ScholarWorks@UMass Amherst

Home > Engineering > CHE > CHE_THESES

Chemical Engineering Masters Theses Collection

Theses from 2024 2024.

Experimentally and Computationally Analyzing Interstitial Flow After Spinal Cord Injury , Hoi Kwon, Chemical Engineering

Engineering Escherichia coli Nissle 1917 to Enable Functional Genomic Interrogation using CRISPR Interference , James M. Moore, Chemical Engineering

Theses from 2023 2023

Machine Learning Modeling of Polymer Coating Formulations: Benchmark of Feature Representation Schemes , Nelson I. Evbarunegbe, Chemical Engineering

Optimizing Channel Formation in PEG Maleimide Hydrogels , Bakthavachalam Kannadasan, Chemical Engineering

Theses from 2022 2022

Engineering and Evaluation of Reconstituted HDL Nanoparticles to Target Tumor-Associated Macrophages. , Aishwarya Menon, Chemical Engineering

Chromatographic Dynamic Chemisorption , Shreya Thakkar, Chemical Engineering

Theses from 2021 2021

UNDERSTANDING COMPLEX COACERVATION OF LOW CHARGE DENSITY COPOLYMERS AND LATEXES , Nicholas Bryant, Chemical Engineering

FREE RADICAL POLYMERIZATION OF NOVEL COPOLYMER; ETHYLENE-CO-DIETHYL METHYLENE MALONATE COPOLYMERS , Sydney Foster, Chemical Engineering

Surface Functionalized Electrospun Cellulose Nanofilters for High-Efficiency Particulate Matter Removal , Shaohsiang Hung, Chemical Engineering

Synthesis of Hybrid Inorganic-Organic Microparticles , Shreyas Joshi, Chemical Engineering

Metabolic Modeling of Bacterial Co-cultures for CO-to-Butyrate Conversion in Bubble Column Bioreactors , Naresh Kandlapalli, Chemical Engineering

Ultrasound-Responsive Crosslinking with Temporal Control and Rheological Tunability , Yinghong Liu, Chemical Engineering

Effect of Phase Composition of Tungsten Carbide on its Catalytic Activity for Toluene Hydrogenation , Aditya Rane, Chemical Engineering

Incorporating Epoxy and Amine into Poly(Methyl Methacrylate) for a Crosslinkable Waterborne Coating , Jichao Song, Chemical Engineering

Spatiotemporal Metabolic Modeling of Pseudomonas aeruginosa Biofilm Expansion , Robert Sourk, Chemical Engineering

Cryptic Materials And Coacervates , Yimin Sun, Chemical Engineering

Synthesis of Functionalized Acrylic Nanoparticles as a Precursor to Bifunctional Colloids , Guinevere E. Tillinghast, Chemical Engineering

Metabolic Modeling of Cystic Fibrosis Airway Microbiota from Patient Samples , Arsh Vyas, Chemical Engineering

Theses from 2020 2020

Asymmetric Large Area Model Biomembranes , Paige Liu, Chemical Engineering

Theses from 2019 2019

Electrospinning Nanofibers from Chitosan-Hyaluronic Acid Complex Coacervates , Juanfeng Sun, Chemical Engineering

Noncovalent Functionalization of Latex Particles using High Molecular Weight Surfactant for High-Performance Coatings , Lei Zheng, Chemical Engineering

Theses from 2016 2016

Modeling the Thermodynamics and Dynamics of Fluids Confined in Three-Dimensionally Ordered Mesoporous (3DOm) Carbon Materials , Anish Julius Desouza, Chemical Engineering

Theses from 2015 2015

Thermo-Responsive Poly(N-Isopropylacrylamide) and its Critical Solution Temperature Type Behavior in Presence of Hydrophilic Ionic Liquids , Purnendu K. Nayak, Chemical Engineering

Theses from 2014 2014

Effect of Chemotherapeutic Treatment Schedule on a Tissue Transport Model , Dan E. Ganz, Chemical Engineering

Metabolic Modeling of Secondary Metabolism in Plant Systems , Lisa M. Leone, Chemical Engineering

Theses from 2012 2012

Catalytic Fast Pyrolysis of Biomass in a Bubbling Fluidized Bed Reactor with Gallium Promoted Zsm-5 Catalyst , Jian Shi, Chemical Engineering

Theses from 2011 2011

Self-nucleated Crystallization of a Branched Polypropylene , Dhwaihi Alotaibi, Chemical Engineering

Theses from 2009 2009

Patterned Well-Ordered Mesoporous Silica Films for Device Fabrication , Todd A. Crosby, Chemical Engineering

Theses from 2008 2008

Molecular-Beam Mass-Spectrometric Analyses of Hydrocarbon Flames , Saugata Gon, Chemical Engineering

Theses from 2007 2007

Synthesis and Adsorption Studies of the MIcro-Mesoporous Material Sba-15 , Eunyoung You, Chemical Engineering

Theses from 1976 1976

Computer simulation of an ethylene plant , Charles David Weinstein, Chemical Engineering

Advanced Search

- Notify me via email or RSS

- Collections

- Disciplines

Author Corner

- Login for Faculty Authors

- Faculty Author Gallery

- Expert Gallery

- University Libraries

- Chemical Engineering Website

- UMass Amherst

This page is sponsored by the University Libraries.

© 2009 University of Massachusetts Amherst • Site Policies

Privacy Copyright

- Conferences

Chemical and Process Engineering Research

- Current Issue

- Back Issues

Announcements

- Full List of Journals

- Migrate a Journal

- Special Issue Service

- Conference Publishing

- Editorial Board

- OPEN ACCESS Policy

- Other Journals

Chemical and Process Engineering Research is a peer reviewed journal published by IISTE. The journal publishes original papers at the forefront of chemical engineering, process management and instrumentations. The journal is published in both printed and online versions. The online version is free access and download.

IISTE is a member of CrossRef .

The DOI of the journal is: https://doi.org/10.7176/CPER

Vol 65 (2023)

Table of contents.

Paper submission email: [email protected]

ISSN (Paper)2224-7467 ISSN (Online)2225-0913

Please add our address "[email protected]" into your email contact list.

This journal follows ISO 9001 management standard and licensed under a Creative Commons Attribution 3.0 License.

Copyright © www.iiste.org

- Knowledge & Networks /

Peer-reviewed research

IChemE, in partnership with publisher Elsevier, produces seven journals:

- Chemical Engineering Research and Design

- Process Safety and Environmental Protection

- Food and Bioproducts Processing

- Education for Chemical Engineers

- Sustainable Production and Consumption

- Digital Chemical Engineering (open access)

- Carbon Capture, Science and Technology (open access)

An eighth journal, Molecular Systems Design & Engineering , is jointly published by IChemE and the Royal Society of Chemistry (RSC).

Each of our journals contains original, peer-reviewed chemical, process and related engineering research.

Members can access journals content from the Knowledge Hub . Enter your search term and filter the results by selecting ‘journals’ as the source material.

Our digitalised journal archive goes back to 1923 and is fully searchable by volume and author, and by keyword across the full text of every article. To find out more or place your order for outright purchase or subscription access, please contact our publications sales team on +44 (0)1788 534470. View the journals archive leaflet.

Subscriptions

Members can subscribe to print editions of the journals at discounted rates. To subscribe, log in to 'My IChemE', select 'Pay my subscriptions' and 'Subscribe to a new journal'. Please note that only Chemical Engineering, Research and Design, Process Safety and Environmental Protection , and Food and Bioproducts Processing are available in print format.

Non-member subscriptions are available from the Elsevier books and journals shop or via the individual journals' websites linked above.

IChemE's annual medals and awards programme recognises excellence in chemical engineering practice and outstanding contributions to the Institution or the wider community.

The medals awarded in the publications area are:

- Senior Moulton Medal for the best paper published by IChemE

- Junior Moulton Medal for the best paper published by IChemE by an author, or co-author, who has graduated within the last 10 years (excluding career breaks) at the time of submission of the paper

- Hanson Medal for the best article published in The Chemical Engineer magazine

- Hutchison Medal for the most catalytic or thought-provoking paper published by IChemE.

Medal winners are recommended by the Publications Medals Board.

Information on the full range of awards made by IChemE can be found on the Medals homepage.

Catherine Cliffe, Managing Editor Manuscripts accepted for publication manuscripts under peer review proposals for special issues/conference issues and appointments to the editorial board if you would like to discuss a proposal for a paper contact the relevant subject editor.

Claudia Flavell-While, Director of Publications Publication strategy.

Peter White, Marketing Executive

- Open access

- Published: 06 February 2019

Chemical engineering role in the use of renewable energy and alternative carbon sources in chemical production

- Gabriele Centi ORCID: orcid.org/0000-0001-5626-9840 1 ,

- Gaetano Iaquaniello 2 , 3 &

- Siglinda Perathoner 4

BMC Chemical Engineering volume 1 , Article number: 5 ( 2019 ) Cite this article

53k Accesses

47 Citations

19 Altmetric

Metrics details

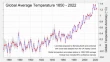

There is a demand for new chemical reaction technologies and associated engineering aspects due to on-going transition in energy and chemistry associated to moving out progressively from the use of fossil fuels. Focus is given in this review on two main aspects: i) the development of alternative carbon sources and ii) the integration of renewable energy in the chemical production. It is shown how addressing properly these aspects requires to develop also a) new tools for chemical engineering assessment and b) innovative methodologies for the development of the materials, reactors and processes. This review evidences the need to accelerate studies on these directions, being a crucial element to catalyze the transition to a more sustainable use of energy and chemistry. It is remarked, however, the need to go beyond the traditional approaches, with some examples given. In fact, the presence of radical changes in the way of production is underlined, requiring thus novel fundamentals and applied engineering approaches.

There are increasing evidences of an irreversible and fast-proceeding transition in energy and chemical technologies [ 1 , 2 , 3 ], characterized from the progressive substitution of fossil fuels and the introduction of renewable energy sources (RES) and alternative carbon feeds [ 4 , 5 , 6 , 7 , 8 ]. While still several scientists argue if and when this transition may occur, new investments are already in this direction. In addition, looking at the past decade, most of the negative opinions in terms of growing rate, due to supposed too high costs, were disavowed from recent data [ 4 ]. There are clear complex economic aspects determining the transition to novel energy and chemical production systems, but also technological facets. In fact, this transition does not imply the use of only the current available technologies in the area of chemical engineering, with just some adaptation, but involves a cultural revolution in terms of way of production [ 5 , 8 ].

It is thus necessary to understand where are the bottlenecks, both in terms of fundamental knowledge and technological aspects, limiting the possibility to realize the challenges related to this transition and reach the target to make sustainable and economic these novel technologies. Even if there are increasing papers and reviews in this area, for example on photocatalysts for solar-driven overall water splitting [ 9 ] or photoelectrochemical water splitting [ 10 ], they are still oriented to analyze only the scientific aspects, including for example the type of materials to use [ 11 , 12 ], rather than to present an holistic view of science and technology aspects. These two aspects should be developed in an integrated manner, rather than sequential, as exemplified from the development of photoelectrocatalytic materials and devices [ 13 ].

In addition, still often the specific research directions are not based on an analysis of how the technology should be implemented. For example, producing H 2 and O 2 from water splitting, without generating them in physically separated zones, creates major issues of safety due to the formation of H 2 -O 2 explosive mixtures and relevant costs for downstream separation to reach the required purity. In addition, producing H 2 which has to be used later to hydrogenated CO 2 , rather than converting directly CO 2 in photo/electrocatalytic devices, has major costs related to the energy necessary in producing, compressing and catalytically use H 2 to convert CO 2 . There are also often relevant aspects underestimated. For example, under practical use, temperature of operation of photoelectrocatalytic devices, under full solar irradiation, may easy reach temperatures above 60–80 °C, while several of the materials proposed for these cells are not stable above 50 °C [ 13 ]. Materials development should be related to engineering and operations of the device. There are several of such a type of examples, in which research, even if excellent from the scientific perspective, is not put in the right technological perspective.

While progresses in fundaments are always necessary, there is the need to accelerate the development of the technologies enabling to meet the necessary targets, in the case of energy and chemistry in transition. Note also that a successful transitional strategy requires identifying critical processes in a timeline perspective, with solutions for short-, medium- and long-term [ 14 ]. The crucial point is that cost-effective solutions are only those integrating within the current systems and value chains, to minimize investments and thus reduce the initial cost barriers. A proper synchronism between technological capabilities and socio-economic context is the decisive issue.

We feel that today the limiting factor is the capability to identify properly the key aspects on which focus development areas from the timeline perspective of a fast evolving scenario for chemistry and energy in transition. This review will thus analyze, from a personal perspective, the possible impact on chemical reaction technologies deriving from the transition in energy and chemistry, with focus on needs, gaps and opportunities.

Developing alternative carbon sources

Current petrochemistry is largely based, over 95%, on the use of fossil fuels, particularly oil [ 15 , 16 , 17 ]. There are various motivations indicating the need to decrease this very high dependence. Among them: i) decrease greenhouse gas emissions in order to contribute to climate change mitigation and to reach CO 2 emission targets, ii) security and diversification of resources, iii) promote rural development by using the local resources, and iv) use of C-sources less depending on fluctuations and uncertainty in future costs of fossil raw materials.

It is often argued that cheap oil will be still available in the future to make useless the development of alternative routes. The same argument was used up to few years ago to indicate that energy from fossil fuels would remain also in the future the most competitive one. Recent reports like that by IRENA [ 4 ] have demonstrated that instead already today this is no long valid. In the area of petrochemistry, uncertain in predicting future costs is already a major factor determining investments in new plants, with a panorama where very few new technologies have been put on the market in the last decade.

The future decade for chemical companies is market from the need to reinvent their interface with oil refining and manage the transition to a circular economy [ 18 ]. In fact, the last decade has been characterized for petrochemical companies from an erosion in the product margin, due to low-cost of feeds. Consequently, new models for value creation are necessary [ 18 ], because the advantaged-feedstock-opportunity window is closing.

Crude-to-chemicals (COTC), i.e. direct production of chemicals and petrochemicals such as olefins and aromatics directly from crude oil, as opposed to via thermal cracking of naphtha/ethane (for olefins) and via traditional refining reforming (for aromatics), is one current industrial tendency [ 19 ], together with the development of direct routes for methane to olefins and aromatics [ 20 , 21 ]. Silura OCM (oxidative coupling of methane) process is one example of technology under development attracting increasing interest. On the other hand, these technologies are interesting for countries with low fossil fuel costs and one major challenge is the expected high capital investment required to construct the plants. In fact, an opposite tendency for chemical industry is to reduce the rising CAPEX costs [ 18 ], even more critical when cost forecast are difficult, and thus to adopt strategic agility [ 22 ], i.e. the capability to rapidly transform product and service portfolios in response to dynamically changing market and stakeholder needs.

Olefins and aromatics could be produced alternatively from CO 2 and H 2 , also in direct processes [ 23 ], and these technologies are instead suitable for distributed, small size, productions. Worth to note, the range of possible investors for the latter type of technology is much larger than the quite limited type of investors for COTC and OCM technologies, which, in addition, will have internal competition (they own also current technologies to produce olefins/aromatics). There are additional benefits in terms of incentives for CO 2 reduction: i) promotion of bioeconomy (CO 2 could derive from biogas or fermentation processes) and integration with renewable energy sources [ 24 , 25 ], ii) integration within local economy, iii) promotion of circular economy, etc. Thus, it may be argued whether COTC and OCM technologies will be game changer for chemicals industry, as announced, or instead, more likely, just a piece in the puzzle for transition in economy.

The main difference between the two approaches, apart from large vs. small-medium sizes plants, is that COTC and OCM aim to reduce costs by using less-expensive raw materials (crude oil rather than naphtha, methane), although still based on fossil fuels, with thus a cost highly fluctuating and unpredictable in trend. CO 2 /H 2 process is instead using a waste raw material (CO 2 ), with very low cost (some even negative considering carbon taxes) and another product (H 2 ) which could be manufactured using renewable energy sources, which are currently already competitive (in some cases) to the use of fossil fuels [ 4 ]. In addition, COTC and OCM needs to be produced in large plants, with costs of transport of chemicals, safety and geopolitical issues. Distributed processes allow instead a much better integration into local economies, including aspects related to circular economy [ 26 ]. It is evident that there are two different approaches, with the latter (producing raw materials for chemicals from waste and renewable energy) being based on a different, more sustainable economic model of development.

The analysis of the two production models should be thus not based on the traditional economic models and concepts, such as scale-economy. It is necessary to use new assessment tools, which include the capability to analyze socio-economical macro-trends, market evolution, competitiveness related to entire ecosystems, sustainability and integration into territory (rather than globalization), non-linear dynamic of changes and costs evolution, extended life-cycle cost and social analysis [ 18 , 27 , 28 ].

Therefore, new techno-economic engineering assessment tools should be developed. In transition periods, new conceptual assessment modes, including to evaluate the feasibility from a chemical engineering viewpoint, are necessary and it is historically demonstrated that in the absence of this approach a company may rapidly lose their market positions being their innovation capacity (a crucial aspect in chemical production) rapidly lost [ 17 ].

- Waste-to-chemicals

Waste-to-Chemicals (WtC), as argued from above analysis, is an important element of the strategy to diversify carbon sources for chemical production. Biomass use is another relevant component of this strategy [ 25 , 29 , 30 , 31 , 32 , 33 , 34 , 35 ]. However, when based on dedicated biomass (i.e. grown for the specific use), the negative implications on land change use and competition with other utilization, the impact on water resources, the relevant greenhouse gas emissions and high costs related to biomass growing, harvesting and pretreatment (for example, drying, size reduction, operations to improve processability) have to be taken into account.

From a process engineering perspective, the major issues are related to the presence of a complex matrix, which should be transformed to high purity chemicals in the presence of several contaminants, which can influence the use of catalysts. Solutions have been identified and made possible, but in general terms, this translates to high costs of production. Therefore, differently from a decade or more ago, when a large optimism was present, today the general perception is that the production of chemicals directly from dedicated biomass sources is applicable in some selected cases, but is not a general solution.

To be competitive to fossil fuels use for chemical production, it is necessary to i) use quite cheap raw materials, ii) integrate well into a regional strategy (also in terms of plant size), including circular economy, iii) use technologies flexible in handling a variety of biomass sources, and iv) be flexible in the production of different chemicals, minimizing costs for operations, especially purification and separation [ 36 ]. The use of waste biomass, which includes, but is not limited to, the organic fraction of municipal solid waste – MSW, which is called in different ways, one of them being RdF (refuse-derived fuel), is clearly an opportunity as a low cost raw material. In fact, it is a side production with a cost for disposal. Its valorization is often limited to thermal incineration. There are various attempts for alternative valorization methodologies to create a waste biorefinery [ 37 , 38 ], but reuse is limited to very specific type of biomass waste. For general purpose technologies, following above indications, it is necessary a process technology able to handle a variety of waste sources, including MSW, to reach the necessary dimension for a regional waste biorefinery, but minimizing the transport of raw materials from long distances, i.e. less than about 100–150 km.

There are essentially two routes to produce chemicals from organic waste, particularly from MSW and excluding reuse or recycling technologies which are tailored for specific waste and not suited for mixed wastes: pyrolysis [ 39 , 40 , 41 ] and gasification [ 42 , 43 , 44 ]. By (fast) pyrolysis a liquid fuel and a gas component, with the former especially characterized by a large range of products and quite low quality, are produced (with eventually also a solid residue). Severe upgrading treatments are necessary, and the pyrolysis liquid product can be essentially used only as fuel. The syngas instead produced in the gasification process can be easier purified and further processed to produce, in a flexible way, different chemicals or fuel components [ 36 ], by using essentially available technologies. This flexibility is an important added-value term allowing a much better tailoring to different demands. This is a crucial aspect to minimize developing costs for WtC, by adapting to the large variety of locals demands. We thus limit the further discussion to waste gasification as the first step, to produce syngas to be further converted to different chemicals.

Options in gasifiers for the WtC process. Gasification can be considered a process in between the endothermic anaerobic pyrolysis process (typically occurring in the 400–700 °C temperature range), and the exothermic combustion process with excess of air (800–1400 °C temperature range). The latter produces a hot gas to be used only for electrical energy generation or heat recovery. In gasification, instead, a syngas (a CO-CO 2 -H 2 mixture), with CO x to H 2 ratios depending on operation conditions and feed, is produced by using a controlled air or O 2 feed. The oxygen is typically one-fifth to one-third of the stoichiometric amount. Steam and CO 2 , in some cases, are also co-fed. The heat for gasification derives from the partial biomass combustion in the gasifier.

Biomass gasification has been extensively analyzed and discussed [ 44 , 45 , 46 ], but the used of mixed feeds, particularly containing the organic fraction of MSW, determines specific issues [ 47 , 48 , 49 ]. There are various crucial aspects in the design of the reactor: i) the gasifier should be designed to produce a tar-free syngas, because otherwise downstream cleaning is costly, ii) the formation of CO 2 should be minimized, iii) the inorganic part of the biowaste should be eliminated in a form allowing an easy disposal, and iv) pretreatment of the biowaste should be minimized as much as possible.

Different gasifier designs are used for biomass, the most common being, in the order, a downdraft fixed bed, fluidized-bed system (bubbling/circulating or dual) and an updraft fixed bed [ 45 ]. Fluidized beds for gasification processes allow high conversion and low tar yields, due to high heat and mass transfer rates, excellent gas-solid contact and good control of temperature. Besides the higher reactor costs and operations, biowaste should be grinded and sieved to small particles of uniform size, requiring additional costs.

Plasma gasification is of rising interest, for the possibility to obtain complete cracking of tar compounds and high gas yields [ 50 ]. Microwave plasma shows various advantages with respect to alternative ways to produce the plasma [ 51 ], but still there are many challenges to solve for industrial implementation. Gasification in supercritical or near-to-supercritical water [ 52 , 54 , 55 ] is another valuable option, but also having main challenges related to cost, thermal efficiency, plugging and corrosion problems.

The general question is that may be often unclear when and for which cases these different options should be applied. There are clear scale-up and cost issues, and different situations for which one technology should be preferable over the other [ 56 ]. Most of the considerations, however, refer to either gasification for energy purposes, or for H 2 production, with the production of optimal syngas production and integration with downstream processing to valuable chemicals scarcely considered. There are specific, but interesting cases to consider, as the MSW treatment in small touristic islands, where the produced MSW actually needs to be costly transported by ship to remote areas for disposal. The gasification in supercritical water allows to have compact reactors, and reduce downstream cleaning processes. The syngas could be upgraded to methane for local use, being these islands not reached by the natural gas grid. This is an example of a case when a technology otherwise too costly can be instead considered.

The missing knowledge are thus in suitable multicriteria assessment tools able to guide selection along the different solutions and technologies, and to identify the engineering aspects limiting the overall performances. Robustness, minimization of downstream operations, flexibility in variable composition feed handling, minimization of sludges downstream treatment, safety aspects are some of the keyword to consider for the selection.

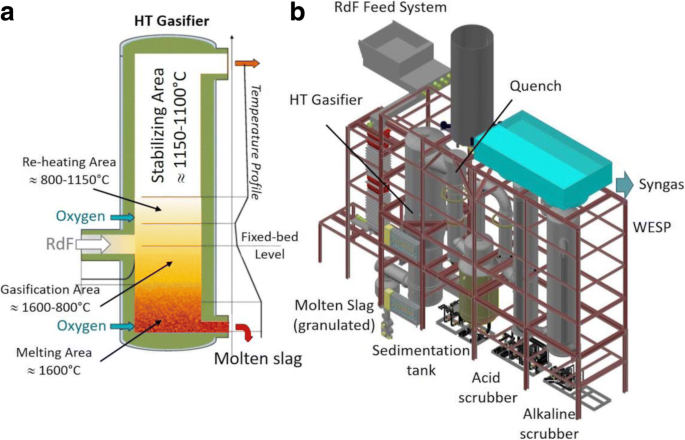

We believe that based on these aspects, the use of a high temperature (HT) converter as that presented in Fig. 1 is preferable [ 57 , 58 ]. A temperature gradient is present along the vertical axis with two oxygen injections in the heating (800–1000 °C) and melting (1000–1600 °C) areas. The biowaste (RdF) is fed from the side. The partial oxidation leads to the formation of a syngas, moving to the upper part of the reactor (stabilization area), where the temperature is above 1000 °C to crack the tars and eliminate possible toxic molecules such as dioxins and furans. The sludges are removed from the bottom (melting area) where temperatures of about 1600 °C are maintained, to allow discharge of molten slag, which by rapid cooling could be easy vitrified and made inert, for safe disposal. A relevant advantage is that the reactor allows to feed relative large particles, and thus avoiding grinding costs.

( a ) HT converter for waste-to-chemical plant with indications of different reaction zones and of the temperature profile. b Unit of HT gasification and related purification section. Reproduced with permission from ref. [ 58 ]. Copyright Elsevier, 2017

By using RdF, a typical composition of the syngas produced is the following (% vol): CO 2 8–16, CO 37–43, H 2 36–40, H 2 O 6–8, with few percentages of N 2 , O 2 and methane. The use of RdF and other biowaste is possible, with influence on the composition of the syngas. Temporal variations in the syngas flowrate and composition derive from the non-uniformity of the reactor bed, related to the use of large and non-uniform in size RdF particles. The partial clogging of the bed (bridge formation) later collapsing, is also another mechanism causing variations of syngas. However, a dimensioned downstream gasometer and operations with multiple parallel units, can avoid that this could be a problem in operations.

There are some main issues in this reactor. The first is that the very high-temperature operations create problems of lifetime of the refractory materials used for the reactor walls, with thus the need of frequent maintenance. The second, is that modelling of this type of gasifier is difficult and thus of its optimization. The third issue is related to the possibility of using catalysts to increase conversion and reduce the temperature of operations.

Catalytic gasification is a valuable option to promote energy efficiency [ 45 , 59 , 60 ], but only in few cases it is applied to improve MSW gasification. Ni-based catalysts [ 61 , 62 ] could be used, but they cannot be utilized in a gasifier as that shown in Fig. 1 . Low costs catalysts should be used to be continuously co-fed with RdF, remaining then in the molten slug. Olivine or similar natural materials, which are available in large amount at low cost, could be used [ 63 , 64 ]. Alternatively, a catalytic bed at the top of the gasifier could be used to improve the polishing of the syngas, but catalysts stable at high temperature and to the presence of fly ashes, tars, metals and salts should be developed.

Among other aspects, these three areas evidence who new chemical reaction technologies challenges are opened from the development of new technologies for using biowaste as carbon source.

Downstream processing for WtC

The syngas from the HT converted contains various impurities, which typical values (mg/Nm 3 ) are the following: sulphur compounds (H 2 S 100–1500, COS 10–150, < 10 for other S compounds), small acids (HCN < 10, HCl < 5, HF < 1), metals (Hg < 0.2, Ti + Cd < 0.2, heavy metals < 1) and particulate matter (< 3). These impurities should be removed before the downstream catalytic processes (Fig. 1 b), with the severity of the purification depending on the sensitivity of the catalysts to the poisoning by these contaminants.

Downstream operations to upgrade syngas to chemicals are in principle similar to those already available, but with catalysts and operations that should be specifically tailored for four aspects: i) the typical higher CO 2 content with respect to current operations, ii) the higher presence of impurities, iii) the need of optimal operations in smaller reactor units and iv) fluctuations in the feed (flow rate and composition). These fluctuations can be minimized by a downstream gasometer, but remain higher than in conventional reactors, for example for methanol synthesis. Also in this case, thus new dedicated engineering solutions have to be developed.

The syngas after purification and adjustment of the CO x /H 2 ratio, is sent to a conversion unit to obtain different possible chemicals, ranging from fuels to raw materials for chemistry and fertilizers. Methanol, urea, H 2 , CH 4 , olefins, aromatics are some of the possibilities, starting from RdF. They are feasible from a techno-economic perspective [ 36 , 57 , 58 ]. The use of mixed RdF and biowaste from agro-food production is also possible. In addition, with respect to incineration of the same waste, there are environmental advantages. For example, in waste-to-urea process, a reduction of about 0.8 tons of CO 2 emitted per ton of urea produced can be estimated [ 57 ].

This short excursus on some aspects of the development of novel routes for the use of alternative carbon sources evidences thus that many scientific and technological questions are opened by addressing this possibility. The aspects discussed are examples, and will thus not exclude other areas. However, already they remark the complexity of the problem to be addressed in a short term. It is thus very important to focus the analysis on the most critical aspects, and guide scientific advances by using a more holistic view of the full problems.

Integration of renewable energy in the chemical production (electrify chemistry)

The direct use of renewable energy sources (RES) in chemical production, i.e. electrification of the chemical industry, is another great challenge crucial for chemical engineering. Rather than use heat (produced from fossil fuels) to run operations, electrical energy (deriving from renewable sources) should be used. This is not only a technological change in supplying the energy for the chemical transformation, but determines a full change in the engineering of chemical processes design, where heat recovery and transfer is a major designing element and one of the key factors determining the need to have large plants.

Moving in this direction will allow passing to plants optimal for small-medium size (distributed) productions. Even more important, the scale-up in electrocatalytic processes is by parallel units, differently from the conventional approach. Parallelized production will permit a much greater flexibility in production (to follow better market demands and fluctuations) and especially a faster time to market. CAPEX is higher, but compensated from above advantages. Thus, electrification of the chemical industry is not only a technological change, but a full transformation in the engineering, design and marketing of chemical processes. As commented earlier, conventional techno-economics assessment models are not able to consider these aspects. This is one of the reasons why in these transitional periods, several of the conservative predictions fail to be correct and determine relevant marked losses in several companies.

Thus, it integrate RES in the chemical production requires major technological and scientific changes, because catalysts, reactors, operations have to be fully redesigned. There are different ways by which RES can be coupled to chemical production: use of electrons (electrical energy produced from renewable sources) in electrocatalytic or non-thermal plasma processes, and use of photons in photocatalytic processes [ 65 ]. We omit here to consider instead processes, where concentrated solar power (CSP) is used to heat the reactor, or instead radiations (like microwave) are used for heating the reaction medium. Between photo- and electro-driven processes, we consider the latter closest to industrial exploitation [ 66 ], although both are clearly relevant. Their combination in a single photo-electrocatalytic (PEC) reactor is the basis to develop artificial-leaf type devices in the future [ 67 , 68 , 69 ].

Technical hurdles

Electrification has the potential to significantly impact the chemical industry, but some technical hurdles are limiting the actual development, in parallel to the necessary reduction in capital investment and operating costs. Four main technical hurdles can be identified [ 70 ].

Increase the “operating flexibility” is still considered a major objective to go in this direction [ 70 ]. There are, in fact, fluctuating electricity prices, and furthermore an excess of renewable energy production in some periods (night, for example). It is thus often considered that a requirement is to operate flexibly, i.e. with quick start-up and shutdown times coupled with high efficiencies over varying loads. Current processes instead are designed to operate continuously within a limited range of operation conditions.

A crucial question, however, is that in discontinuous operations, the amortization time is also reduced, and thus CAPEX should be charged on limited times of operations. On the other hand, the continuous decrease in costs in producing renewable electrical energy (REE) indicates that it is preferable to have on-purpose production of REE, which combines with the concept mentioned before of distributed production. We thus believe that this question of discontinuous operations for use of REE in chemical production will be no longer an issue in the near future. On the other hand, there is certainly the interest to use a potential low cost energy, as excess REE during night. Rather than switching off and on the devices, it is preferable to have units specifically designed to operate efficiently with a variable load and thus productivity, i.e. operating, for example, at 50% of full load during day and 100% during night. While current design for chemical plants make them economic only for operations in a very restricted productivity range (typically > 85–90% of maximum capacity), the electrocatalytic operations make possible to operate economically, in principle, with a larger range of capacity. This is an aspect not explored currently, but quite relevant from the implementation perspective.

Extension of operating windows (temperature, pressure) is another relevant challenge [ 70 ]. Current commercial electrochemical processes in the area of chemistry are quite limited, essentially adiponitrile synthesis and few minor industrial organic electrosyntheses, in addition to the chlor-alkali process [ 71 ]. New large-scale electrolysis units for H 2 production using RES has been also announced. For example, Shell and ITM Power will build the world’s largest hydrogen electrolysis plant at Rhineland refinery, Germany, with a peak capacity of 10 MW [ 72 ]. However, the development of technologies and materials to operate over a wider range of operating conditions, will result in new processes and business cases, which are essential factors to increase implementation of the electrification concept.

For example, application of electrocatalytic processes in the area of biomass transformation, as commented later in a more detail, requires to operate in a large range of parameters, such as temperature, pressure and pH, which are relevant to increase the reaction rate and to control the selectivity and stability of operations. Extend the range of operating windows is not only a technological aspect, but requires to design materials and catalysts for stable operations. In addition, engineering of the electrochemical cells has also to be revised, and new simulation procedures for optimization are necessary.

We may consider also two other crucial aspects, which, however, are still not well recognized [ 66 ]. The first question is to increase productivity per geometrical area of the electrode. Being capital investment for an electrocatalytic reactor a determining cost element, it is necessary to reduce it by maximizing the ratio between the active electrocatalytic surface and the geometrical electrode surface, i.e. develop what are often indicated as 3D electrode. It must be noted, however, that papers dealing on 3D electrodes refer typically to batteries and analogous devices, or just indicate 3D-like materials, rather than really analyze their use under relevant conditions for electrocatalytic syntheses [ 73 , 74 , 75 ].

There are instead specific engineering cell aspects in designing 3D electrodes for chemical syntheses, largely ignored. The first is the realization of a uniform potential distribution of the potential in a nanostructured electrode (especially in large-size electrodes). A non-uniform potential distribution promotes side reactions and influences negatively the selectivity. The second crucial question is the presence of limitations in mass (and in part heat) transport limitations inside 3D porous electrode. In the conventional cell design, where flow rates are limited, these are critical aspects. In addition, diffusion inside a charged porous electrode is different from the case when the potential is not applied. These cell-engineering aspects are generally not considered up to now, or in a very limited extent. They can be instead quite relevant in determining the performances, especially selectivity, when multiple reactions are possible at relatively close applied potential. Examples are in CO 2 hydrogenation or biomass electrocatalytic conversion.

A proper engineering modelling of fluidodynamic in a cell and porous electrode should be developed, accounting also for charge distribution. There are similar problems also in photocatalytic electrodes, where the problem of developing higher productive systems also exists. Quite few studies exist on the engineering of photocatalytic electrodes [ 76 , 77 ].

There are several studies on how to develop advanced nanoarchitectures for solar photocatalytic applications [ 78 ]. Attention is focused on aspects such as light harvesting, charge-separation, band gap broadening and cocatalysis effects. Low dimensional [ 12 ] or hollow [ 79 ] nanostructures show several potential advantages for photocatalytic materials, such as enhanced light harvesting, potential reduced charge recombination rate by decreasing charge transfer distance and directing separation of charge carriers, and increased accessible surface areas. This is often masked, however, by an increase in defects, acting as centers for charge recombination. However, the engineering issues in developing photocatalytic electrodes, especially of large size as necessary for industrial applications, are many, and typically not investigated.

For example, the questions of whether there is a homogeneous current density over all the photoanode, of how to improve current collection and of how the interface with electron collecting elements (for example, by introducing carbon nanotubes in an oxide semiconductor) may create local resistances to electron transport. Nanostructure may create local charge accumulation, which can influence light adsorption and charge separation. In addition, there is the question of microfluidodynamics inside a porous semiconductor, with generation of gas bubbles (H 2 or O 2 ) and presence of a charged surface, with perhaps a not homogeneous surface charge distribution and a liquid (electrolyte) flowing tangential to the surface in pseudo-laminar flow. Other questions regards of how identify the optimal thickness in a nanostructured semiconductor [ 80 ], and of how realize an optimal combination between photocurrent generation and transport of protons to a proton-conductive membrane in photoelectrocatalytic devices with compact design [ 13 , 81 ].

In addition, when a gas is generated by the reaction (for example, O 2 in water oxidation or splitting), there is the problem of bubble formation, which often remain sticked on the electrode, reducing the active surface. This problem is even more critical in nanoporous electrodes, where a gas cap can avoid inside diffusion of the electrolyte.

Therefore, in addition to a proper modelling as a tool for optimization (particularly in scaled-up electrodes), a different reactor design from the conventional ones (typically based on simple electrodes immersed in an electrolyte, or a PEM fuel cell design) is necessary. While the first can be used just for lab testing, the second one (fuel cell) is closer to the design for application. However, this design is not optimal for more complex electrocatalytic reactions than H 2 and O 2 reaction (or the reverse). In the latter reaction, problems of selectivity are not present and thus it is not crucial to maximize the reaction rate (productivity) at low overpotential.

Extending the use of electrocatalytic technologies to a broader range of reactions of interest for a sustainable chemical production, thus not only requiring broadening of the operating windows, but also to revise completely the electrocatalytic reactor engineering and develop novel optimized flow cells, easy scalable and which minimize the CAPEX costs. Redesign of operations and cells to have an easy (low-energy-intensive) recover of the reaction products under continuous operations has also to be considered. All these aspects are scarcely considered, but it is evident how the push to new technologies deriving from energy and chemistry in transition is opening new perspectives for chemical engineering.

A third critical hurdle [ 70 ] is to reduce CAPEX as well as OPEX, working on i) improved electrocatalysts (with higher energy efficiency and stability, but also based on non-critical raw materials), ii) cell and membrane materials, iii) in-situ product separation, and iv) reduction of processing steps. The latter aspect is further discussed later regarding the opportunities in process intensification. Volume production and supply chain development in parallel with increased deployment of electrocatalytic reactors are important aspects in cost reduction, but which cannot be effective without a proper engineering of the systems and the development of suitable mass fabrication methods for components, for example roll to roll techniques for electrodes manufacture. A reduction ranging from 2 to 4, and possibly higher, can be expected, making possible to extend the use of these technologies to a large range of cases.

- Electrocatalysis

The core factor limiting often today developments is to identify high efficient and productive electrocatalysts for areas such as electrocatalytic CO 2 reduction and conversion of biomass platform molecules, on which attention is currently focused in the area. EU projects focused on these aspects, especially on the industrial development, are the OCEAN (Oxalic acid from CO 2 using eletrochemistry at demonstration scale; Project ID: 767798), TERRA (Tandem electrocatalytic reactor for energy/resource efficiency and process intensification; Project ID: 677471) and PERFORM (Power platform: establishment of platform infrastructure for highly selective electrochemical conversions; Project ID: 820723), the first two also being coordinated by us.

The word electrocatalysis as opposite to the most common term of electrochemistry should be clarified. They are often considered synonymous [ 66 ], but instead understanding their difference is the real challenge facing currently the area.

In fact, an electrocatalyst is not just a catalyst working in the presence of an applied potential, but rather an opportunity to go beyond electrochemistry through catalysis. This is not just a definition, but a concept opening new possibilities still largely underestimated today. For example, when several reactions are possible at quite similar potentials (the case of CO 2 reduction and biomass conversion), based on the electron transfer theory, it is not possible to obtain high Faradaic selectivities to a specific product. The presence of a catalyst, by creating different pathways of conversion, allows combining both higher rate and selectivity. Instead, the rate of electron transfer and reaction depends in conventional electrochemistry on the applied potential, which increase makes possible side reactions, with thus a lowering of the selectivity. Scarcely investigated, however, is how the electrocatalyst active surface changes under application of a potential [ 82 ].

While understanding how the catalyst features determine the performances is beginning, using both in-situ/operando methods and theoretical approaches, still many aspects are underestimated. For example, it is known that the electrocatalytic behavior may depend on the facets of the catalyst nanoparticles [ 83 , 84 ]. However, it is often considered that this is the only aspect determining the reaction paths, for example in CO 2 reduction [ 85 , 86 ]. On the contrary, we have shown that by changing the effective surface concentration of CO 2 at the electrocatalyst surface, the nature of the products may be considerably influenced. Specifically, products involving C-C bond formation (>C1) theoretically excluded to be possible on the Pt-based electrocatalyst used in these tests, can be instead formed with selectivity of about 60% by using a combination of reactor and electrode design aimed both to increase the effective surface concentration of CO 2 [ 87 ]. It was also shown recently that the conventional assumptions in electrokinetic studies (for example, related to Tafel plot) to derive a reaction mechanism in the reduction of CO 2 may not always be valid [ 88 ].

Therefore, the methodology used largely up to now was a combination of conventional electrochemistry and catalysis concepts, but not in an integrated approach, which goes beyond and takes advantages from new possibilities given from a broader vision of electrocatalysis required from the new fields addressed. There are still many emerging possibilities, which should be rationalized, in a holistic approach integrated with the engineering of the electrodes and electrocatalytic reactors.

Status in the electrochemical CO 2 reduction

The electrochemical reduction of CO 2 is perhaps the reaction, in the area of electrocatalysis, must intensively studied recently. A large variety of materials has been investigated, from single-atom catalysts [ 89 ], to colloidal nanocrystals [ 90 ], metal-organic framework (MOF) materials [ 91 , 92 ], doped carbon materials [ 93 ], gold nanoparticles [ 94 ] and manganese-based molecular catalysts [ 95 ], just to cite some recent examples of less-conventional type of electrocatalysts.

However, crucial aspects for exploitability, such as productivity, current density, Faradaic efficiency under full loading and stability under practical conditions have been scarcely considered in most of the cases. Electrochemical cells used have typically not considered decisive aspects for development, such as cost-effectiveness, compactness, continuous operations, easy recovery of the products, stability (including by applying full loading) and scalability. New design for the electrocatalytic cells, such as for operations without liquid electrolytes [ 96 ], could solve some of these aspects, but have been scarcely considered. Most of the studies are made in conventional cells in the wrong idea that cell engineering is a separate aspect from the development of the electrocatalyst.

A variety of products of CO 2 reduction, going from two-electron reduction as for the production of CO [ 94 ] or formic acid/formate [ 89 ], to more complex reactions such as the 6 electron reduction to methanol [ 97 ] or 8 electron reduction to methane [ 98 ], or to even more challenging reactions involving C-C bond formation, such as acetic acid/acetate formation [ 99 ] or ethylene and ethanol production [ 100 ]. Even the possibility of a selective 18e − reduction of CO 2 to isopropanol was shown [ 101 ]. It was often argued that simple reactions (two-electron reduction) should be investigated, for their potential higher productivity and higher Faradaic efficiency. However, this concept is valid, when the electrocatalytic process is considered without its applicative context [ 66 ]. Cost of downstream processes, need to realize process intensification and reduction in process steps, minimization of the process steps not using renewable energy sources (compression, thermal catalysis, separation), sustainability, distributed production are some of the elements to evaluate to determine the preferable path. While specific quantitative assessments from this perspective are missing, we would indicate that the preferable directions is towards reactions leading to final products rather than intermediates like syngas. We would also remark that this is another example remarking how the scientific development of the electrocatalysts should be dependent on the engineering assessment of the techno-economic feasibility, an aspect still largely missing in the area of the electrochemical reduction of CO 2 . In addition, the technical development has to be put in relation to the strategic vision of the possibilities to create new markets and competitiveness opportunities, as evidenced in the following section.

Creating new value chains

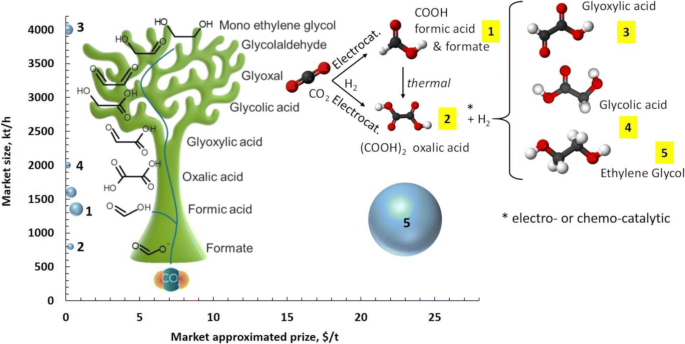

The exploration of above concepts allows to develop innovative value chains. An example is explored in the above cited EU project OCEAN, where the value chain deriving from the possibility to convert electrocatalytically CO 2 with formation of products involving C-C bond formation is explored (Fig. 2 ). Oxalic acid could be produced either directly by reductive dimerization of CO 2 , or via formic acid (or K-formate) electrocatalytic synthesis and further thermal conversion to oxalic acid. From this intermediate, which itself is a chemical with a good market, other products with higher added-value (glyoxylic or glycolic acids), or larger-volume production chemicals such as ethylene glycol, can be produced. These products are actually produced by selective catalytic hydrogenation, but in the future new electrocatalytic processes, with in-situ generation of the H 2 -equivalent (H + and e − ) necessary for CO 2 reduction, will be possible. In situ water electrolysis or photoelectrolysis could be used to generate the protons/electrons necessary for the reduction of CO 2 .

CO 2 to C2 value chain. Electrocatalytic conversion of CO 2 to oxalic acid (direct or via formic acid or the corresponding salts) and value chain which can derive from the further reduction of oxalic acid. The graph indicates the approximated market size and product value, with the bubble size corresponding to market value (27,6 M$/y for product 5, ethylene glycol). Reproduced with permission from ref. [ 66 ]. Copyright Elsevier, 2018

Ethylene glycol is worldwide produced (from ethylene oxide) in over 20 Mt. scale, being used in large-volume polyester fibers and resins. Ethylene glycol is also used in new “renewable” polymers like PEF (polyester polyethylene-furanoate). The production from this route, using CO 2 deriving from biosources (biogas, for example), will allow to produce 100% fossil-free PEF.

Further examples of new value-chains are presented in the next section. In all these cases, which are feasible from an industrial perspective (as explored in the cited EU projects), it is necessary to develop both improved electrocatalysts and novel scalable electro-reactors and units. As commented before, they push chemical reaction engineering to explore new directions, but going beyond the current approaches.

Process intensification

This is an opportunity beginning to be explored [ 102 , 103 ], being a major change with respect to engineering of conventional plants for chemical production. Process intensification is also a necessary step to move to distributed production.

We refer here only to process intensification related to the use of the electrocatalysis approach, because this is an aspect scarcely considered [ 66 ]. There are at least two aspects to mention. The first is the possible relevant reduction in the number of steps and process complexity, which reflects then in lowering the CAPEX/OPEX, the environmental impact and the need to have very large plants. The example illustrated in Table 1 is the difference between the conventional synthesis of ammonia and that possible in an electrocatalytic approach. The actual dominant process of ammonia synthesis starts from methane as H 2 source and requires several steps to arrive to ammonia. In the electrocatalytic approach (direct synthesis), water is the source of H 2 , and thus in a single electrocatalytic reactor N 2 and H 2 O are converted to NH 3 .

The possible reduction in the carbon foot print is over 90%. There are thus game-charger advantages in this approach: i) large reduction in the process steps, ii) milder operations, iii) elimination of the use of fossil fuels, iv) suitability for distributed production (avoiding impact of large-scale processes and relevant local impact, cost and impact of transporting ammonia), and v) use for the chemical storage of excess renewable energy. While the abundant recent literature focusses essentially only on reaching high Faradaic selectivities (the parallel side reaction is the recombination of protons/electron formed by water electrolysis to give H 2 ) [ 104 , 105 ], this is only part of the problem. It is necessary to develop electrocatalysts based on earth-abundant materials and use flow reactors with easy, non-energy-intensive, recover of ammonia [ 106 ], and especially designed to obtain higher productivities per geometrical surface area of the electrode. Most of the data reported in literature for high Faradaic efficiency were obtained at extremely low productivities, or current densities. There are other issues, however, which have been not considered up to now. The current industrial ammonia synthesis technology starting from methane uses air as N 2 source, because the oxygen is then consumed in the process.

In the direct electrocatalytic approach, pure N 2 has to be fed, because otherwise oxygen recombines with protons/electrons at the cathode side to form water. A membrane for N 2 and O 2 separation should be integrated with the electrocatalytic unit, but still some residual oxygen will be present. Therefore, the challenge (not considered up to now) is how to develop electrocatalysts for ammonia synthesis (from N 2 and H 2 O) operating efficiently in the presence of some residual O 2 after air separation. The problem is thus significantly different from current studies on the reaction [ 107 , 108 , 109 ], where the only issue considered is a high Faradaic selectivity to NH 3 .

The problem of oxygen contamination, the recovery of ammonia and flow reactor operations, the design to minimize ammonia crossover through the membrane [ 110 ], a compact scalable reactor design, the use of low-cost scalable synthesis of electrocatalysts, stability under operation are some of the problems to consider from an engineering perspective, which are not separated from the development of the electrocatalysts, and may instead determine different selections, as remarked before for water splitting catalysts.

Another relevant example of possible significant reduction in the process steps, and carbon footprint, is given by the direct electrocatalytic synthesis of acetic acid or acetate from CO 2 [ 99 , 111 , 112 , 113 ]. Acetic acid is also a large-volume chemical (about 14 Mt. annually) with a market in expansion. Current production routes use fossil sources, apart from few based on fermentation processes. The current main industrial route is a multi-step process, via production of syngas from methane, production of methanol, and carbonylation of the latter. The overall energy efficiency is about 15%, which can significantly increase in direct electrocatalytic routes, with also a reduction of the carbon footprint over 50%. The key aspect is also in this case how to control selectivity and favor reactions leading to C-C bond formation [ 99 ], but considering that often mechanistic studies provide contrasting results, because they do not consider the role of surface coverage (or reactants and products, electrolyte) in determining the paths of electrocatalytic transformations [ 87 , 113 ], the use of different reactor configurations (in the presence or not of an electrolyte of support [ 114 ]), and the dependence on the potential applied [ 82 ].

There are thus several fundamental open questions to understand, but requiring a broader approach than the limited often currently used. A closer relationship between fundamental and applied/engineering aspects is necessary. On the other hand, new value chains and opportunities will derive from these studies.

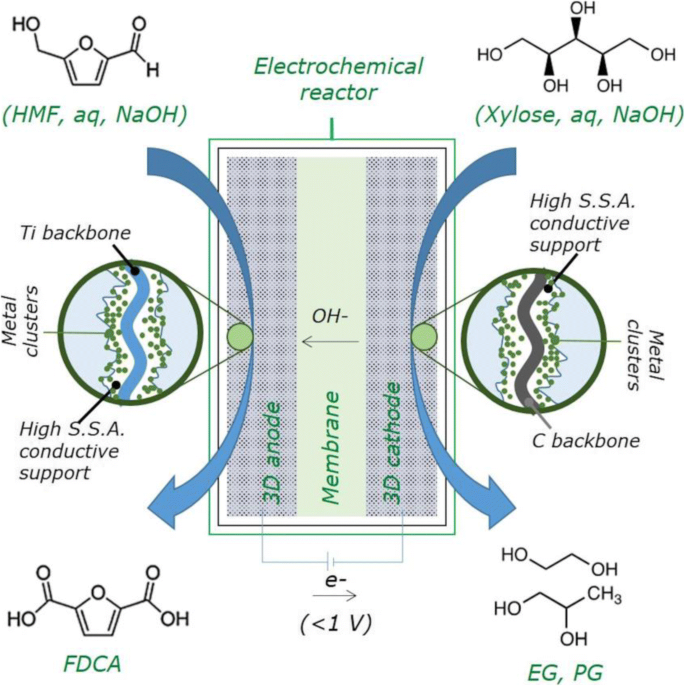

A second and different possibility for process intensification is related to the application of the electrocatalytic approach to the production of chemicals from biosources. Here the point is that in these processes, both catalytic oxidation and reduction steps are often present. They can be conveniently joined in a single tandem or paired electrocatalytic reactor, as explored in the previously cited EU TERRA and PERFORM projects.

The specific business case, and tandem electrocatalytic reactor, explored in the TERRA project regards the synthesis of PEF, a novel biobased polymer which should substitute polyethylene-terephthalate (PET), a major polymer (> 20Mt production).

PEF is synthetized by co-polymerization of FDCA (2,5-furandicarboxylic acid) with ethylene glycol. Avantium e BASF created two year ago the joint venture Synvina to construct a new plant (50,000 t/y) for the production of this polymer. FDCA derives from fructose as raw materials via intermediate HMF formation, while ethylene glycol still derives from fossil sources (via ethylene and ethylene oxide). The production of ethylene glycol from biobased byproducts such as xylose, as in the case discussed before from bioderived CO 2 , could thus produce 100% bioderived PEF. Interesting is that the two monomers for PEF could be synthetized one by oxidation and one by reduction of platform biomolecules (HMF and xylose) deriving from cellulose and hemicellulose, the main components of biomass.

TERRA project thus explores the development and scale-up of a tandem electrocatalytic reactor, schematically shown in Fig. 3 , where the two monomers (FDCA and ethylene glycol) are produced in the same reactor. The approach avoids the need of oxidizing and reducing agents for the two redox reactions and the process intensification decreases the process steps and allow better energetic integrations. The result is a decrease of CAPEX and OPEX by more than 20%. There are, on the other hand, a series of technological aspects to solve, besides to develop the electrocatalysts allowing high selectivity and stability.

Innovative intensified electrochemical process developed in the EU TERRA project

One of the crucial issues is the fact that the optimal temperature of operation could be not the same for the two sides of the electrocatalytic reactor. Inside the TERRA project, a technological solution to decouple the temperature of the two sides of the reaction (within a certain range) has been developed, although cannot be discussed in detail here. This is a new innovation aspect not present in conventional electrochemical approaches, but opening a range of new possibilities in coupling redox reactions.

Moreover it represent an example of how the need to solve critical questions from the application side pushes the development of new engineering solutions, which, on the other hand, open new fields of application.

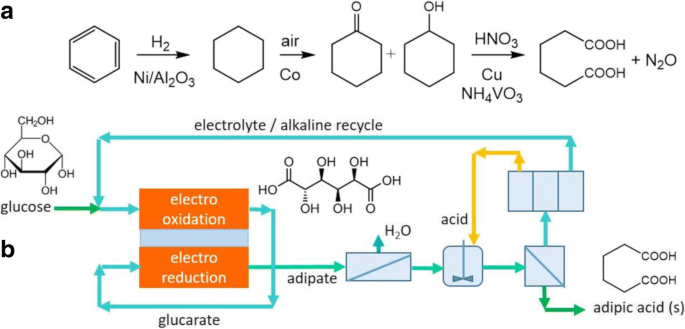

In fact, a range of new possibilities opens in the area of biomass valorization using electrocatalytic approaches. Some of them are explored in the cited PERFORM project. An interesting example is that coupled redox reactions are present in the synthesis of other biobased monomers such as adipic acid, one of the most important of the commercially available aliphatic dicarboxylic acids [ 17 , 115 ]. A major route for its industrial production is based on the hydrogenation of benzene to cyclohexane, which is then oxidized to a mixture of cyclohexanol and cyclohexanone (indicated as KA oil).

KA oil is then oxidized with nitric acid producing N 2 O as byproduct, a powerful greenhouse gas (Fig. 4 a). The full process thus involves many steps, uses toxic chemicals (benzene), produces N 2 O as byproduct, and requires both reducing agents (H 2 ) and oxidants (O 2 , HNO 3 ). The new electrocatalytic process starts from a safer raw material (glucose) and uses a single electrocatalytic reactor, with a relatively simple downstream separation. The entire process, avoiding the use of reductants and oxidants, significantly decreases the carbon footprint, greenhouse gas emissions and the environmental impact. In addition, the process is well suited for distributed production allowing thus to develop novel business models.

( a ) Process reaction network for the actual industrial synthesis of adipic acid. b Novel innovative process scheme developed in the EU PERFORM project using a paired electrocatalytic reactor

There are many novel electrocatalytic, reactor engineering and process technology aspects to develop for enabling the implementation of the process, but which can open novel market opportunities for various other applications.

Conclusions

Many aspects, from economic to sustainability, social and political, are inducing a radical transition in both the energy and chemical production systems. This creates a push for new chemical reaction technologies and associated engineering aspects. We have identified in this review two main aspects on which focus the discussion: i) the development of alternative carbon sources and ii) the integration of renewable energy in the chemical production. These areas cannot be considered just an extension of the current ones. Therefore, they should be properly addressed by developing new tools for chemical engineering assessment, in parallel to innovative methodologies for development of the materials, reactors and processes needed to enable from the technological side the realization of the necessary targets in an integrated fundamental and applied/engineering vision. Often these aspects are still underestimated. Some R&D aspects are highlighted, to remark that they are crucial elements to accelerate transition to a more sustainable use of energy and chemistry. Moving in the indicated directions will produce radical changes in the way production is made, requiring thus new fundamentals and applied engineering approaches.

In conclusion, we hope to have demonstrated that exists a push for new chemical reaction technologies deriving from energy and chemistry in transition. However, the speed to which this transition will be enabled will also depend on the capability to have a broader and integrated view on the problems. Some of the needs have been discussed here.

Abbreviations

Capital expenditure

Crude-to-chemicals

Concentrated solar power

Furandicarboxylic acid

Hydroxymethylfuran

High temperature

Municipal solid waste

Oxidative coupling of methane

Operating expenses

Photo-electrocatalytic

Polyester polyethylene-furanoate

Proton-exchange membrane

Polyethylene-terephthalate

Refuse-derived fuel

Renewable electrical energy

Renewable energy sources

Beller M, Centi G, Sun L. Chemistry future: priorities and opportunities from the sustainability perspective. ChemSusChem. 2017;10:6–13.

Article CAS PubMed Google Scholar

Čejka J, Nachtigall P, Centi G. New catalytic materials for energy and chemistry in transition. Chem Soc Rev. 2018;47:8066–71.

Article PubMed Google Scholar

Schlögl R. E-mobility and the energy transition. Angew Chem Int Ed. 2017;56:11019–22.

Article CAS Google Scholar

IRENA (International Renewable Energy Agency). Renewable power generation costs in 2017. Abu Dhabi: IRENA; 2018.

Bazzanella AM, Ausfelder F. Low carbon energy and feedstock for the European chemical industry. Frankfurth AM: DECHEMA pub; 2017.

Ager JW, Lapkin AA. Chemical storage of renewable energy. Science. 2018;360:707–8.

Perathoner S, Gross S, Hensen EJM, Wessel H, Chraye H, Centi G. Looking at the future of chemical production through the European roadmap on science and Technology of Catalysis the EU effort for a long-term vision. ChemCatChem. 2017;9:904–9.

Lanzafame P, Abate S, Ampelli C, Genovese C, Passalacqua R, Centi G, Perathoner S. Beyond solar fuels: renewable energy-driven chemistry. ChemSusChem. 2017;10:4409–19.

Wang Z, Li C, Domen K. Recent developments in heterogeneous photocatalysts for solar-driven overall water splitting. Chem Soc Rev. 2018. https://doi.org/10.1039/C8CS00542G .

Yang W, Moon J. Recent advances in earth-abundant photocathodes for Photoelectrochemical water splitting. ChemSusChem. 2018. https://doi.org/10.1002/cssc.201801554 .

Su T, Shao Q, Qin Z, Guo Z, Wu Z. Role of interfaces in two-dimensional Photocatalyst for water splitting. ACS Catal. 2018;8:2253–76.

Heard CJ, Čejka J, Opanasenko M, Nachtigall P, Centi G, Perathoner S. 2D oxide nanomaterials to address the energy transition and catalysis. Adv Mat. 2018. https://doi.org/10.1002/adma.201801712 .

Perathoner S, Centi G, Su D. Turning perspective in Photoelectrocatalytic cells for solar fuels. ChemSusChem. 2016;9:345–57.

Science and Technology Roadmap of Catalysis for Europe. A Path to create a Sustainable Future. Bruxelles: European Research Institute of Catalysis Pub.; 2016. ISBN 979–12–200-1453-3

Ulber R, Sell D, Hirth T. Renewable Raw Materials: New Feedstocks for the Chemical Industry. Weinheim: Wiley-VCH; 2011.

Valencia RC. The future of the chemical industry by 2050. Weinheim: Wiley-VCH; 2013.

Cavani F, Centi G, Perathoner S, Trifirò F. Sustainable Industrial Chemistry: Principles, Tools and Industrial Examples. Weinheim: Wiley-VCH; 2009.

Cetinkaya E, Liu N, Simons TJ, Wallach J. Petrochemicals 2030: reinventing the way to win in a changing industry. New York: McKinsey & Co; 2018.

Corma A, Corresa E, Mathieu Y, Sauvanaud L, Al-Bogami S, Al-Ghrami MS, Bourane A. Crude oil to chemicals: light olefins from crude oil. Catal Sci Technol. 2017;7:12–46.

Gambo Y, Jalil AA, Triwahyono S, Abdulrasheed AA. Recent advances and future prospect in catalysts for oxidative coupling of methane to ethylene: a review. J Ind Eng Chem. 2018;59:218–29.

Schwach P, Pan X, Bao X. Direct conversion of methane to value-added chemicals over heterogeneous catalysts: challenges and prospects. Chem Rev. 2017;117:8497–520.

Guertzgen S. Major Trends for the Chemical Industry In 2018. Digitalist Magazine; 2017. https://www.digitalistmag.com/digital-economy/2017/12/18/major-trends-for-chemical-industry-in-2018-05652353 . Accessed 25 Nov 2018.

Li Z, Wang J, Qu Y, Liu H, Tang C, Miao S, Feng Z, An H, Li C. Highly selective conversion of carbon dioxide to lower olefins. ACS Catal. 2017;7:8544–8.

Lanzafame P, Centi G, Perathoner S. Catalysis for biomass and CO 2 use through solar energy: opening new scenarios for a sustainable and low-carbon chemical production. Chem Soc Rev. 2014;43:7562–80.

Abate S, Lanzafame P, Perathoner S, Centi G. New sustainable model of biorefineries: biofactories and challenges of integrating bio-and solar refineries. ChemSusChem. 2015;8:2854–66.

Meyer B, Keller F, Wolfersdorf C, Lee RP. A concept for the circular carbon economy sector coupling of the energy, waste, and chemical industry. Chemie Ing Techn. 2018;90:241–8.

Elser B. Taking the European Chemical Industry into the Circular Economy. Accenture; 2017. https://www.accenture.com/us-en/insight-circular-economy-european-chemical-industry . Accessed 25 Nov 2018.

Jenner F, Neumann C. The chemical industry reimagined — vision 2025. EYGM Limited; 2018. https://www.ey.com/Publication/vwLUAssets/ey-the-chemical-industry-reimagined-vision-2025/$FILE/ey-the-chemical-industry-reimagined-vision-2025.pdf . Accessed 25 Nov 2018.

Mika LT, Cséfalvay E, Németh Á. Catalytic conversion of carbohydrates to initial platform chemicals: chemistry and sustainability. Chem Rev. 2018;118:505–613.

Mikkola JP, Sklavounos E, King AWT, Virtanen P. The biorefinery and green chemistry. In: ionic liquids in the biorefinery concept: challenges and perspectives, Bogel-Lukasik R. Ed., RSC pub. Green Chemistry Series. 2016;36:1–37.

CAS Google Scholar

Venkata Mohan S, Nikhil GN, Chiranjeevi P, Nagendranatha Reddy C, Rohit MV, Kumar AN, Sarkar O. Waste biorefinery models towards sustainable circular bioeconomy: Critical review and future perspectives. Bioresource Techn. 2016;215:2–12.

Choi S, Song CW, Shin JH, Lee SY. Biorefineries for the production of top building block chemicals and their derivatives. Metab Eng. 2015;28:223–39.

Li H, Riisager A, Saravanamurugan S, Pandey A, Sangwan RS, Yang S, Luque R. Carbon-increasing catalytic strategies for upgrading biomass into energy-intensive fuels and chemicals. ACS Catal. 2018;8:148–87.

Cavani F, Albonetti S, Basile F, Gandini A. Chemicals and fuels from bio-based building blocks. Weinheim: Wiley-VCH; 2016.

Kumar CA, Kumar G, Kumar SA, Fernandes FA, da Silva SS. The path forward for lignocellulose biorefineries: bottlenecks, solutions, and perspective on commercialization. Bioresource Techn. 2018;264:370–81.

Iaquaniello G, Centi G, Salladini A, Palo E, Perathoner S. Waste to chemicals for a circular economy. Chem–A Eur J. 2018;24:11831–9.

Sanchez AS, Silva YL, Kalid RA, Cohim E, Torres EA. Waste bio-refineries for the cassava starch industry: new trends and review of alternatives. Renew Sustain Energy Rev. 2017;73:1265–75.

Mata MT, Martins AA, Caetano NS. Bio-refinery approach for spent coffee grounds valorization. Bioresource Techn. 2018;247:1077–84.

Ma H, Cao Y, Lu X, Ding Z, Zhou W. Review of typical municipal solid waste disposal status and energy technology. Energy Procedia. 2016;88:589–94.

Czajczynska D, Nannou T, Anguilano L, Krzyzynska R, Ghazal H, Spencer N, Jouhara H. Potentials of pyrolysis processes in the waste management sector. Energy Procedia. 2017;123:387–94.

Hassan H, Lim JK, Hameed BH. Recent progress on biomass co-pyrolysis conversion into high-quality bio-oil. Bioresource Techn. 2016;221:645–55.

Lombardi L, Carnevale E, Corti A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015;37:26–44.

Chen P, Xie Q, Addy M, Zhou W, Liu Y, Wang Y, Cheng Y, Li K, Ruan R. Utilization of municipal solid and liquid wastes for bioenergy and bioproducts production. Bioresource Techn. 2016;215:163–72.

Widjaya ER, Chen G, Bowtell L, Hills C. Gasification of non-woody biomass: a literature review. Renew Sustain Energy Rev. 2018;89:184–93.

Claude V, Courson C, Kohler M, Lambert SD. Overview and essentials of biomass gasification technologies and their catalytic cleaning methods. Energy Fuel. 2016;30:8791–814.

Mahinpey N, Gomez A. Review of gasification fundamentals and new findings: reactors, feedstock, and kinetic studies. Chem Eng Sci. 2016;148:14–31.

Klinghoffer NB, Castaldi MJ. Gasification and pyrolysis of municipal solid waste (MSW). Woodhead Publishing Series in Energy. 2013;29:146–76.

Liu HB, Gu J. Research on MSW (municipal solid waste) gasification by CFB (circulating flue bed). Adv Mater Res. 2014;881-883:560–3.

Maya DMY, Sarmiento ALE, Oliveira CAVB, Lora EES, Andrade RV. Gasification of municipal solid waste for power generation in Brazil, a review of available technologies and their environmental benefits. J Chem Chem Eng. 2016;10:249–55.

Sanlisoy A, Carpinlioglu MO. A review on plasma gasification for solid waste disposal. Int J Hydrog Energy. 2017;42:1361–5.

de la Fuente JF, Kiss AA, Radoiu MT, Stefanidis GD. Microwave plasma emerging technologies for chemical processes. J ChemTechn & Biotechn. 2017;92:2495–505.

Arregi A, Amutio M, Lopez G, Bilbao J, Olazar M. Evaluation of thermochemical routes for hydrogen production from biomass: a review. Energy Conv & Manag. 2018;165:696–719.

Rodriguez Correa C, Kruse A. Supercritical water gasification of biomass for hydrogen production – review. J Supercrit Fluids. 2018;133:573–90.

Adar E, Ince M, Bilgili MS. Gasification of municipal sewage sludge by supercritical water: a review. Fresenius Environ Bull. 2017;26:1503–19.

Yakaboylu O, Harinck J, Smit KG, de Jong W. Supercritical water gasification of biomass: a literature and technology overview. Energies. 2015;8:859–94.

Warnecke R. Gasification of biomass: comparison of fixed bed and fluidized bed gasifier. Biomass Bioenergy. 2000;18:489–97.

Antonetti E, Iaquaniello G, Salladini A, Spadaccini L, Perathoner S, Centi G. Waste-to-Chemicals for a Circular Economy: the case of urea production (waste-to-urea). ChemSusChem. 2016;10:912–20.

Iaquaniello G, Centi G, Salladini A, Palo E, Perathoner S, Spadaccini L. Waste-to-methanol: process and economics assessment. Bioresource Techn. 2017;243:611–9.

Lopez G, Artetxe M, Amutio M, Alvarez J, Bilbao J, Olazar M. Recent advances in the gasification of waste plastics. A critical overview. Renew Sust Energ Rev. 2018;82:576–96.

Tong X, Chen H, Hu J, Bi Y, Sun Z, Fan W. The efficient and sustainable pyrolysis and gasification of biomass by catalytic processes. ChemBioEng Rev. 2015;2:157–74.

Zhang L, Wu W, Zhang Y, Zhou X. Clean synthesis gas production from municipal solid waste via catalytic gasification and reforming technology. Catal Today. 2018;318:39–45.

Blanco PH, Wu C, Onwudili JA, Dupont V, Williams PT. Catalytic pyrolysis/gasification of refuse derived fuel for hydrogen production and tar reduction: influence of nickel to citric acid ratio using Ni/SiO 2 catalysts. Waste and Biomass Valoriz. 2014;5:625–36.

Berdugo Vilches T, Seemann MC, Thunman H. Influence of in-bed catalysis by ash-coated olivine on tar formation in steam gasification of biomass. Energy Fuel. 2018;32:9592–604.

Rapagnà S, Gallucci K, Foscolo PU. Olivine, dolomite and ceramic filters in one vessel to produce clean gas from biomass. Waste Manag. 2018;71:792–800.

Article PubMed CAS Google Scholar

Navarrete A, Centi G, Bogaerts A, Martín Á, York A, Stefanidis G. Harvesting renewable energy for CO 2 catalysis. Energy Techn. 2017;5:796–811.

Article Google Scholar

Perathoner S, Centi G. Catalysis for solar-driven chemistry: the role of electrocatalysis. Catal Today. 2018. https://doi.org/10.1016/j.cattod.2018.03.005 .

Nocera DG. The artificial leaf. Acc Chem Res. 2012;45:767–76.

Joya KS, de Groot HJM. Artificial leaf goes simpler and more efficient for solar fuel generation. ChemSusChem. 2014;7:73–6.