Solar Panel Manufacturing Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Green & Eco-friendly » Renewable Energy » Solar Panel Manufacturing

Are you about starting a solar panel manufacturing plant ? If YES, here is a complete sample solar panel manufacturing plant business plan template & feasibility report you can use for FREE .

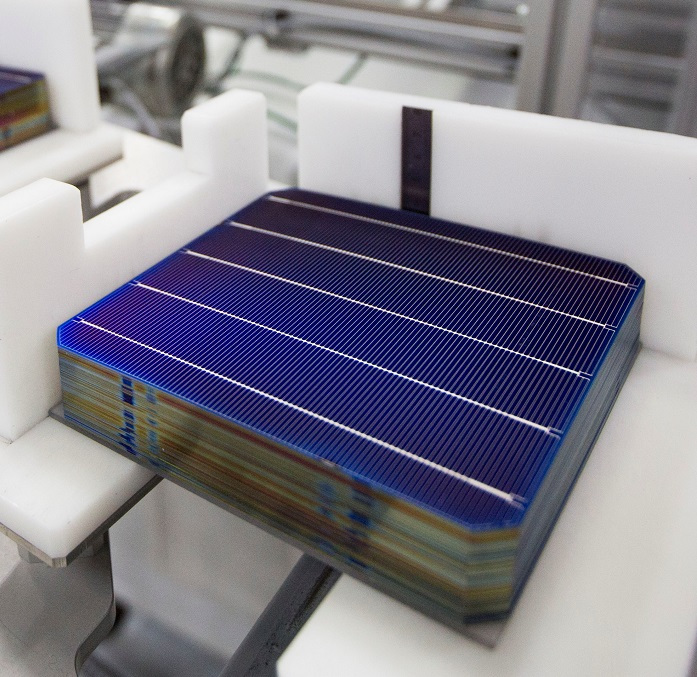

Solar panel is rapidly gaining huge market acceptance all over the globe because of how effective and useful it has become to people.

Solar panel is simply a device that helps convert sunlight into electrical energy and store it for use. There are lots of areas where you can use solar energy and that is the reason why a lot of inventions being powered by solar energy keep propping up.

No doubt, solar energy has become one of the most reliable sources of power supply especially in the operation of lifts in commercial buildings. The market for solar panels is increasing and it is still open for new investors to come in.

So, if you are thinking of starting a business that is into the production of technological components, then you should consider starting your own solar panel manufacturing company. Below is a sample solar panel manufacturing company business plan template that will help you successfully write yours with little or no stress.

A Sample Solar Panel Manufacturing Plant Business Plan Template

1. industry overview.

Players in the solar panel manufacturing industry are responsible for manufacturing solar panels and solar cells and supply these products to solar panel installers and downstream residential, commercial and utility customers. Please note that a solar panel manufacturing company may also engage in the sale and installation of solar panels to end users.

If you have been keeping tabs with the solar panel manufacturing industry, you will agree that the industry has experienced only modest growth between 2012 and 2017.

The industry has been beleaguered by high competition from low-cost Asian solar panel manufacturing companies and an appreciating US dollar, while the volatile prices of natural gas and steaming coal have decreased the cost of other forms of energy and shifted demand away from solar energy.

Going forward, the industry is expected to continue its modest growth due to increased demand for solar panels and cells. This projected rise in demand is expected to be the result of government programs, including an increase in the number of states with renewable portfolio standards.

The truth is that the solar panel manufacturing industry has galloped ahead in recent years as a result of the rapid technological developments in our world, and favorable government policies. Going forward, the demand for solar panel installation is projected to continue to experience rapid growth.

With the ongoing government aid in the form of tax credits and rebates, along with technological advances in solar energy, as well as the rising popularity of solar power purchase agreements (SPPAs), the revenue generated in the industry is expected to grow sharply.

The Solar Panel Manufacturing industry is indeed a large and growing industry especially in countries such as China, Japan, South Korea, India, Malaysia, Russia and the united states of America. Statistics has it that the Solar Panel Manufacturing industry in the United States of America is worth $1bn, with an estimated growth rate of 0.4 percent.

There are about 65 registered and licensed solar farm developer businesses in the United States and they are responsible for directly employing about 7,851 people. First solar is the leading player in this industry; they have the largest market share.

A report recently published by IBISWorld shows that the Solar Panel Manufacturing industry is in a declining phase of its life. Industry value added, which measures an industry’s contribution to the overall economy, is forecast to decrease at an annualized rate of 3.3 percent in the 10 years to 2022.

The report also stated that during the same period, US GDP is projected to grow at an annualized rate of 2.1 percent. As a result, this industry’s importance to the overall economy is decreasing, indicating a declining industry.

The report further stated that while government assistance to industry manufacturers and downstream customers has fueled the growth of solar power, most gains have been made in solar installation and solar power generation. Domestic manufacturers have performed poorly due to competition from imports, especially those from low-cost Asian countries like Malaysia and China.

Most people who have stakes in the industry will agree that the solar panel manufacturing industry has come to stay and of course it is one industry that plays key roles in the business world and in our homes because it is one eco – friendly way of generating power.

Over and above, the solar panel manufacturing industry is very open to any investor who has the required startup capital, acquired the required training, skills and perhaps professional certifications to start his or her own solar panel manufacturing plant.

2. Executive Summary

Generation Next® Solar Technologies, LLC is a U.S based solar panel manufacturing company. We have been able to secure a standard and well – positioned government approved plant – facility in Corpus Christi – Texas. We are a solar panel manufacturing company that is also into after sales services such as solar panel installation, maintenance and repair that is set to compete in the highly competitive the solar panel manufacturing industry.

Generation Next® Solar Technologies, LLC will engage in the manufacturing of solar panels, solar cells, silicon modules and cells, thin-film modules and cells and other related solar panel installation, maintenance and repair services.

Our business goal is to become one of the leading solar panel manufacturing companies in the United States and we will make sure that we will do all we can to compete favorably with leaders in the industry.

Our workers are going to be selected from a pool of certified and highly experienced solar panel engineers and technicians in and around Corpus Christi – Texas and also from any part of the United States of America as the business grows.

We will make sure that we take all the members of our workforce through the required training that will position them to meet the expectation of the company and to compete with leading solar panel manufacturing plants and solar panel installation, maintenance and repair companies in the United States.

At Generation Next® Solar Technologies, LLC, our client’s best interest will always come first, and everything we do will be guided by our values and professional ethics. We will ensure that we hold ourselves accountable to the highest standards by meeting our client’s needs precisely and completely.

Generation Next® Solar Technologies, LLC is founded by Engr. Nelson Givens, a solar energy engineer par excellence who graduated from Illinois Institute of Technology (B.Engr.), and his friend and business partner for many years Lincoln Faraday.

They have a combine experience that can help them build Generation Next® Solar Technologies, LLC to favorably compete with other leading solar panel manufacturing plants in the United States of America and all around the globe.

3. Our Products and Services

Generation Next® Solar Technologies, LLC was established with the aim of maximizing profits in the Solar Panel Manufacturing industry .

We want to compete favorably with the leading solar panel manufacturing plants and of course solar panel installation, maintenance and repair companies in the United States which is why we have but in place a competent quality assurance team that will ensure that every solar panels that leaves of plant meet and even surpass our customers’ expectations and conform to international best practices.

We will work hard to ensure that Generation Next® Solar Technologies, LLC is not just accepted in Corpus Christi – Texas but also in other cities in the United States of America and other countries of the world. Our products and services are listed below;

- Manufacture solar panels

- Manufacture solar cells

- Silicon modules and cells

- Thin-film modules and cells

- Other related solar panel installation, maintenance and repair services

4. Our Mission and Vision Statement

- Our vision is to establish a world class solar panel manufacturing company whose products and brand will not only be accepted in Corpus Christi – Texas, but also in other cities in the United States of America and other countries of the world.

- Our mission is to manufacture standard solar panels that can be used by corporate organizations and households all around the United States of America and other countries of the world.

Our Business Structure

Generation Next® Solar Technologies, LLC, is a solar panel manufacturing company that intends starting small in Corpus Christi – Texas, but hopes to grow big in order to compete favorably with leading solar panel manufacturing companies both in the United States and on a global stage.

We are aware of the importance of building a solid business structure that can support the kind of world class business we want to own.

At Generation Next® Solar Technologies, LLC, we will ensure that we hire people that are qualified, hardworking, creative, customer centric and are ready to work to help us build a prosperous business that will benefit all the stakeholders.

As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of five years or more as agreed by the board of trustees of the company. In view of the above, we have decided to hire qualified and competent hands to occupy the following positions;

- Chief Executive Officer

Plant Manager/Head, Technical Services

Human Resources and Admin Manager

- Sales and Marketing Executive

- Plant Technicians (Solar Panel Installation, Repair and Maintenance Engineers / Technicians (10))

Client Service Executive

5. Job Roles and Responsibilities

Chief Executive Officer – CEO:

- Escalates management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions;

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Generates, connects, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for signing checks and documents on behalf of the company

- Assesses the success of the organization

- Reports to the board

- Supervises the smooth running of the plant

- Attends to issues as project manager of the organization; works directly with employees

- Develops strategic plan by studying technological, and financial opportunities; presenting assumptions; recommending objectives

- Maintains quality service by establishing and enforcing organization standards

- Makes certain that the technical department perform efficiently, coordinate employee efforts, and facilitate communications between management and solar panel installation, repairs and maintenance engineers and technicians

- Ensures that the organization work in line with international best practices

- Responsible for overseeing the smooth running of HR and administrative tasks for the organization

- Designs job descriptions with KPI to drive performance management for clients

- Regularly hold meetings with key stakeholders to review the effectiveness of HR Policies, Procedures and Processes

- Maintains office supplies by checking stocks; placing and expediting orders; evaluating new products.

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Defines job positions for recruitment and managing interviewing process

- Carries out induction for new team members

- Responsible for training, evaluation and assessment of employees

- Responsible for arranging travel, meetings and appointments

Sales and Marketing Manager

- Manages external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Models demographic information and analyze the volumes of transactional data generated by customers

- Writes winning proposal documents, negotiate fees and rates in line with organizations’ policy

- Responsible for handling business research, market surveys and feasibility studies for clients

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develops, executes and evaluates new plans for expanding increase sales

- Creates new markets cum businesses for the organization

- Empowers and motivates the sales team to meet and surpass agreed targets

Accountant/Cashier:

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyzes financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting for one or more properties.

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensures compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization.

Plant Technicians (Solar Panel Installation, Repair and Maintenance Engineers (2) and Technicians (8))

- Works with the team of engineers in manufacturing solar panels, solar cells, silicon modules and cells, thin-film modules and cells and other modules and cells

- Handles solar panel and accessories installation, solar tracking panel installation, ground mounted panel installation, fixed rack panel installation, and monitoring services

- Handles other related solar panel installation, maintenance and repair services as requested by clients

- Welcomes clients and potential clients by greeting them in person or on the telephone; answering or directing inquiries

- Ensures that all contacts with clients (e-mail, walk-In center, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Manages administrative duties assigned by the creative director in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to ensure accurate and helpful information is supplied to clients when they make enquiries

6. SWOT Analysis

Generation Next® Solar Technologies, LLC engaged the services of a core professional in the area of business consulting and structuring to assist our organization in building a well – structured solar panel manufacturing plant that can favorably compete in the highly competitive Solar Panel Manufacturing industry in the United States.

Part of what the team of business consultant did was to work with the management of our organization in conducting a comprehensive SWOT analysis for Generation Next® Solar Technologies, LLC. Here is a summary from the result of the SWOT analysis that was conducted on behalf of Generation Next® Solar Technologies, LLC;

We are a solar panel manufacturing company that is well – positioned to take advantage of government subsidies and other grants, we are game when it comes to development of new products and we have the ability to comply with environmental regulations.

So also, we have a team of certified and highly trained and experience solar panel installation, maintenance and repair engineers and technicians, a team with excellent qualifications and experience in various niche areas in the solar panel manufacturing industry.

Aside from the synergy that exists in our carefully selected workforce, our services will be guided by best practices in the industry.

As a new solar farm and solar panel manufacturing company in Corpus Christi – Texas, it might take some time for our organization to break into the market and gain acceptance especially from top profile clients (solar panel distributors) in the already highly competitive Solar Panel Manufacturing industry; that is perhaps our major weakness.

Another weakness is that we may not have the required cash to pump into promoting our business the way we would want to.

- Opportunities:

No doubt, the opportunities in The Solar Panel Manufacturing industry is massive considering the support from the government and of course the number of individuals and corporate organizations who are now switching over to alternative energy.

In the United States, even with tariffs against Chinese manufacturers in place, the value of imports has risen. Increased government initiatives will help spur demand from downstream customers. As a solar panel manufacturing company, we are ready to take advantage of any opportunity that is available in the industry.

High import competition has been the main threat to the industry over the five-year period. Just like any other business, other threats that we are likely going to face is economic downturn. Another threat that may likely confront us is the arrival of a new solar farm or solar panel manufacturing company in same location where our target market exists and who may want to adopt same Business model like us.

7. MARKET ANALYSIS

- Market Trends

If you are keeping tabs with happenings in the solar panel manufacturing industry, you will agree that the demand for solar panel powered devices has skyrocketed many thanks to substantial government support. So also, technological advancements in solar panel construction will definitely lead to a greater supply of low-cost panels, making solar panels more accessible for individual consumers, also lowering demand.

Another trend is that the solar panel manufacturing industry has galloped ahead in recent years as a result of the rapid technological developments in our world, falling solar panel costs and favorable government policy. In the coming years, demand for solar panel installation is projected to continue growing.

Ongoing government aid in the form of tax credits and rebates, along with technological advances in solar energy, as well as the rising popularity of solar power purchase agreements (SPPAs), are expected to help revenue grow sharply going forward.

The demand for new solar panels has been backed primarily by government incentives such as the Solar Investment Tax Credit (ITC), which encouraged private investment into solar technologies by offering tax credits.

With these incentives, solar panels and other solar-power development projects have been built at accelerating rates over the past five years. Because solar technology is not yet cost-competitive with other types of energy used in electricity generation, such as coal and natural gas, government incentives have been the driving force behind industry growth.

8. Our Target Market

Before building our solar panel manufacturing plant in Corpus Christi – Texas, we conducted a market survey and feasibility studies and we are certain that there is a wide range of clients who cannot successfully run their businesses without purchasing solar panels.

In view of that, we have created strategies that will enable us reach out to various corporate organizations and households who we know can’t do without our product. Below is a list of the people and organizations that will market our products and services to;

- Banks, Insurance Companies and other related Financial Institutions

- Corporate Organizations

- Manufacturers and Distributors

- Real Estate Owners, Developers, and Contractors

- Research and Development Companies

- Schools (High Schools, Colleges and Universities)

- Sport Facilities

- Religious Organizations

- Branding and Advertising agencies

Our Competitive Advantage

In as much as the market for solar panel is growing all over the globe, you must adopt a workable marketing strategy to be able to make good sales and huge profits. We have solid plans to go into contract agreements with those who manufacture products that use solar energy so that we can be in charge of supplying solar panels to them.

We know that we can also make more sales if we work with our customers to produce customized solar panels that can suit their purposes. There are regions where solar panels sell like wild fire and we will ensure that we push our products to these regions.

Solar panels come in different sizes, shapes, and capacities; hence, our solar panel manufacturing companies take all these factors into account so that we can be able to meet the needs of various categories of customers.

Our competitive advantage lies in the power of our team. We have a team of certified, highly trained and experience solar panel installation, maintenance and repair engineers and technicians, a team with excellent qualifications and experience in various niche areas in the solar panel industry.

Lastly, all our employees will be well taken care of, and their welfare package will be among the best within our category in the industry. It will enable them to be more than willing to build the business with us and help deliver our set goals and achieve all our business aims and objectives.

9. SALES AND MARKETING STRATEGY

- Sources of Income

Generation Next® Solar Technologies, LLC is established with the aim of maximizing profits in the solar panel manufacturing industry and we are going to go all the way to ensure that we do all it takes to meet and surpass the expectations of all our clients.

Generation Next® Solar Technologies, LLC will generate income by selling and offering the following solar panel installation, maintenance and repair related services;

- Other modules and cells

10. Sales Forecast

One thing is certain; there would always be organizations and individuals who would need solar panels. We are well positioned to take on the available market in the solar panel manufacturing industry and we are quite optimistic that we will meet our set target of generating enough profits from the first six months of operation and grow our solar panel manufacturing company to enviable heights.

We have been able to critically examine the solar panel manufacturing market and we have analyzed our chances in the industry and we have been able to come up with the following sales forecast. The sales projections are based on information gathered on the field and some assumptions that are peculiar to similar startups in Corpus Christi – Texas.

Below is the sales projection for Generation Next® Solar Technologies, LLC, it is based on the location of our business and of course the wide range of our products, services and target market;

- First Year: $750,000

- Second Year: $1.5M

- Third Year: $2.5M

N.B : This projection was done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same solar panel designs and solar panel installation, maintenance and repair services as we do within same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

We are mindful of the fact that there are stiff competitions in the solar panel manufacturing industry; hence we have been able to hire some of the best marketing experts to handle our marketing.

Our sales and marketing team will be recruited based on their vast experience in the solar panel installation, maintenance and repair services industry and they will be trained on a regular basis so as to be well equipped to meet their targets and the overall business goal of Generation Next® Solar Technologies, LLC.

Our corporate goal is to grow Generation Next® Solar Technologies, LLC to become one of the top 10 solar panel manufacturing brands in the United States of America which is why we have mapped out strategy that will help us take advantage of the available market and grow to become a major force to reckon with not only in Corpus Christi – Texas but also in other cities in the United States of America.

Generation Next® Solar Technologies, LLC is set to make use of the following marketing and sales strategies to attract clients;

- Introduce our solar panel manufacturing company and products by sending introductory letters alongside our brochure to manufacturing companies, households, corporate organizations and other stakeholders

- Promptness in bidding for solar panel supply, installation, repair, and maintenance contract from the government and other cooperate organizations

- Advertise our business in relevant technology magazines, newspapers, TV and radio stations

- List our business on yellow pages ads (local directories)

- Attend relevant international and local expos, seminars, and business fairs et al

- Create different packages for different categories of clients in order to work with their budgets and still deliver excellent services

- Leverage on the internet to promote our business

- Engage direct marketing approach

- Encourage word of mouth marketing from loyal and satisfied clients

11. Publicity and Advertising Strategy

We have been able to work with our brand and publicity consultant to help us map out publicity and advertising strategies that will help us walk our way into the heart of our target market.

We are set to become the number one choice for both corporate and individual clients in the whole of the United States and beyond which is why we have made provisions for effective publicity and advertisement of our solar panel manufacturing company. Below are the platforms we intend to leverage on to promote and advertise Generation Next® Solar Technologies, LLC;

- Place adverts on both print (newspapers and magazines) and electronic media platforms

- Sponsor relevant community based events / programs

- Leverage on the internet and social media platforms like Instagram, Facebook, twitter, YouTube, Google + et al to promote our services

- Install our Bill Boards on strategic locations all around Corpus Christi – Texas

- Engage in roadshow from time to time in targeted neighborhoods

- Distribute our fliers and handbills in target areas

- List our solar energy company in local directories/yellow pages

- Advertise our solar panel manufacturing company in our official website and employ strategies that will help us pull traffic to the site.

- Ensure that all our staff members wear our branded shirts and all our vehicles are well branded with our company logo et al.

12. Our Pricing Strategy

At Generation Next® Solar Technologies, LLC we will keep the prices of our products and services below the average market rate for all of our customers by keeping our overhead low and by collecting payment in advance from major distributors and corporate organizations who would hire our services.

In addition, we will also offer special discounted rates to all our customers at regular intervals. The prices of our product and services will be same as what is obtainable in the United States’ open market.

- Payment Options

The payment policy adopted by Generation Next® Solar Technologies, LLC is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that Generation Next® Solar Technologies, LLC will make available to her clients;

- Payment via bank transfer

- Payment with cash

- Payment via Point of Sale Machine (POS)

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our client make payment for purchase of solar panels without any stress on their part. Our bank account numbers will be made available on our website and promotional materials.

13. Startup Expenditure (Budget)

When it comes to building a solar panel manufacturing plant, you should be ready to spend loads of cash because it is indeed a capital-intensive business. When it comes to setting up a business, the tools and equipment that will be used are nearly the same cost everywhere, and any difference in prices would be minimal and can be overlooked.

As for the detailed cost analysis for starting a standard solar panel manufacturing company; it might differ in other countries due to the value of their money. However, this is what it would cost us to set up Generation Next® Solar Technologies, LLC in the United of America;

- Business incorporating fees in the United States of America will cost – $750

- The budget for Liability insurance, permits and license will cost – $3,500

- Acquiring a standard government approved plant – facility large enough to fit into our design will cost – $250,000.

- The amount required to purchase the needed solar energy equipment, tool box and repair equipment – $150,000

- Equipping our office facility (computers, printers, projectors, markers, servers / internet facility, furniture, telephones, filing cabinets, and electronics) will cost – $30,000

- Amount required to purchase the needed software applications to run our business – $3,500

- Launching an official Website will cost – $500

- Amount need to pay bills and staff members for at least 2 to 3 months – $150,000

- Additional Expenditure such as Business cards, Signage, Adverts and Promotions will cost – $5,000

Going by the report from the market research and feasibility studies conducted, we will need about $750,000 to successfully set up a medium scale but standard solar panel manufacturing company in the United States of America.

Generating Startup Capital for Generation Next® Solar Technologies, LLC

Generation Next® Solar Technologies, LLC is a business that will be owned and managed by Engr. Nelson Givens and his friend and business partner for many years Lincoln Faraday. They are the sole financiers of the business which is why they decided to restrict the sourcing of the startup capital for the business to just three major sources.

These are the areas we intend generating our startup capital;

- Generate part of the startup capital from personal savings and sale of his stocks

- Generate part of the startup capital from friends and other extended family members

- Generate a larger chunk of the startup capital from the bank (loan facility)

N.B: We have been able to generate about $250,000 ( Personal savings $200,000 and soft loan from family members $50,000 ) and we are at the final stages of obtaining a loan facility of $500,000 from our bank. All the papers and document has been duly signed and submitted, the loan has been approved and any moment from now our account will be credited.

14. Sustainability and Expansion Strategy

The future of a business lies in the number of loyal customers that they have, the capacity and competence of the employees, their investment strategy and the business structure. If all of these factors are missing from a business, then it won’t be too long before the business closes shop.

One of our major goals of starting Generation Next® Solar Technologies, LLC is to build a business that will survive off its own cash flow without the need for injecting finance from external sources once the business is officially running.

We know that one of the ways of gaining approval and winning customers over is to sell our solar panels and offer our solar panel installation, maintenance and repair services a little bit cheaper than what is obtainable in the market and we are well prepared to survive on lower profit margin for a while.

Generation Next® Solar Technologies, LLC will make sure that the right foundation, structures and processes are put in place to ensure that our staff welfare are well taken of. Our company’s corporate culture is designed to drive our business to greater heights and training and re training of our workforce is at the top burner.

We know that if that is put in place, we will be able to successfully hire and retain the best hands we can get in the industry; they will be more committed to help us build the business of our dreams.

Check List/Milestone

- Business Name Availability Check: Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts various banks in the United States: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Securing government approved plant – facility: Completed

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Generating part of the startup capital from the founders: Completed

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of Logo for the business: Completed

- Purchase of repair and installation tools and equipment: Completed

- Graphic Designs and Printing of Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of the needed furniture, office equipment, software applications, electronic appliances and facility facelift: In progress

- Creating Official Website for the business: In Progress

- Creating Awareness for the business: In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

Related Posts:

- Scrap Metal Recycling Business Plan [Sample Template]

- Pet Bottle Recycling Business Plan [Sample Template]

- Solar Water Heater Installation Business Plan [Sample Template]

- Waste Paper Collection Business Plan [Sample Template]

- Biogas Production Business Plan [Sample Template]

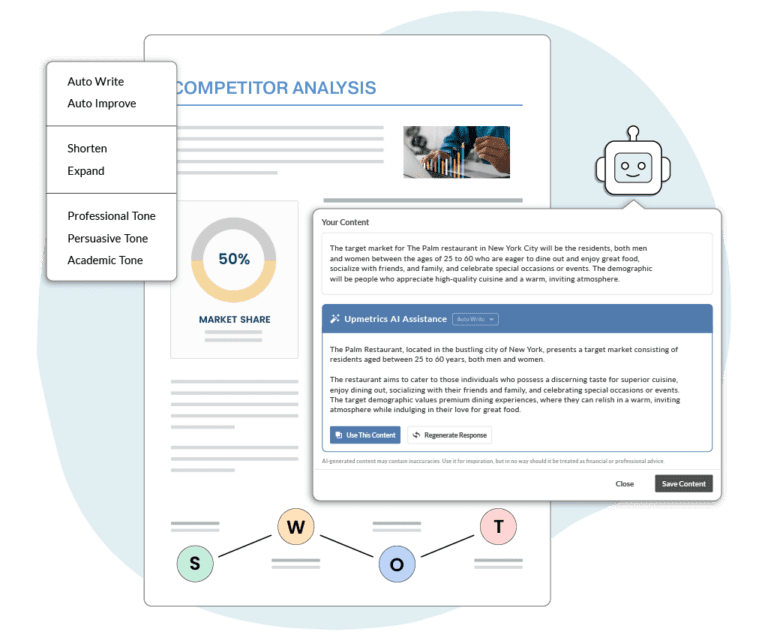

Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai pitch deck generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customers Success Stories

Business Plan Course

Small Business Tools

Strategic Canvas Templates

E-books, Guides & More

- Sample Business Plans

- Manufacturing & Wholesale

Solar Panel Business Plan

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Solar Panel Business Plan?

Writing a solar panel business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

Start your executive summary by briefly introducing your business to your readers.

Market Opportunity:

Products and services:.

Highlight the solar panel services you offer your clients. The USPs and differentiators you offer are always a plus.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

Describe your business in this section by providing all the basic information:

Describe what kind of solar panel company you run and the name of it. You may specialize in one of the following solar panel businesses:

- Solar Panel Manufacturing

- Solar project development

- Solar panel installation

- Solar Panel retailing

- Describe the legal structure of your solar panel company, whether it is a sole proprietorship, LLC, partnership, or others.

- Explain where your business is located and why you selected the place.

Mission Statement:

Business history:.

If you’re an established solar panel service provider, briefly describe your business history, like—when it was founded, how it evolved over time, etc.

Additionally, If you have received any awards or recognition for excellent work, describe them.

Future Goals

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

Start this section by describing your target market. Define your ideal customer and explain what types of services they prefer. Creating a buyer persona will help you easily define your target market to your readers.

Market size and growth potential:

Describe your market size and growth potential and whether you will target a niche or a much broader market.

Competitive Analysis:

Market trends:.

Analyze emerging trends in the industry, such as technology disruptions like virtual site assessments, smart energy management, Integrated photovoltaics, etc. Explain how your business will cope with all the trends.

Regulatory Environment:

Here are a few tips for writing the market analysis section of your solar panel business plan::

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Products And Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Describe your products:

Mention the products offered by your solar panel business. This list may include different types of solar panels,

- Monocrystalline solar panels

- Polycrystalline solar panels

- Thin film solar panels

- Bifacial solar panels

Describe your services:

Mention the solar panel services your business will offer. This list may include services like,

- Installation

- Consultation and site assessment

- System design

- Repair and Mantainence

Quality measures

:This section should explain how you maintain quality standards and consistently provide the highest quality service.

Additional Services:

In short, this section of your solar panel plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

Define your business’s USPs depending on the market you serve, the equipment you use, and the unique services you provide. Identifying USPs will help you plan your marketing strategies.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your solar panel installation business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your solar panel business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Mention your solar panel business’s staffing requirements, including the number of employees needed. Include their qualifications, the training required, and the duties they will perform.

Operational Process:

Equipment & machinery:.

Include the list of equipment and machinery required for the solar panel business, such as manufacturing and installation equipment, testing and maintenance machinery, transport vehicles, office equipment, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your solar panel business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

Introduce your management and key members of your team, and explain their roles and responsibilities.

Organizational structure:

Compensation plan:, advisors/consultants:.

Mentioning advisors or consultants in your business plans adds credibility to your business idea.

This section should describe the key personnel for your solar panel services, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

Cash flow statement:, balance sheet:, break-even point:.

Determine and mention your business’s break-even point—the point at which your business costs and revenue will be equal.

Financing Needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the solar panel industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your solar panel business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample solar panel business plan will provide an idea for writing a successful solar panel plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our solar panel business plan pdf .

Related Posts

Welding Business Plan

Machine Shop Business Plan

Free Sample Business Plans

Table of Contents in Business Plan

Writing a Business Plan from Scratch

Best Business Planning Tools

Frequently asked questions, why do you need a solar panel business plan.

A business plan is an essential tool for anyone looking to start or run a successful solar panel business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your solar panel company.

How to get funding for your solar panel business?

There are several ways to get funding for your solar panel business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

What is the easiest way to write your solar panel business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any solar farm business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

How detailed should the financial projections be in my solar panel business plan?

The level of detail of the financial projections of your solar panel business may vary considering various business aspects like direct and indirect competition, pricing, and operational efficiency. However, your financial projections must be comprehensive enough to demonstrate a comprehensive view of your financial performance.

Generally, the statements included in a business plan offer financial projections for at least the first three or five years of business operations.

Can a good solar panel business plan help me secure funding?

Indeed. A well-crafted solar panel business will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can certainly help you secure your business funding.

What's the importance of a marketing strategy in a solar panel business plan?

Marketing strategy is a key component of your solar panel business plan. Whether it is about achieving certain business goals or helping your investors understand your plan to maximize their return on investment—an impactful marketing strategy is the way to do it!

Here are a few pointers to help you understand the importance of having an impactful marketing strategy:

- It provides your business an edge over your competitors.

- It helps investors better understand your business and growth potential.

- It helps you develop products with the best profit potential.

- It helps you set accurate pricing for your products or services.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

How To Write a Business Plan for Solar Panel Manufacturing Plant in 9 Steps: Checklist

By alex ryzhkov, resources on solar panel manufacturing plant.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

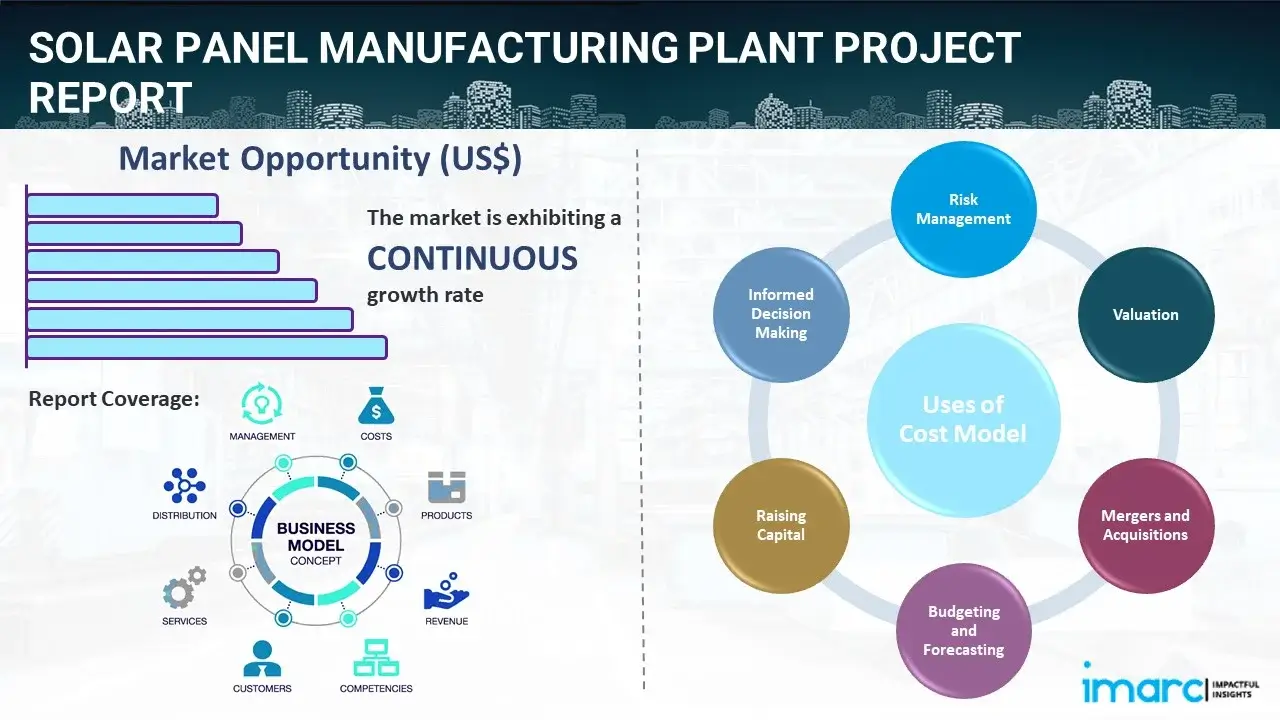

- Marketing Plan

Are you interested in starting a solar panel manufacturing plant? With the increasing demand for renewable energy, the solar panel industry is experiencing remarkable growth. According to the latest statistics, the global solar panel market is projected to reach $42.78 billion by 2027, growing at a CAGR of 19.0%. Now is the perfect time to enter this lucrative industry and contribute to the transition towards sustainable energy.

To ensure the success of your solar panel manufacturing plant, it is essential to have a well-crafted business plan. In this blog post, we will guide you through the nine crucial steps to develop a comprehensive business plan for your plant. From defining your objectives and conducting market research to identifying potential investors, this checklist will assist you in every aspect of your planning process.

Let's dive into the first step: defining your objectives and vision. This involves clarifying your long-term goals and determining the direction in which you want your solar panel manufacturing plant to grow. Setting clear objectives right from the beginning will help you stay focused and make strategic decisions that align with your vision.

Next, you need to conduct thorough market research. Understanding the current market trends, customer preferences, and industry challenges is vital for positioning your plant effectively. By analyzing market data and gathering valuable insights, you can identify untapped opportunities and develop strategies to gain a competitive edge.

Once you have a better understanding of the market, it's time to identify your target market. Narrowing down your customer base will allow you to tailor your marketing efforts and provide customized solutions that meet the specific needs of residential and commercial customers, government entities, and utility companies.

After identifying your target market, it's crucial to analyze the competition. Identifying your competitors and assessing their strengths and weaknesses will help you differentiate your plant and develop unique selling propositions. By understanding the competitive landscape, you can identify areas where you can excel and capitalize on market gaps.

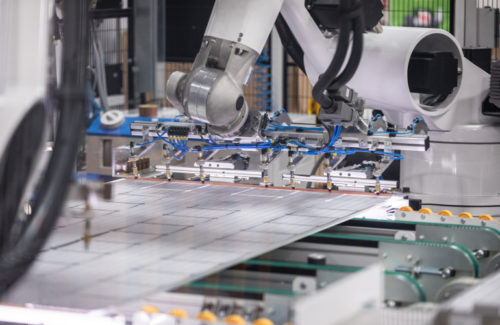

Now that you have a clear understanding of the market and your competition, it's time to determine the necessary resources and equipment for your manufacturing plant. Analyze the production process, calculate the required workforce, and identify the machinery and technology needed to produce high-quality solar panels efficiently.

Assessing the financial feasibility of your solar panel manufacturing plant is another essential step. Determine the startup costs, projected revenue, and potential return on investment. With a strong financial plan in place, you can attract potential investors and secure the necessary funding to bring your business idea to life.

Developing a production plan is crucial to streamline your manufacturing processes. Define the steps involved in producing solar panels, establish quality control measures, and optimize efficiency. Efficient production planning will enable you to meet customer demand, maximize productivity, and ensure consistent product quality.

Establishing a pricing strategy is essential for the success of your solar panel manufacturing plant. Consider factors such as production costs, market demand, and competition when determining the price of your products. A well-thought-out pricing strategy will help you achieve profitability while remaining competitive in the market.

Finally, identifying potential investors or sources of funding is crucial to secure the financial resources necessary to start and grow your manufacturing plant. Explore various funding options, such as venture capital, crowdfunding, or government grants. Present a compelling business plan to attract potential investors who share your vision for sustainable energy.

By following these nine steps, you will be well-prepared to write an effective business plan for your solar panel manufacturing plant. Stay tuned for our upcoming blog posts, where we will dive deeper into each step and provide you with actionable insights and tips. Together, let's contribute to a greener, more sustainable future with solar energy!

Define Your Objectives And Vision

Before starting your solar panel manufacturing plant, it is crucial to define your objectives and establish a clear vision for your business. This step will guide your decision-making process and help you stay focused on your long-term goals.

Identify your purpose: Determine the reason behind starting a solar panel manufacturing plant. Is it to provide sustainable energy solutions, contribute to environmental conservation, or meet the increasing demand for renewable energy sources? Clearly defining your purpose will give your business a sense of direction and purpose.

Set measurable goals: Establish specific and achievable objectives that can be measured. These goals can include targets for production capacity, market share, revenue, or expansion plans. Having measurable goals will enable you to track your progress and make necessary adjustments to ensure success.

Develop a compelling vision: Craft a vision statement that encapsulates your aspirations for the future of your solar panel manufacturing plant. This vision should inspire and motivate both your team and potential investors. It should reflect your commitment to innovation, quality, and sustainability.

- Involve key stakeholders: Engage with industry experts, potential customers, and your team to gain valuable insights and perspectives when defining your objectives and vision.

- Be realistic: While it is important to dream big, ensure that your objectives and vision are attainable and based on market research and financial feasibility.

- Revisit and refine: Regularly review and refine your objectives and vision as your business evolves and adapts to market dynamics.

Conduct Market Research

Before starting a solar panel manufacturing plant, it is crucial to conduct comprehensive market research . This step will help you gather relevant data and insights to make informed decisions about your business venture.

Market research involves collecting and analyzing information about the solar panel industry, including its current market size, growth potential, and trends. It also entails studying your potential customers' needs, preferences, and purchasing behavior.

To conduct effective market research, consider the following steps:

- Identify your research objectives: Clearly define what you want to learn from your research. It could be understanding customer demand, identifying market opportunities, or assessing potential challenges.

- Gather data: Utilize various sources such as industry reports, government databases, and online resources to collect relevant data. Focus on key metrics like market size, growth rate, and customer demographics.

- Interview potential customers: Conduct surveys or interviews to gather insights directly from your target market. This will help you understand their needs, preferences, and willingness to adopt solar panel technology.

- Study the competition: Analyze your competitors' offerings, pricing strategies, and market positioning. Identify gaps in the market and determine how you can differentiate your solar panel manufacturing plant.

Tips for conducting market research:

- Utilize online survey tools to reach a wider audience and gather data efficiently.

- Stay up-to-date with industry news and trends to anticipate market shifts and adapt your business strategy accordingly.

- Consider hiring a professional market research firm if you require specialized expertise or in-depth analysis.

By conducting thorough market research, you can make informed decisions about your solar panel manufacturing plant, including target market selection, product positioning, and marketing strategies. This step will lay the foundation for a successful and sustainable business.

Identify Your Target Market

In order to successfully market and sell your solar panels, it is crucial to have a clear understanding of your target market. Identifying your target market will allow you to tailor your marketing efforts and product offerings to meet the specific needs and preferences of your potential customers.

When identifying your target market, consider the following:

- Demographics: Consider the age, gender, income level, and education level of your potential customers. These factors can influence their willingness and ability to purchase solar panels.

- Location: Determine the geographical area in which you plan to sell your products. This could be a specific city, region, or even a country. Understanding the local climate and energy consumption patterns will help you position your solar panels accordingly.

- Customer Needs: Identify the specific needs and pain points of your target market. Are they looking to reduce their energy bills, decrease their carbon footprint, or gain energy independence? Tailor your messaging and product features to address these needs.

- Market Segmentation: Consider dividing your target market into distinct segments based on common characteristics or preferences. This will allow you to focus your marketing efforts and develop customized offerings for each segment.

Tips for Identifying Your Target Market:

- Conduct surveys, interviews, or focus groups to gather data and insights from potential customers.

- Utilize social media and online analytics tools to gather information about your target audience's online behavior and preferences.

- Study industry reports, market research, and competitor analyses to understand the dynamics of the solar panel market and identify gaps or untapped opportunities.

- Stay up-to-date with industry trends and technological advancements to align your product offerings with the evolving needs of your target market.

Analyze The Competition

When starting a solar panel manufacturing plant, it is crucial to analyze the competition in order to position your business effectively in the market. Understanding who your competitors are, what products or services they offer, and how they market themselves can give you valuable insights to differentiate your business and target your ideal customers. Here are some steps to help you analyze the competition:

- Identify your direct competitors: Make a list of companies that manufacture and sell solar panels in your target market. Look for both local and national competitors to get a comprehensive understanding of the industry landscape.

- Assess their strengths and weaknesses: Research each competitor to determine their strengths and weaknesses. This can include factors such as product quality, pricing, customer service, design innovations, or marketing strategies. Identifying gaps or areas for improvement can help you position your business as a viable alternative.

- Study their product offerings: Examine the types of solar panels and related products offered by your competitors. Pay attention to their features, pricing structures, warranties, and any unique selling points they may have. This analysis can help you identify opportunities to differentiate your own products and services.

- Analyze their target market: Understand who your competitors are targeting and how they are reaching their customers. This information can help you narrow down your own target market and develop effective marketing strategies.

- Review their online presence: Take a look at your competitors' websites, social media profiles, and online reviews. This will provide insights into their branding, customer engagement, and overall reputation. Identify areas where you can improve your own online presence and customer experience.

- Keep an eye on emerging competitors and new entrants in the solar panel manufacturing industry.

- Attend industry trade shows and conferences to network with competitors and stay updated on the latest market trends.

- Consider conducting customer surveys or focus groups to gain insights into perceptions and preferences related to your competitors' products or services.

Determine The Necessary Resources And Equipment

Once you have defined your objectives and conducted market research, it's time to determine the necessary resources and equipment for your solar panel manufacturing plant. This step is crucial as it directly affects the efficiency and productivity of your operations. Here are some key considerations:

- Space: Assess the amount of space required for your manufacturing plant, taking into account the production capacity and the size of the equipment. Ensure that the facility has sufficient space for storage, assembly lines, and any specialized areas such as testing or quality control.

- Equipment: Identify the specific machinery and equipment needed for your manufacturing process. This may include solar panel assembly machines, solar cell coating equipment, testing equipment, soldering machines, and packaging equipment. Research reputable suppliers to ensure you choose high-quality and efficient equipment.

- Raw Materials: Determine the necessary raw materials for manufacturing solar panels. This typically includes silicon wafers, photovoltaic cells, glass, encapsulants, frames, and connectors. Establish relationships with reliable suppliers to ensure a steady and cost-effective supply chain.

- Skilled Workforce: Assess the number and type of personnel required to operate and maintain the manufacturing plant. This may include engineers, technicians, production workers, quality control specialists, and administrative staff. Ensure that you have a plan in place for recruiting and training skilled workers.

- Utilities: Consider the utilities required to power your manufacturing plant. Solar panel manufacturing plants often require significant amounts of electricity, so ensure you have access to a reliable power source. Additionally, assess the need for water, gas, and other utilities.

- Technology and Software: Determine the software and technology required to streamline operations and enhance productivity. This can include inventory management systems, production planning software, data analysis tools, and customer relationship management (CRM) systems.

- Ensure you have a contingency plan in place for any equipment breakdowns or disruptions in the supply chain.

- Consider conducting a cost-benefit analysis of purchasing versus leasing equipment to determine the most cost-effective option for your business.

- Regularly review and update your equipment to keep pace with advancements in solar panel manufacturing technology.

By carefully determining the necessary resources and equipment, you can set a solid foundation for the success of your solar panel manufacturing plant. This step will help you ensure efficient operations, deliver high-quality products, and meet the demands of your target market.

Assess Financial Feasibility

Assessing the financial feasibility of your solar panel manufacturing plant is crucial to ensure the viability and profitability of your business venture. This step involves analyzing various financial factors and determining whether your business idea is financially sustainable.

To assess the financial feasibility, you need to consider several key aspects:

- Capital requirements: Determine the initial investment required to set up the manufacturing plant, including the cost of land, building, machinery, and equipment. Consider the costs involved in obtaining necessary permits and certifications. Also, estimate the working capital needed for day-to-day operations.

- Revenue projections: Conduct market research to estimate the demand for solar panels and forecast your potential sales revenue. Consider factors such as market size, target customers, and pricing strategy. It is essential to have a realistic and achievable revenue projection to ensure financial success.

- Operating costs: Calculate your ongoing operating expenses, including raw materials, labor, utilities, maintenance, and overhead costs. Take into account any potential cost fluctuations and ensure that your revenue can cover these expenses without putting a strain on profitability.

- Profitability analysis: Project your profitability based on revenue and operating costs. Analyze the financial metrics such as gross profit margin, net profit margin, and return on investment. Evaluating the profitability of your business will help you understand the potential return on your investment and whether it aligns with your financial objectives.

Tips for Assessing Financial Feasibility:

- Consult financial experts or engage with a professional accountant to help you with accurate calculations and financial forecasting.

- Consider conducting sensitivity analysis to understand the impact of potential risks, market fluctuations, and changes in your assumptions on the financial viability of your business.

- Explore financing options such as bank loans, grants, or partnerships to secure the necessary capital for your solar panel manufacturing plant.

- Regularly review and update your financial feasibility analysis as market conditions and business dynamics may change over time.

By thoroughly assessing the financial feasibility of your solar panel manufacturing plant, you can confidently move forward in your business planning process, ensuring that your venture has a solid financial foundation.

Develop A Production Plan

Developing a production plan is crucial for the success of your solar panel manufacturing plant. This plan will outline the steps and processes involved in manufacturing your products and ensure that your operations run smoothly and efficiently.

Here are some key steps to consider when developing your production plan:

- Define your production goals: Clearly outline the quantity of solar panels you aim to produce within a specific timeframe. This will help you determine your production capacity and set realistic targets.

- Map out the production process: Identify each step involved in manufacturing your solar panels, from sourcing raw materials to the final assembly. Create a detailed flowchart to visualize the production process and ensure that all necessary tasks are included.

- Estimate the required resources: Determine the resources and materials needed for each stage of production. This includes the machinery, equipment, and components required to manufacture the solar panels.

- Establish quality control measures: Define quality standards and implement quality control processes to ensure that each solar panel meets your specified requirements. Conduct regular inspections and tests throughout the production process to maintain high-quality standards.

- Create a production schedule: Develop a timeline that outlines the start and end dates for each production step. This will help you allocate resources effectively and ensure timely completion of each phase.

- Optimize efficiency: Identify opportunities to improve efficiency and reduce manufacturing costs. This could include streamlining workflows, implementing automation technologies, or optimizing inventory management.

- Train your production team: Ensure that your workforce is adequately trained in each aspect of the production process. Provide ongoing training and support to enhance their skills and knowledge.

Tips for Developing a Production Plan:

- Regularly review and update your production plan to adapt to changing market demands and technological advancements.

- Consider partnering with suppliers or outsourcing certain production processes to optimize efficiency.

- Implement a feedback system to gather insights from your production team and incorporate their suggestions for process improvement.

- Monitor key performance indicators (KPIs) to track the effectiveness of your production plan and make necessary adjustments.

Establish a Pricing Strategy

When establishing a pricing strategy for your solar panel manufacturing plant, it is important to consider various factors that can impact your pricing decisions. Here are some key steps to follow:

- 1. Analyze your costs: Begin by thoroughly understanding your production costs, including raw materials, labor, overhead expenses, and any other associated costs. This will help you determine the minimum price you need to set to cover your expenses.

- 2. Consider market demand: Evaluate the current market demand for solar panels and assess how responsive potential customers are to price changes. Understanding the demand elasticity will help you determine the optimal pricing level that maximizes profit while remaining attractive to customers.

- 3. Evaluate competitors' pricing: Research and analyze the pricing strategies of your competitors in the solar panel manufacturing industry. This will give you insights into the pricing benchmarks and help you position your products competitively.

- 4. Segment your market: Identify different customer segments within your target market and tailor your pricing strategy accordingly. Consider factors such as customer size, geographic location, and purchasing power to determine if differentiated pricing or volume discounts would be beneficial.

- 5. Value-based pricing: Instead of solely relying on costs, consider the unique value proposition of your solar panels and the benefits they offer to customers. Assess the additional value you provide, such as energy efficiency or durability, and adjust your pricing accordingly.

- 6. Bundling and pricing tiers: Explore the option of offering various pricing tiers or bundling complementary products or services with your solar panels. This can create additional value and potentially justify higher prices for certain customer segments.

- Regularly review and revise your pricing strategy to adapt to changing market conditions, industry trends, and customer preferences.

- Consider offering flexible payment options or financing plans to make your solar panels more accessible to customers.

- Be transparent about your pricing structure and clearly communicate the value customers can expect from purchasing your solar panels.

- Continuously monitor and analyze the impact of your pricing strategy on sales volume, revenue, and profitability.

Establishing a well-thought-out pricing strategy for your solar panel manufacturing plant is crucial for positioning your products competitively in the market, maximizing profitability, and attracting a wide range of customers.

Identify Potential Investors or Sources of Funding

Securing adequate funding is crucial for establishing and running a successful solar panel manufacturing plant. Here are some steps to help you identify potential investors or sources of funding:

- Research and compile a list of potential investors or financial institutions that specialize in funding renewable energy projects. Look for investors who have shown interest in solar energy or sustainable ventures in the past.

- Attend industry conferences and networking events to meet potential investors and build relationships. These gatherings often attract professionals who are well-connected in the renewable energy sector and may be interested in investing in your business.

- Reach out to venture capital firms and angel investors who specialize in clean technology or renewable energy investments. Tailor your business plan and investment pitch specifically to their interests and investment criteria.

- Consider government funding and incentives that may be available for solar panel manufacturing plants. Research and apply for grants, loans, or other funding programs offered by local, state, or national government entities.

- Explore crowdfunding platforms that are dedicated to supporting renewable energy projects. These platforms provide an opportunity to raise funds from a wide range of individual investors who are passionate about environmental sustainability.

- Approach strategic partners who may be interested in investing in your solar panel manufacturing plant. Look for companies in the solar energy industry or related sectors that could benefit from a partnership with your business.

Tips for Finding Potential Investors:

- Develop a compelling elevator pitch that clearly communicates the unique value proposition of your solar panel manufacturing plant.

- Prepare a comprehensive investor presentation that highlights the potential return on investment, market opportunity, and growth prospects of your business.

- Network extensively within the renewable energy industry to gain insights and connections that can lead to potential funding opportunities.

- Stay up to date with industry trends and advancements to showcase your knowledge and expertise to potential investors.

- Consider partnering with a financial advisor or consultant who specializes in renewable funding to guide you through the investment process and help you connect with suitable investors.

In conclusion, writing a comprehensive business plan for a solar panel manufacturing plant is essential for success in the industry. By following these nine steps and carefully considering each aspect of the business, you can establish a strong foundation to attract investors, meet the needs of your target market, and achieve financial feasibility. Remember to continuously evaluate and update your business plan as the industry evolves and market conditions change. Good luck in your solar panel manufacturing venture!

$169.00 $99.00 Get Template

Related Blogs

- Starting a Business

- KPI Metrics

- Running Expenses

- Startup Costs

- Pitch Deck Example

- Increasing Profitability

- Sales Strategy

- Rising Capital

- Valuing a Business

- How Much Makes

- Sell a Business

- How To Avoid Mistakes

Leave a comment

Your email address will not be published. Required fields are marked *

Please note, comments must be approved before they are published

How to Start a Solar Cell Manufacturing Company

- Small Business

- Setting Up a New Business

- Starting a Company

- ')" data-event="social share" data-info="Pinterest" aria-label="Share on Pinterest">

- ')" data-event="social share" data-info="Reddit" aria-label="Share on Reddit">

- ')" data-event="social share" data-info="Flipboard" aria-label="Share on Flipboard">

Loss & Waste Analysis in Manufacturing

Businesses that have high failure rates, how to start a battery manufacturing business.

- What Is the Success or Failure Rate for a Sole Proprietorship?

- What Is the Meaning of Competitive Environment?

If you're thinking about starting a solar cell manufacturing company, it may be because you've followed the industry news about the rapidly increasing number of commercial and residential solar cell adopters in this country. Before proceeding further, though, you should also be aware of some obstacles facing any entrepreneur entering the U.S. solar cell manufacturing industry.

Stiff Competition: Chinese Imports

For several years, American solar cell manufacturers have been under fire with many company failures, some of them attributable to inexpensive Chinese solar cell imports. To counter this advantage, in January 2018, the Trump administration put significant new tariffs on solar cells imported from China with the stated purpose of restoring the battered American solar cell industry.

Tariffs: Win or Lose?