- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Wiki , Six Sigma

DMAIC Model | The 5 Phase DMAIC Process to Problem-Solving

- 5 mins to read

- July 1, 2020

- By Reagan Pannell

Summary: An Introduction to DMAIC

Dmaic – the dmaic model.

The 6 Sigma DMAIC model remains the core roadmap for almost all Lean Six Sigma problem-solving approaches that drive quality improvement projects. It is used to ensure a robust problem-solving process is followed to give the best chance of the best solution being found.

A note about the structure and the approach used in this article.

Our approach to DMAIC follows Quentin Brook’s book “Lean Six Sigma & Minitab” which for anyone wishing to study Lean Six Sigma is a must for the Green Belt Course and the Black Belt Course .

What is the dmaic model.

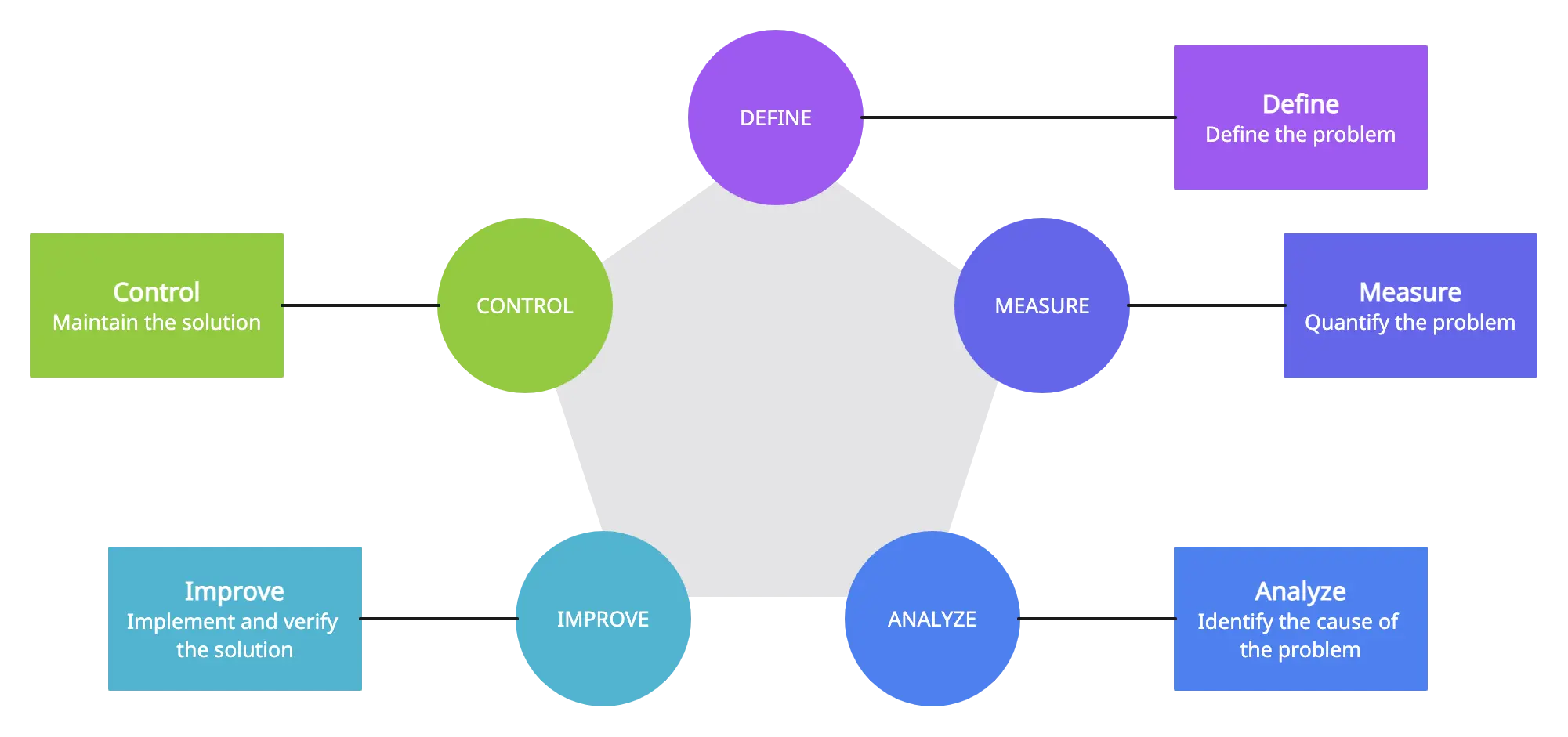

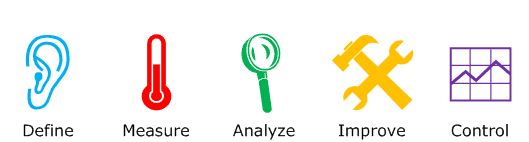

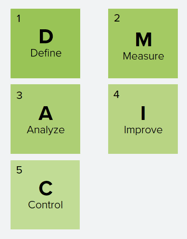

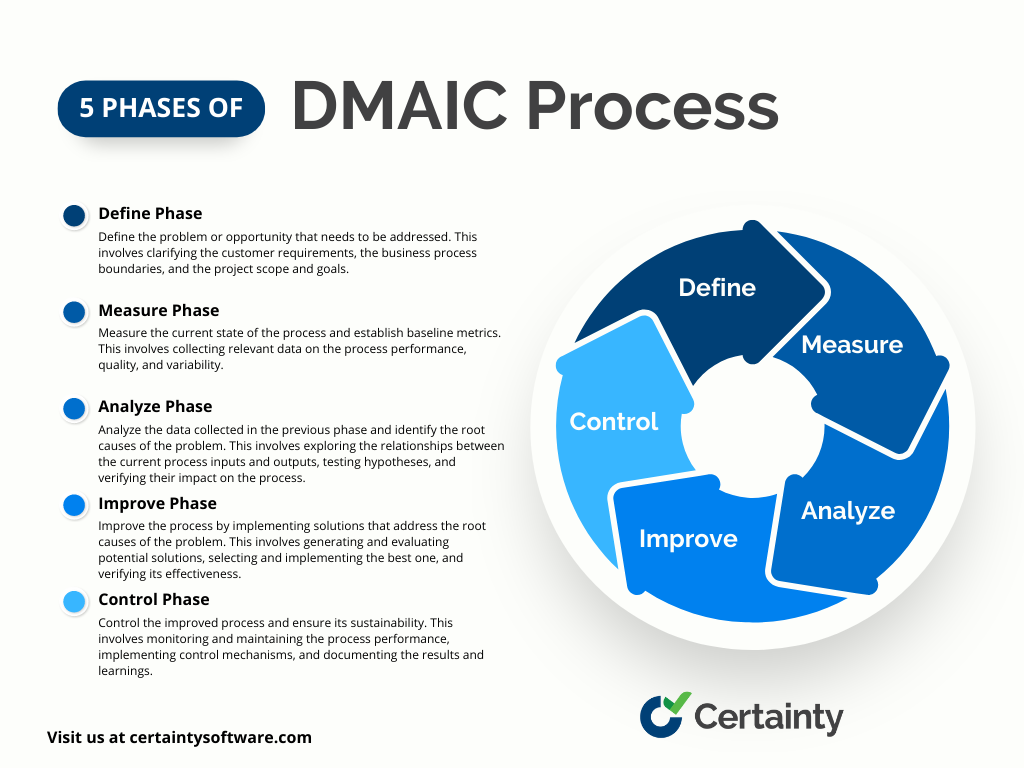

DMAIC is short for: Define, Measure, Analyse, Improve and Control. These are the key phases that each project must go through to find the right solution. This flow is the concept behind DMAIC Analysis of an issue and its the DMAIC cycle all projects must go through.

As you can quickly see from the 5 DMAIC phases they follow a logical sequence as we will go through in more detail below. But they also make sure you do not try to jump to implementing a solution before you have properly, defined and measured what you are going to be an improvement.

We all love to jump to solutions, but the DMAIC problem-solving structure helps us have a more rigorous approach so that we do not short cut the process and perhaps miss the best solution or perhaps implement the wrong solution as well. It can help companies better structure their problem-solving approaches and be more robust in their approach.

DMAIC – The 5 DMAIC Process Phases

The phases throughout the DMAIC model have and can be broken down in many different ways. One of the best approaches we have found is from Opex Resources which shows how to examine the existing processes, and with a project team, and the sigma improvement process, we can solve complex issues.

DMAIC Define Phase

The purpose of the Define phase is ultimately to describe the problems that need to be solved and for the key business decision-makers to be aligned on the goal of the project. Its about creating and agreeing the project charter .

All too often, teams have identified solutions without actually defining what it is they will actually be trying to do or perhaps not do. This can lead to internal confusion and often solutions which completely miss the business requirements and needs.

- Define the Business Case

- Understand the Consumer

- Define The Process

- Manage the Project

- Gain Project Approval

DMAIC Measure Phase

In the measure phase, the goal is to collect the relevant information to baseline the current performance of the product or the process. In this stage, we want to identify the level of “defects” or the errors that go wrong and use the baseline to measure our progress throughout the project.

The key goal of this phase is to have a very strong and clear measure/baseline of how things are performing today so that we can always monitor our progress towards our goals. We need to understand our cycle times , process times, quality metrics.

Many projects are delivered without clear benefits being shown because the team never fully baseline the current status before making changes.

The Measure phase can be broken down into 5 key areas:

- Develop Process Measures

- Collect Process Data

- Check the Data Quality

- Understand Process Behaviour

- Baseline Process Capability and Potential

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

We can’t solve problems by using the same kind of thinking we used when we created them” Albert Einstein Tweet

DMAIC Analyse Phase

The goal of the DMAIC Analyse phase with the lean six sigma improvement process is to identify which process inputs or parameters have the most critical effect on the outputs. In other words, we want to identify the root cause(s) so that we know what critical elements we need to fix.

During this phase, the teams need to explore all potential root causes using both analytical approaches, statistical approaches or even graphical tools such as VSM’s and Process maps to uncover the most important elements which need to be changed/fixed.

The Analyse phase can be broken down into:

- Analyse the Process

- Develop Theories and Ideas

- Analyse the Data

- and finally, Verify Root Causes

DMAIC Improve Phase

The goal of the improvement phase is to identify a wide range of potential solutions before identifying the critical solutions which will give us the maximum return for our investment and directly fix the root cause we identified.

During this phase, the team brainstorm, pilot, test and validate potential improvement ideas before finally implementing the right solutions. With each pilot, the team can validate how well it improves the key measures they identified back in Define and Measure. When the team finally roll out the solution, the results should be seen if the right solution has been found and implemented correctly.

The Improve phase can be broken down into:

- Generate Potential Solutions

- Select the Best Solution

- Assess the Risks

- Pilot and Implement

DMAIC Control Phase

The final part of the DMAIC Model is the Control phase where we need to ensure that the new changes become business as normal and we do not revert to the same way of working as before.

During this phase, we want to ensure that we close the project off by validating the project savings and ensuring the new process is correctly documented. We also need to make sure that new measures and process KPI’s are in place and, finally that we get the business champion to sign off on both the project and the savings. We may need to redesign the workplace following the 5S principles .

The Control phase can be broken down into:

- Implement Ongoing Measurements

- Standardise Solutions

- Quantify the Improvement

- Close The Project

The key closing documents of the Control Phase is a Control Plan that documents all the changes and process steps with key risks, standard work instructions and the Project Close-Out document signed by the business owners to accept the change and the validated benefits.

The DMAIC Model vs. A3 Management vs. 8D Problem Solving

The DMAIC model is not the only project management roadmap. Two others which are important is the A3 format which originally comes from Toyota and is very Lean focused and the 8D which draws more of the DMAIC structure but with the 1-page idea of the A3.

Everyone has their own preference but each method is interchangeable. The DMAIC Structure lends its self naturally to a multi-slide Powerpoint presentation. Whereas the A3 is a single-page document which is perfect for internal communication and adding into War Rooms and Control Towers.

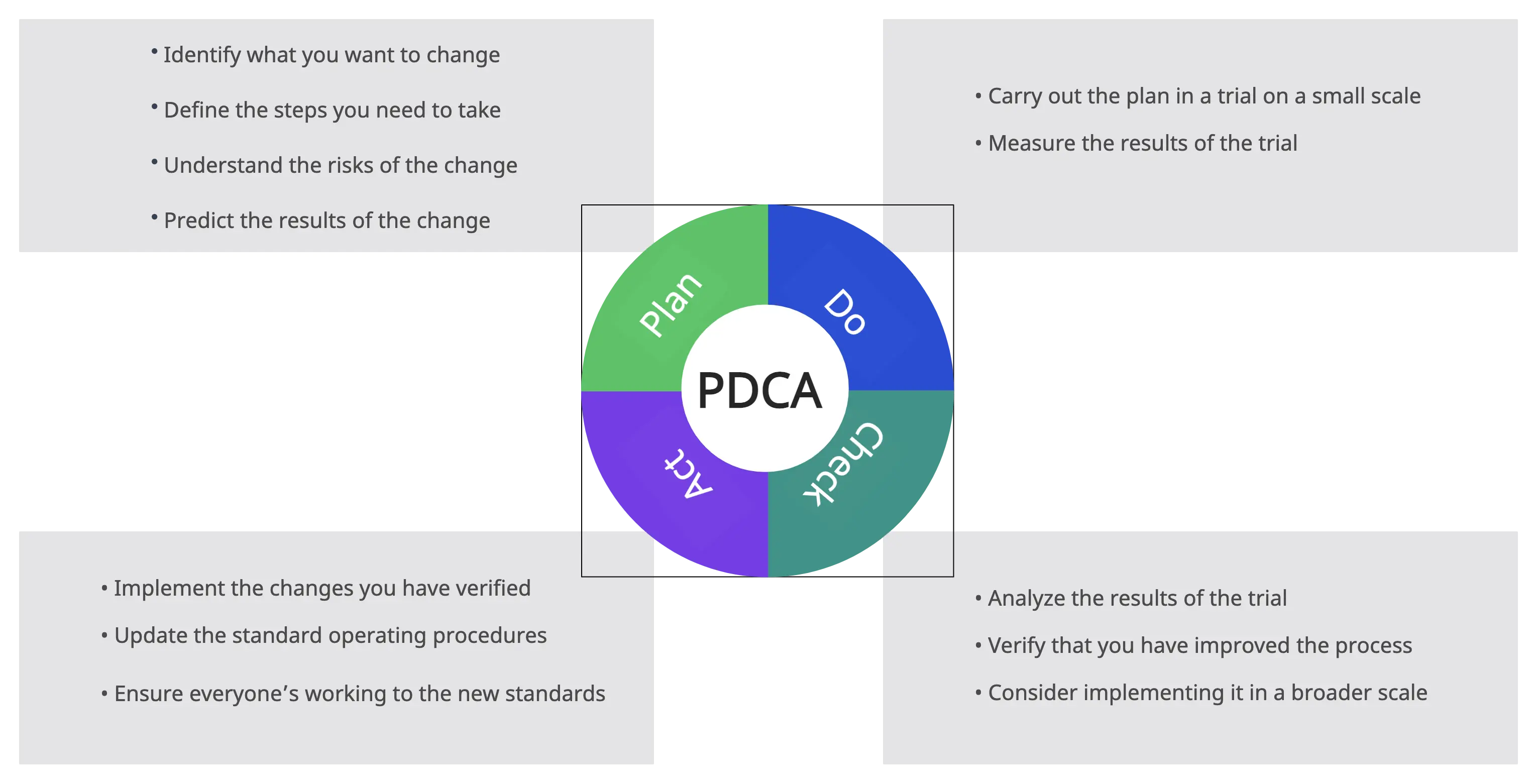

What’s important is that every problem-solving approach follows the PDCA (Plan, Do, Check and Act) Scientific Problem Solving format. The reset is just a preference or using the right tool in the right circumstances.

- Corporate Training

- Courses for Individuals

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

Fundamentals of lean.

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, developing the change management mindset, principe 8: use throughly tested technology | principles of lean, principle 1: use long term goals to drive short term decisions, one piece flow and how it reduces waste and increases productivity, an introduction to measure system analysis, elearning affiliate program | online business courses, a deep dive into the a3 problem-solving approach, how to find out the minimum sample size for lean six sigma, the box-cox transformation: what it is and how to use it, what is the 1 sample t-test, what are the different types of wastes in lean (muda, muri, mura), histogram: a comprehensive guide, related articles, what is a sigma level: a key metric in process capability, an introduction to correlation and regression analysis, lean lifestyle design, 5 essential elements of operational learning, what is the design of experiments tool, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

DMAIC: The Five Steps to Process Improvement Success

Updated: June 3, 2023 by Lori Kinney

At the production line weekly meeting, it’s once again brought to everyone’s attention that the team has failed to meet the quota for the week, missing it by 25%. Tension hangs thick in the air, as assembly, test, quality, material handling, and supply chain are all pointing fingers at each other as to the cause of the lack of production.

The cause of the problem is not obvious, and you need to bring everyone together to better understand the problem, unveil the root cause, and determine the right solutions to put in place.

This situation is a great candidate for using DMAIC.

An overview: What is DMAIC?

DMAIC is a data-driven process-improvement methodology that focuses on properly identifying the problem, utilizing data to determine the root cause, developing and implementing the solution, and verifying that the solution continues to be effective over time.

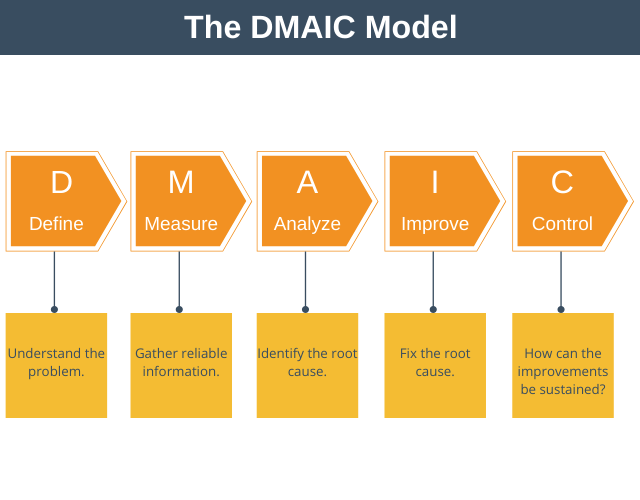

DMAIC is an acronym that stands for Define, Measure, Analyze, Improve, and Control.

The Define stage is when the team defines the problem in clear, concise language. It covers the basic who, what, when, where, why, and how many parts of the situation. This also means it covers the scope of the project, key process metrics, the resources and team members available, the project champion and stakeholders, voice of the customer, budgets, and the project goals.

The Measure stage is when the team measures and documents the current state of the situation and establishes a baseline. Be sure to collect as much quantitative data as possible, and where quantitative data is not available, collect qualitative data. Be sure to collect as much data as your resource constraints allow that is connected to the problem statement key metric, as well as value stream maps , process maps, and process documentation that make up the process. Take time to determine how the data will be collected and how various sources of data compare to each other.

The Analyze stage involves taking the data collected during the Measure stage, and analyzing and identifying the key opportunities for improvement. This is the phase that identifies the root cause of the problem. It’s also the phase where the team identifies what’s working correctly in the process, as these characteristics need to be preserved when the solution to the root cause is selected.

The Improve stage involves the generation, selection, and implementation of the best solutions. These solutions should be within cost and time guidelines, justifying the time and effort it takes to implement the solution.

The Control stage installs and monitors controls into the system to verify that the solution has been institutionalized and continues to hold the gains over time. Eventually, when the metrics in question begin to drift, it may be time to start a new DMAIC problem-solving process, and the entire process begins again.

RELATED: PDCA vs. DMAIC

Benefits of utilizing dmaic , understanding the problem before you find a solution.

Albert Einstein once said, “If I had an hour to solve a problem, I’d spend 55 minutes thinking about the problem and 5 minutes thinking about solutions.” Companies have a bad habit of trying to solve a problem before they fully understand the problem. By completing Define at the beginning and getting the team to agree to the terms, you can keep from wasting problem-solving efforts, increasing your odds of identifying the correct root cause and problem solutions.

Making a complex problem easier to understand

By using the phases of DMAIC and documenting your efforts, a complex problem can be made much easier to understand. Clear problem statements, non-anecdotal data, and visual process maps can go a long way toward getting multiple team members from different departments to understand the true situation.

Improve upon the documentation of the process

It’s common to find out that process documentation is lacking, and during the use of DMAIC, the team will likely unearth sources of tribal knowledge that need to be documented.

3 DMAIC best practices

1. Be sure to have a high-level champion assigned to your project. DMAIC projects are subject to time and budget constraints, so it’s important to have someone at a high enough level within the organization supporting the DMAIC efforts. Be sure to have a clear problem statement, with scope and constraints clearly identified, for the project champion to support.

2. When developing your problem, be sure to scope the problem correctly. If too large a scope is chosen, you will limit the team’s ability to reach and implement a solution within an acceptable amount of time and budget. These projects are often known as “solve world hunger” projects, as these projects never have any chance of reaching completion. If too small a scope is chosen, then the return found by the solution risks not being of a size that justifies the time, budget, and labor required to traverse a DMAIC project.

3. L arger DMAIC situations typically call for additional group focusing techniques, such as holding a Kaizen Event .

Frequently Asked Questions (FAQ) about DMAIC

Should i use dmaic for every problem-solving effort.

While it can be used for any problem, DMAIC is better suited for larger, more complex problems. For problems with simple-to-understand root causes and solutions that are easier to identify and implement, the effort the DMAIC process requires is likely to be overkill.

What are some tools used during DMAIC?

There are numerous tools that may assist your problem-solving efforts. Here are examples of some tools used (note that some may not apply to your specific project; choose wisely):

- Define: Project Worksheet, Voice of the Customer (VOC) , Kaizen Pre-event checklist

- Measure: SIPOC, Standard Work Layout, Time Measurement Worksheet, Process Map

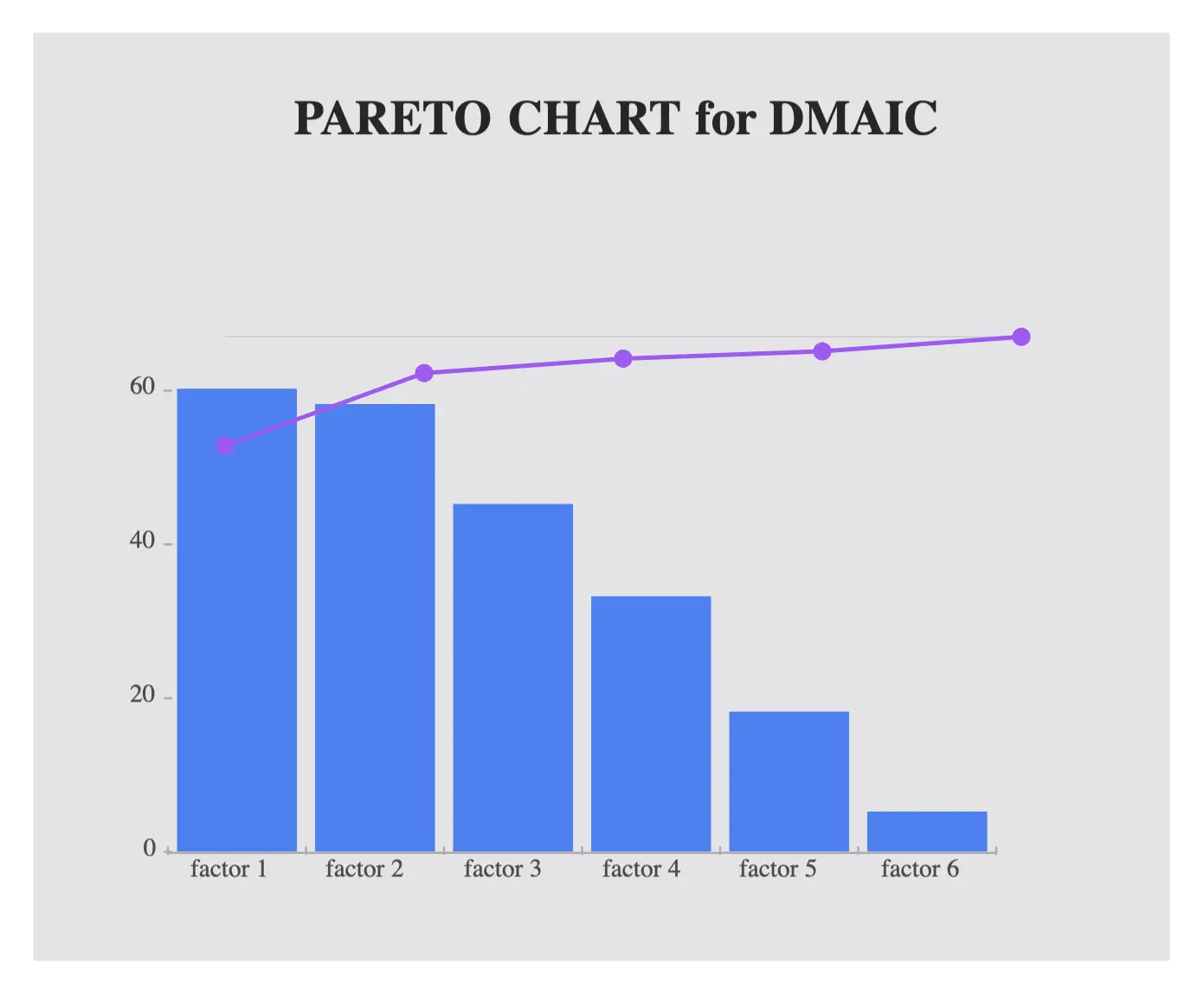

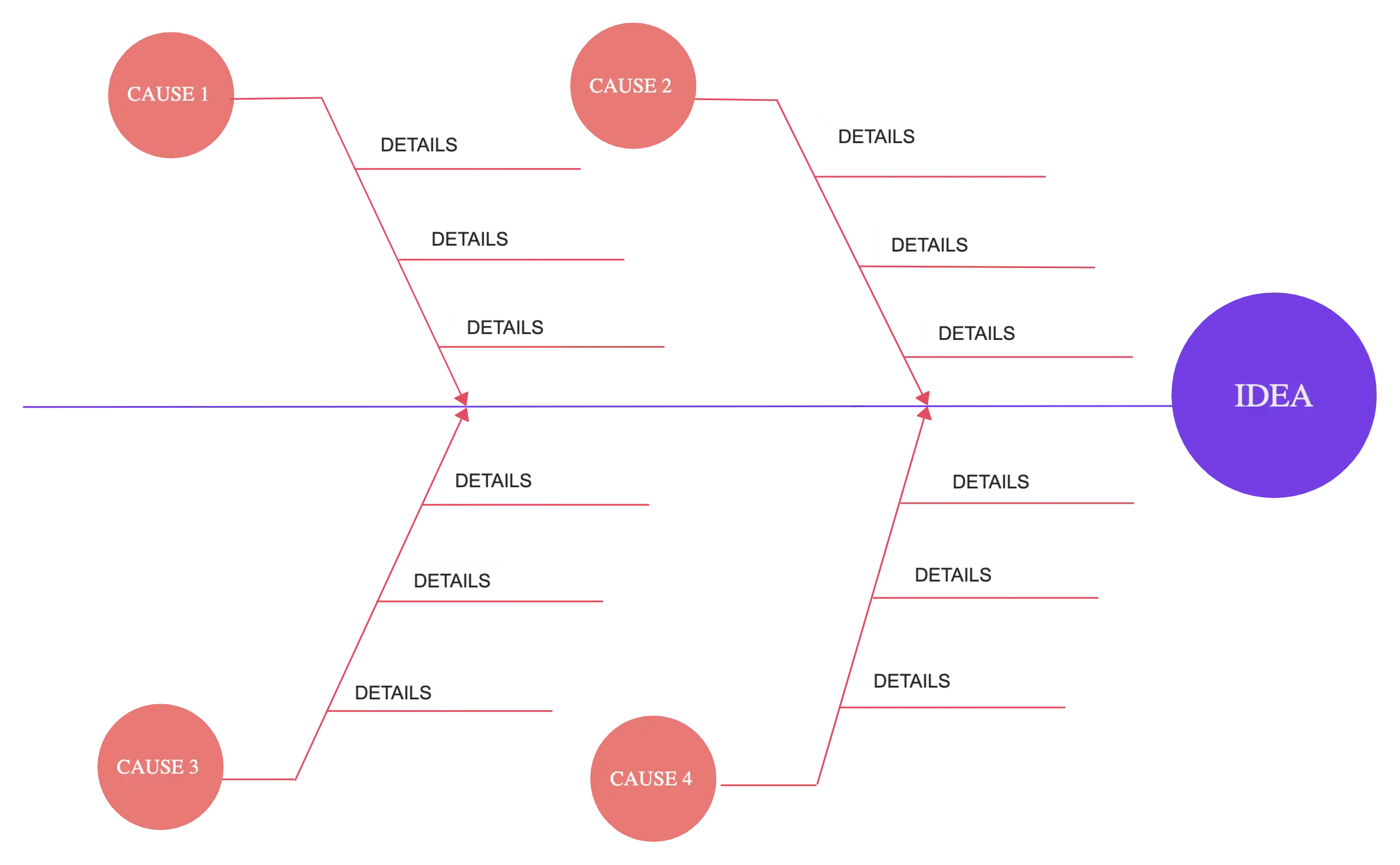

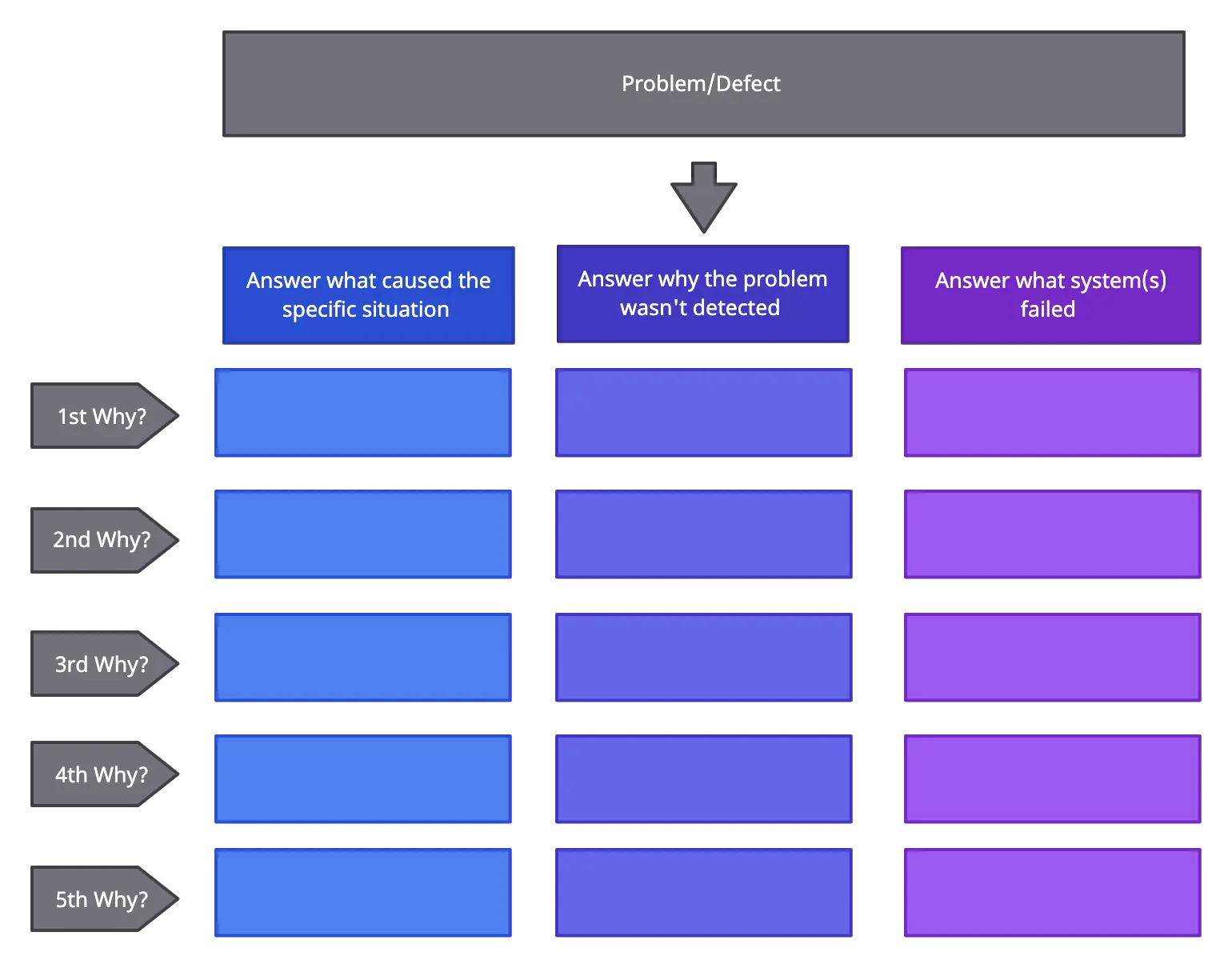

- Analyze: Fishbone , 5 Whys , Pareto Chart , Trend Charts, Paynter Chart

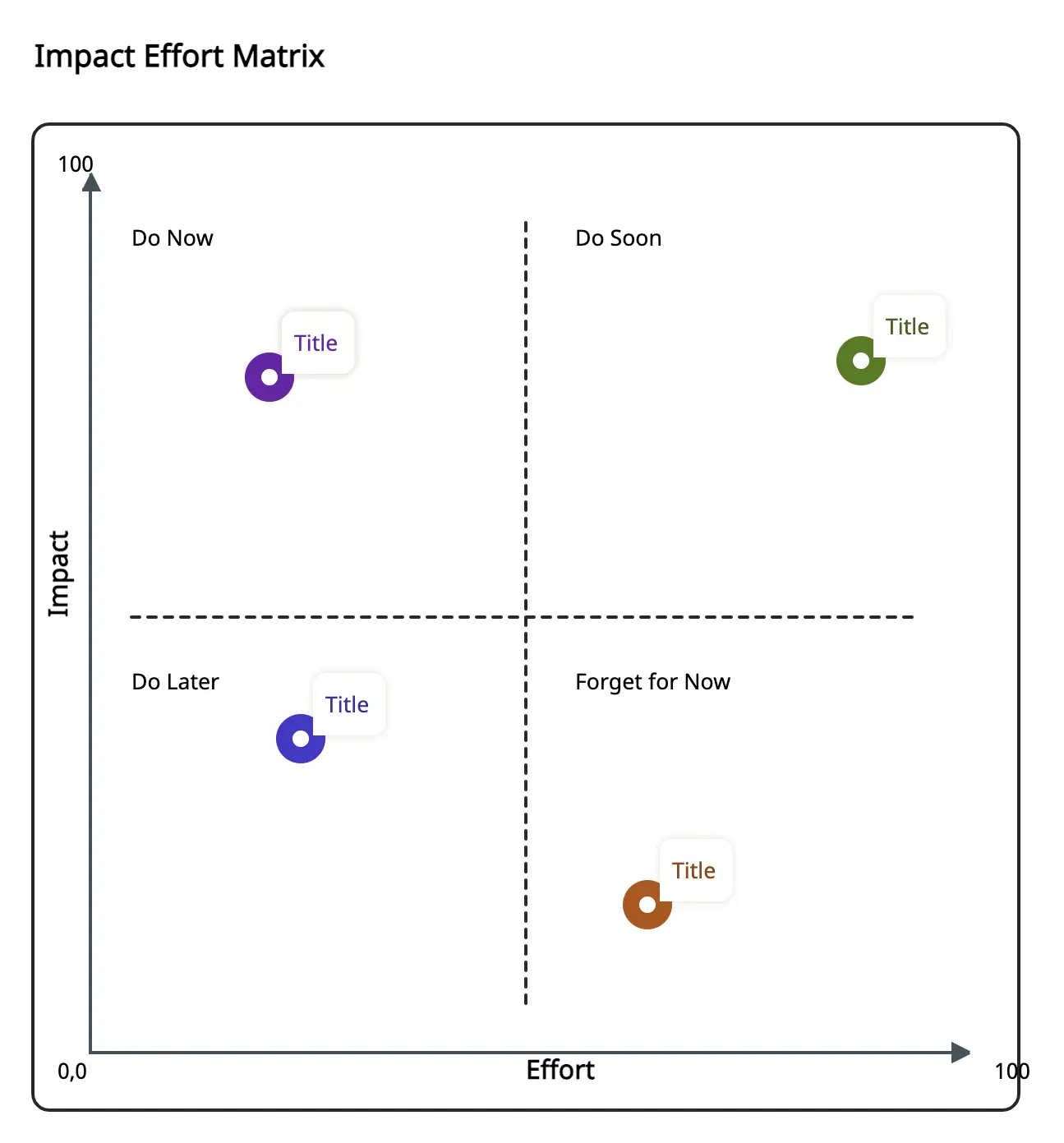

- Improve: PICK Chart, Continuous Improvement Progress Report, Line Balancing

- Control: Control Plan , Gemba Walk Checklist

Is DMAIC the only problem-solving methodology to consider using?

There are other problem-solving methodologies to consider using, though they all have remarkably similar components. Problem-solving alternatives include PDCA , DMADV, A3, and 8D .

DMAIC helps efficiently solve complex problems

DMAIC is a great process for getting teams of people together to better understand the current state of a problem. It leads to a streamlined process of revealing the root cause of the problem, identifying, and implementing effective solutions, and monitoring future success. DMAIC is best suited for more complex problems and for projects that will need higher levels of support to complete. DMAIC is a great tool for reaching your financial, on-time, quality, and safety-based goals.

About the Author

Lori Kinney

The Easy Guide to Solving Problems with Six Sigma DMAIC Method

The most commonly used methodology in Six Sigma is the DMAIC process. Many use it to solve problems and identify and fix errors in business and manufacturing processes.

In this post, we will look at how to use the DMAIC process to solve problems. You will also find useful and editable templates that you can use right away when implementing DMAIC problem-solving in your organization.

- What are 5 the Steps of Six Sigma

DMAIC Process and Problem-Solving

Common mistakes to avoid when using six sigma dmaic methodology, how to use the dmaic methodology for problem solving in project management, what are the 5 steps of six sigma.

DMAIC is one of the core methodologies used within the Six Sigma framework. It is a data-driven method used to systematically improve the process. The approach aims to increase the quality of a product or service by focusing on optimizing the process that produces the output. This way DMAIC seeks to provide permanent solutions when it comes to process improvement.

It provides a structured problem-solving framework to identify, analyze, and improve existing processes. DMAIC guides practitioners through a series of steps to identify the root causes of process issues, implement solutions, and sustain the improvements over time.

Following we have listed down the 5 phases of the DMAIC process along with the steps you need to take when using it to solve problems. Different tools for each phase is provided with editable templates.

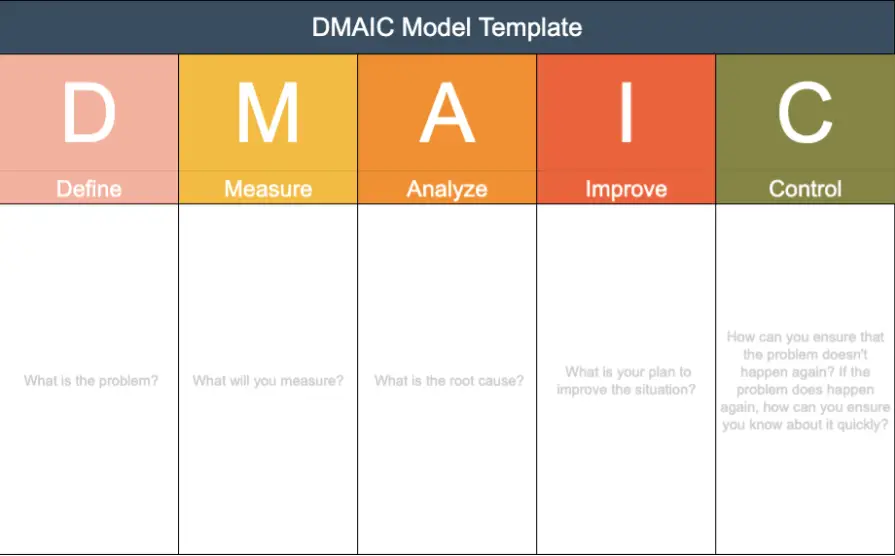

Step 1: Define the Problem

So there’s a problem that affects your customer or your company processes. In this first step of the DMAIC problem solving method , you need to focus on what the problem is and how it has affected you as a company.

There are a few steps you need to follow in this phase.

• Create a problem statement which should include a definition of the problem in quantifiable terms and the severity of the problem.

• Make sure necessary resources such as a team leader and competent team members, and funds etc. are available at hand.

• Develop a goal statement based on your problem statement. It should be a measurable and time-bound target to achieve.

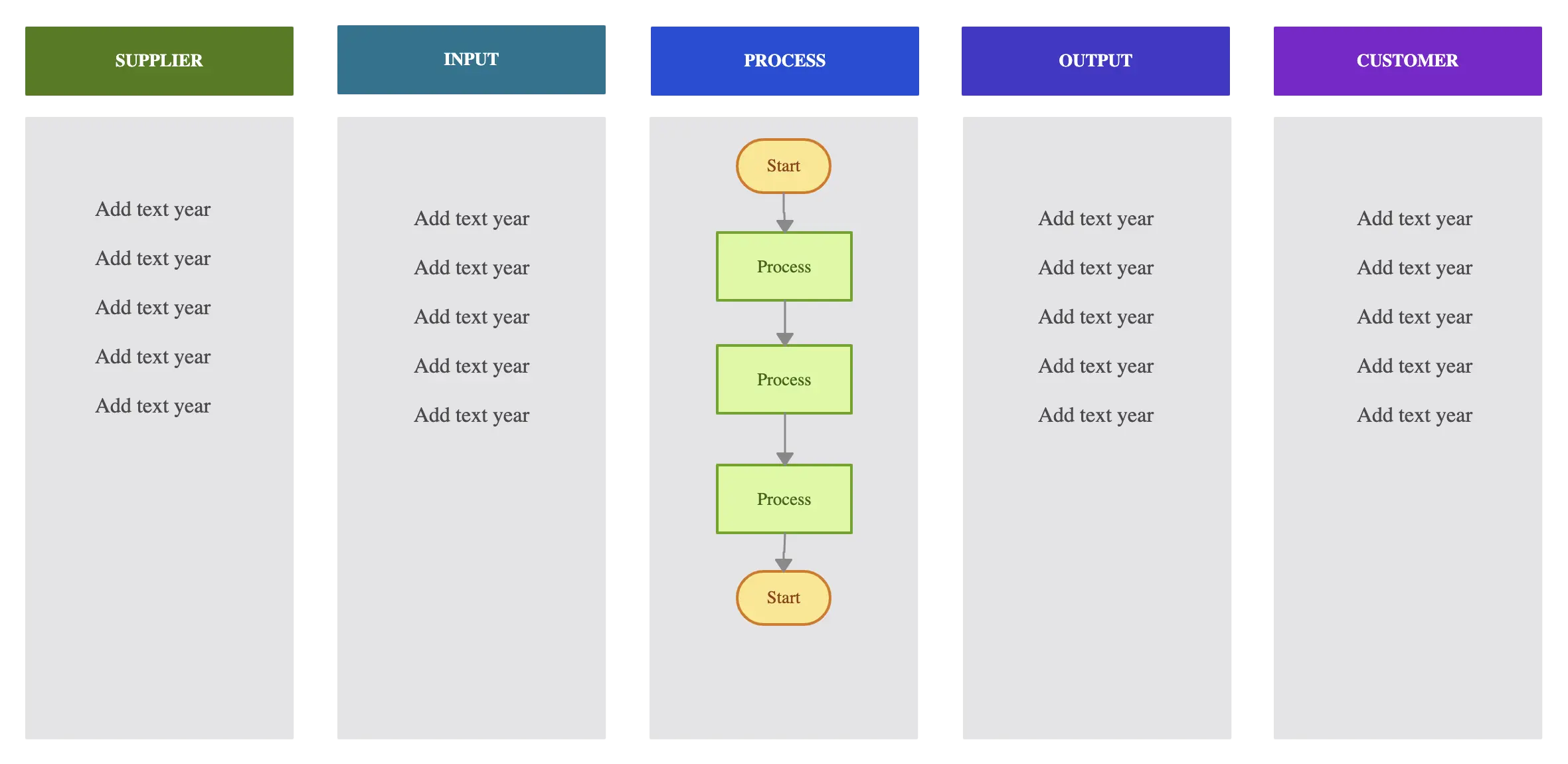

• Create a SIPOC diagram which will provide the team with a high-level overview of the process (along with its inputs, outputs, suppliers, and customers) that is being analyzed. You can also use a value stream map to do the same job.

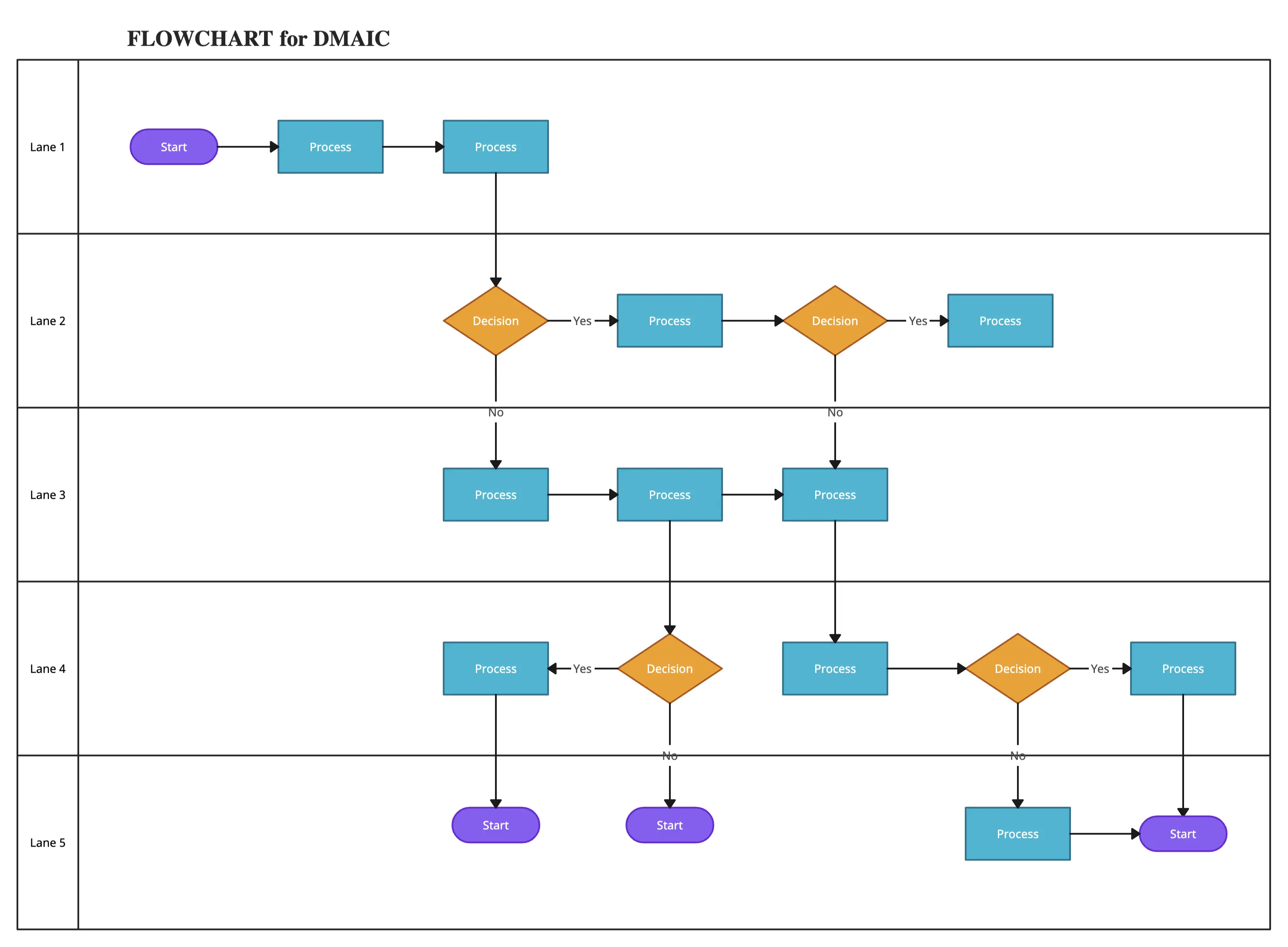

• Try to understand the process in more in-depth detail by creating a process map that outlines all process steps. Involve the process owners when identifying the process steps and developing the map. You can add swimlanes to represent different departments and actors responsible.

Step 2: Measure the Problem

In this step, you should measure the extent of the problem. To do so you need to examine the process in its current state to see how it performs. The detailed process map you created in the ‘Define’ phase can help you with this.

The baseline measurements you will need to look into in this phase, are process duration, the number of defects, costs and other relevant metrics.

These baseline measurements will be used as the standards against which the team will measure their success in the ‘Improve’ phase.

Step 3: Analyze the Problem

The analyze phase of the DMAIC process is about identifying the root cause that is causing the problem.

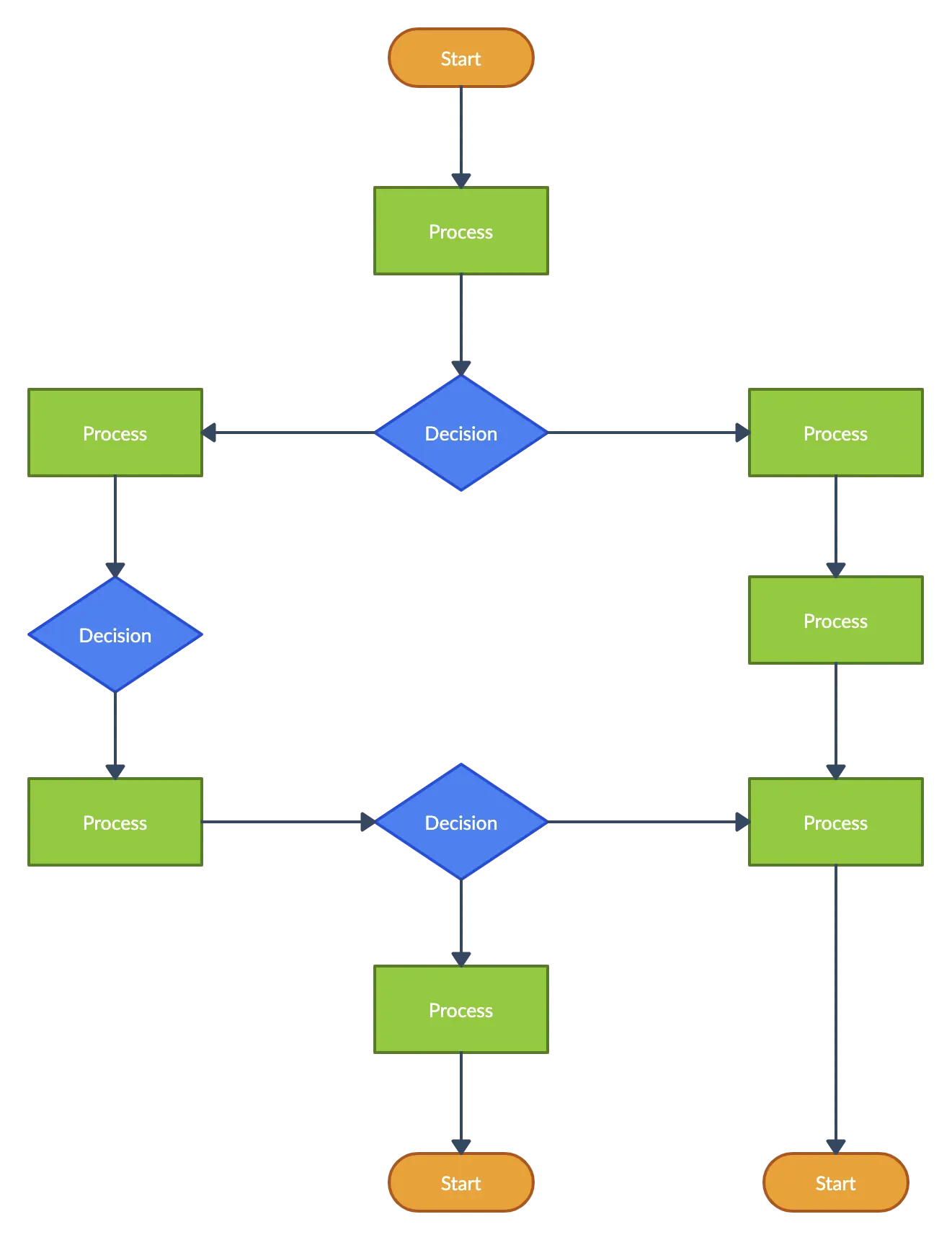

• Referring to the process maps and value stream maps you have created, further, analyze the process to identify the problem areas.

• Visualize the data you have collected (both in the ‘Measure’ phase and the analyze phase) to identify signs of problems in the processes.

• Use Pareto charts, histograms, run charts etc. to represent numerical data. Study them with team leaders and process owners to identify patterns.

• With the results of your process analysis and your data analysis, start brainstorming the root causes of the problem. Use a cause and effect diagram/ fishbone diagram to capture the knowledge of the process participants during the session.

• Using a 5 whys diagram, narrow down your findings to the last few causes of the problem in your process.

Step 4: Improve (Solve the Problem)

In this phase, the focus is on mitigating the root cause identified and brainstorming and implementing solutions. The team will also collect data to measure their improvement against the data collected during the ‘Measure’ phase.

• You may generate several effective solutions to the root cause, but implementing them all would not be practical. Therefore, you will have to select the most practical solutions.

To do this you can use an impact effort matrix . It will help you determine which solution has the best impact and the least effort/ cost.

• Based on different solutions, you should develop new maps that will reflect the status of the process once the solution has been applied. This map is known as the to-be map or the future-state map. It will provide guidance for the team as they implement changes.

• Explore the different solutions using the PDCA cycle and select the best one to implement. The cycle allows you to systematically study the possible solutions, evaluate the results and select the ones that have a higher chance of success.

Step 5: Control (Sustain the Improvements)

In the final phase of the DMAIC method , the focus falls on maintaining the improvements you have gained by implementing the solutions. Here you should continue to measure the success and create a plan to monitor the improvements (a Monitoring plan).

You should also create a Response plan which includes steps to take if there’s a drop in the process performance. With new process maps and other documentation, you should then proceed to document the improved processes.

Hand these documents along with the Monitoring plan and the response plan to the process owners for their reference.

Insufficiently defining the problem can lead to a lack of clarity regarding the problem statement, objectives, and scope. Take the time to clearly define the problem, understand the desired outcomes, and align stakeholders' expectations.

Failing to engage key stakeholders throughout the DMAIC process can result in limited buy-in and resistance to change. Ensure that stakeholders are involved from the beginning, seeking their input, addressing concerns, and keeping them informed about progress and outcomes.

Collecting insufficient or inaccurate data can lead to flawed analysis and incorrect conclusions. Take the time to gather relevant data using appropriate measurement systems, ensure data accuracy and reliability, and apply appropriate statistical analysis techniques to derive meaningful insights.

Getting caught up in analysis paralysis without taking action is a common pitfall. While analysis is crucial, it’s equally important to translate insights into concrete improvement actions. Strive for a balance between analysis and implementation to drive real change.

Failing to test potential solutions before implementation can lead to unintended consequences. Utilize methods such as pilot studies, simulation, or small-scale experiments to validate and refine proposed solutions before full-scale implementation.

Successful process improvement is not just about making initial changes ; it’s about sustaining those improvements over the long term. Develop robust control plans, standard operating procedures, and monitoring mechanisms to ensure the gains achieved are maintained and deviations are identified and corrected.

Applying DMAIC in a one-size-fits-all manner without considering the organization’s unique culture, context, and capabilities can hinder success. Tailor the approach to fit the specific needs, capabilities, and culture of the organization to enhance acceptance and implementation.

In the project management context, the Define phase involves clearly defining the project objectives, scope, deliverables, and success criteria. It entails identifying project stakeholders, understanding their expectations, and establishing a project charter or a similar document that outlines the project’s purpose and key parameters.

The Measure phase focuses on collecting data and metrics to assess the project’s progress, performance, and adherence to schedule and budget. Key project metrics such as schedule variance, cost variance, and resource utilization are tracked and analyzed. This phase provides insights into the project’s current state and helps identify areas that require improvement.

The Analyze phase involves analyzing the project data and identifying root causes of any performance gaps or issues. It aims to understand why certain project aspects are not meeting expectations. Techniques such as root cause analysis, Pareto charts, or fishbone diagrams can be used to identify factors impacting project performance.

In the Improve phase, potential solutions and actions are developed and implemented to address the identified issues. This may involve making adjustments to the project plan, reallocating resources, refining processes, or implementing corrective measures. The goal is to optimize project performance and achieve desired outcomes.

The Control phase focuses on monitoring and controlling project activities to sustain the improvements made. It involves implementing project control mechanisms, establishing performance metrics, and conducting regular reviews to ensure that the project remains on track. Control measures help prevent deviations from the plan and enable timely corrective actions.

What are Your Thoughts on DMAIC Problem Solving Method?

Here we have covered the 5 phases of Six Sigma DMAIC and the tools that you can use in each stage. You can use them to identify problem areas in your organizational processes, generate practical solutions and implement them effectively.

Have you used DMAIC process to improve processes and solve problems in your organization? Share your experience with the tool with us in the comment section below.

Also, check our post on Process Improvement Methodologies to learn about more Six Sigma and Lean tools to streamline your processes.

Join over thousands of organizations that use Creately to brainstorm, plan, analyze, and execute their projects successfully.

FAQs about Six Sigma and DMAIC Approaches

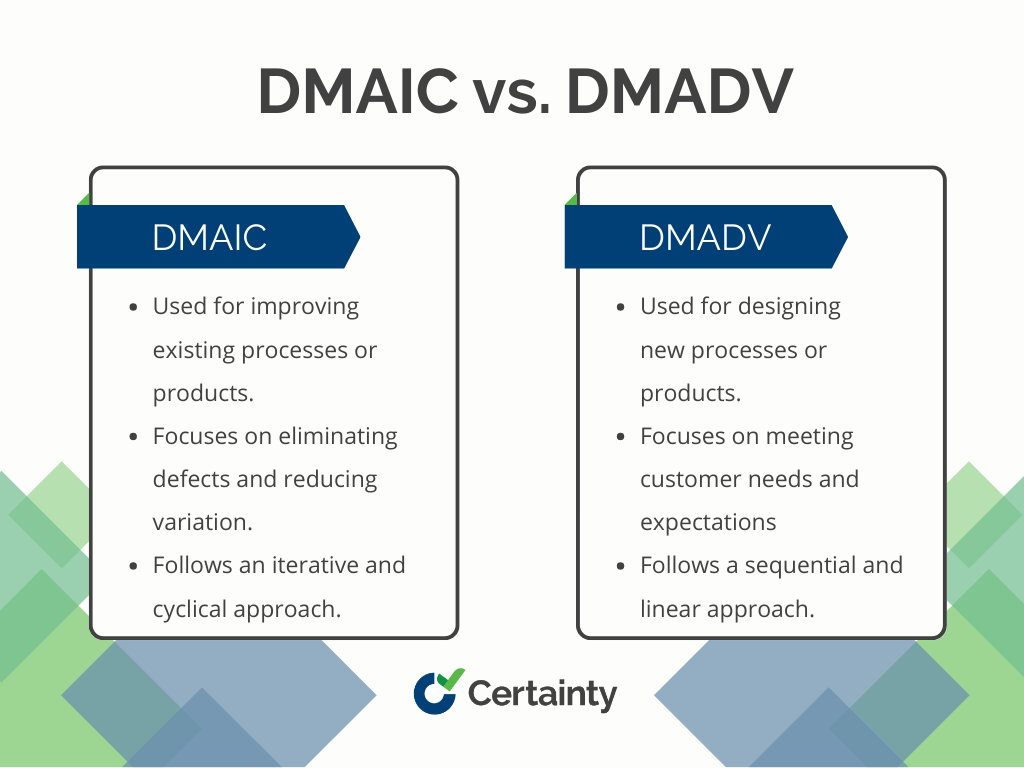

DMAIC and DMADV are two methodologies used in Six Sigma. DMAIC is employed to enhance existing processes by addressing issues and improving efficiency, while DMADV is utilized for creating new processes or products that meet specific customer needs by following a structured design and verification process.

- Used for improving existing processes

- Define, Measure, Analyze, Improve, Control

- Identifies problem areas and implements solutions

- Focuses on reducing process variation and enhancing efficiency

- Used for developing new products, services, or processes

- Define, Measure, Analyze, Design, Verify

- Emphasizes meeting customer requirements and creating innovative solutions

- Involves detailed design and verification through testing

Problem identification : When a process is not meeting desired outcomes or experiencing defects, DMAIC can be used to identify and address the root causes of the problem.

Process optimization : DMAIC provides a systematic approach to analyze and make improvements to processes by reducing waste, improving cycle time, or enhancing overall efficiency.

Continuous improvement : DMAIC is often used as part of ongoing quality management efforts. It helps organizations maintain a culture of continuous improvement by systematically identifying and addressing process issues, reducing variation, and striving for better performance.

Data-driven decision making : DMAIC relies on data collection, measurement, and analysis. It is suitable when there is sufficient data available to evaluate process performance and identify areas for improvement.

Quality control and defect reduction : DMAIC is particularly useful when the primary objective is to reduce defects, minimize errors, and enhance product or service quality. By analyzing the root causes of defects, improvements can be made to prevent their occurrence.

More Related Articles

Amanda Athuraliya is the communication specialist/content writer at Creately, online diagramming and collaboration tool. She is an avid reader, a budding writer and a passionate researcher who loves to write about all kinds of topics.

Six Sigma Study Guide

Study notes and guides for Six Sigma certification tests

DMAIC Overview

Posted by Ted Hessing

DMAIC is Six Sigma’s signature framework for process improvement. It provides a structured way of improving a process.

Key Attributes

A DMAIC improvement process:

- Is data-driven.

- Is followed in a strict sequence.

- Uses all five steps.

The Five DMAIC Stages

The five stages we use are:

- Define : Collate what we already know about the existing process.

- Measure : Collect further data about the existing process.

- Analyze : Identify the core problems that we’ll address.

- Improve : Plan, test, and implement solutions.

- Control : Set up supports to ensure that successful solutions are sustainable.

Note how this is reminiscent of the Deming wheel or Shewhart Wheel: Plan-Do-Study-Act ).

History of DMAIC

Michel Harry & Bill Smith created “MAIC” – the methodology that evolved to become DMAIC.

Harry includes the following strategy elements in the traditional approach to Six Sigma:

- (R) Recognize the true state of your business

- (S) Standardize the systems that prove to be best-in-class

- (I) Integrate best-in-class systems into the strategic planning framework.

What’s the difference between Six Sigma and DMAIC?

Six Sigma and DMAIC are closely related, as DMAIC is the problem-solving methodology used in Six Sigma. Six Sigma is a data-driven approach to process improvement that aims to minimize defects and variability in products and services. It uses statistical analysis and other tools to identify and eliminate the root causes of defects, and ultimately improve business performance.

DMAIC, on the other hand, is the acronym that describes the five-step problem-solving process used in Six Sigma projects. It stands for Define, Measure, Analyze, Improve, and Control. DMAIC provides a structured and disciplined approach to problem-solving that enables organizations to achieve Six Sigma levels of quality and efficiency.

Can you use DMAIC outside of Six Sigma?

Absolutely! DMAIC can be used for non-Six Sigma purposes as well.

DMAIC is a structured and disciplined problem-solving methodology that can be applied to a wide range of industries and situations beyond just Six Sigma. The five steps of DMAIC (Define, Measure, Analyze, Improve, and Control) provide a framework for identifying and eliminating problems, improving processes, and achieving better outcomes.

For example, DMAIC can be used in healthcare to improve patient care processes, reduce medical errors, and increase patient satisfaction. In the software industry, DMAIC can be used to identify and fix software bugs, improve user experience, and optimize software development processes. In construction, DMAIC can be used to improve safety practices, reduce waste, and increase productivity.

The key benefit of using DMAIC outside of Six Sigma is that it provides a standardized and data-driven approach to problem-solving that can be applied in any industry or situation. By using DMAIC, organizations can identify and address the root causes of problems, improve processes, and achieve better outcomes, regardless of whether they are formally practicing Six Sigma or not.

The DMAIC Phases

Define phase.

In the Define phase, you collate a lot of information you already have available. You’ll:

- Understand the project, including its purpose and scope.

- Map the current process.

- Determine whether the process is a good candidate for DMAIC.

- Detail customer expectations.

- Estimate timelines and costs.

Should you use DMAIC?

Some projects aren’t suitable for this process. For example:

- It’s already very clear what the problem is and how to solve it.

- There’s no or little available data on the process to be improved.

- Managers and leaders do not support improvements to this process.

- The process does not directly impact key performance indicators.

- Measuring process improvements would be difficult or impossible.

Further information about the Define phase

For more information about the Define phase, the steps to go through, and the tools to use, see Define Phase (DMAIC) .

Measure Phase

You’ve mapped the existing process, understood the project, and decided that this is a good DMAIC candidate. You’ve listed customer expectations and estimated the times and costs involved.

Your next phase involves a lot of measurements. You need to have baseline figures to assess progress accurately in later phases.

During this phase, you will:

- Identify the data that you need to collect.

- Decide what measurements to use.

- Figure out what methods to use to collect your measurements.

- Determine the level of variation that you’ll be dealing with.

- Collect the data as per previous points.

Further information about the Measure phase

For more information about the Measure phase, the steps to go through, and the tools to use, see Measure Phase (DMAIC) .

Analyze Phase

In the Analyze phase, you work with the data that you collected in the Measure phase. You’ll:

- Identify defect causes.

- Analyze these to pinpoint the root cause.

Further information about the Analyze phase

For more information about the Analyze phase, the steps to go through, and the tools to use, see Analyze Phase (DMAIC) .

Improve Phase

You’ve identified the root cause of your issue in the Analyze phase. Now you need to come up with a solution. You’ll:

- Pull in people who perform or oversee the process.

- Brainstorm potential solutions.

- Determine criteria for selecting a solution.

- Weigh potential solutions against the criteria.

- Pick a solution.

- Test the chosen solution.

- Measure the results and compare them to the Measure phase data.

Further information about the Improve phase

For more information about the Improve phase, the steps to go through, and the tools to use, see Improve Phase (DMAIC) .

Control Phase

Once you’re happy that the chosen solution will improve the process, it’s time to implement the Control phase. This is where you actually implement the said solution, but there are some other tasks too:

- Document the solution.

- Collect data about how the solution is working in production.

- Put supports in place to ensure the solution is permanent, not temporary.

- Set up a plan to deal with any issues that might arise.

- Plan handover to the operations personnel.

Further information about the Control phase

For more information about the Control phase, the steps to go through, and the tools to use, see Control Phase (DMAIC) .

DMAIC Tollgate Reviews

You’ll typically review progress regularly with your sponsors. This kind of review, especially when ending one phase and moving on to the next, is called a Tollgate review.

Learn more about DMAIC tollgate reviews here.

Comments (8)

Is there suppose to be a “what makes a good DMAIC project” video attached?

There will be soon. We’re currently reconstructing this page to have a different organization and more details.

Can DMAIC tools or methodology can be used in FOCUS PDCA project? what tools are relevant? What tools are not relevant?

I hadn’t heard of FOCUS so thank you for mentioning it so I could look it up.

DMAIC is an offshoot of the PDCA process (As is Agile and many other frameworks) so I’m inclined to say yes, it is.

Here’s how I would see it stacking up:

Plan -> D: Define, M: Measure, A: Analyze Do – > I: Implement. Check -> C: Control. Act -> C: Control (specifically Control Plans which could be a simple process, return to Implement and do a new thing, or even return to Define / Measure / Analyze)

Thanks for the great question!

Hi, could DMAIC be used as a root cause analysis method, specifically for the resolution of failures/problems/deviations not necessarily generated in a project but by normal operations within a process?

Hi Jennifer,

DMAIC is an acronym for the framework (Define, Measure, Analyze, Improve, Control). Root cause analysis is one step inside the Analysis phase.

I just wanted to let you know that while studying for my Green Belt in Six Sigma I have found this an invaluable resource that has demystified the whole concept of lean and DMAIC! I work in the intellectual disability sector where it is not the norm to apply lean / DMAIC to quality improvement, but where it absolutely can be applied to great effect. Thanks and kind regards, Emer

Thank you so much for the kind words, Emer! We work hard to make these concepts clear and it’s gratifying to know it’s helpful!

I don’t want to presuppose, but you might be interested in a few articles that Jamie Garret contributed about how he applied Lean Six Sigma teaching – another field where Six Sigma is not traditionally applied.

- How Lean Six Sigma Saved my Teaching Career

- How Control Charts Made Me a Better Teacher

- How Advanced Control Charts Can Save Our Schools

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Insert/edit link

Enter the destination URL

Or link to existing content

- > Unlocking Success with the DMAIC Model: Your Essential Guide

Unlocking Success with the DMAIC Model: Your Essential Guide

Posted by Danielle Yoon

Oct 5, 2023 2:16:41 PM

It is often associated with the Lean Six Sigma business methodology, but it can be valuable for any organization.

The Purpose of DMAIC

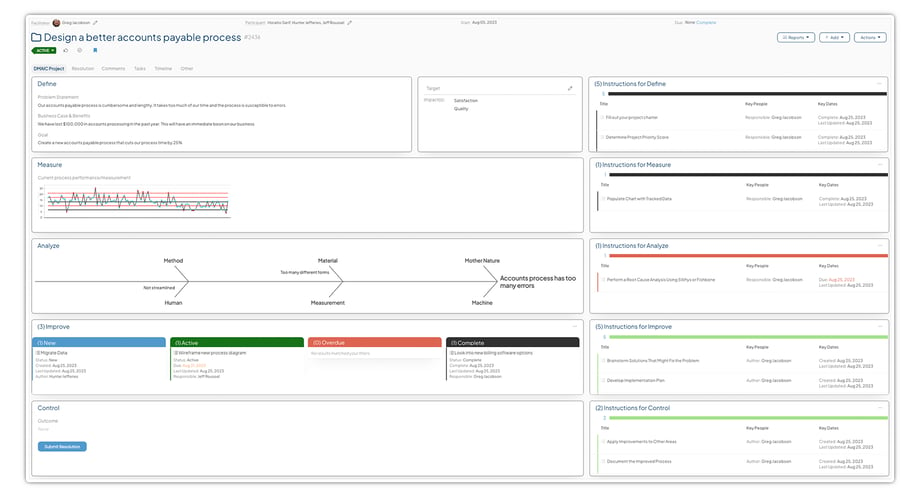

The goal of the DMAIC approach is to bring structure to problem-solving. When organizations consistently use the model, employees become better at addressing process issues and finding an effective solution. Cross-functional collaboration is enhanced, and change becomes easier to control. Teams can use DMAIC to implement a new process or improve an existing process. Because change is based on collected data, it is possible to determine whether business results are improved and by what measure.

DMAIC is popular because it is repeatable and easy to understand. It provides quantifiable evidence that improvements are working. For example, a tire manufacturer in Portugal was able to save more than $200,000 a year using DMAIC to address waste in the rubber extrusion process.

Let's take a deeper dive into each of the five steps of DMAIC.

During the Define phase, high-impact opportunities for improvement are selected.

The critical steps during Define are:

- Identify the opportunity for improvement

- Delineate the scope of the project

- Develop customer requirements

- Estimate project impact

- Identify all stakeholders

- Form the team

Resist the temptation to rush through this step and start experimenting with change.

During the Measure phase, existing processes are documented, data is collected, and a baseline upon which to improve is established.

Critical activities include:

- Develop the methods of data collection

- Identify input, processes, and output indicators

- Gather and analyze current state data

- Complete failure modes and effects analysis

Consider control charts to map process behavior and identify trends.

The Analyze phase aims to identify and test the root causes of problems and ensure that improvement is focused on them.

- Develop a problem statement

- Complete a root cause analysis

- Implement process control

- Design measurable improvement experiments

- Develop a plan for improvement

Many organizations use value stream mapping and the 5 Whys problem-solving technique during this stage.

Now you'll start to implement the changes that the study and measurement have prescribed.

The following activities are typical:

- Generate and discuss solution ideas

- Determine expected solution benefits

- Develop revised process maps and plans

- Define a pilot solution and plan

- Communicate solutions to all stakeholders

Improvement management software plays an integral part at this stage. Leaders make assignments and track activities as the project progresses. Email and in-app alerts help ensure that no tasks are missed. Executives and managers can follow the progress of all DMAIC projects using dashboards and charts.

It's time to ensure that the win will be lasting and that results will be measured over the long run.

Your team will:

- Verify reduction in failures due to the targeted cause

- Determine if additional improvements are required to achieve the goal

- Identify and document the new Standard work

- Integrate and share the lessons learned

If you have improvement technology in place, you can set up your measurement activities to ensure that key performance indicators continue to show the expected results.

How to Use DMAIC

If you'd like to put the DMAIC model to work in your organization, the following implementation steps are useful:

Step 1: Training

Start by educating your team about the DMAIC approach and how it will be used in your organization. Emphasize the data collection aspects of the model.

Step 2: Support and Tools

Many Lean Six Sigma tools can be used during a DMAIC cycle, including control charts, the 5 Whys, fishbone diagrams, and Catchball. Determine which tools your team will use and how they will be documented and shared. Improvement management software is the ideal home for all DMAIC related documents and progress notes.

Step 3: Provide Examples

It helps to provide your team members with examples of the types of existing or new processes within your organization that are good targets for the DMAIC approach. Once they understand how it can be used, make sure there is an easy way for employees to suggest process improvement opportunities.

Step 4: Conduct a Pilot Project

Once you've completed these steps, you're ready to give it a try! Choose a simple project to begin with, preferably one that involves people from multiple teams. Pay attention to each step in the cycle and be sure that each is complete before moving to the next.

DMAIC takes discipline, but once your team gets comfortable with the approach, it will become second nature, enabling them to create more positive change quickly and efficiently.

Topics: Improvement Methodology , DMAIC

Add a Comment

Subscribe via email, recent posts.

- Our Customers

Why KaiNexus

- Collaboration

- Standardization

- Customer Success Manager

- Lean Strategy

- Solutions Engineering

- Customer Marketing

- Configuration

- Continuous Enhancements

- Employee Driven

- Leader Driven

- Strategy Development

- Process Driven

- Daily Huddles

- Idea Generation

- Standard Work

- Visual Management

- Advanced ROI

- Notifications

- Universal Badges

- Case Studies

- Education Videos

Copyright © 2024 Privacy Policy

Table of Contents

What is dmaic, why the dmaic process, the five phases of dmaic, benefits of dmaic: why it’s needed, dmaic vs. dmadv, dmaic process: the 5 phases of lean sigma you must know.

Reviewed and fact-checked by Sayantoni Das

Dmaic six sigma: The DMAIC model is used for Six Sigma applications in order to improve the quality of results produced by a company's processes. Defining, Measuring, Analyzing, Improving and Controlling are the four letters of DMAIC.

It has always been the end goal of companies to improve their sales and profits — numbers that in a way, represent product and service quality. With new technologies continually making their way into the business landscape, the race to the bottom line is more competitive than ever. Organizations are scrambling to improve their operations and become more efficient, in general. This is one of the reasons why more businesses are adopting DMAIC, one of the core techniques that act as the foundation for Six Sigma projects or any process improvement project, for that matter.

With proper implementation of DMAIC, businesses have shown to benefit in several areas, including cutting down the cost of poor quality , boosting revenue , and improving business performance and productivity on the whole.

Get an overview of Six Sigma and the DMAIC methodology with the Lean Six Sigma Green Belt Certification course. Enroll Now!

Define, Measure, Analyze, Improve, and Control is a DMAIC acronym. The process includes five phases: defining the problem, improving the activity, identifying the opportunities for improvement, setting project goals, and meeting the needs of the customer (internal and external).

DMAIC refers to a cycle of process improvement that is data-driven and aims at improving, optimizing, and stabilizing business processes and designs. A Six Sigma project is driven by the DMAIC improvement cycle.

When we look into the definition of DMAIC , it is a five-phase strategy for improving a wide variety of organizational processes, whether it’s software development, manufacturing, or some other process. While it’s associated with Six Sigma , this strategy can also be applied to lean and other process-improvement strategies. DMAIC is a data-driven problem-solving technique designed to identify and address inefficiencies in a process, which improves its outcomes and makes these improvements more predictable.

The acronym stands for the five phases — Define, Measure, Analyze, Improve, and Control, and it is pronounced “duh-may-ik.”

The DMAIC methodology has its roots in the PDSA (“plan, do, study, act”) cycle developed by statistician Walter A. Shewhart at Bell Laboratories in the 1930s. But the technique as we know it today has been shaped by some of the largest organizations in the world such as Toyota, Motorola, GE, and Ford Motor Company. You can read more about the history behind DMAIC and Six Sigma developments here .

Before we dive into the main process, there’s one additional step that some companies employ in order to figure out whether DMAIC is the right approach to solve their problems. This step is called “Recognize”.

The reason why this step is important, despite not being formally a part of DMAIC, is that DMAIC cannot be applied to all situations. There are specific conditions where this technique can be the right fit for process improvement. Recognizing the right conditions and choosing the right problem to solve are key to understanding whether DMAIC is the right tool for you.

How do you evaluate those conditions? Here are three main factors to consider:

- There are apparent inefficiencies and defects in the existing process.

- There is potential to reduce variables such as lead times or other flaws while improving variables like productivity or cost savings.

- The condition is assessable, and the outcomes can be understood appropriately through quantifiable means.

After you have evaluated the above factors, you can conclusively determine if your process can benefit from implementing DMAIC.

Become a Quality Management Professional

- 10% Growth In Jobs Of Quality Managers Profiles By 2025

- 11% Revenue Growth For Organisations Improving Quality

Certified Lean Six Sigma Green Belt

- 4 hands-on projects to perfect the skills learnt

- 4 simulation test papers for self-assessment

Lean Six Sigma Expert

- IASSC® Lean Six Sigma Green Belt and Black Belt certification

- 13 Projects, 12 Simulation exams, 18 Case Studies & 114 PDUs

Here's what learners are saying regarding our programs:

Xueting Liu

Mechanical engineer student at sargents pty. ltd. ,.

A great training and proper exercise with step-by-step guide! I'll give a rating of 10 out of 10 for this training.

Abdus Salam

I have completed the Lean Six Sigma Expert Master’s Program from Simplilearn. And after the course, I could take up new projects and perform better. My average pay rate for a research position increased by 21%.

The DMAIC process follows five key phases, which are intended to lay the groundwork for your process improvement, chart goals, track progress, and analyze results. The five phases (and an explanation of each) are:

During this phase, we select the most critical and impactful opportunities for improvement. This phase is also about mapping the process, focus, scope, and the ultimate goal as well as understanding how the problem affects all stakeholders. The way to jumpstart a DMAIC cycle is by crafting the problem statement .

The other critical steps at this stage are:

- Identify the opportunities with high potential for improvement

- Outline the scope of the project

- Create a value stream map ( VSM ) to document every step in the process

- Develop a voice of the customer table ( VOCT ) to pinpoint the customer needs

- Identify all stakeholders

- Estimate project impact and completion

- Identify and document business opportunity

- Draw out other related processes

A successful Define phase helps you move forward with clear, well-defined objectives and timeline for project completion.

The Measure phase is where baselines are drawn to assess the performance of a given process. Without having sound benchmarks for comparison, it’s difficult to track improvements. Hence, at this stage, we:

- Develop the data collection methods to be used to measure success

- Recognize input, processes, and output indicators

- Collect and examine current state data

- Outline the failure modes and effects analysis

- Implement process capability analysis

The use of visual management tools such as control charts, bar charts, and run charts etc. can help you achieve better results at this stage

In this phase, your goal is to identify and test the underlying causes of problems to make sure that improvement takes place from deep down where the problems stem from.

The critical steps at this stage include:

- Performing a complete root cause analysis (RCA), which covers a broad range of techniques and methodologies, including change analysis, events and causal factor analysis, and the Kepner-Tregoe Problem Solving and Decision Making model.

- Doing failure mode and effects analysis (FMEA) to identify all possible problem areas, inefficiencies, flaws, defects, and shortcomings.

- Getting a visual representation of the variations within a given process using a multi-vari chart .

- Implementing process control

- Developing a plan for improvement

After this phase, you will be able to capture and document all opportunities for improvement successfully, and your plan of action will start taking shape.

With the analysis done and the data in front of you, now is the time to start making the improvements.

This stage includes the following activities:

- Brainstorm and put forth solution ideas

- Develop a design of experiments (DOE) to determine the expected benefits of a solution

- Revise process maps and plans according to the data collected in the previous stage

- Outline a test solution and plan

- Implement Kaizen events to improve the process

- Inform all stakeholders about the solution

The use of improvement management software is helpful at this stage. This helps to move the process seamlessly, achieve cross-functional collaboration and makes it easier for the management and executives to follow the progress of a given DMAIC project.

After changes are in place and are successfully addressing the problems to improve your operations, it’s time to bring the process under control to ensure its long-term effectiveness.

This is where you:

- Identify and document the new work standard

- Develop a quality control plan which ensures the entire team is working with the same techniques and metrics

- Confirm reduction in failures due to the targeted cause

- Use statistical process control (SPC) to monitor process execution and identify any issues that arise

- Determine additional improvements, if needed, to meet process objectives

- Streamline process improvements using the “ Five S’s ” of Lean

- Integrate, document, and communicate the lessons learned

After the Control phase, you can quantify the complete impact of process changes in terms of cost reduction, efficiency, quality improvement , productivity increase, and customer satisfaction.

This phase continues until new opportunities for improvements arise, and then, the DMAIC cycle runs from start all over again. Starting a DMAIC process involves time, effort, and discipline, but once your team gets the hang of it, they will become comfortable with the approach.

When your organization is trying to improve a particular process, such as decreasing the number of defects or increasing overall quality, it’s important to have a clear path for reaching your goals. The main benefit of the DMAIC process is its simple but highly structured approach. Without this kind of structure, organizations will have a difficult time tracking what works (and why) or eliminating process changes that don’t work. And without implementing effective controls, even the best process changes won’t be properly adhered to.

Since this approach is so structured and requires detailed documentation, it allows businesses to hone their approach to problem-solving and increase productivity continually. Data collected through the process can be used for other projects within the same organization, providing more accurate baselines along the way.

Test your understanding of siz sigma and the DMAIC methodology with the Lean Six Sigma Green Belt Exam Practice Test . Try answering now!

DMAIC is similar to the DMADV methodology, which is another core tenant of Six Sigma . The key difference is that while DMAIC is intended for incremental improvements to existing processes, DMADV is used when the existing process needs to be completely redesigned.

The letters DMADV stand for:

As you can see, the first three letters of the acronyms are the same. So it’s the design and verifies phases of DMADV that differ from DMAIC. In the third phase, teams design and implement the new processes required for the redesign, and then the fourth phase involves verification of whether the desired results were achieved. Therefore, DMADV is more appropriate for addressing problematic processes or products.

Check out the video below that will help you understand all about DMAIC.

Master the DMAIC Process with the Lean Six Sigma Certification Training

The DMAIC process, a key fundamental of the six sigma methodology, is designed to create efficiencies and improve productivity. By achieving the Lean Six Sigma Green Belt certification , professionals will not only master DMAIC but also how to apply these principles to real-world situations. Simplilearn’s Online Lean Six Sigma Green Belt certification course will help you pass the certification exam and get you career-ready in the latest six sigma methods all from the comfort of your own home. When you reach the level of a Six Sigma Black Belt , you move beyond the DMAIC foundations and become a master of process optimization. A Certified Lean Six Sigma Black Belt is the culmination of your experience with Simplilearn, which continues after you obtain your Green Belt. With the help of this curriculum, you will learn DMAIC more thoroughly and be more equipped to handle challenging situations.

Our Quality Management Courses Duration And Fees

Explore our top Quality Management Courses and take the first step towards career success

Recommended Reads

Free eBook: Guide To Scrum Methodology

4 Stage Cycle to Improve Business Results

Understanding Agile Process: Everything You Need to Know

Free eBook: 37 Resources for Android App Developers

Quality Improvement in Six Sigma

An Introduction to Design Thinking Process

Get Affiliated Certifications with Live Class programs

- PMP, PMI, PMBOK, CAPM, PgMP, PfMP, ACP, PBA, RMP, SP, and OPM3 are registered marks of the Project Management Institute, Inc.

TheLeanSuite

Got a question? Call us at +1-616-433-6688

People and Morale

Suggestions, suggestion platform.

Collect and implement million dollar ideas

Compentency Planning

Track and upscale workforce skills with ease

Learning Management System

Build and deploy on-demand training with ease

Job Cover Matrix

Loss and cost management.

Collect data and compile production loss trees

Quality Management

Prioritize internal and external quality defects

Issue Tracker

Identify, assign and close shop-floor anomalies quickly

Continuous Improvement

Document and manage quick to complex kaizens

Gemba Walker

Make the most out of the shop floor walks

CILR Management

Schedule & plan maintenance activities

Suggestion Management

Issue tracker for quality, issue tracker for operations, issue tracker for safety, suggestions, suggestion system for hr, suggestion system for operations.

- Why TheLeanSuite

FEATURED BLOG POST

What is a Continuous Improvement Culture (CIC)?

Pdca cycle: what is the plan-do-check-act cycle, five benefits of continuous improvement in manufacturing.

- The 8 Wastes of Lean: DOWNTIME

- Continuous Improvement vs Process Improvement: the Differences

- The Most Popular Lean Six Sigma Tools and Techniques

- SCHEDULE FREE DEMO

1. The ‘define' phase

The first phase of the DMAIC methodology is “Define.” This initial phase involves clearly outlining the problem or opportunity that needs to be addressed. It’s crucial to establish project goals, objectives, and the scope during this phase. That’s because, defining the problem helps to set the direction for the entire process improvement project. This ensures that efforts are focused on the most critical issues. What’s more, by defining the problem accurately, project teams can lay a solid foundation for the subsequent phases of the DMAIC methodology.

2. The ‘measure' phase

The second phase of the DMAIC methodology is “Measure.” This phase is crucial for collecting data to understand the current state of the process being analyzed. Additionally, it focuses on quantifying the problem identified in the Define phase through KPIs and other metrics. By establishing a baseline measurement, project teams can compare current performance against desired targets and identify gaps that need to be addressed. Essentially, this phase helps ensure that decisions made in the subsequent Analyze and Improve phases are based on accurate data.

3. The ‘analyze' phase

The third phase of the DMAIC methodology is “Analyze.” This phase involves collecting and analyzing data to gain insights into what factors are contributing to the issue at hand. By using various tools such as root cause analysis, regression analysis, and hypothesis testing, project teams can pinpoint where the problem originates and why it’s occurring. In short, the goal of the Analyze phase is to provide a clear understanding of the underlying causes. This ensures that effective solutions can be developed in the subsequent phases of the process.

4. The ‘improve' phase

The fourth phase of the DMAIC methodology is “Improve.” In this phase, the focus is on implementing solutions to address the root causes of the issues identified in the previous phases. Moreover, this phase involves brainstorming, testing, and evaluating potential solutions to improve existing business processes. It’s essential to prioritize solutions based on their potential impact and feasibility. This is because the goal of the Improve phase is to make sustainable process changes that can lead to enhanced process performance and ultimately, achieve the desired results.

5. The ‘control' phase

The final phase of the DMAIC methodology is “Control.” The focus of this final phase is on sustaining the improvements made during the project. This phase involves implementing controls to ensure that the process remains stable and continues to meet the desired performance levels. Key activities in this phase include:

- 1. Developing standard operating procedures

- 2. Establishing monitoring system, and

- 3. Creating a plan for ongoing measurement and feedback

By putting these controls in place, organizations can prevent the recurrence of issues and maintain the benefits achieved through the improvement efforts.

Practical DMAIC examples

DMAIC is commonly used across different industries to improve processes and enhance business operations. Here are a few practical examples of DMAIC in action:

Manufacturing

The DMAIC model is widely used in the manufacturing industry to streamline operations, reduce defects, improve productivity, and enhance overall efficiency. For example, a manufacturing plant has been experiencing high defect rates in one of their assembly lines. As a result, this has lead to increased rework and customer complaints. By applying the DMAIC model, the project team first defines the problem by specifying the type and frequency of defects. Then they measure the current process performance to establish accurate baselines for improvement.

Next, the project team analyzes the data to identify potential causes of the defects. For example, equipment malfunctions or operator errors. Based on their findings, they develop and implement solutions to address the root causes, such as implementing preventive maintenance schedules or providing additional training to operators. Finally, the project team establishes controls, such as regular performance monitoring and audits, to ensure that the changes are sustained and that the defect rate remains low in the long term.

In short, by making improvements using the DMAIC model, this can lead to reduced lead time, quality improvements for the manufacturing plant, higher cost savings, and increased customer satisfaction.

The DMAIC model can also be used in healthcare to optimize patient care procedures and enhance operational efficiency. For example, a hospital has been experiencing low patient satisfaction levels, leading to high customer complaints. By applying the DMAIC model, the project team would first identify specific metrics for patient satisfaction. For instance, wait times, communication with staff, or cleanliness. Then they collect data during the Measure phase to quantify the existing performance levels in these areas.

Next, the project team analyzes the data to identify root causes of any issues or inefficiencies. For example, long wait times might be due to a bottleneck in the registration process. Based on their findings, they develop and implement solutions to address the underlying causes, such as streamlining the registration process or increasing staff training on communication skills. Finally, the project team monitors and sustains the changes made, ensuring that they are effective in the long term. So, by applying the DMAIC model to improve patient satisfaction, hospitals can enhance the overall quality of care and experience for their patients.

Supply chain management

Using DMAIC is beneficial for optimizing various aspects of supply chain processes. For example, a company has been experiencing frequent stock-outs in its warehouses. By applying the DMAIC model, the project team would first define the problem by quantifying the frequency and impact of stockouts. Then they would calculate current inventory levels, order processing times, and customer demand patterns.

Next, by analyzing the data collected, the project team might discover that inaccurate demand forecasting is the reason for the stock-outs. Based on their findings, they might implement changes like refining forecasting methods or increasing safety stock levels. Finally, by establishing control measures such as regular performance monitoring and adjusting inventory levels as needed, the company can sustain these changes over time.

The benefits of using DMAIC

The DMAIC model offers several benefits to businesses who employ this methodology:

Structured problem-solving

DMAIC provides a systematic framework for identifying, analyzing, and solving problems within a process. By following a step-by-step approach, project management teams can methodically address issues and implement sustainable solutions.

Data-driven decision making

One of the core principles of DMAIC is the emphasis on data collection and analysis. By measuring process performance and using data to identify the underlying causes of issues, businesses can make informed decisions based on facts rather than assumptions.

Continuous improvement

DMAIC fosters a culture of continuous improvement by encouraging teams to identify opportunities for enhancement and implement changes to drive efficiency and effectiveness. Through the iterative nature of DMAIC, businesses can strive for ongoing progress and excellence in their operations.

Customer focus

By defining customer requirements and expectations at the beginning of the DMAIC process, businesses can ensure that changes are aligned with customer needs. This customer-centric approach helps in delivering products and services that meet or exceed customer expectations.

Standardization and documentation

DMAIC promotes standardization of processes and documentation of best practices. This not only helps in ensuring consistency in operations, but also facilitates knowledge sharing and training for future projects and improvement team members.

The DMAIC model in relation to the Six Sigma methodology

The DMAIC model is commonly associated with Six Sigma since it stems from that methodology and serves as the primary working model for Six Sigma. In other words, the DMAIC model and Six Sigma go hand in hand, as Six Sigma provides the overall framework for process improvement, while DMAIC serves as a practical process map to achieve measurable improvement results. Together, they empower organizations to make data-driven decisions, foster a continuous improvement culture , and drive towards operational excellence . Nevertheless, it’s worth noting that the DMAIC model can also operate independently of Six Sigma or with other improvement initiatives such as lean process management .

DMAIC vs. DMADV

Like DMAIC, DMADV is another popular framework used in the field of Six Sigma. However, the main distinction lies in the fact that DMAIC is designed for making gradual enhancements to current processes, whereas DMADV is employed when a complete redesign of the existing process is necessary.

DMADV stands for:

As you can see, the initial three letters in the acronyms are identical. So, the contrasting phases of DMADV and DMAIC lie in the design and verification stages. During the third phase, project teams develop and execute the new processes necessary for the redesign, followed by the fourth phase, which focuses on confirming if the desired outcomes were met. Therefore, DMADV is better suited for tackling faulty processes or products.

Share this:

Related blogs.

The adoption of a continuous improvement culture has become increasingly

The Plan-Do-Check-Act (PDCA) cycle is a timeless and iterative management

In the fast-paced world of manufacturing, the quest for excellence

360 Degree view of Lean Program

Ready to Digitze your Lean Manufacturing Journey?

Fill out the form and an advisor will reach out to you at the earliest..

Invalid value

Discover more from TheLeanSuite

Subscribe now to keep reading and get access to the full archive.

Type your email…

Continue reading

What is the DMAIC Methodology?

You likely won’t get far into your belt or Lean Six Sigma training without hearing the term ‘DMAIC.’

DMAIC, an acronym for Define, Measure, Analyze, Improve, and Control, is a data-driven method for solving problems, typically in the form of process improvement ‘projects’. First applied to processes on the factory floor in the manufacturing industry in the 1980s, it has since been used successfully in healthcare, finance, technology, and service industries.

While there are several other roadmaps for problem-solving in the Lean Six Sigma universe, like PDCA (or Plan, Do, Check, Act ), DMAIC is commonly used for Green Belt and Black Belt process improvement projects.

The DMAIC methodology is a process performance tool that uses statistics and data to help improve current workplace procedures.

DMAIC is an acronym for Define, Measure, Analyze, Improve, Control, and is rarely a linear process.

Each DMAIC phase plays a critical role in the project management process; sometimes more than once.

So When Do You Use DMAIC?

As long as measurable data exists, DMAIC is a good candidate for approaching a process problem. A few examples of problems that would make great candidates for DMAIC improvement projects include:

- Improving customer satisfaction

- Reducing defects

- Reducing variability within processes and in process output

- Eliminating overproduction and excess inventory

DMAIC is a comprehensive problem-solving approach driven by asking the right questions in the right order and employing tools to answer those questions with the goal of eliminating waste and defects in processes.

Each phase has its own questions to ask and tools to use. It is also not a one-and-done solution to process problems. The phases of DMAIC can be employed cyclically . Complete a DMAIC project to improve the baseline performance of a process, then progress through the roadmap again to further improve that new baseline.

How Do You Choose Which Problem to Solve?

Within your organization, it’s doubtful that you would only have one problem that needs solving. Some guidelines to keep in mind when deciding on a new process improvement project include:

- Prioritize the existing processes, challenges, or setbacks your business faces and tackle the most important one first.

- Make sure that the project aligns with the organization’s imperatives.

- Identify who the customer is and what the voice of the customer is. This exercise is how all Lean Six Sigma projects begin.

Let’s dive into the individual steps of DMAIC and explore how each phase is critical to your operational excellence and the success of your improvement projects.

The Define Phase

The first step of the process is to define the problem. Take a step back to establish the magnitude of the problem, whom it impacts, at what frequency it occurs, and the conditions in which it arises.

Consider using the following questions to develop a clear direction for your project:

- Who is the customer?

- What is important to the customer?

- Why are we working on this project?

- What is the scope of this project? Is it broad enough to be important but narrow enough to be doable?

- What is the current process, and why do we need to improve it?

Standard tools used in the Define Phase include process maps, project charter, customer surveys, affinity diagrams, and Gantt Charts.

The Measure Phase

If define is the project planning phase, the Measure Phase is for figuring out how to accurately assess process performance and determine how much of a gap needs to be closed.

Measurements are going to drive your entire Lean Six Sigma improvement project. Therefore, knowing what to measure and how accurately you can measure it is essential. In the Measure Phase, you’ll want to ask questions like:

- How is the current process performing?

- What should be the target for success (in the customer’s terms)?

- Have potentially significant process inputs been identified for further screening?

- What is the data collection plan for all of the above?

- Is the measurement system capable of providing valid and reliable values with an acceptable degree of error?

- Are there opportunities for “quick hits” to realize immediate improvements?

The Measure Phase is also an excellent opportunity to pause and implement any possible short-term containment actions to prevent customers from experiencing defects while project work is underway to resolve root causes.

Standard tools used in the Measure Phase include Measurement System Analysis, Statistical Process Control (SPC), Data Collection Plan, Throughput Yield, and Process Capability.

The Analyze Phase

The Analyze Phase is when you will identify and test underlying root causes of process variability. The whole point of a DMAIC project is to sort through the ocean of process inputs to identify the few truly significant inputs that can be adjusted to achieve a more desired output.

Understanding root cause starts with drawing upon experience and process knowledge to develop hypotheses about the relationship between causes and effects. You’ll develop theories of causality and confirm or discard them based on data and testing.

Use the following questions to guide you in this phase:

- What are the significant inputs, or “X’s”, affecting the output, or “Y”?

- Are those significant input processes stable and capable?

- What are the underlying sources of process variability?

- What levels of those inputs, or “X’s”, will optimize performance?

- Have alternate methods or approaches been validated as effective?

Standard tools used in the Analyze Phase include cause and effect diagrams , hypothesis testing, design of experiments, and multiple regression analysis.

The Improve Phase

The Improve Phase of DMAIC is when you’ll turn analysis into action and implement corrective decisions. And as enticing as it can be to finally solve problems, this can be a challenging phase, as both processes and people often resist the change that improvement requires.

In the Improve Phase, you will:

- Identify, evaluate, and implement process improvements.

- Implement short-term countermeasures.

- Identify and address unintended consequences of improvement actions.

Use these questions to guide you through the Improve Phase:

- What improvement actions are necessary to achieve targeted performance levels?

- Have you established a process to track implementation?

- Are there any obstacles to improvement? What about unintended consequences?

- How might the current system push back?

- Have you evaluated improvement action alternatives?

Standard Tools in the Improve Phase include continuous flow, quick changeover, pull scheduling, and FMEA.

The Control Phase

The Control Phase is the final step in a process improvement project and is arguably the most challenging step to implement . But it is also the most critical.

Once you have implemented corrective actions, the Control Phase verifies results and ensures changes are sustained. This phase often requires people in your organization to change their behaviors and procedures. Anticipating resistance to change and engaging in purposeful change management can alleviate many of these difficulties.

During this phase, you'll want to:

- Verify corrective actions and validate any new measurement systems.

- Track the new process capability.

- Document and share best practices and lessons learned.

The Control Phase is also a chance to reflect. What did you learn? What worked well? What could use further improvement? Are current practices being monitored and improved over time? Are people able to see that data?

Standard tools in the Control Phase include the control plan, statistical process control, process capability, 5S, and visual management.

The Bottom Line

DMAIC is a powerful roadmap for applying Lean Six Sigma to a wide variety of process problems. Rooted in data and guided by organized critical thinking and common sense, this process has resulted in countless successful projects across all industries.

For more information on methods and processes like the DMAIC method, check out our toolbox .

Erin Valusek

Content Writer

Related Topics