pay Item Level.

34 Figure 3.4 MnDOT Unit Price Model for Common Excavation 2008-2012 Traditional cost indexing approaches have a limited capacity to consider the economies of scale principle. For example, a traditional indexing approach could indicate a reduction in the price of excavation if the unit price paid last year for 10,000 cubic yards of common excavation is compared against the price paid today for 200,000 cubic yards. However, the price difference could actually be due to the significant difference in the amount of excavation delivered under each contract. To address this problem, the two previous studies using the MCCI approach (Gransberg and Rueda 2014; Pakalapati and Rueda 2018) defined a number of quantity ranges for each pay item. Assuming that quantities of work within each range have comparable unit prices, they proceeded to track price changes for each quantity range. A single price change measure for each item was then estimated as a weighted average of all quantity ranges. Although the use of quantity ranges proved to be an effective approach, it required considerable quantitative efforts to establish quantity ranges, track price changes within each range, and combine measures from all quantity ranges into a single measure of change. This study has proposed an improvement to that approach by tracking the average movements of the power regression curve. For instance, if a curve for a given item moves up 10%, the index for that pay item is increased by 10%. More details about the calculation of the cost indexes at the Pay Item Level can be found in the Transportation Cost Forecasting Guidebook. Step 2: Bottom-Up Calculation of Indexes at Upper Levels The second major step in the development of an MCCI refers to bottom-up calculations to define indexes at the upper levels. To calculate the indexes on the Sub-Division Level 1, indexes at the Pay Item Level are grouped based on similar characteristics and aggregated to produce a single overall cost index per group. It means that, for CDOTâs MCCI in Figure 3.3, 28 groups were formed out of the 40 pay item cost indexes, resulting in the 28 indexes at Sub-Division Level 1. In a similar way, these 28 indexes were divided into 22 groups to produce the 22 indexes at Sub- Division Level 2, and so on until calculating a single Agency Level index with the 5 indexes from the Division Level. The combination of similar indexes into a higher-level index is just the

35 weighted average of the grouped items at the lower level. Weights for this calculation are proportional to the dollar amounts spent on the items under consideration during each indexing period. Indexes at all levels are grouped according to the coding scheme used by each STA to classify its pay items. Pay item identification numbers could communicate information about the scope, materials, and/or activities associated with each item. Thus, pay items with similar identification numbers can be assumed to be closely related. STAsâ pay item coding schemes, which usually align with their standard specification books, are also used in this study to label each of the cost indexes in the MCCI. Table 3.3 shows how some of the indexes were grouped and labeled across all CDOTâs MCCI versions. This table only shows identification labels for indexes across the bottom-up pathways of the 13 pay item indexes under Division 2. Divisions 3 to 5 also have downward ramifications, but those are not shown in Table 3.3. Table 3.3 CDOTâs MCCI Levels and Configuration Pay Item Level Sub-Division Level 1 Sub-Division Level 2 Division Level Agency Level 202-00035 202-000 202 2 1 202-00210 202-002 202-00220 202-00240 202-00250 203-00010 203-000 203 203-00060 203-00100 203-001 206-00000 206-000 206 206-00065 206-00100 206-001 206-00360 206-003 207-00205 207-002 207 - - - 3 - - - 4 - - - 5 The MCCIs developed for MnDOT and DelDOT have slightly different configurations than the one shown in Table 3.3, but those are also five-level MCCIs and the bottom-up calculation process and upward ramifications follow the same general principles. A complete version of Table 3.3, as well as the corresponding tables for MnDOT and DelDOT can be found in Appendix B. Each STAâs MCCI configuration should be adjusted according to its unique pay item classification system. Table 3.4 shows the number of cost indexes developed at each MCCI level for each agency.

36 Table 3.4 Number of Cost Indexes per Level per Case Study Agency Agency MnDOT CDOT DelDOT Agency Level 1 1 1 Division Level 12 5 7 Sub-Division Level 2 21 22 14 Sub-Division Level 1 28 28 21 Pay Item Level 61 40 37 Total No. of Cost Indexes 123 96 80 As moving from the Pay Item Level to the Agency Level, the number of digits used to identify the MCCI indexes is reduced, meaning that now the index represents a broader scope of work. In other words, the degree of detail of an index is given by its MCCI level, with the scope becoming increasingly broader at upper levels. For example, cost indexes 203-00010 and 203-00060 in Table 3.3 only represent these two specific pay items. Bid data from these two indexes was then used to calculate cost index 203-000 at Sub-Division Level 1, which is intended to represent all items that start with 203-000. In the same way, index 203 represents all pay items that start with 203 and index 2 represents all pay items starting with 2. The Division Level corresponds to the actual construction divisions from the STAâs standard specification book. All the construction divisions in CDOT Standard Specification Book are listed below (CDOT 2019). Thus, in the case of CDOT, index 2 represents the overall market behavior of earthwork activities, comprising all pay items starting with 2. ï· Division 2 â Earthwork ï· Division 3 â Bases ï· Division 4 â Pavements ï· Division 5 â Structures 3.6.3 Development of Scope-Based CCIs As mentioned before in this report, one of the most important benefits offered by MCCIs is the ability to customize the cost forecasting process to meet the specifics of each project or program through the use of scope-based CCIs. This section presents the process to generate scope-based CCIs from an MCCI at both the project and program level. Project-Specific Cost Indexes The process of generating a project-specific CCI is illustrated with the asphalt paving project shown in Table 3.5. This is a real project awarded by MnDOT. In summary, a project-specific cost index is developed by combining individual relevant MCCI indexes; one MCCI index for each anticipated pay item. Each pay item is paired with the MCCI index that best represents its scope, as indicated by its item identification number. The final project-specific CCI is just the weighted average of the selected MCCI indexes. The weight for each pay item is proportional to its contribution to the total estimated project cost. Weights are calculated using engineering estimates since actual awarded prices would not be known until awarding the project. Likewise, engineering estimates are calculated based on current prices observed at the moment of developing the project-

37 specific CCI. It should be noted that, at this point of the process, the relative relevance of each item is more important than predicting the actual prices to be submitted by the successful contractor at eh letting date. Table 3.5 Asphalt Paving Project â MnDOT Sample Project Item Number Description Units Weight MCCI Index 2021501/00010 Mobilization LS 2.3781% 2 2051501/00010 Maintenance and Restoration of Haul Roads LS 0.0001% 2 2104509/00055 Remove Twisted End Treatment EACH 0.1203% 2104 2104521/00220 Salvage Guard Rail-Plate Beam L F 0.1077% 2104521/00220 2104601/01011 Haul Salvaged Material LS 0.0595% 2104 2105501/00010 Common Excavation C Y 0.0773% 2105501/00010 2221501/00010 Aggregate Shouldering Class 1 TON 1.9326% 2 2221604/00010 Aggregate Shouldering S Y 0.1231% 2 2232501/00040 Mill Bituminous Surface (1.5\'') S Y 0.3325% 2232501/00040 2232602/00010 Milled Rumble Strips EACH 0.3266% 2232602/00010 2357606/00010 Bituminous Material for Shoulder Tack GAL 0.0195% 2357606/00010 2360501/22200 Type SP 12.5 Wearing Course Mixture (2,b) TON 82.7320% 2360501/22200 2411507/00060 Concrete End Post EACH 1.5658% 2411 2540602/00150 Mail Box Support EACH 0.1359% 2 2554501/00001 Traffic Barrier Design Special L F 0.6992% 2554501 2554501/02007 Traffic Barrier Design B8307 L F 0.3703% 2554501/02007 2554501/02038 Traffic Barrier Design B8338 L F 0.6268% 2554501/02038 2554521/00020 Anchorage Assembly-Plate Beam EACH 0.1364% 2554 2554523/00028 End Treatment-Tangent Terminal EACH 0.2610% 2554 2563601/00010 Traffic Control LS 4.1618% 2 2580603/00010 Interim Pavement Marking L F 0.5916% 2580603/00010 2582501/03008 Pavement Message (Stop Ahead) Epoxy EACH 0.1567% 258 2582502/41104 4\'' Solid Line White-Epoxy L F 2.4801% 258 2582502/41524 24\'' Stop Line White-Epoxy L F 0.0266% 258 2582502/42104 4\'' Solid Line Yellow-Epoxy L F 0.3017% 258 2582502/42204 4\'' Broken Line Yellow-Epoxy L F 0.2770% 258 TOTAL 100.00% Table 3.5 shows the weight and MCCI index selected for each item. The latter refers to the index identification labels in the last column of the table (see the configuration of MnDOTâs MCCI in Appendix B). Those labels are equivalent to the labels shown in Table 3.3 for CDOT. For example, an item like 2580606/00010 - Interim Pavement Marking in Table 3.5 has its own index at the Pay Item Level. On the other hand, item 2582502/41104 - 4\'' Solid Line White-Epoxy had to move up to the MCCI Division Level to find its best matching index. It should be noted that cost indexes at MnDOTâs Division Level are identified with three-digit labels (e.g., 258). Likewise, the identification number for all MnDOTâs pay items always start with 2; therefore, that is the single- digit label for the Agency Level index (see Appendix B). The weighted sum for the combination of the selected MCCI indexes is a simple process. It is exactly the same as the bottom-up calculation process explained in the previous section for the development of indexes at upper levels. A more detailed description of this process can be found in NCHRP Research Report 953. Table 3.6 and Figure 3.5 show an example of a project-specific CCI generated for the asphalt paving project in Table 3.5 using one of the MCCI versions

38 developed for MnDOT (see Section 3.6.4). All project- and program-specific CCIs developed with the proposed methodology are set to start with an index value of 100. Index values in the order of hundreds are commonly used in CCIs (Gransberg and Rueda, 2014). Table 3.6 Example of Project-Specific CCI â CCI for MnDOTâs Sample Asphalt Paving Project Date Index Date Index Date Index Date Index P1-1999 100.00 P1-2004 98.33 P1-2009 167.73 P1-2014 206.80 P2-1999 95.56 P2-2004 107.63 P2-2009 154.21 P2-2014 234.74 P1-2000 104.65 P1-2005 111.53 P1-2010 180.67 P1-2015 232.07 P2-2000 102.32 P2-2005 129.98 P2-2010 211.10 P2-2015 208.51 P1-2001 103.47 P1-2006 137.55 P1-2011 176.54 P1-2016 250.10 P2-2001 119.04 P2- 2006 160.08 P2-2011 135.62 P2-2016 174.95 P1-2002 114.94 P1-2007 146.38 P1-2012 202.39 P1-2017 223.16 P2-2002 100.77 P2-2007 170.48 P2-2012 168.01 P2-2017 236.04 P1-2003 100.13 P1-2008 158.46 P1-2013 205.13 P1-2018 245.06 P2-2003 104.46 P2-2008 162.91 P2-2013 224.80 P2-2018 278.82 Figure 3.5 Example of Project-Specific CCI â MnDOTâs Asphalt Paving Project Program-Specific Cost Indexes The first step in the creation of program-specific cost indexes is to understand the composition of the scope of work associated with the program. Some programs, like bridge or pavement management programs, are aimed to plan construction activities for a specific type of work. In those cases, the program-specific cost index could be a project-specific index for a carefully selected sample project intended to represent the scope of the intended program. For example, the asphalt paving project in Table 3.5 was originally identified as a good representative of MnDOTâs typical asphalt paving activities. Thus, a planning program focused only on asphalt paving could use the index shown in Table 3.6 and Figure 3.5 to determine a program-specific inflation rate.

39 The process to develop program-specific indexes for programs that involve various types of work (such as LRTPs) has a few additional steps, but it is still a simple four-step process: 1. Identify the different types of work contained in the program. 2. Approximate the percentage of the total program that corresponds to each type of work. These percentages will be used as weights in Step 4. 3. Identify a sample project that reasonably represents each type of work and develop project- specific CCIs for those projects. This step may not always be required since the agency could create and maintain a library of generic cost indexes for typical types of work. 4. Combine all project-specific indexes through a weighted average calculation using the weights defined at Step 2. The simplicity of this methodology also facilitates sensitivity analyses to evaluate multiple scenarios or to quantify the risk of having drastic changes in the anticipated distribution of work within the program. For example, Figure 3.6 shows three possible program-specific indexes that could be developed by MnDOT for a statewide pavement program that combines asphalt paving (AP) and concrete paving (CP) activities. Figure 3.6 Example of Program-Specific CCI â MnDOT Paving Program The three program-specific indexes in Figure 3.6 correspond to three different distributions of the amounts of work associated with each pavement material (50%/50%; 30%/70%; and 70%/30%). These hybrid indexes are the result of a weighted average calculation between an Asphalt Paving and a Concrete Paving CCI. The Asphalt Paving CCI is the same project-specific CCI shown in Figure 3.5, which is assumed to represent all asphalt paving activities. Similarly, the Concrete Paving CCI in Figure 3.6 is a project-specific CCI for a representative concrete paving project. All the examples of project- and program-specific CCIs presented in this chapter were developed with one of the 20 MCCI versions developed for MnDOT: a statewide MCCI calculated with all unit 80 100 120 140 160 180 200 220 240 260 280 6/ 30 /1 99 9 6/ 29 /2 00 0 6/ 29 /2 00 1 6/ 29 /2 00 2 6/ 30 /2 00 3 6/ 29 /2 00 4 6/ 29 /2 00 5 6/ 30 /2 00 6 6/ 30 /2 00 7 6/ 29 /2 00 8 6/ 30 /2 00 9 6/ 30 /2 01 0 6/ 30 /2 01 1 6/ 29 /2 01 2 6/ 30 /2 01 3 6/ 30 /2 01 4 6/ 30 /2 01 5 6/ 30 /2 01 6 6/ 30 /2 01 7 6/ 30 /2 01 8 In de x Va lu e Date Aphalt Paving CCI Concret Paving CCI ProgramâSpecific CCI (50% AP; 50% CP) ProgramâSpecific CCI (30% AP; 70% CP) ProgramâSpecific CCI (70% AP; 30% CP)

40 prices submitted by both successful and unsuccessful contractors. The following section provides more information about all the MCCI versions developed for each of the three case study agencies. 3.6.4 MCCI Versions Under Consideration As mentioned before, various MCCI versions were developed for each agency in an attempt to identify the most effective one at representing the regional construction market. All MCCI versions for each agency follow the configurations in Appendix B. The difference between versions lies in their geographic scope (statewide and regional) and their type of price input: awarded unit prices (submitted by the selected contractors); average unit prices per project; median unit prices per project; and all unit prices received from both successful and unsuccessful contractors. Tables 3.7 to 3.9 outline the different MCCI versions developed for each agency. Table 3.7 MnDOT - Multilevel Construction Cost Index Classification Geographic Classification Description Statewide Multilevel Construction Cost Indexes Statewide MCCI with Awarded Unit Prices Statewide MCCI with Average Unit Prices per Project Statewide MCCI with Median of Unit Prices per Project Statewide MCCI with All Unit Prices Regional Multilevel Construction Cost Indexes Region Description North North MCCI with Awarded Unit Prices North MCCI with Average Unit Prices per Project North MCCI with Median of Unit Prices per Project North MCCI with All Unit Prices North Central North Central MCCI with Awarded Unit Prices North Central MCCI with Average Unit Prices per Project North Central MCCI with Median of Unit Prices per Project North Central MCCI with All Unit Prices South Central South Central MCCI with Awarded Unit Prices South Central MCCI with Average Unit Prices per Project South Central MCCI with Median of Unit Prices per Project South Central MCCI with All Unit Prices South South MCCI with Awarded Unit Prices South MCCI with Average Unit Prices per Project South MCCI with Median of Unit Prices per Project South MCCI with All Unit Prices

41 Table 3.8 CDOT - Multilevel Construction Cost Index Classification Geographic Classification Description Statewide Multilevel Construction Cost Indexes Statewide MCCI with Awarded Unit Prices Statewide MCCI with Average Unit Prices per Project Statewide MCCI with Median of Unit Prices per Project Statewide MCCI with All Unit Prices Regional Multilevel Construction Cost Indexes Region Description Northwest Northwest MCCI with Awarded Unit Prices Northwest MCCI with Average Unit Prices per Project Northwest MCCI with Median of Unit Prices per Project Northwest MCCI with All Unit Prices Northeast Northeast MCCI with Awarded Unit Prices Northeast MCCI with Average Unit Prices per Project Northeast MCCI with Median of Unit Prices per Project Northeast MCCI with All Unit Prices Southwest Southwest MCCI with Awarded Unit Prices Southwest MCCI with Average Unit Prices per Project Southwest MCCI with Median of Unit Prices per Project Southwest MCCI with All Unit Prices Southeast Southeast MCCI with Awarded Unit Prices Southeast MCCI with Average Unit Prices per Project Southeast MCCI with Median of Unit Prices per Project Southeast MCCI with All Unit Prices Table 3.9 DelDOT - Multilevel Construction Cost Index Classification Geographic Classification Description Statewide Multilevel Construction Cost Indexes Statewide MCCI with Awarded Unit Prices Statewide MCCI with Average Unit Prices per Project Statewide MCCI with Median of Unit Prices per Project Statewide MCCI with All Unit Prices Regional Multilevel Construction Cost Indexes Region Description North North MCCI with Awarded Unit Prices North MCCI with Average Unit Prices per Project North MCCI with Median of Unit Prices per Project North MCCI with All Unit Prices Central Central MCCI with Awarded Unit Prices Central MCCI with Average Unit Prices per Project Central MCCI with Median of Unit Prices per Project Central MCCI with All Unit Prices South South MCCI with Awarded Unit Prices South MCCI with Average Unit Prices per Project South MCCI with Median of Unit Prices per Project South MCCI with All Unit Prices The evaluation of the different MCCI versions outlined in Tables 3.7 to 3.9 was intended to determine if different geographic conditions could result in different inflationary trends in the construction industry, as well as to determine what index input would more effectively represent the local construction market. Different geographic conditions bring different challenges and

42 requirements at the program and project level. Therefore, different prices could be obtained for the same type of work or commodity in different locations. Price variability across the country or state depends on multiple factors including: the local climate and geological conditions; the availability of qualified local labor, suppliers, subcontractors, and general contractors; and the local applicable regulations (Akanni, Oke, and Akpomiemie 2015; Cuervo and Sui 2003; Kaming et al. 1997). Extensive research has been performed to investigate the factors that make current construction prices at Location A higher than those at Location B. However, little has been done to investigate if construction prices at Location A grow at higher/lower rate than those at Location B. There is a knowledge gap on how different geographic considerations affect inflation rates in the construction sector. In an attempt to address this gap, the research team developed separate MCCIs for the different geographic regions shown in Figures 3.7 to 3.9. Figure 3.7 MnDOT Geographic Regions

43 Figure 3.8 CDOT Geographic Regions Figure 3.9 DelDOT Geographic Regions The geographic classification of indexes is just an additional partition to the available data in an attempt to analyze price volatility at the regional level. Thus, DelDOTâs âStatewide MCCI with Awarded Unit Pricesâ was developed with historical data from all available projects across the state and using only unit prices submitted by the awarded contractors. On the other hand, DelDOTâs âNorth MCCI with Awarded Unit Pricesâ was also built with low-bid proposals, but only with bid data from Sussex County. Therefore, this MCCI and any findings from this data are only applicable to that region.

44 The regional classification done for each agency was intended to produce regions large enough to provide a constant stream of bid data, but at the same time, not too large to keep them relevant geographic-wise. The regional classification also tried to meet the apparent criteria followed by the selected agencies for the designation of their operational districts/regions. For example, each geographic region in Figure 3.5 is a combination of two of MnDOTâs operational districts. Each region in Figure 3.6 is associated with a given regional office, except for the Northeast Region, which combines CDOTâs Regions 1 and 4. On the other hand, having only three counties, DelDOT treats each county as a separate district. 3.6.5 Regional Levels of Competition in MCCIs Although little is known about the relationship between the level of competition and inflation rates in the construction industry, it does not prevent MCCIs from taking into consideration potential impacts associated with the numbers of contractors that might compete for the forecasted construction activities. A review of this issue revealed the following three main aspects influencing levels of competition in construction: ï· Local availability of general contractors, unions vs. right-to-work laws, and other geographic considerations. ï· Nature and complexity of the intended scope of work. ï· Seasonal changes in local construction industry. In general, impacts to the forecasting process associated with local geographic conditions, including level of competition, is accounted for, to some extent, by the geographic classification discussed in the previous section. If low levels of competition were affecting a given region, those would be reflected in the recorded unit prices from that region. Thus, any level-of-competition effects would indirectly considered in the forecasting process through the regional MCCIs, which were developed with local historical cost data. The level of competition for complex scopes of work can reasonably be expected to be considerably lower than the intensity of competition in simple projects. High technical and management requirements associated to some scopes of work could limit the letting process to a few number large construction companies with relevant experience. Likewise, some types of work could be more attractive to potential bidders due to the expectation of higher returns, increasing the number of competing contractors. Potential changes in levels of competition associated with different scopes of work can be factored into the cost forecasting process through the development of scope-based inflation rates, which is allowed by the MCCI methodology as explained in Section 3.6.5. If, for example, asphalt paving projects attract more contractors than other types of projects, and if that higher level of competition has an impact on inflation rates, that impact would be indirectly accounted for if the cost forecasting process is customized to asphalt paving projects. Finally, construction markets tend to have a seasonal behavior, which is more marked in northern states like Minnesota, where the majority of construction activities are performed during non- winter months. Although further research is required to better understand seasonal contractorsâ and supplierâs pricing patterns, any possible seasonal effects on inflations rates can be considered

45 by MCCIs by matching index updating frequencies with in- and out-of-season months. Figure 3.10 clearly illustrates a seasonal pattern in MnDOTâs contracting activities with the vast majority of the annual construction program awarded during the first six months of every calendar year. Thus, any seasonal changes in levels of competition would be capture by an MCCI with a semi-annual updating frequency, as the one used in this study. Figure 3.10 Number of Contract Awarded by MnDOT per Period (2009-2018) After developing all the statewide and regional MCCIs for each agency, and after identifying the existing cost indexing alternatives to be considered in the case studies (those listed in Table 3.2), the research team proceeded to design and perform a comparative analysis to identify the most suitable cost indexing approach for each region under each case study. This comparative analysis process and the results of its application on the case study agencies are discussed in the next chapter.

Predicting the future of the construction market is always a challenging task - regardless of whether it is over the next one or 20 years - since it involves several uncertainties.

The TRB National Cooperative Highway Research Program's NCHRP Web-Only Document 283: Improving Mid-Term, Intermediate, and Long-Range Cost Forecasting for State Transportation Agencies documents the research that led to the development of a Cost Forecasting Approach Selection Framework that can assist state transportation agencies to select and implement effective mid-term (3 to 5 years), intermediate-range (up to 15 years), and long-range (more than 15 years) cost forecasting procedures.

Supplemental information to the technical report includes NCHRP Research Report 953: Improving Mid-Term, Intermediate,and Long-Range Cost Forecasting: Guidebook for State Transportation Agencies , a presentation , and videos .

Welcome to OpenBook!

You're looking at OpenBook, NAP.edu's online reading room since 1999. Based on feedback from you, our users, we've made some improvements that make it easier than ever to read thousands of publications on our website.

Do you want to take a quick tour of the OpenBook's features?

Show this book's table of contents , where you can jump to any chapter by name.

...or use these buttons to go back to the previous chapter or skip to the next one.

Jump up to the previous page or down to the next one. Also, you can type in a page number and press Enter to go directly to that page in the book.

To search the entire text of this book, type in your search term here and press Enter .

Share a link to this book page on your preferred social network or via email.

View our suggested citation for this chapter.

Ready to take your reading offline? Click here to buy this book in print or download it as a free PDF, if available.

Get Email Updates

Do you enjoy reading reports from the Academies online for free ? Sign up for email notifications and we'll let you know about new publications in your areas of interest when they're released.

The Prince2 Methodology In The Construction Industry: A Case Study

Table of contents.

- Use of PRINCE2 products and templates

- Techniques for managing project risks

- Tailoring PRINCE2 to suit different types of projects

- Roles and responsibilities in a PRINCE2 project

- Processes of PRINCE2

- Principles of PRINCE2 Themes of PRINCE2

- PRINCE2 terminology and concepts

- PRINCE2 Salary

- PRINCE2 Exam Study Guide

- PRINCE2 Exam History

- Overview of PRINCE2 methodology

- Management of project stakeholders and communication

- Examining the relationships between the themes

- Effective leadership and management of project teams

- Application of PRINCE2 principles

Norman J. Francisco

Imagine overseeing a construction project where every detail is meticulously planned, every task is assigned to the right team member, and every milestone is successfully achieved. This level of precision and efficiency is not just a dream, but a reality with the implementation of the PRINCE2 methodology in the construction industry.

In this article, we will explore how this project management approach has revolutionized construction projects, providing a practical and effective solution to the challenges faced by construction project managers. Through a detailed case study, we will delve into the key principles and processes of PRINCE2 and how they can be applied in the construction industry.

From the initial planning stages to the successful completion of a project, we will examine the benefits, challenges, and solutions in implementing PRINCE2. Join us on this journey as we uncover the secrets to achieving success in construction projects through the PRINCE2 methodology.

Key Takeaways

- PRINCE2 methodology provides a structured approach to project management in the construction industry.

- Implementation of PRINCE2 in construction projects leads to improved project execution, decision-making, and control.

- The key principles of PRINCE2, such as continued business justification and defined roles and responsibilities, are crucial for successful implementation in the construction industry.

- Challenges in implementing PRINCE2 in construction can be addressed through strategic approaches like change management, stakeholder engagement, and resource management.

Overview of the PRINCE2 Methodology

Let’s dive into the fascinating world of the PRINCE2 methodology, which provides a structured approach to project management in the construction industry. As a construction project manager or industry expert, you understand the importance of practicality and efficiency in delivering successful projects.