Build my resume

- Resume builder

- Build a better resume in minutes

- Resume examples

- 2,000+ examples that work in 2024

- Resume templates

- 184 free templates for all levels

- Cover letters

- Cover letter generator

- It's like magic, we promise

- Cover letter examples

- Free downloads in Word & Docs

5 Industrial Electrician Resume Examples for 2024

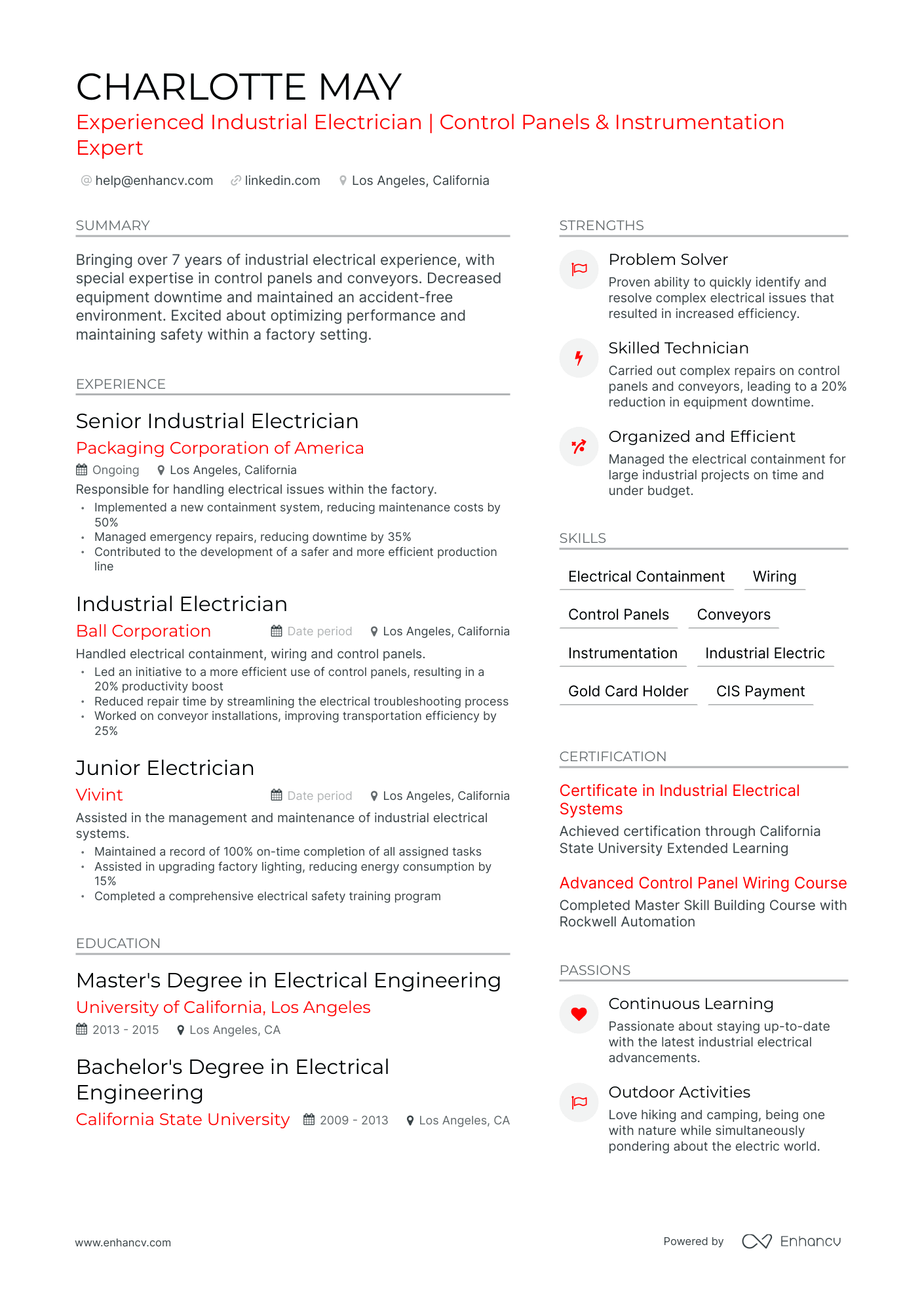

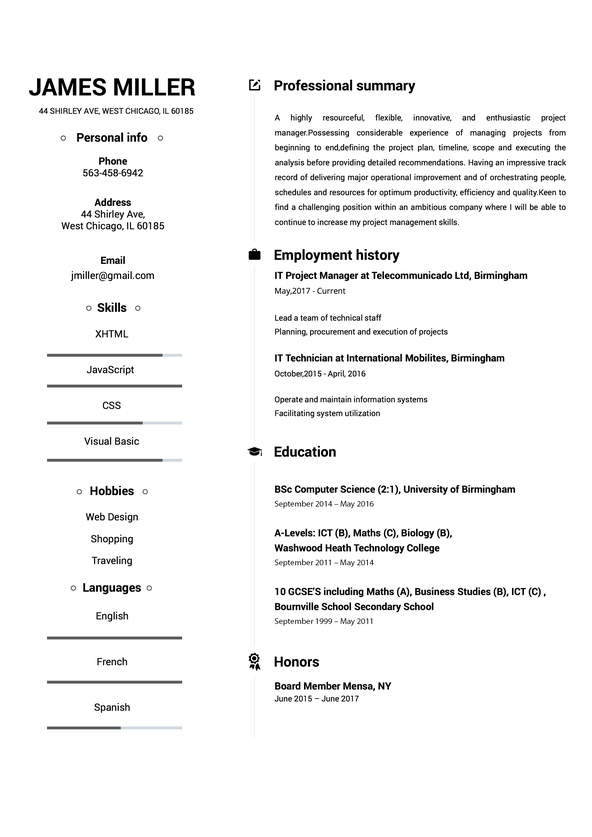

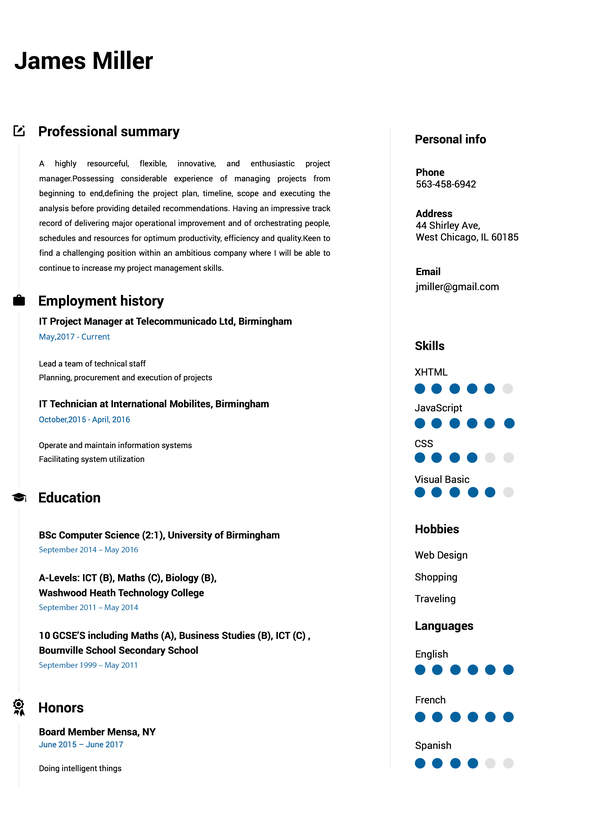

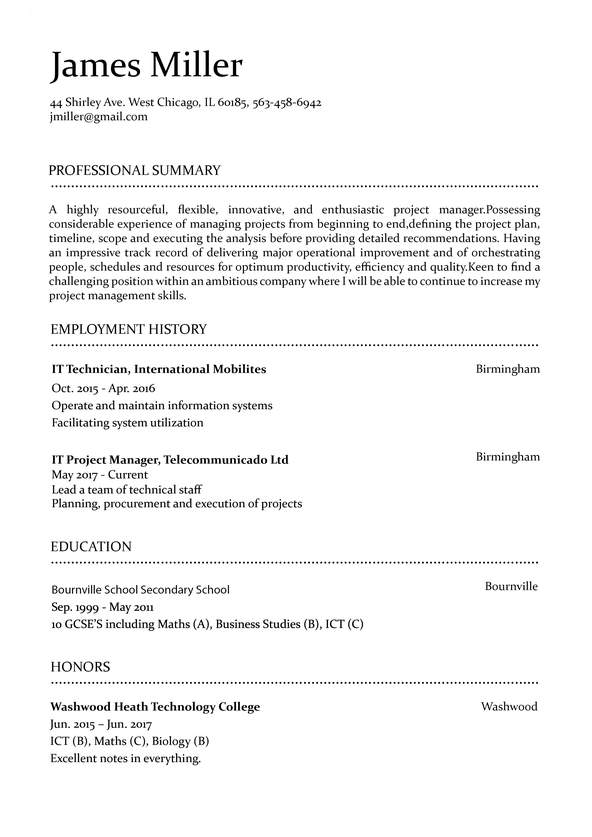

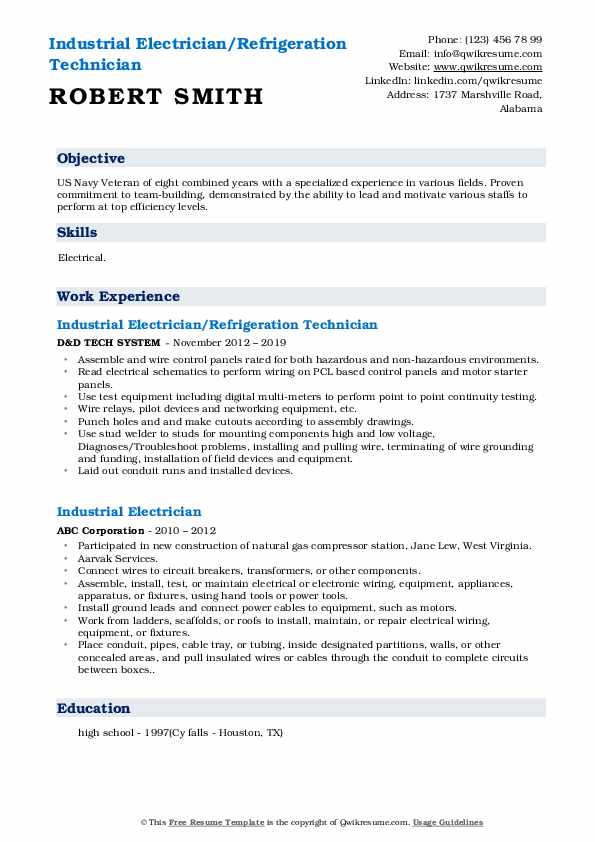

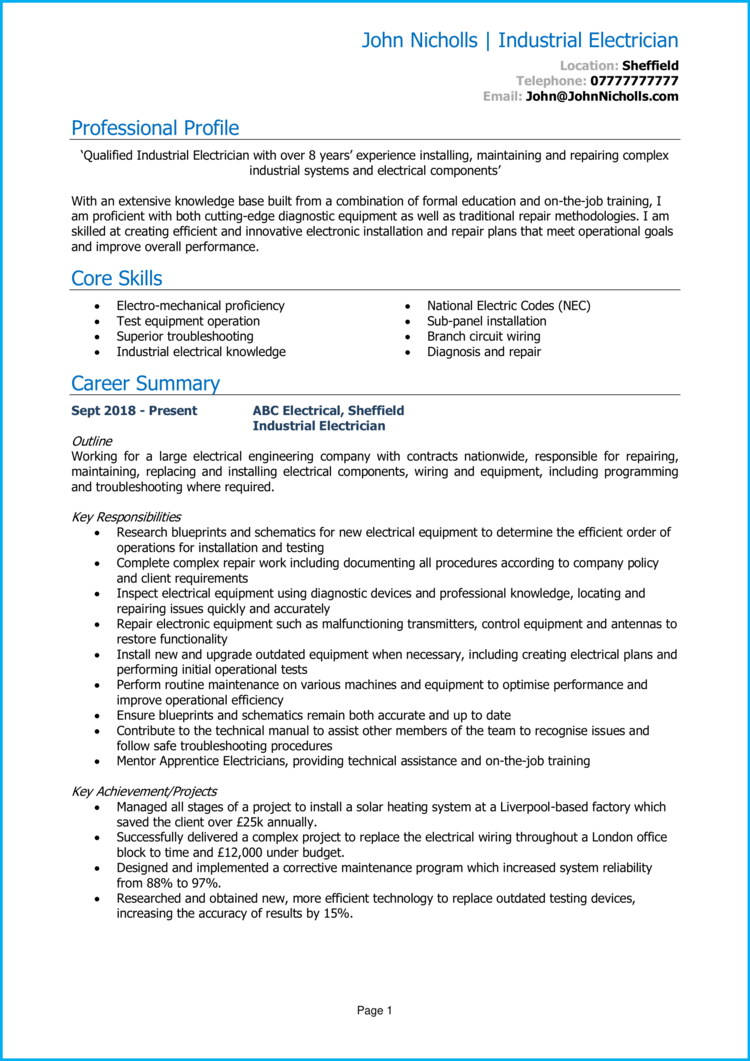

Industrial Electrician Resume

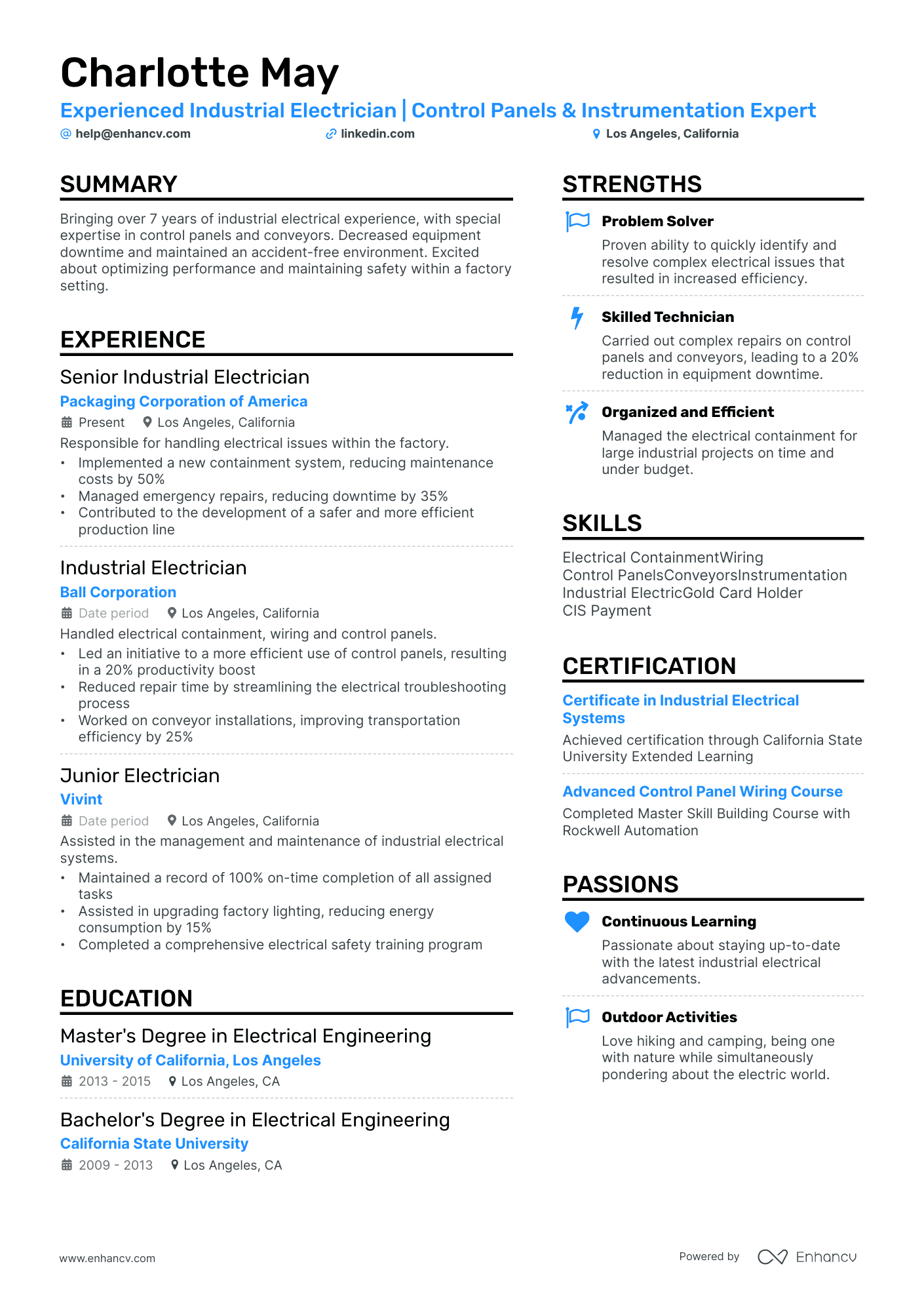

- Industrial Electrician 2

- Industrial Electrician 3

- Industrial Electrician 4

- Industrial Electrician 5

- Industrial Electrician Resume Writing 101

Working as an industrial electrician, you play a pivotal role in powering industrial operations. You install, maintain, and repair complex electrical systems and ensure the highest levels of safety compliance and proper documentation.

While you’re adept at interpreting technical manuals, creating an effective resume may feel like uncharted territory.

You might be surprised—our industrial electrician resume templates helped countless professionals land their dream jobs. We’ll help you pinpoint the exact formatting, style, and content you need to stand out from the competition.

or download as PDF

Industrial Electrician 2 Resume

Industrial Electrician 3 Resume

Industrial Electrician 4 Resume

Industrial Electrician 5 Resume

Related resume examples

- Journeyman Electrician

- Maintenance Electrician

- Electrical Apprentice

- Auto Mechanic

- Electrician

What Matters Most: Your Skills & Experience As An Industrial Electrician

Your job is just about as technical as it gets. You work with industrial machinery, design blueprints, and troubleshoot electrical systems when something goes wrong. Good news—this will make filling out this part of your resume a lot easier.

When it comes to your resume skills list , an easy way to hit the keywords recruiters are looking for is to avoid generalized topics and get specific about technologies, equipment, and software.

For example, instead of listing “blueprint design and interpretation,” list the CAD software you use to create blueprints and other technical diagrams.

This approach also demonstrates your industry knowledge and clearly shows you have professional experience, which helps you get your foot in the door during the initial screening process.

9 best industrial electrician skills

- Industrial Machinery

- Power Tool Operation

- PLC Programming

- System Maintenance

- Blueprint Interpretation

Sample industrial electrician work experience bullet points

The “classic” way to add work experience to a resume is to describe the role and list your responsibilities. However, you can make things more personal and eye-catching if you list your achievements instead.

This showcases your expertise in the role, demonstrates a self-starting attitude, and shows that you understand the impact of your work and the value of your skills.

To take this strategy to the next level, use figures and metrics to highlight exactly how well you did the job. For example, don’t just say that you worked on electrical system reliability—quantify your impact and say that you improved it by 47% to make more of an impression.

Here’s how to use this tactic in your resume:

- Achieved a 16% improvement in energy efficiency by identifying and implementing power-saving measures, resulting in annual cost savings of $45,000

- Optimized motor control circuits by implementing variable frequency drives, resulting in a 22% reduction in energy consumption

- Spearheaded the installation of a lightning protection system, ensuring the facility’s compliance with safety standards and reducing the risk of electrical damage by 75%

- Developed and implemented standardized procedures for emergency troubleshooting, resulting in a 41% reduction in average downtime per incident

Top 5 Tips for Your Industrial Electrician Resume

- As an industrial electrician, your certifications are very important and should definitely have their own section. Since you may have a number to choose from, make sure to include the ones most relevant to the job in question, such as the OSHA or NFPA 70E.

- In your industry, prioritizing safety is not just a regulation—it’s a life-saving practice. Demonstrate your commitment to safety by mentioning real-life instances where you prioritized safety, such as leading a campaign to reduce safety incidents or implementing enhanced safety training procedures.

- Spellcheck and grammar check your resume to completely ensure it’s error-free. It’s best to make this a habit since you should also be making constant changes to your work experience and skills list to tailor them to each application, swapping skills in and out based on the job description .

- Mentioning improvements is good, but you should also mention instances where you solved a problem or overcame a challenge. This can mean responding to a critical failure call or spotting an error in the blueprint before production started.

- You’ve likely worked on quite a number of projects during your career, so you’ll need to be selective about which you mention. Make sure to choose projects of varying types that display broad knowledge and experience.

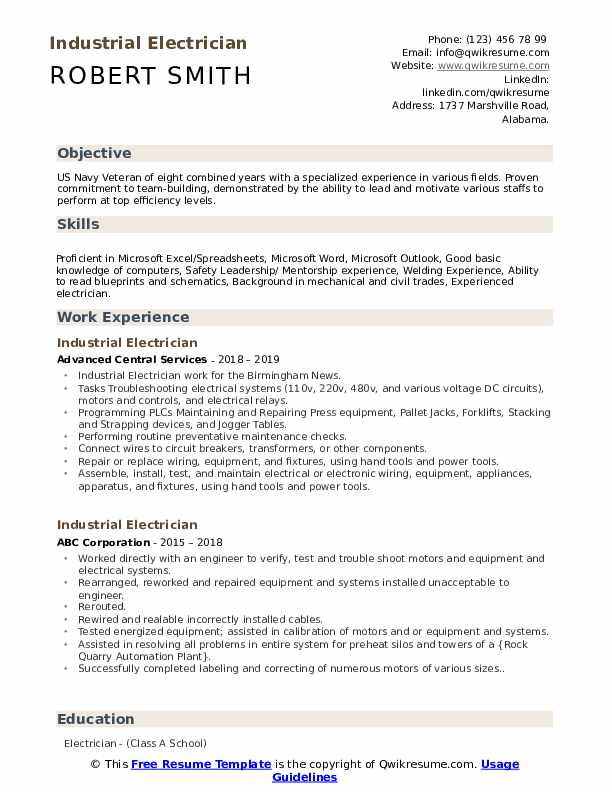

Use an elegant font and clear headings to format your resume into easy-to-read sections. Include your education, certifications, and skills in a wide margin and bullet point your work experience in the main section. Your contact information should be at the top under your name and title.

The initial stages of the application process often include AI-powered resume screenings. To make your resume ATS-friendly, use standard text formatting and simple fonts, and make sure to include industry-specific keywords and vocabulary. You should also mirror the keywords used in the job advert itself.

If you’re particularly enthusiastic about the job you’re applying to or the job post mentioned cover letters , it’s best to take the time and include one. It gives you space to expand on your resume, create a more personal impression, and address the company directly.

- • Implemented a new containment system, reducing maintenance costs by 50%

- • Managed emergency repairs, reducing downtime by 35%

- • Contributed to the development of a safer and more efficient production line

- • Led an initiative to a more efficient use of control panels, resulting in a 20% productivity boost

- • Reduced repair time by streamlining the electrical troubleshooting process

- • Worked on conveyor installations, improving transportation efficiency by 25%

- • Maintained a record of 100% on-time completion of all assigned tasks

- • Assisted in upgrading factory lighting, reducing energy consumption by 15%

- • Completed a comprehensive electrical safety training program

5 Industrial Electrician Resume Examples & Guide for 2024

Your industrial electrician resume must clearly demonstrate your expertise with electrical systems in a manufacturing or production setting. Highlight your proficiency in installing, troubleshooting, and maintaining industrial electrical equipment. Ensure that your resume showcases your adherence to safety standards and regulations. Detail your experience with electrical schematic interpretation and your ability to work effectively with a team.

All resume examples in this guide

Resume Guide

Structuring your industrial electrician resume to engage recruiters, strategies for crafting your industrial electrician resume experience section, creating your industrial electrician resume skills section: balancing hard skills and soft skills, detailing your education and top industrial electrician certifications on your resume, should you add a summary or objective to your industrial electrician resume, enhancing your industrial electrician resume with additional sections, key takeaways.

Industrial Electricians often face the challenge of effectively translating complex technical skills and on-the-job experiences into understandable terms for a non-technical hiring manager. Our guide can help by providing industry-specific language and actionable examples to describe these skills, aiding in the creation of a comprehensive and appealing resume that recruiters from any background can understand.

Enhance your application for the industrial electrician role with our concise guide on how to:

- Format your industrial electrician resume, ensuring a balance between professionalism and creativity, in line with best practices.

- Align your resume with the industrial electrician job requirements by incorporating relevant industry keywords.

- Utilize distinct resume sections to highlight your skills and achievements, making a case for why you're the top pick for the industrial electrician role.

- Draw from leading industrial electrician resume examples to effectively tailor your experience.

Recommended reads:

- Maintenance Mechanic resume

- Diesel Mechanic resume

- Electrician Apprentice resume

- Journeyman Electrician resume

- Maintenance Electrician resume

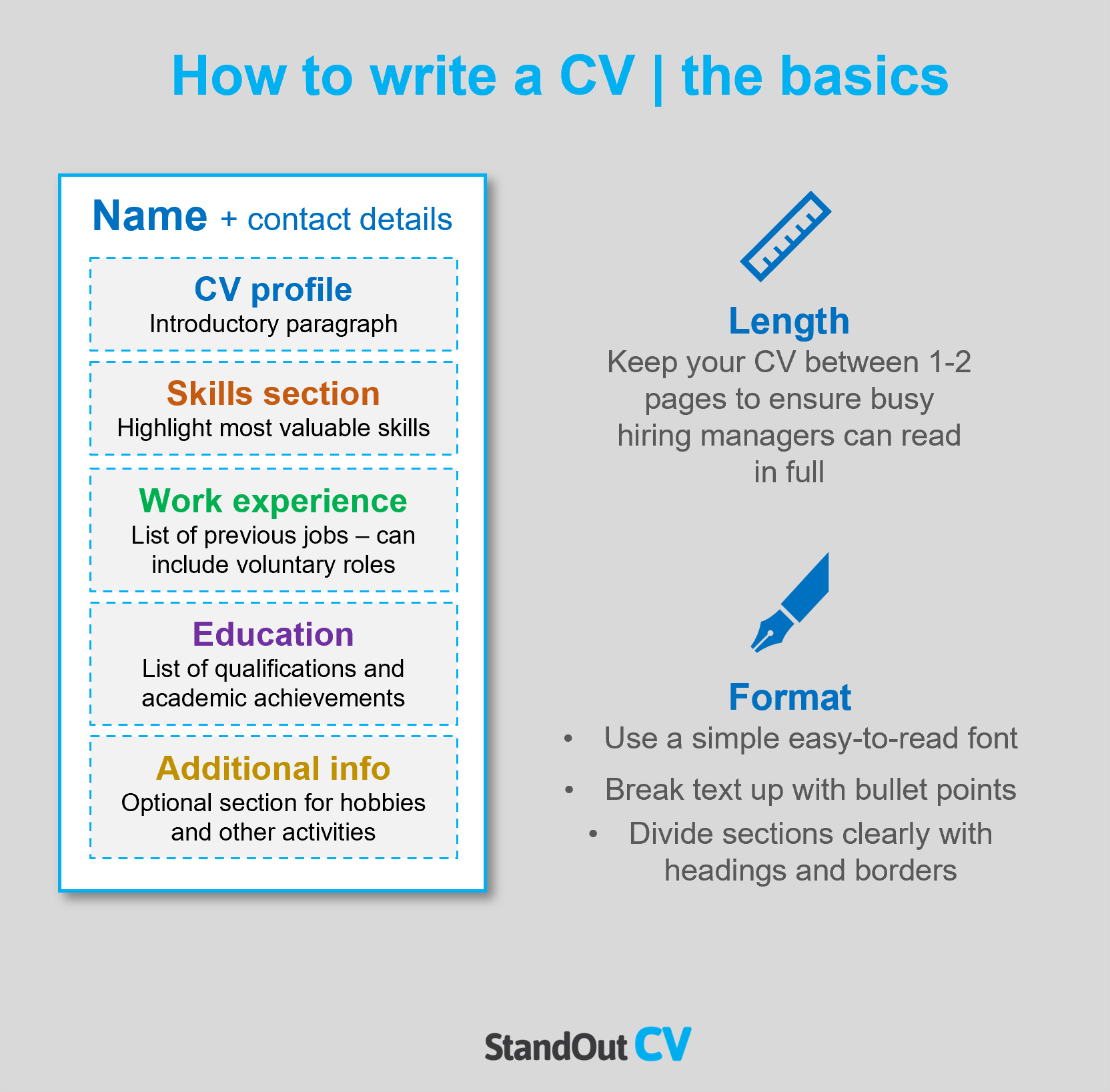

The presentation of your industrial electrician resume is crucial.

Is it easy to read and well-organized? Does it have a logical flow?

Avoid overwhelming recruiters with a cluttered document. Instead, follow these best practices to ensure a consistent resume format :

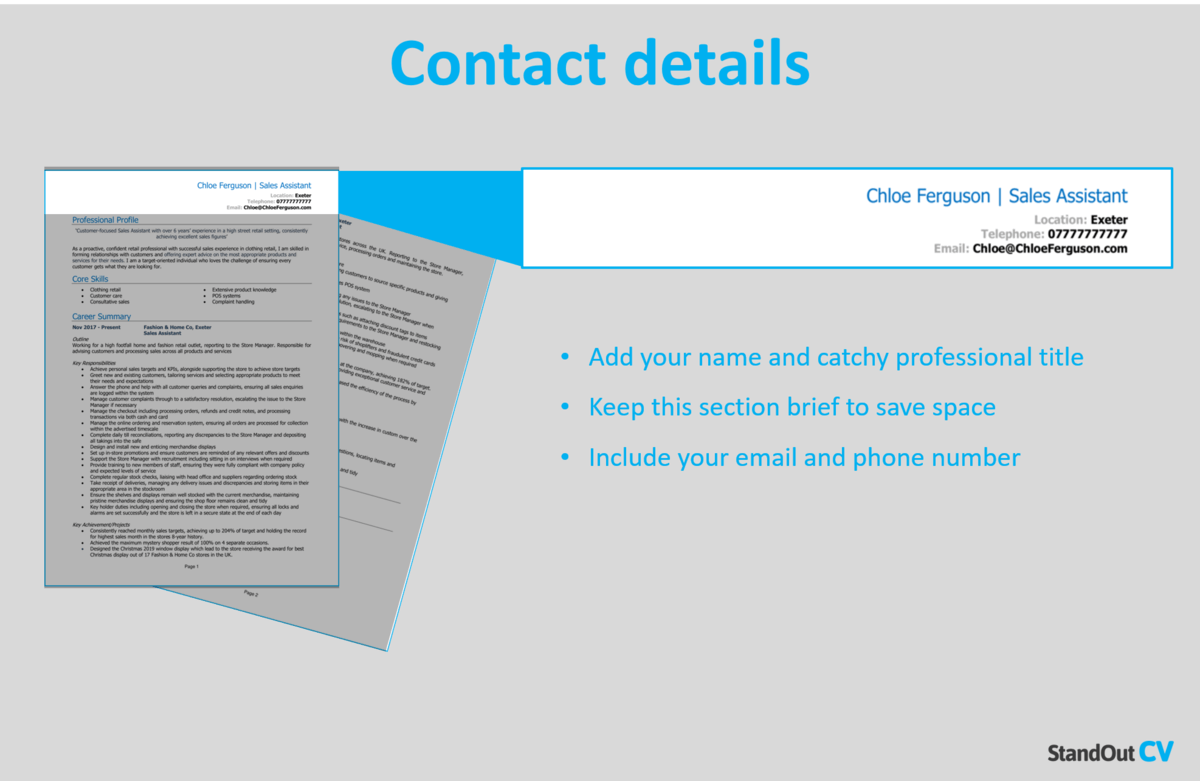

- Include a header in the top third of your industrial electrician resume for easy contact and quick access to your professional portfolio or LinkedIn profile.

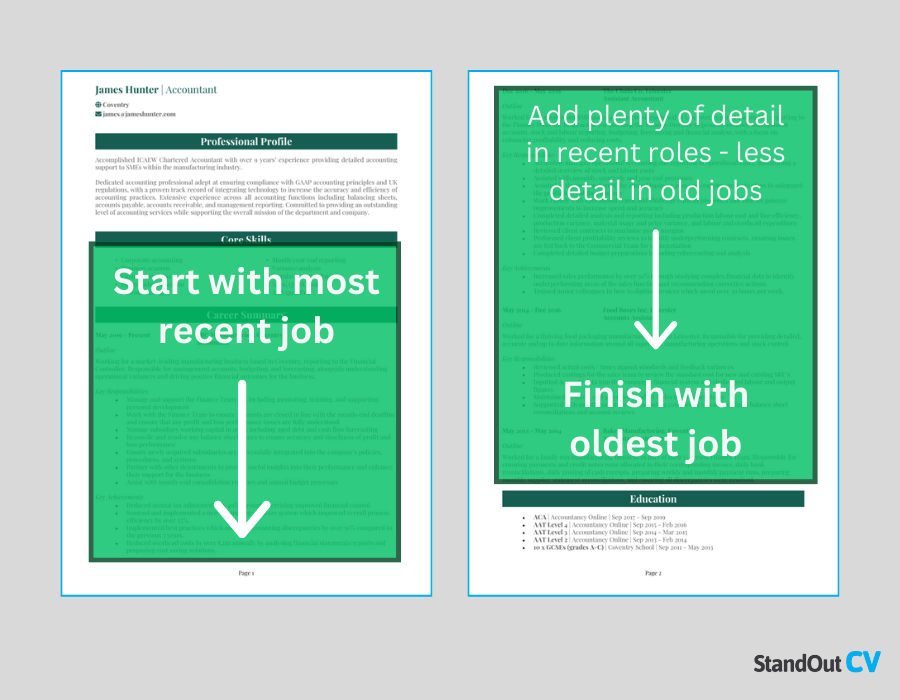

- In the experience section, start with your most recent role and detail your career in a reverse-chronological order .

- Unless specified, submit your resume as a PDF to maintain its layout. Some companies might request other formats.

- If you're applying for a senior position and have over a decade of relevant experience, a two-page industrial electrician resume is acceptable. Otherwise, aim for a single page.

Upload your resume

Drop your resume here or choose a file . PDF & DOCX only. Max 2MB file size.

Prioritize clarity and organization in your industrial electrician resume. Use ample white space, choose readable fonts, and clearly delineate each section.

Essential components for your 911 dispatcher resume:

- Header: Feature your name prominently. If you have a notable degree or certification, append it next to your name. Include contact details, a link to your portfolio, and a concise headline.

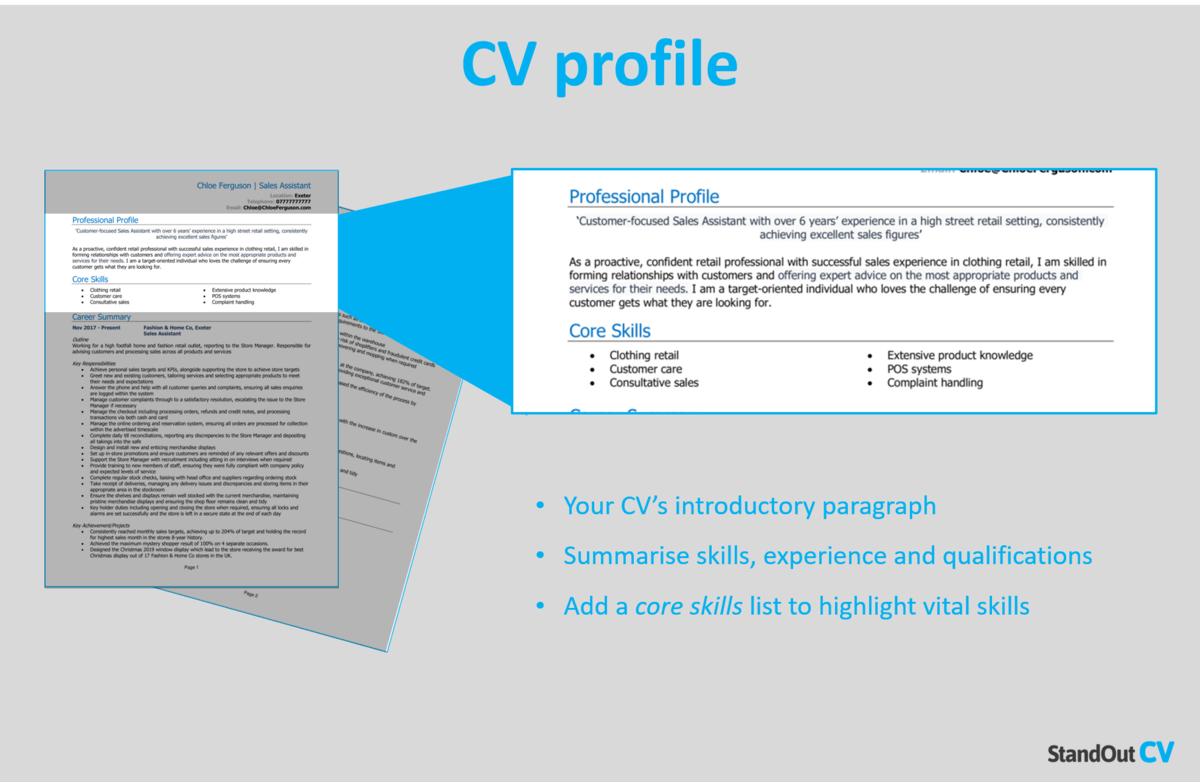

- Summary or Objective: Align your professional trajectory and standout achievements with the desired role.

- Experience: Craft concise bullet points, highlighting tangible successes and contributions.

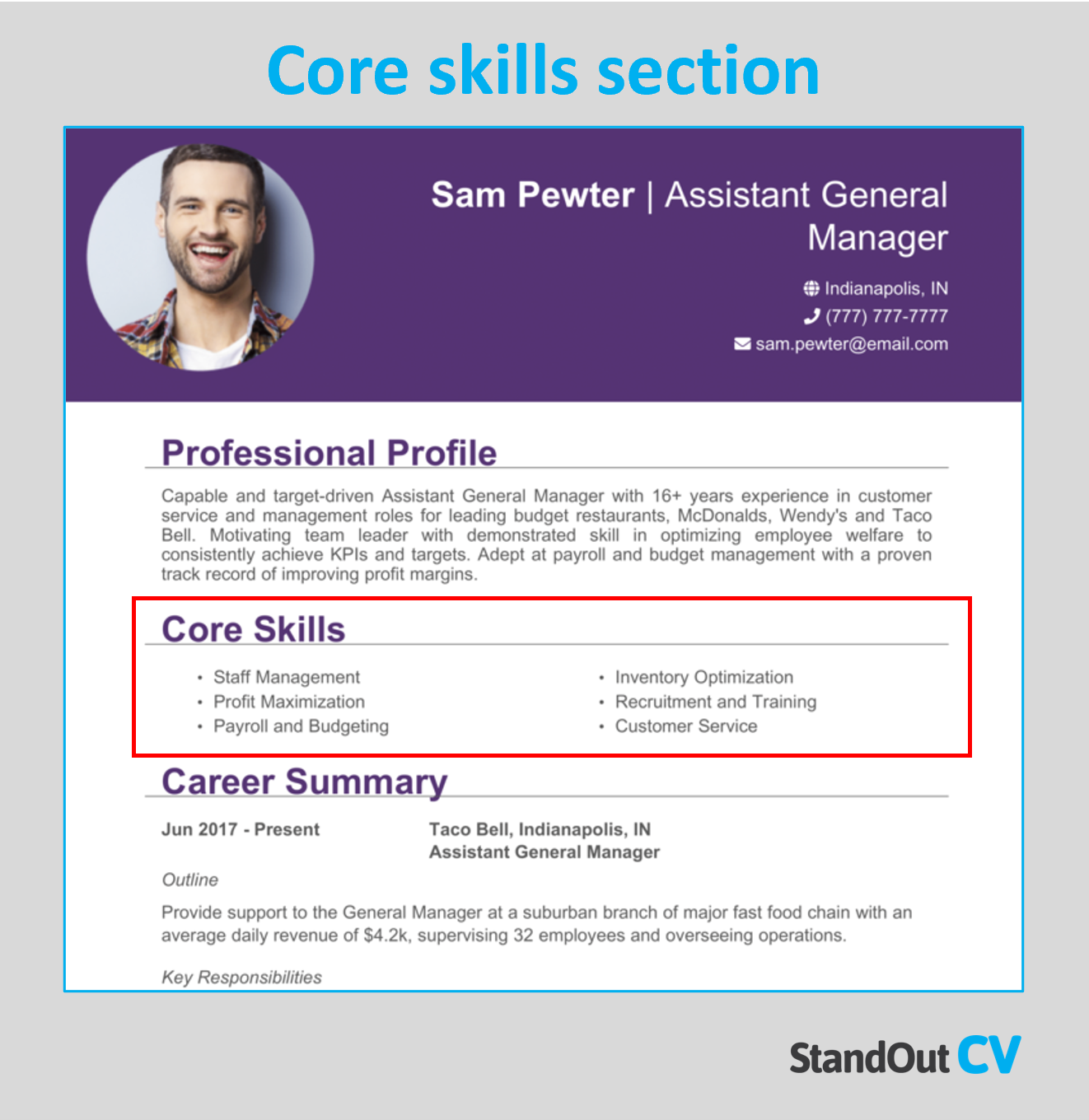

- Skills: Showcase them throughout your resume and consider a dedicated sidebar for emphasis.

- Education & Certifications: Reinforce your credibility and demonstrate your commitment to the industry.

What recruiters want to see on your resume:

- Experience in Industrial Electrical Work: Specific experience working as an electrician in industrial settings is highly valued. This can include maintenance, installations, troubleshooting, and repair of industrial electrical systems.

- Qualifications/Certifications: Proven qualifications such as a Journeyman or Master Electrician certification, or an Associate's degree in Electrical Technology can be a key factor. These show you have received formal training and are knowledgeable on the subject.

- Familiarity with Safety Standards: Knowledge of safety standards like OSHA regulations and the National Electrical Code (NEC) are important in this work to help maintain a safe working environment.

- Technical Skills: Proficiency in using electrical diagnostic tools, understanding schematics, PLC programming and automation systems are critical technical skills for an industrial electrician.

- Problem-Solving Skills: The ability to diagnose and solve complex electrical issues is crucial. Employers often prioritize applicants who can demonstrate strong problem-solving skills in their previous roles.

- Resume Font

- Color on Resume

When detailing your industrial electrician resume experience , it's essential to pair responsibilities with tangible achievements.

Consider including:

- Key responsibilities, emphasizing their significance to your role, team, or organization.

- Experiences that have fostered your technical acumen or professional growth.

- Metrics that underscore your contributions and successes.

- Challenges you've addressed and the solutions you've implemented.

- Strategies you've devised and their measurable impact on growth.

Your experience section is pivotal in making a lasting impression on recruiters. To inspire you, we've curated real-world industrial electrician examples:

- Installed and maintained electrical systems for industrial machinery, resulting in improved operational efficiency by 20%.

- Performed troubleshooting and repaired electrical faults, reducing downtime by 30%.

- Collaborated with engineering team to design and implement electrical upgrades for production lines, enhancing productivity by 15%.

- Conducted regular inspections and preventive maintenance on electrical equipment, ensuring compliance with safety standards.

- Assisted in the installation and commissioning of a new control system for a manufacturing facility, leading to a 25% reduction in energy consumption.

- Wired and connected electrical components for industrial equipment, adhering to wiring diagrams and specifications.

- Diagnosed and resolved complex electrical issues, resulting in a 40% decrease in equipment breakdowns.

- Upgraded and retrofit existing control panels with modern PLC systems, improving automation capabilities.

- Collaborated with cross-functional teams to execute major electrical installations, ensuring project completion within budget and timeline.

- Implemented predictive maintenance techniques that reduced unscheduled downtime by 25%.

- Inspected and repaired electrical systems in compliance with NEC regulations, ensuring safe working conditions.

- Developed and executed preventive maintenance plans for critical equipment, resulting in a 15% increase in uptime.

- Collaborated with automation engineers to integrate robotic systems into production lines, enhancing efficiency by 30%.

- Trained and mentored junior electricians on best practices for electrical installations and troubleshooting techniques.

- Implemented energy-saving initiatives, leading to a 20% decrease in electricity consumption.

- Assembled and installed electrical panels for control systems, ensuring compliance with industry standards.

- Conducted regular calibration and adjustment of instruments, maintaining accurate measurements and process control.

- Assisted in the design and implementation of a plant-wide electrical safety program, reducing workplace accidents by 50%.

- Collaborated with engineering team to upgrade motor control circuits, resulting in improved equipment performance.

- Contributed to the installation and commissioning of a new wastewater treatment system, optimizing resource utilization by 25%.

- Troubleshot and repaired electrical faults on complex machinery, minimizing production downtime by 35%.

- Developed and implemented preventive maintenance procedures, reducing equipment failures by 25%.

- Collaborated with engineering team to automate manual processes, resulting in a 40% increase in overall production capacity.

- Designed and executed electrical modifications to support the introduction of new manufacturing lines, enabling a 30% boost in productivity.

- Led a team of electricians during major shutdowns, coordinating tasks and ensuring timely completion within strict deadlines.

- Installed, maintained, and repaired electrical systems in a heavy industrial environment, ensuring continuous operation.

- Collaborated with engineering team to develop and implement energy-efficient lighting solutions, resulting in a 20% reduction in electricity consumption.

- Performed load calculations and circuit design for new equipment installations, ensuring optimal electrical distribution.

- Assisted in the implementation of a comprehensive arc flash safety program, reducing the risk of electrical accidents.

- Contributed to the successful relocation and setup of a production facility, minimizing downtime and ensuring uninterrupted operations.

- Inspected and tested electrical systems and components using specialized tools and equipment, ensuring functionality and safety compliance.

- Repaired and replaced faulty electrical components, resulting in a 30% decrease in equipment breakdowns.

- Assisted in the installation and configuration of control panels for manufacturing processes, improving automation capabilities.

- Collaborated with maintenance team to develop preventive maintenance schedules, optimizing equipment performance.

- Implemented energy-saving initiatives, resulting in a 15% reduction in electricity costs.

- Performed troubleshooting and repair of electrical systems and equipment, ensuring minimal production downtime.

- Conducted regular inspections and maintenance of electrical control panels, ensuring proper functionality.

- Collaborated with automation engineers to integrate advanced PLC systems, improving process efficiency by 25%.

- Assisted in the implementation of an energy management system, resulting in a 20% reduction in overall energy consumption.

- Provided technical expertise and guidance to optimize electrical installations and enhance equipment performance.

- Installed, repaired, and maintained electrical systems for industrial machinery, adhering to safety standards and regulations.

- Developed and executed preventive maintenance plans, reducing equipment failures by 30%.

- Collaborated with engineering team to design and implement electrical upgrades, enhancing operational efficiency.

- Diagnosed and resolved complex electrical issues, minimizing production downtime.

- Contributed to the successful completion of a major plant expansion project, ensuring seamless integration of new electrical systems.

- Performed electrical installations and repairs in compliance with safety regulations and industry standards.

- Conducted regular testing and calibration of instruments and controls, maintaining accuracy and reliability.

- Collaborated with engineering team to implement energy-saving measures, resulting in a 15% reduction in electricity usage.

- Assisted in the commissioning of new production lines, ensuring seamless integration with existing electrical systems.

- Provided training and guidance to junior electricians, promoting skill development and knowledge sharing.

Quantifying impact on your resume

- Include the number of years of experience you have in the industrial electrical field. This quantifies your level of expertise and shows recruiters your commitment to the profession.

- List the specific number of projects you have completed successfully. This provides a clear picture of your on-the-job experience.

- Indicate the size of teams you've worked with or managed. This communicates your ability to work in a group or oversee a team.

- Specify the largest budget you've managed or saved for an electrical project. This demonstrates your fiscal responsibility and capacity to deliver cost-effective solutions.

- Mention any measurable improvement in efficiency or productivity due to your work. This indicates your ability to optimize processes and contribute to business growth.

- State the highest number of fault diagnostics or repairs performed within a certain time period. This can illustrate your problem-solving skills and your ability to work under pressure.

- Quantify the scale of the facilities you have worked in (e.g., square footage or number of machinery units serviced). This gives insight into your capabilities to handle large-scale industrial electrical operations.

- Highlight any reduction in downtime or accidents at your past workplaces, if applicable. This shows your dedication to safety and maintaining operational continuity.

Navigating the resume landscape without experience

It's not uncommon for candidates lacking direct experience to secure entry-level positions. Their resumes often share these characteristics:

- They opt for a functional or skill-based format, emphasizing strengths over chronological work history.

- Transferrable skills, gleaned from diverse life and work experiences, take center stage.

- The objective section melds career highlights, the motivation behind the application, and the unique value proposition for the role.

- Skills are tailored to meet basic job prerequisites while also spotlighting any specialized expertise.

- Targeted Resume

- How to Write Your First Job Resume Guide

Remember, the experience section isn't just about traditional roles. It's a space to highlight all professional learning, whether from internships, contract roles, research projects, or other relevant experiences. If it's added value to your skill set for the industrial electrician role, it deserves a mention.

Recruiters hiring for industrial electrician roles are always keen on hiring candidates with relevant technical and people talents.

Hard skills or technical ones are quite beneficial for the industry - as they refer to your competency with particular software and technologies.

Meanwhile, your soft (or people) skills are quite crucial to yours and the company's professional growth as they detail how you'd cooperate and interact in your potential environment.

Here's how to describe your hard and soft skill set in your industrial electrician resume:

- Consider what the key job requirements are and list those towards the top of your skills section.

- Think of individual, specific skills that help you stand out amongst competitors, and detail how they've helped you succeed in the past.

- Look to the future of the industry and list all software/ technologies which are forward-facing.

- Create a separate, technical skills section to supplement your experience and further align with the industrial electrician job advert.

Find the perfect balance between your resume hard and soft skills with our two lists.

Top skills for your industrial electrician resume

Installation and maintenance of industrial electrical systems

Troubleshooting electrical problems

Understanding of electrical schematics and blueprints

Knowledge of PLC programming

Proficiency with electrical testing equipment

Knowledge of local and national electrical codes

Wiring and cabling

Experience with high-voltage systems

Knowledge of electrical safety procedures

Ability to perform physically demanding tasks

Problem-solving skills

Excellent communication

Attention to detail

Time management

Safety consciousness

Physical fitness

Good hand-eye coordination

Patience in troubleshooting and repair

Adaptability to new technology and techniques

Sometimes, basic skills mentioned in the job ad can be important. Include them in your resume, but don't give them too much space.

Your education section can reflect a variety of skills and experiences relevant to the position.

- List post-secondary qualifications, noting the institution and duration.

- If you're currently studying, mention your expected graduation date.

- Exclude qualifications unrelated to the role or industry.

- If relevant, delve into your educational background, especially if it was research-intensive.

Including both relevant education and certifications on your industrial electrician resume can set you apart. It not only showcases your qualifications but also your commitment to the profession.

When listing these on your industrial electrician resume, make sure to:

- Highlight degrees and certificates relevant to the role.

- Mention the awarding institution for credibility.

- Include the start and end dates, or if the education/certification is ongoing.

- If relevant, incorporate a few keywords from the job advert within the description of the certification or degree.

If you have additional certifications not directly related to the role, consider placing them towards the end of your resume. This way, they can be viewed as personal interests rather than core qualifications.

For a quick update, check out our list of popular industrial electrician certifications curated by the Enhancv team.

Best certifications to list on your resume

- NCCER Electrical Level 1-4 Certification - NCCER

- Certified Electrical Safety Compliance Professional (CESCP) - NFPA

- Electrical Inspector Certification - ANSI

- Certified Automation Professional (CAP) – ISA

Listing your relevant degrees or certificates on your industrial electrician resume is a win-win situation. Not only does it hint at your technical capabilities in the industry, but also at a range of soft skills, including perseverance, adaptability, and motivation.

- High School on Resume

- GPA on Resume

Choose between:

- Resume summary to match job needs with your top wins.

- Resume objective to share your career goals.

Both should tell recruiters about your best moments. Keep them short, around five sentences. Check out our sample structures for guidance.

Resume summary and objective examples for a industrial electrician resume

- Seasoned Industrial Electrician with over a decade of experience, specializing in complex machinery and automation systems. Demonstrated proficiency in troubleshooting, repairing, and maintaining industrial electrical equipment. Notable accomplishment includes leading a team to upgrade the electrical system of a large manufacturing facility, resulting in a 20% reduction in energy consumption.

- Skilled Electrical Engineer transitioning to an Industrial Electrician role. Brings forward a rich 7-year background in designing and implementing electrical systems for infrastructural projects. Acclaims for achieving a record-high efficiency rate for a city-wide lighting project.

- Experienced Facility Manager venturing into the field of Industrial Electrician. Possesses a comprehensive 8-year background in managing operational maintenance, including basic electrical tasks. Successfully managed a budget cut by 15% through effective resource allocation and preventive maintenance measures.

- A dedicated professional with 15 years' experience as a Commercial Electrician, now seeking to leverage skills in an Industrial Electrician capacity. Highly skilled in planning and executing electrical repairs and installations; commended for minimizing downtime by 30% through proactive routine checks at a large shopping mall.

- Ambitious graduate with a Bachelor's degree in Electrical Engineering, eager to embark on a career as an Industrial Electrician. Keen to apply theoretical knowledge gained during academic projects, including designing and testing circuitry, to real-world industrial settings. Committed to continually developing technical skills and applying them to improve operational efficiency.

- Recent vocational school graduate with a specialization in industrial electricity, looking to launch a career as an Industrial Electrician. Adept in applying learned principles of electrical theory and related knowledge in the installation, repair, and maintenance of electrical apparatuses. Looking forward to harnessing these skills to contribute to industry-level operations and processes.

Make your industrial electrician resume truly distinctive by adding supplementary sections that showcase:

- Awards that underscore your industry recognition.

- Projects that bolster your application's relevance.

- Hobbies , if they can further your candidacy by revealing facets of your personality.

- Community involvement to highlight causes you champion.

- Structure your resume to spotlight career highlights and relevance to the role.

- Keep your resume concise, prioritizing relevant experiences.

- Detail specific achievements that showcase your suitability for the role.

- Both technical and interpersonal skills should be evident throughout your industrial electrician application.

Looking to build your own Industrial Electrician resume?

- Resume Examples

What Are Action Words Used For In A Resume

How to answer: “do you want to tell us anything else about you”, how to answer: “what’s the reason for leaving your job”, the stay-at-home parent resume: transferable skills & getting your career back on track, burnout in the workplace: causes and preventive care, 2024 resume statistics from over 12 000 us-based job-seekers.

- Create Resume

- Terms of Service

- Privacy Policy

- Cookie Preferences

- Resume Templates

- AI Resume Builder

- Resume Summary Generator

- Resume Formats

- Resume Checker

- Resume Skills

- How to Write a Resume

- Modern Resume Templates

- Simple Resume Templates

- Cover Letter Builder

- Cover Letter Examples

- Cover Letter Templates

- Cover Letter Formats

- How to Write a Cover Letter

- Resume Guides

- Cover Letter Guides

- Job Interview Guides

- Job Interview Questions

- Career Resources

- Meet our customers

- Career resources

- English (UK)

- French (FR)

- German (DE)

- Spanish (ES)

- Swedish (SE)

© 2024 . All rights reserved.

Made with love by people who care.

Resume Builder

- Resume Experts

- Search Jobs

- Search for Talent

- Employer Branding

- Outplacement

- Resume Samples

Industrial Electrician Resume Samples

The guide to resume tailoring.

Guide the recruiter to the conclusion that you are the best candidate for the industrial electrician job. It’s actually very simple. Tailor your resume by picking relevant responsibilities from the examples below and then add your accomplishments. This way, you can position yourself in the best way to get hired.

Craft your perfect resume by picking job responsibilities written by professional recruiters

Pick from the thousands of curated job responsibilities used by the leading companies, tailor your resume & cover letter with wording that best fits for each job you apply.

Create a Resume in Minutes with Professional Resume Templates

- Provide assistance to interdepartmental personnel; machinists, re-builders and mechanics. Performs other related duties as assigned or requested

- Performs preventive maintenance on machinery, equipment and control circuitry to insure proper operation. Makes necessary adjustments or repairs

- Investigate, recommend and execute modifications to improve existing equipment performance

- Make recommendations to improve equipment operation/efficiency, reduce maintenance costs and improve maintenance service to customers

- Operating mobile equipment, including forklift trucks, lifts, and booms to assist with all production work

- Performing work requiring extensive knowledge of electrical schematics, including electronic theory and principles

- Evaluate potential risks to similar processes and develop work orders and plans to resolve issue

- Follows approved, safe working procedures including Lock Out Tag Out, etc

- Keeps work area clean and hazard free

- Replaces faulty electrical components of machine such as relays, switches, and motors and positions sensing devices

- Installs power wiring and conduit

- Align, adjust and calibrate equipment according to specifications

- Replace defective components and wiring and adjust mechanical parts

- Replace faulty electrical components of machine such as relays, switches, motors and position sensing devices

- Analyzes and resolves work problems, or assists workers in solving work problems

- Operates a variety of equipment such as hand tools, laptop computers and diagnostic hardware to perform work

- Performs preventive maintenance as scheduled in the Computerized Maintenance Management System (CMMS)

- Responds and provides service and feedback to the customer on all work orders while assuring compliance to codes, regulations and industry standards

- Recommends measures to improve maintenance methods and equipment performance

- Operates various measuring, diagnostic and testing instruments to help provide energy efficiency solutions

- Assures work conforms to NEC guidelines

- Strong working knowledge of job site safety as well as ability to complete a company specific safety orientation

- Basic knowledge of quality assurance principles

- Strong team work and communication skills, with an ability to resolve problems and work towards agreeable solutions

- Basic knowledge of heating and air-conditioning systems

- Working knowledge of three phase motors, programmable controls, circuits, computer interfaces and National Electrical Code

- Be knowledgeable about any chemicals that you work with or that are in your immediate environment

- Knowledge of applicable electrical codes, standards, and regulations

- Proficient at working with up to 600 VAC, including 480 VAC, 277 VAC 12 VAC volt controls, 24 VDC controls and a working knowledge of programing inverters

- Strong computer skills such as the ability to navigate through program screens

- Good knowledge of the OES code

15 Industrial Electrician resume templates

Read our complete resume writing guides

How to tailor your resume, how to make a resume, how to mention achievements, work experience in resume, 50+ skills to put on a resume, how and why put hobbies, top 22 fonts for your resume, 50 best resume tips, 200+ action words to use, internship resume, killer resume summary, write a resume objective, what to put on a resume, how long should a resume be, the best resume format, how to list education, cv vs. resume: the difference, include contact information, resume format pdf vs word, how to write a student resume, industrial electrician resume examples & samples.

- P&H cranes and hoists, conveyors, furnaces, washers, ABB robots

- Operate measurement and feedback scales and encoder systems, including

- Minimum of 3 years experience in the electrical repair of machine tools and related equipment in an industrial environment OR equivalent military experience OR completion of an approved, field-related college/technical program

- WIllingness to work overtime to support production demands

- Diagnoses equipment malfunctions using appropriate test instruments and circuit diagrams

- Maintains and repairs electrical/electronic/electromechanical systems

- Fabricates and/or installs electrical/electronic/electromechanical systems

- Follows all safety precautions and procedures. Ensures that all equipment is safe before releasing to production

- Able to do simple fabrication of mechanical components using toolroom equipment for bracketry or installation modifications of electrical devices

- Performs all electrical Preventive Maintenance related inspections, records results and reports results as per procedure

- Reports all electrical issues to the Supervisor immediately

- Report to his or her employer or supervisor the absence of or defect in any equipment or protective device of which the worker is aware and which may endanger himself, herself or another worker

- Report to his or her employer or supervisor any contravention of the Act or the regulations or the existence of any hazard of which he or she knows

- Not remove or make ineffective any protective device

- Not use or operate any equipment, machine, device or thing or work in a manner that may endanger himself, herself or any other worker; or

- Not engage in any prank, contest, feat of strength, unnecessary running, or rough and boisterous conduct

- Read and interpret drawings and electrical code specifications to determine layout of industrial electrical equipment installations

- Read electrical and electronic schematics as well as basic hydraulic and pneumatic circuits

- Install, examine, replace and repair electrical wiring, receptacles, switch boxes, conduits, feeders, cable assembles, light fixtures and other electrical components

- Test electrical and electronic equipment and components for continuity, current, voltage and resistance

- Troubleshoot programmable logic controllers such as Allen Bradley, Bosch and Omron

- Track various SPC charts on machine performance

- Request maintenance manager to requisition materials and supplies as needed

- Follows the policies and guidelines as outlined in the Employee Handbook

- Certified Industrial Electrician

- Intermediate knowledge of PLC programming

- Completion of an industrial electrician apprenticeship program (or equivalent) with five (5) years of experience in electronic control systems

- Knowledge of CNC machines

- Knowledge of blueprint reading and electrical and electronic control schematics

- Knowledge of electrical code of Ontario

- Sound knowledge of hydraulic and pneumatic systems

- Must be able to work independently and as a team player

- Be able to wire and troubleshoot power and control circuits

- Evaluate and improve our processes for uptime and repeatability

- Evaluate downtime situations for root cause and suggest/implement improvements

- Preventative maintenance on Equipment – identifies weakness in design and implements improvements. Take pride in workmanship and when performing skilled work develop procedures to educate and train other team members performing the same work. Note – Monitor progress of repair to ensure problem is resolved

- Monitor and participate in ensuring all Key Performance Indicators (Safety, Quality and Productivity) are being achieved and if not develop action plan to ensure success

- Ensure all key information is captured and exchanged at shift change to support the other shifts

- Maintain safety standards of equipment and work area and perform all duties in a safe manner in accordance with the safety policies of P&F Tool & Die

- Assist in developing and/or updating preventive maintenance procedures

- Live up to agreement as maintenance technician and support cross-functional repairs to the equipment

- Ability to troubleshoot equipment using the appropriate tools and meters

- Maintain top 3 issue list

- C of Q Industrial Electrician

- Should have served a recognized apprenticeship, or have the relevant years of experience in the above trade

- Knowledge of the Ontario Electrical Code

- Must be physically able to perform duties as a Maintenance Electrician

- Should have a working knowledge and be able use the PLC as trouble shooting tool, using the Allen Bradley Controller Family of Processors

- Root cause analysis

- Min 5 yrs. years as an industrial maintenance electrician in an automated assembly line environment

- ble to be flexible in hours of work in order to meet internal/external customer requirements

- Makes constructive suggestions

- Makes sound decisions

- Analyzes problems skillfully and uses logic to reach solutions

- Able to work well with staff, co-workers, peers and managers

- Shares information with everyone involved and report outs to supervisor after each shift

- Coordinates own work with that of others

- Maintains high standard of workmanship

- Works the necessary hours to complete the assigned work, if required

- Understands and carries out the principles of integrated safety management

- Applies and demonstrates knowledge of techniques, skills, equipment, procedures and materials

- Exercises a professional approach with others using all appropriate tools of communication

- Respects all external and internal customers

- Anticipates how a problem and its solution will affect others

- Adapts well to changing priorities, deadlines and directions

- Analyzes current procedures for possible improvement

- Responds to requests for service in a timely manner

Millwright / Industrial Electrician Resume Examples & Samples

- Perform maintenance functions required in the plant, warehouse or its offices in order to keep the plant operating to full capacity

- Troubleshoot/diagnose malfunctions and repair equipment and services in the plant

- Conduct routine maintenance of the equipment and services as instructed by the Manager

- Submit list of parts required in order to carry out a job well in advance

- Maintain a daily log of time spent on each job

- Assist other maintenance staff in carrying out maintenance work as instructed by the Manager

- Order maintenance supplies necessary to maintain adequate inventory

- Adhere to the responsibilities and duties for Gas Shut Off as set forth under Section 4.0 of the Emergency Response Team requirements located on the Health and Safety web site, and as outlined by the department manager

- Perform all job functions in a safe and healthful manner, abiding by all health, safety and environmental rules and regulations, promoting safety in the workplace

- Report all accidents/incidents and unsafe conditions/behavior

- Adhere to applicable quality systems and TS16949 standards

- Adhere to and promote the Employee Charter and work within the rules, regulations and guidelines of the Plastcoat Employee Handbook

- Participate in and support Continuous Improvement initiatives

- Maintain work area in accordance with the principles of 5S and operate daily within these standards

- Ensure work area is kept neat and organized

- Certificate of qualification as a Millwright/Industrial Electrician

- Minimum 5 years’ experience in Injection Moulding

- Proven excellent troubleshooting abilities

- Able to operate with minimum supervision

- Computer literate in word & spreadsheet programs

- Demonstrated ability to effectively solve problems

- Well-developed organizational and time management skills

- Repairs/replaces/maintains/installs electrical components, wiring and electrical equipment and/or plant fixtures (including programming and troubleshooting)

- Locates/determines reasons for electrical failure

- Completes PMs as assigned by Supervisor

- Participates in the training of apprentices as assigned by a supervisor

- Follow plant lockout procedure

- Insures all guards including panel doors are in place

- Uses proper safety equipment on aerial work platforms or above 9 feet

- Assist other maintenance trades as required

- Uses Maintenance Reliability Manager Maintenance Program

- Current Industrial Electrician license

- Equivalent to completion of community college or specialized trade courses up to 2 academic years

- Industrial experience considered an asset, especially the ability to function effectively in a team environment

- Skill gained by experience - over 1 year and including 2 years

- Own tools required

- Ability to work all three shifts

- Troubleshoot and maintain production equipment, which includes electrical, hydraulic, mechanic and pneumatic systems. Work from wiring diagrams, engineering drawings and equipment specifications

- Repair and replace electric and electronic components such as motors, contactors, relays, timers, any kind of switches, PLC’s, light curtains, motor controls, etc. Make calculations for load requirements for circuits and choose appropriate size and grade components

- Run new power supply lines to new and relocated equipment according to Hydro codes and other applicable standards and regulations. Works to Electrical Safety Code and company codes

- Wire new control panels according to drawings, and verbal instructions under consideration of Hydro Codes and other applicable standards, and regulations. Locate and diagnose faults on electrical equipment or systems, which may involve complex interlocking or inter-related circuits

- Inform Maintenance Manager or Team Leader about changes in electric circuits and provide a drawing of any modifications or update the original diagrams. Work primarily on voltages up to 575V

- Maintain all production equipment to maximize operating performance

- Record on the Stock Room Sign out sheet any spare parts that are removed from stock room spare part inventory for the repair of any machine or in new installation

- Complete all MPC work orders, PM’s DIN’s and WR’s in detail, filling in the required fields and detailed description of the work that was performed and immediately enter into MPC Maintenance Software

- Inspect assigned production lines daily a per Daily Inspection check sheet, preform any minor repairs immediately

- Work in a cost-effective manner and maintain high standard of quality and excellent workmanship

- Install, examine, replace and repair electronic wiring, receptacles, switch boxes, conduits, feeders, cable assemblies, lighting fixtures and other electrical components

- Assist Manager with training of electrical apprentices as requested

- Able to do simple fabrication of mechanical components using Toolroom equipment for bracketry and installation modifications of electrical devices

- Pass on information, experiences and knowledge to other maintenance employees in regards to repair jobs, preventive maintenance, problem symptoms, etc. which he/she got involved with during the shift

- Listen to information, experiences and knowledge passed on by previous shift employees to ensure effective, non-repetitive problem solving and machine repair

- Assist the Production and Set Up Teams to identify adjust presses to ensure parts are produced according to customer and Unimotion-Gear requirements

- Identify, plan and implement tooling improvements for quality and productivity

- Comply with the applicable responsibilities related to effective quality management in accordance with Unimotion-Gear’s Quality Management System (QMS) TS 16949

- Perform other duties as assigned by the Maintenance Manager or designate

- High School (grade 12) or equivalent and valid Electrician’s license with knowledge of applicable electrical codes

- Two (2) to three (3) years experience in similar role, ideally in production orientated environment, with emphasis on stamping, forming, processes

- Working knowledge of electric circuitry consisting of relays, PC and PLC logic

- Hands-on experience with hydraulics, pneumatics, and mechanical theory

- Basic machine shop skills (i.e. lathes, grinders, milling machines)

- Ability to use programming devices for troubleshooting and modification of programs

- Ability to perform basic wiring work, conduit bending and control cabinet wiring

- Excellent communication skills, both written and verbal

- Able to relate/communicate well with people

- Must have good organization skills, be a self-starter and a team player

- Able to work with minimum supervision

- Assist with and learn troubleshooting of production and facilities equipment breakdowns

- Safety precautions and proper isolation of circuits up to and including 600 volts single and three phase systems

- Strong academics in math and physics

- Perform all duties in a safe manner in accordance with Section 28 of the Occupational Health & Safety Act and Regulations for Industrial Establishments—Duties of Workers

- Maintain safety standards of equipment and work area and perform all duties in a safe manner in accordance with the safety policies of Karmax

- Assembles and installs new equipment and machines and is able to make modifications to existing equipment as requested

- Carries out preventative maintenance procedures on electrical equipment as laid out by the manufacturer’s specifications

- Coordinate activities of co-op students, apprentices, helpers and assigned contractors

- Assist in determining and setting up spare part requirements

- Perform all duties in an environmentally responsible manner in accordance with the Karmax Environmental Policy

- Certificate of Qualification Industrial Electrician 442 or Electrician 309

- PLCs experience required (Siemens Experience Preferred)

- Automotive Experience

- Excellent mathematical, analytical and organizational skills

- Able to perform various computer functions (Microsoft Office, Karmax Software)

- Able to safely operate all Material Handling Equipment (Forklift, crane, buggy) in assigned area of responsibility

Certified Industrial Electrician Resume Examples & Samples

- Troubleshoot electrical and mechanical systems and devices to maintain production

- Perform electrical and mechanical repair work on all machines, equipment and facilities

- Diagnose and make changes to programs as required, with the aid of programmable logic controllers

- Perform preventive maintenance checks and provide documentation

- Document electrical changes for plant inspections as well as basic administration including computer entry and documentation of work performed

- Able to interpret written reports, correspondence, instructions, procedures and guidelines

- Maintain electrical spares, tools and equipment and store in designated locations, requisition replacement parts as required

- Working knowledge of equipment safety standards

- Follow and abide by all government legislation and guidelines

- Adhere to customer requirements

- Maintain excellent housekeeping and follow the 5S principles. Practice our “safety first” policy by addressing: hazards, defective equipment, wearing personal protective equipment as required, and by reporting unsafe conditions immediately

- Participate in continuous improvement initiatives

- Attend all company scheduled internal or external training; pre-shift meetings; and employee meetings

- Train others as required

- Perform other reasonable duties as required by, Supervisor and Management

- Work within the Magna Culture supporting Employee Charter, Principals ,Open Door Process

- Minimum Grade 12 diploma or equivalency

- Ontario Certification of Qualification as an Industrial Electrician (certificate proof required)

- Certified Forklift Driver (or able to be trained)

- Certified Crane Operator (or able to be trained)

- Certified Aerial Platform (or able to be trained)

- Millwright and / or Mechatronics experience considered an asset

- PLC Programming experience (Allen Bradley, Beckhoff, and Siemens) considered an asset

- Robotics (Fanuc) experience considered an asset

- Metal stamping and assembly experience an asset

- Must be able to work in various changing work conditions

- Must be physically able to perform the essential duties of the position

- Required to work in a multi – discipline and fast paced work environment

- Must have good safety, performance and attendance records

- Able to use MS Office, MS Project, TRANS4M, Q.S.I, Lotus Notes, etc

- Able to work with minimal supervision when required and also as part of a team

- Minimum 5 years’ experience with industrial equipment

- Maintain safety standards of equipment and work area and perform all duties in a safe manner in accordance with the safety policies of P&F Systems

- Co-ordinate activities of apprentices, helpers and assigned contractors

- Live up to agreement as maintenance technician and support cross-functional repairs to the equipment that includes Electrical, Robotics, Mechanical, and Tooling provided it could be done safely

- Read, Update, and accurately modify electrical blueprints

- Working knowledge of process cooling water, compressed air supply, air dryers and waste water treatment system

- Good knowledge of hydraulic and pneumatic circuits and the ability to trouble shoot valves, accumulators, pilot operated valves, cylinders and all associated hardware

- Good knowledge of welding process such as mig, tig, resistance, projection and arc welding

- Working knowledge of rebuilding pumps

- Ability to trouble shoot safety devices such as jokab relays, light curtains, gate circuits, power and control circuits with minimal supervision

- Troubleshoot equipment using Alan Bradley PLC Family

- Good knowledge of Alan Bradley HMI

- Ability to troubleshoot safety devices

- Participate in new electrical and mechanical designs and ensure equipment build standards meet P&F’s Build Specifications

- Up to date knowledge of new electrical standards involving Pre Health and Safety reviews

- Build panels and other electrical installations and wiring according to CSA, OESC and company electrical and safety standards

- Can read electrical drawings and/or create them to at least a limited extent

- Inspect, maintain and repair electrical and electromechanical equipment using a variety of electrical tests equipment, meters, powered and non-powered tools and equipment

- Has the ability to program or exposure to PLCs and /or robot programming

- Troubleshoot and diagnose electric/electronic systems faults

- Perform PM’s as distributed

- Follow all workcell and/or department standardized work instructions/procedures

- Comply with Section 28 of the OHSA

- Adhere to all applicable Business Operating Systems Procedures

- Any other reasonable request made by Management

- Minimum five (5) years hands-on experience

- Ontario Electrician Certificate/Industrial Certificate required

- Must be able to communicate effectively in English, both written and oral

- Must have a 2 year technical degree in a related field or equivalent on the job experience

- Must possess a high level of Electrical troubleshooting ability in a manufacturing environment including but not limited to: Allen Bradley PLC’s and Frequency Drives

- Must have strong mechanical and electrical aptitude

- Must operate with a high degree of proficiency with little or no supervision, particularly as such involves the specific trade area

- Required to work independently in carrying out generalized instructions pertaining to operations of the Maintenance Department under the direction of management

- Must read and interpret blue prints, drawings and manuals

- Must lay out work and estimate materials and costs

- Must be skilled in the use of instruments, tools and equipment of the specific trade and be moderately skilled in the use of tools of various trades

- Ability to work an alternative work schedule and shifts

- Maintain records and inventories as required and keep an orderly and clean work area

- Must be a motivated team player

- Individuals MUST have previous ON THE JOB EXPERIENCE and be a motivated team player

- ConAgra Foods offers a very competitive wages ($23.05-$24.95) and benefits package

- Rotating shift: 7am – 3p, 3pm – 11pm and 11pm – 7am

- Troubleshoot and repair power, motor control, machine controls and instrumentation including PLC’s, controllers, and process computers

- Perform prescribed preventive maintenance of electrical equipment

- Perform adjustment and optimization of electrical equipment and machine controls

- Assist in identifying, investigating and recommending solutions for repeat equipment failures

- Continue to improve technical skills through formal, informal and hands-on training

- Perform various mechanical repairs, typically assisting Shift Mechanic

- Valid PA Driver’s License and safe driving record

- AA Degree in Electronics

- Ability to work rotating shifts

- Ability to commit to work safely and to perform complete and safe repairs

- Familiarity with electrical safe work practices and NFPA 70E (National Fire Prevention Association, Safe Electrical Work Practice Standard)

- Ability to work with a minimum of supervision, as well as working well in a team environment

Industrial Electrician / Maintenance Mechanic Resume Examples & Samples

- Troubleshoot and Repair down equipment: Mechanical, minor electrical, pneumatic and hydraulic systems

- Perform preventative maintenance on assigned pieces of equipment

- Complete improvement projects as assigned

- Perform package changes as the schedule dictates

- Support line calls when requested (operator reports issues) or while walking around

- Monitor/work with Ammonia system as needed. Most issues performed by outside contractor

- Be able to adjust high speed conveyor lines utilizing Allen-Bradly variable frequency drives

- Complete work orders / PM's on an electronic maintenance system (INFOR)

- Support improvement programs: LSS, Total Productive Maintenance, Break Down Analysis and Resource Conservation

- Perform annual rebuilds on equipment

- Support training of new maintenance technicians

- Be able to effectively communicate with all departments

- A minimum of 5 years experience as an Industrial Electrician or posses demonstrated automation and electronic knowledge

- Ideal candidate will be capable of troubleshooting and repairing 480 volt 3 phase, 220 volt 3 phase, control circuits and should expect to perform regular maintenance as required

- Must be proficient in PLC and variable frequency drive programming, preferably in the Allen-Bradley family of controllers

- This is a third shift position - 10PM until 6:30AM

- Perform preventative maintenance, repair, and troubleshooting of processing equipment, packaging lines and other industrial equipment

- Changeover and set-up high speed packaging equipment

- Adhere to all identified GMP's

- Follow all safety guidelines

- Actively participate in continuous improvement activities

- Must be able to work well in a team-based environment with limited supervision

- Work from verbal information, schematics, blueprints, wiring diagrams, documents, vendor manuals and applicable national, state and municipal specifications and codes

- Use electrical/electronic and mechanical test equipment, instruments, measuring devices and shop tools such as: resistance soldering units, meters, scopes, probes, microbrazers, generators, counters, potting equipment, ovens, molds, etc

- Perform functional and/or operational tests of refurbished, repaired and modified equipment

- Transport mobile power generators, when required

- Maintain logs, charts, graphs and records, as required

- Must maintain security clearance, area permit(s), licenses, certifications, etc. required for performance of assigned tasks

- Must possess a valid Florida Driver’s License

- Performs other related and/or associated duties as required

- Electrical troubleshooting of baking ovens, food processing equipment and high speed packaging machines. Ability to read and interpret electrical schematics. 40%

- Trouble shooting using Allen Bradley PLC families. Primarily Control Logix and PLC 5’s. Making process

- Improvements to meet production productivity goals and repair down production lines. 20%

- Electrical construction projects. Includes installation of new production lines, modifications to existing equipment. Ability to read blue prints and electrical schematics. 10%

- Use of computers. Using SAP and Microsoft software to help management track maintenance work and preventative maintenance program. 10%

- Performing preventative maintenance routines on process and packaging equipment. Keep facility uptime and equipment utilization at a world class standard 20%

- Prepares machinery for production (including code date changes, test running machines, setting glue pattern, checking for electrical malfunctions, etc.) before startup of shift

- Inspect, troubleshoot, repair and maintain manufacturing equipment in processing and packaging areas

- Check machines in operation on a continual basis in order to detect problems; exercise judgment when executing necessary adjustments as required in order to maintaining quality control standards

- Perform electrical repairs on machines as trained

- Plans, schedules and completes P.M.’s with direction of Maintenance Leader

- Share questions, learning’s and best practices with fellow maintenance colleagues in order to contribute to machine efficiency levels and decreasing machine breakdowns and downtime

- Keep accurate maintenance records both journals and electronically using SAP software

- Work in conjunction with the Engineering department with regards to machine modifications and the installation of new machinery and production systems

- Work closely with operation colleagues to ensure that high quality products are produced while maintaining budgeted efficiencies

- Observe all safety rules and procedures; participate in all safety initiatives as required

- Maintains clean working habits (5S)

- Will be required to operate forklift

- Performs other miscellaneous tasks as required

- Provides mentoring to crafts and operations colleagues as needed

- High School Diploma or GED is required

- Electrician license is preferred

- Minimum 5 years of experience in Industrial Electrician

- Functional Work Experience

- Good hygiene in regards to food safety

- Self-driven

- Troubleshoots, wires and repairs complex electrical and electronic equipment or machinery. Installs conduit, control boxes, switches, electrical cabinets, circuit breakers, etc., as required. Wires complex electronic equipment such as PLC’s, DNC’s, and CNC’s. Performs all electrical work in lower classifications

- Performs repairs on machinery/equipment to include hydraulic and pneumatic repairs. Problems for which assistance is required are referred to the supervisor for correct action

- Assists in the installation and relocation of production machines and equipment. Sets up precision machinery

- Performs simple layout and fabrication of miscellaneous weldments from sketches or drawings using various welding equipment

- Performs simple machining and forming of parts and material as required

- Performs plant utility maintenance involving the repair, replacement, and installation of electrical, air, water, oil, gas or steam lines

- Operates various industrial vehicles used in material/machinery moving or snow removal

- Assists in on-the-job training of employees in lower classifications. Assists other classifications with work normally assigned to them. May serve as a project leader and direct the activities of lower classification personnel. Capable of performing duties associated with lower classifications

Industrial Electrician Dept Maintenance rd Shift Resume Examples & Samples

- Understand read and interpret blueprints, hydraulic and pneumatic schematics, manufacturer’s manuals and similar documents

- Demonstrate knowledge of PLCs and variable frequency drives. PLC programming experience a plus

- Install high voltage power and cables for new equipment

- Install new equipment and set-up machinery

- Maintain all electrical and electronic equipment, switchgears and electrical power

- Rebuild and upgrade electrical panels and replace fuses

- Troubleshoot electrical problems occurring from the machines to the power supply

- Conduct regular preventative maintenance of equipment based on manufacturer’s recommendations

- Plan and layout electrical projects to be implemented

- Perform repairs and fabricate parts on equipment, trucks, forklifts and trolleys including everyday maintenance (oiling, lubricating, changing belts, seals, motors, gear boxes, chains, pumps, vacuum systems, bearings and radiators) per manufacturer’s recommendations

- Weld and use cutting tools

- Adhere to all facets of safety policies and procedures

- Demonstrate 3 to 5 years’ experience in an industrial/manufacturing work environment

- Looking for someone who can demonstrate an understanding of electrical law, circuit theory and wiring diagrams

- Previous experience with woodworking equipment or in Total Productive Maintenance implementation a plus

- Knowledge of safe work practices

- High School diploma or GED preferred

- Installs and maintains high-speed, industrial process equipment for can and/or end making, power, lighting, control, and PLC logic controls for all production process and control equipment

- Troubleshoots, adjusts, and repairs all electrical equipment, components, transducers, and complex timing and inspection devices

- Performs preventative maintenance on assigned electrical systems

- Diagnoses causes of malfunctions and corrects through programmable logic controls. Ensures efficient equipment operation through proper line control programming and proactively suggests methods to improve line performance

- Installs and troubleshoots facility power distribution and lighting services

- May travel to other plant locations to assist with projects

- Must display competent ability to wire, assemble, and layout electrical/electronic systems in an extremely neat and professional manner and conform to Ball wiring specifications

- Updates wiring schematics and computer program printouts

- Supplies and maintains required hand tools

- Maintains daily log books and records

- Determines all supplies needed for each assignment

- Communicates pertinent information to next shift

- Initiates, reviews, and follows all standard operating procedures (SOPs) for area of responsibility

- Performs duties without posing a direct threat to anyone or to property. Direct threat is defined as a significant risk of substantial harm that cannot be eliminated or reduced to an acceptable level by reasonable accommodation

- Assures and maintains safe and healthful working conditions while enforcing safety rules and regulations

- Install, maintain and troubleshoot electrical systems including installing conduit and wirings, motors, instrumentation, recording devices, starters and temporary wiring setups

- Maintain and repair plant instrumentation

- Develop wiring diagrams as necessary

- Use precision instrumentation such as voltmeter, ammeter, megger, wattmeter, etc

- Repair, maintain, test and calibrate instrumentation an equipment of various types including flow meters, thermocouples, HMI, laboratory control instruments, loop controllers, PLC and process control and related networks, page phones, radios, chart recorder, servo motors and systems and various other forms of electrical/electronic equipment

- Install, maintain and repair a wide variety of cranes, elevators, power doors, hoists and related equipment. Perform all aspects of maintaining overhead crane systems

- Complete records and inventory of supplies necessary for performance of jobs

- Perform preventive maintenance and predictive maintenance on electrical devices and other equipment

- Perform other duties as required to maintain or improve plant reliability

- 2yr technical degree (i.e electrician, electronic technician) and 4 years of relevant work experience

- Current/demonstrated proficiency in Microsoft Office: able to use computer to access email, send and receive email, create and work with spreadsheets and documents using Microsoft Excel, Word and PowerPoint

- High school diploma or GED, electrician journeymen papers & 6 years of relevant/industrial electrician experience

- Minimum 3 years’ experience at Journeyman Electrician level

- Experienced with 480 VAC, 3 phase along with lower voltages

- Able to trouble shoot and repair semi-automated production equipment

- Experience with trouble shooting and preventive maintenance of large DC and AC motors

- Able to effectively use standard electrical test equipment including volt meter, amprobe and megger

- Familiar with and able to safely apply with the National Electrical Code and other local safety codes, policies and procedures

- Able to read and interpret facility blue prints and equipment technical manuals

- Able to perform electrical construction projects and repair

- Must have good written and verbal communication skills. Able to effectively work within a team environment

- Experience with troubleshooting Allen Bradley and Delta V Control Logix PLC’s

- Ability to set up AC and DC drives

- Experience with HMI touch screens

- Requires a strong background in production and facilities equipment maintenance and repair

- Demonstrated ability to determine appropriate methods for installing, adjusting and maintaining advanced industrial systems, electronic controls (including programming of PLC’s), factory machinery and equipment is needed

- Proficiency in the use of electronic and electrical measuring instruments and other relevant tools and equipment is necessary

- The ability to work from blueprints, schematics, circuit diagrams, and verbal or written instructions is required

- Experience designing electrical and electronic circuits is preferred

- Familiarity with lasers is highly desirable

- Applicants selected will be subject to a government security investigation and must meet eligibility requirements for access to classified information requiring a security clearance

- A high School Diploma or GED (General Education Degree) from an accredited institution is required

- Completed Four year State Indentured Electrical Apprenticeship and additional technical education in electronic repair with four years of experience which provided a strong working knowledge of ladder diagram schematics, relay logic and solid state electronics OR Two year diploma in Electronic Servicing and four years of experience as stated above plus, two additional years of experience in electronic repair

- The ability to work in the United States on an ongoing basis without company sponsorship

- No relocation is being offered for this position. Candidates must reside within the 50 miles of Waukesha, WI in order to be considered

- Perform routine electrical maintenance on machinery

- Troubleshoot and repair electrical systems

- Self-directed/Ability to work with minimal supervision

- Willing to work holidays and shutdowns

- Must participate on the Hazwoper Team

- Respond to customer needs in a timely manner

Maintenance Industrial Electrician Resume Examples & Samples

- PLC, Robot & HMI programming, implementation and troubleshooting

- Preventative maintenance of paint and support equipment

- Repair of equipment

- Assist in setting up and maintaining programming, electrical component and schematics standards

- General Electrical duties

Industrial Electrician Plywood Resume Examples & Samples

- Willing and able to work any shift to include variable start times, nights, overtime, weekends, and holiday

- Willing and able to obtain a mobile equipment license and operate mobile equipment

- Able to supply own personal hand tools

- Experience performing mathematical calculations

- Willing to work in a loud/noisy, hot, humid, dusty, greasy and high volume environment

- At least 2 years of electrical experience in a manufacturing, industrial, or similar environment

- Experience interpreting electrical schematics, repairing electric motors, installing conduit and cable tray systems, repairing lighting systems, designing and installing basic electrical control circuits

- Associate’s degree or higher in Electrical Instrumentation or Automated Technology of Industrial Instrumentation

- At least 3 years of experience with programming and troubleshooting all of the following PLC’s: Relay Logic, Control Logix, Rockwell and Allen Bradley PLC-5

- Basic knowledge of HVAC

- Adhering to all safety regulations and procedures including performing proper lockout/tag out procedures

- Performing routine and preventive maintenance on industrial electrical and instrumentation equipment (PLC, DCS, motor controls, AC/DC drives, electrical distribution, control valves, industrial instrumentation for flow, pressure, level & temperature, automated packaging equipment)

- Troubleshooting of instrumentation and electrical problems in plant (up to 600V), including working on live electrical circuits

- Reading/interpreting technical work orders, blueprints, technical manuals, single line electrical drawings, schematics, electrical ladder diagrams, ladder logic, P&IDs and instrument loop drawings

- Installing, examining, replacing or repairing electrical wiring, receptacles, switch boxes, conduits, feeders, cable assemblies, lighting fixtures, and other electrical components

- Keeping accurate records of activities including providing accurate and detailed feedback to the work order system (SAP)

- Cleaning all areas of responsibility to maintain a safe work environment

- Working in a team environment with fellow employees, supervisors and managers

- Certified Industrial Electrician (Trade Code 442A)

- 2 years maintenance experience in a manufacturing facility

- Knowledge of Ontario Electrical Code and compliance to the code

- Physically able perform tasks that involve lifting, walking, climbing, stooping, standing, pushing and/or pulling for 12 hours a day

- 5 years of experience as an Industrial Electrician/Instrumentation Journeyman Technician in a manufacturing facility

- At least one (1) year of experience troubleshooting Programmable Logic Controllers (PLC)

- Ability to program Programmable Logic Controllers (PLC) and Variable Frequency Drives(VFD)

- Experience installing, examining, replacing, or repairing Variable Frequency Drives (VFD) and motor controllers

- Demonstrate a commitment to safety in all behaviors and work related activities

- Knowledge of proper use of mechanical, electrical and precision measurement tools to deliver quality craftsmanship

- Communicate effectively both written and orally

- Ability to demonstrate entrepreneurial leadership by using critical thinking skills, taking initiative, and collaborating with others

- Computer skills for record-keeping and documentation functions

- Experience testing electrical and electronic equipment and components

- Experience installing, examining, replacing and/or repairing electrical wiring, receptacles, switch boxes, conduits, feeders, cable assemblies, lighting fixtures and other electrical components

- Experience with single and three phase electrical repair and troubleshooting up to 480V

- Willing and able to work in high and/or confined spaces

- Willing and able to perform physically demanding tasks repetitively for extended periods of time, e.g.; lifting, pushing/pulling, gripping, reaching, sitting, walking, standing, bending, and climbing ladders and/or stairs

- Willing and able to work overtime, weekends, on-call, and rotating shifts

- Knowledge and experience adhering to NFPA and OSHA requirements regarding electrical safety

- Programmable Logic Controllers (PLC) programming experience

- An electrical journeyman card or Industrial Electrician or Electrician trade school certification

- At least three (3) years of work experience as an electrical, instrumentation, or mechanical technician in a manufacturing or military environment

- Experience diagnosing mechanical or electronic systems using various tools and computers

- Experience using precision installation tools such as lasers for alignment and torque wrenches

- Understanding of machine fits

- Experience using precision measurement devices

- Lift Truck Operator License

- A minimum of three (3) years of electrical experience in an industrial, manufacturing or industrial military environment

- Experience troubleshooting and maintaining Programmable Logic Controllers (PLC’s)

- Experience reading mechanical and electrical schematics/blueprints

- Experience maintaining, troubleshooting and repairing electrical control systems including but not limited to relay logic, motor controls and AC/DC drives

- Experience installing, examining, replacing or repairing Variable Frequency Drives (VFD)’s and motor controllers

- Experience installing, maintaining and programming Allen Bradley Contrologix PLC’s

- Computer skills for record keeping and documentation functions

- Experience working with electrical controls for pneumatic and hydraulic systems

- Willing and able to work in a hot, cold, dusty, and noisy industrial environment

- Willing and able to work on machinery at various heights

- Associate’s degree or higher in Electrical Information Technology

- Experience working with PID Controls in A B Contrologix

- At least 1-2 years of electrical experience in a manufacturing facility

- Experience with single and 3 phase electrical repair/trouble shooting up to 480 volts

- Knowledge of OSHA and National Electrical Safety

- At least three (3) years of electrical and mechanical troubleshooting experience in a manufacturing environment

- Installs and maintains high-speed, industrial process equipment for can and/or end making: power, lighting, control, and logic circuits for all production process and support equipment