Researched by Consultants from Top-Tier Management Companies

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Top 10 Supplier Evaluation Templates with Samples and Examples

Without proper self-evaluation, failure is inevitable.

-John Wooden

Organizations conduct supplier evaluations to analyze potential suppliers and assess ties with existing ones. It is a process that not only evaluates the efficiency and effectiveness of vendor actions but also identifies opportunities for cost savings, risk management, and continuous improvement. Supplier evaluation is one of the most critical activities for organizations to remain competitive in a world where markets change faster than in the blink of an eye.

An organization's success relies heavily on how well its supply chain is streamlined. Therefore, it is vital to keep tabs on the supplier evaluation process to ensure a timely delivery to the manufacturers and customers.

You can move on and outline a comprehensive checklist with SlideTeam's Supplier Evaluation Templates to track the suppliers and their work . These templates use tangible and intangible elements such as materials delivery, quality, pricing, financial situation, communication, and technology to evaluate which provider can provide the best trade-off of all criteria selected.

Without further ado, let us proceed to the following section to conduct an elaborated yet easy to understand evaluation process.

Template 1: Supplier Evaluation PowerPoint Presentation

Download this exclusively-designed PPT to review and evaluate suppliers based on numerous qualitative characteristics before approving them. This PowerPoint Presentation can be instrumental in decreasing corporate risk, enhancing supplier performance, and lowering expenses.

Download Now!

Template 2: Supplier Evaluation PowerPoint PPT Template

If you need a professional Template with an excellent Supplier Evaluation model, then this Template is perfect. This PowerPoint Presentation will assist you in understanding the need for supplier selection, essential sourcing needs, viable supply sources, and determining the supplier evaluation and selection technique. Download it now to gain well-researched B2B marketer advice for practical evaluation.

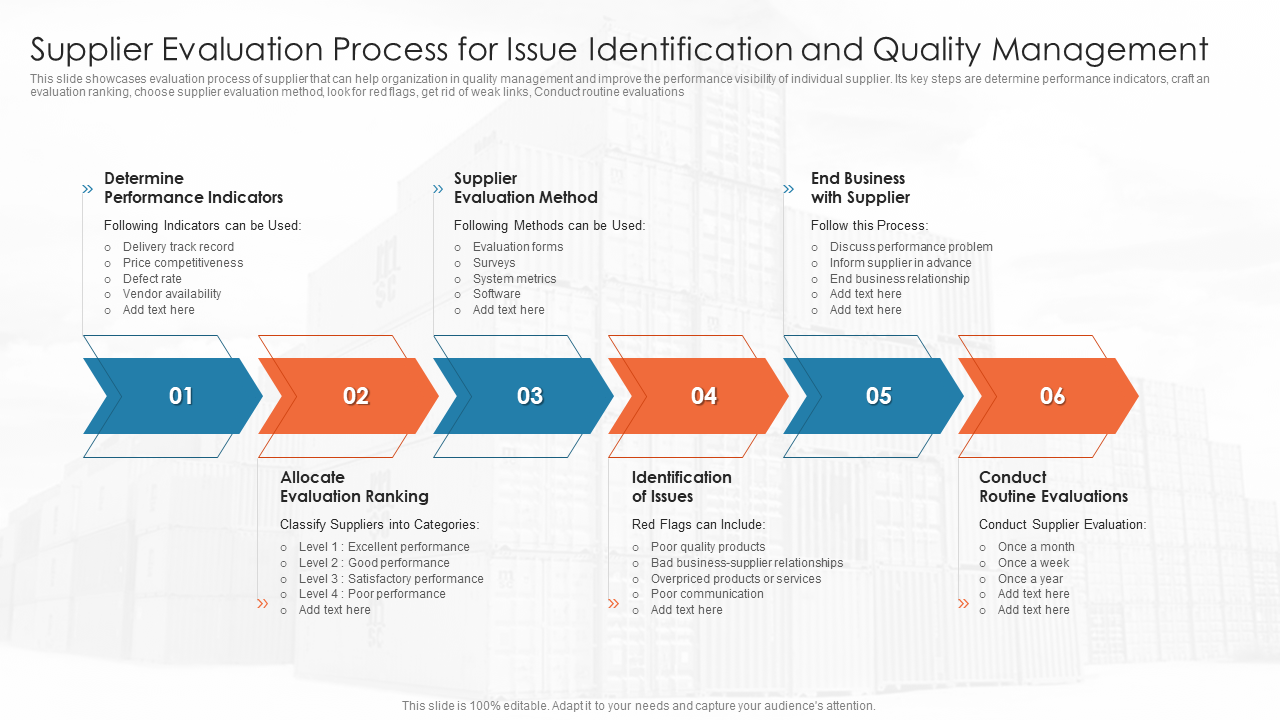

Template 3: Supplier Evaluation Process for Issue Identification

Filter the best suppliers that meet your business standards with this actionable PowerPoint Template. You can use this PowerPoint Slide to create a supplier evaluation process and rank them as per your evaluation. Identify potential problems, performance gaps, and solutions to close them that may impact your business.

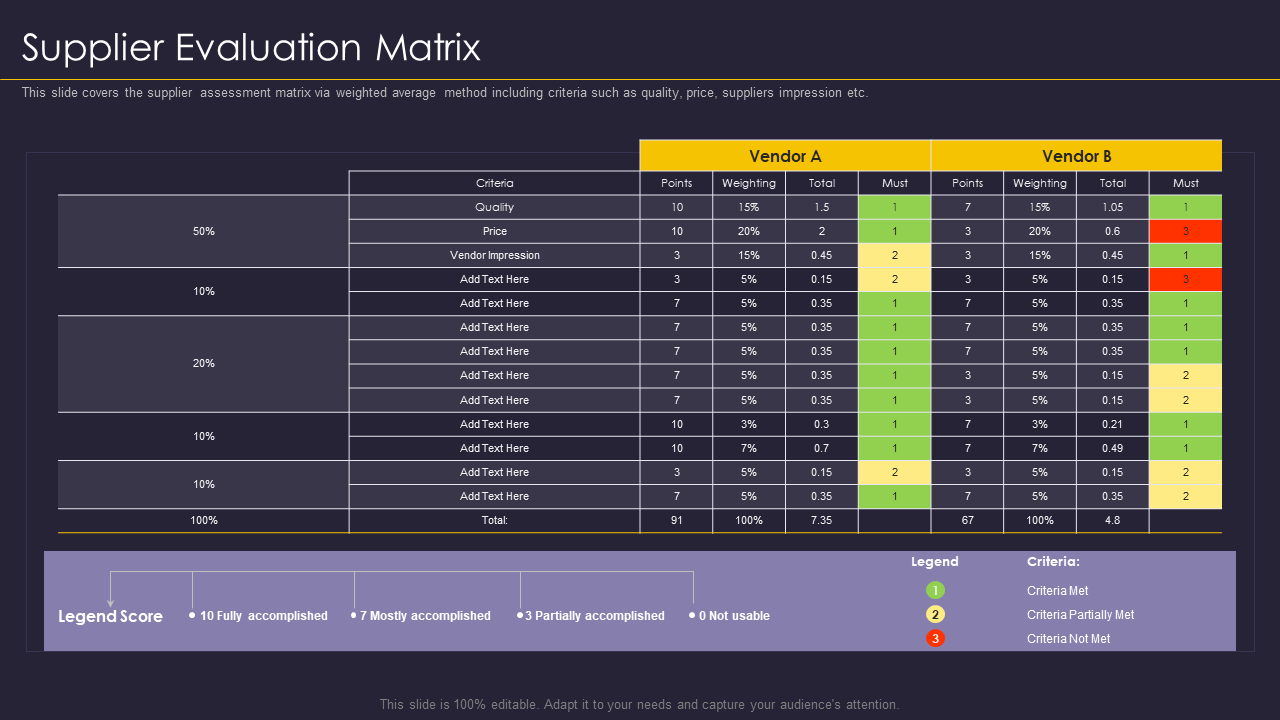

Template 4: Supplier Evaluation Matrix for Tracking Vendor Management

Use this Template to assess the impact of your supplier strategies. This Template will assist you in evaluating suppliers based on identical criteria and weights, allowing you to compare their performance with efficiency. With its clear and well-defined framework, make more informed selections about which providers to engage with.

Template 5: Supplier Evaluation Balance Sheet Marketing Strategies

This Template comprises sections, such as Supplier Assessment, Balance Sheet, Marketing Strategy, and Business Opportunities. It can assist you in identifying providers who regularly deliver high-quality products. Collaborating with such providers may ensure that your products meet or surpass customer expectations. This can then be used as a marketing tactic to distinguish your items from competitors and establish a quality reputation.

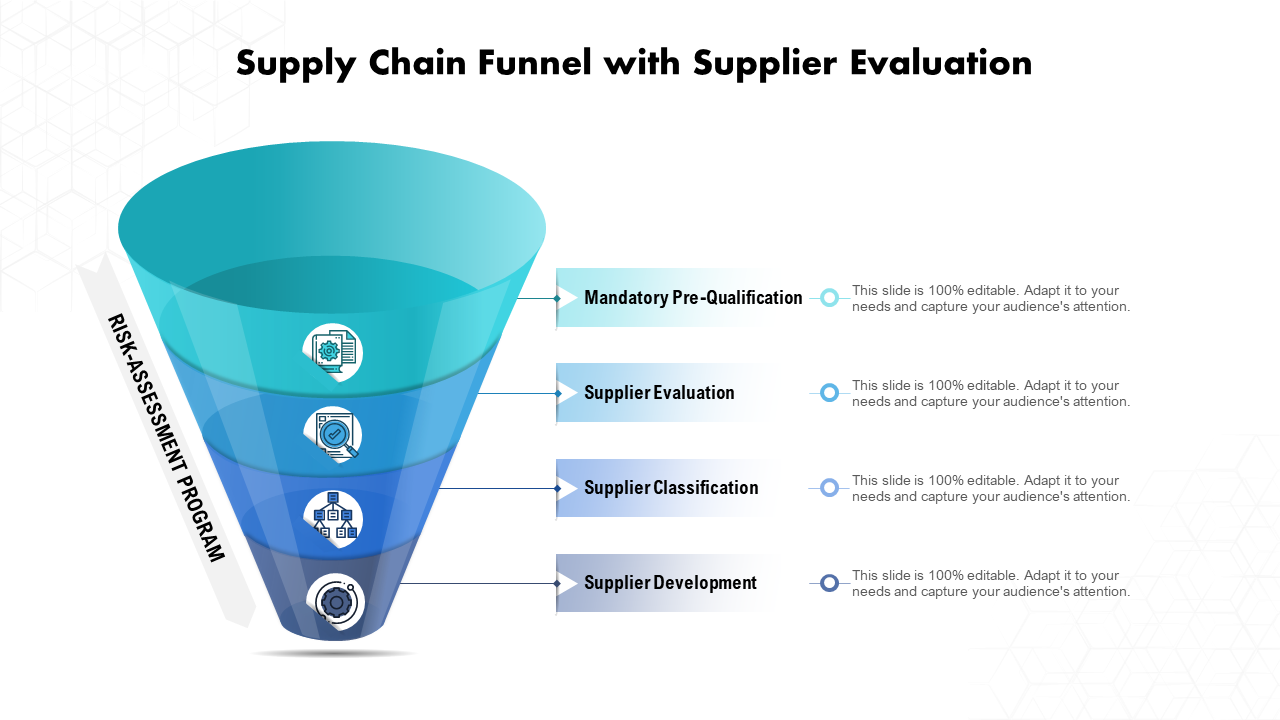

Template 6: Supply Chain Funnel with Supplier Evaluation Template

This is a content-ready PowerPoint Template to help you create a step by step guide to simplify the supply chain of your business. It showcases different sections such as, supplier development, classification, evaluation, etc. to meet the right candidate to manage varied supply chain activities.

Template 7: Supplier Evaluation Matrix Supplier Relationship Management

Download this Template to increase product quality, delivery time, and supply chain efficiency. It not only assists you in identifying areas for improvement and cost savings, but it can also help firms discover possible risks linked with specific suppliers, such as quality difficulties or financial instability.

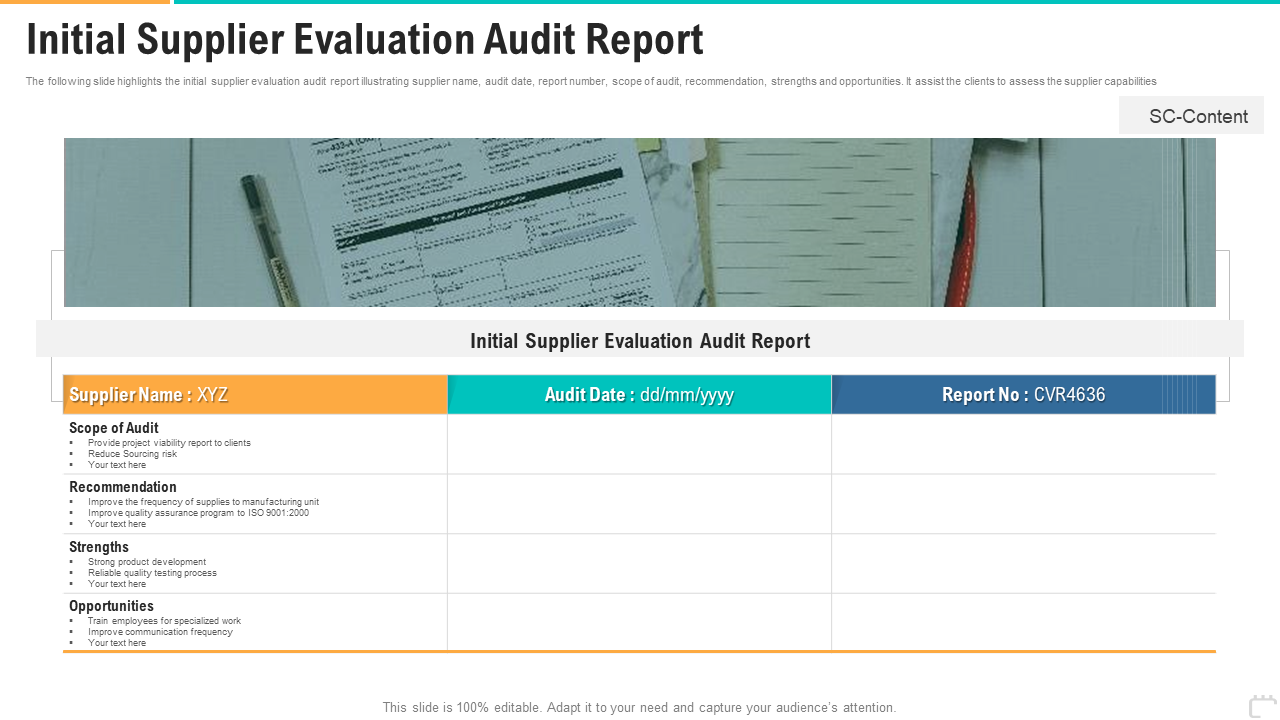

Template 8: Initial Supplier Evaluation Audit Report

An initial supplier evaluation audit report is critical for assessing supplier performance. Use this Template to create a baseline for future evaluations. Businesses can use this PowerPoint to make better decisions about their suppliers and build more significant connections with them.

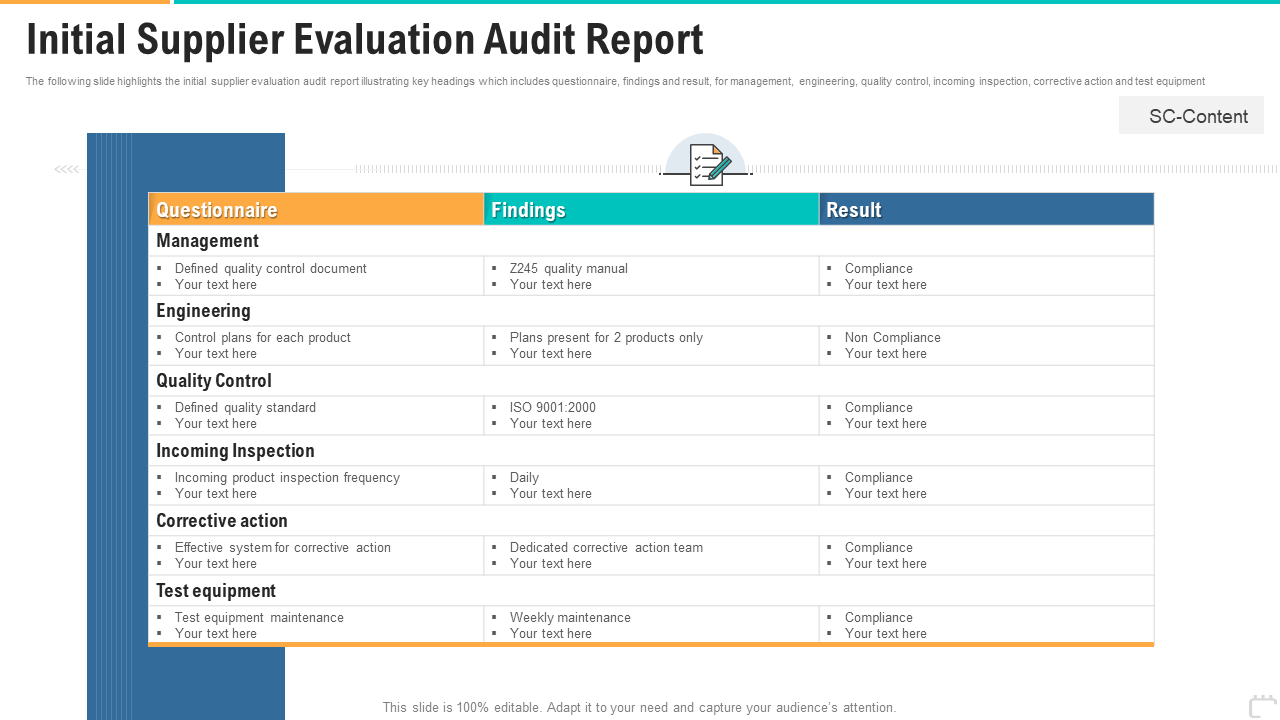

Template 9: Initial Supplier Evaluation Audit Report Each Template

Auditing a supplier on your own can be challenging. Therefore, SlideTeam has designed this Template to help you produce a more effective audit. With this Template, you can assess your supplier's Compliance with specific quality standards and client needs on behalf of the buyer. Without further ado, download it now.

Template 10: Supplier Evaluation Checklist for Audit Report Template

You must have the appropriate Supplier KPI checklist to execute a successful supplier evaluation. This Template includes price, cost, quality, service, quality, delivery, compliance, and many more variables that best meet your company's demands and will assist you in successfully evaluating vendors.

Make your research easy and thorough with SlideTeam’s pre-designed PPT Templates. Make a list of the best suppliers available and take your supply chain activities to the next level. Download these Templates now and kickstart your evaluation process with ease.

FAQs on Supplier Evaluation Templates

What is the supplier evaluation process.

Supplier evaluation refers to the process of examining and approving potential suppliers. This is accomplished through quantitative and qualitative assessments. Supplier evaluation aims to ensure the availability of a portfolio of best-in-class providers. These strategies are also used to analyze and monitor the performance of present providers. The review seeks to cut procurement costs, eliminate supplier risks, and drive continual improvement.

What are the five critical characteristics of a supplier evaluation survey?

Some of the critical elements are:

- Manufacturing Capacity: Supplier evaluations should thoroughly assess the provider's capabilities and limits. A supplier unable to expand production in response to your production cycles will fail any assessment.

- Quality: While defining a product's quality can be difficult, it should always be a vital component of a supplier evaluation.

- Performance: To establish whether a provider can do your regular functions, your organization should ask as many questions as necessary.

- Past experiences with similar companies, recent related projects, and potential product or process advancements are suitable discussion topics.

- Risk: Every business has risks, but its suppliers should actively endeavor to reduce them across the supply chain.

- Environmental Impact: For financial and ethical reasons, sustainability is crucial to a successful organization. An evaluation should include the following:

- A supplier's waste management plans.

- Energy efficiency efforts.

- Any practices used when handling hazardous products.

Why is supplier evaluation critical?

Every procurement organization strives to make the best use of limited resources. This necessitates researching suppliers to secure the finest contracts regarding quality, pricing, flexibility, and dependability.

The supplier evaluation process may be complex, but the rewards of locating low-risk sources of high-quality goods and services and mutually beneficial, long-term business relationships outweigh the effort required. By adequately vetting suppliers, you can reduce the regulatory, contractual, and security risks of dealing with systems outside your organization. Assessing supplier performance assists firms in setting a standard, which leads to more significant results.

How do you write a supplier evaluation?

Follow these steps to write a supplier evaluation:

- Establish the evaluation criteria: It can include several parameters like Quality, delivery, price, communication, response, and flexibility.

- Data collection and analysis: Data can be gathered from various sources, including supplier performance reports, customer feedback, and internal records. Following that, you must assess the supplier's performance against the predefined criteria.

- Summarize the results: In conclusion, you must write about the supplier's overall performance, emphasizing the most notable strengths and weaknesses.

- Give feedback: The next step is to provide feedback to the supplier on their performance.

- Provider evaluation: Using an appropriate scale, you can rate suppliers based on their overall performance.

- Make suggestions: Recommend any modifications to the supplier relationship based on the review.

- Provide your conclusion: Here, you will express your final opinions. In the conclusion part, make sure to utilize concise and precise wording.

Related posts:

- How to Design the Perfect Service Launch Presentation [Custom Launch Deck Included]

- Quarterly Business Review Presentation: All the Essential Slides You Need in Your Deck

- [Updated 2023] How to Design The Perfect Product Launch Presentation [Best Templates Included]

- 99% of the Pitches Fail! Find Out What Makes Any Startup a Success

Liked this blog? Please recommend us

Top 10 Risk Management Dashboard Templates with Samples and Examples

Top 10 Financial Budget Examples With Templates and Examples

This form is protected by reCAPTCHA - the Google Privacy Policy and Terms of Service apply.

Digital revolution powerpoint presentation slides

Sales funnel results presentation layouts

3d men joinning circular jigsaw puzzles ppt graphics icons

Business Strategic Planning Template For Organizations Powerpoint Presentation Slides

Future plan powerpoint template slide

Project Management Team Powerpoint Presentation Slides

Brand marketing powerpoint presentation slides

Launching a new service powerpoint presentation with slides go to market

Agenda powerpoint slide show

Four key metrics donut chart with percentage

Engineering and technology ppt inspiration example introduction continuous process improvement

Meet our team representing in circular format

- Skip to main content

- Skip to primary sidebar

- Skip to footer

- QuestionPro

- Solutions Industries Gaming Automotive Sports and events Education Government Travel & Hospitality Financial Services Healthcare Cannabis Technology Use Case NPS+ Communities Audience Contactless surveys Mobile LivePolls Member Experience GDPR Positive People Science 360 Feedback Surveys

- Resources Blog eBooks Survey Templates Case Studies Training Help center

Home Surveys Assessments

Supplier Evaluation Form : Example, Tools and Benefits

What is a Supplier Evaluation Form?

Supplier evaluation is a term used by many businesses and organizations to evaluate and approve their existing and potential suppliers through a series of assessments. One of the best ways is to create a supplier evaluation form.

This evaluation consists of a series of questions based on parameters like competency, capacity, consistency, quality etc.with a view to assessing the suppliers to ensure a portfolio of best in class vendors.

This evaluation form is essential in order to monitor and measure the supplier’s performance for businesses to reduce the cost associated with the activities, analyze risk management and maintain scope for constant improvement in selecting the suppliers.

Did you know 66% of the organizations don’t have the internal resources to verify their third party supplier!

Learn more: Vendor Security And Assessment Sample Questionnaire Template

Tools for Supplier Evaluation

Evaluating suppliers can be challenging, hence the best practice is to create an evaluation form, that will help any business to organize and evaluate the suppliers more efficiently. There is a Web Electronic RFP/ Tendering system that is used for initial screening but a more robust method is, the Carter 10Cs model that is recognized worldwide.

This model looks into the aspects of evaluating the supplier before being appointed. These are the Cs:

- Capacity – Does the supplier have the bandwidth to deliver?

- Competency – Is the supplier diligent and can complete the task in a given period of time?

- Consistency – Is there a consistent output from the supplier?

- Control of process – Does the supplier offer flexibility and have systematic control over his/her process?

- Commitment to Quality – Is there a system established by the supplier that works constantly for quality management checks?

- Cash – Is the supplier financially independent or is there a third party involvement?

- Cost – Are the products and services offered by him/her cost-effective?

- Culture – Does the supplier have a good work culture and market reputation?

- Clean – Does the supplier have a legal license, doesn’t favor uncertified professionals and is risk management certified?

- Communication efficiency – Does the supplier have the latest means of communication to answer queries put forth to them?

Based on these important parameters the evaluation form can be created and the supplier organization can be asked to furnish all the details right after the screening process is completed.

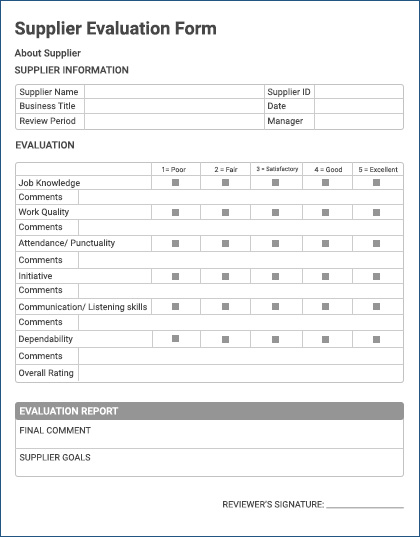

Supplier Evaluation Form Example

3 Benefits of Supplier Evaluation Form

Collecting supplier information before finalizing them is a good practice. For this, the evaluation form plays an important role. The questions asked in the evaluation form help organizations come to a solid conclusion whether or not the supplier should be appointed.

Apart from this, there are other benefits of having an evaluation form ready for supplier or vendor evaluation:

1. Helps in assessing any risk involved: If an organization is not aware of the supplier, getting an assessment done will help the organization know their supplier and they can assess any risk associated with hiring them. As the Carters 10C model suggests, risk management can be associated with capacity, competency, and commitment to quality.

2. Helps in protecting the brand reputation: Through these evaluation forms, organizations can hire suppliers with a good market repute and in turn minimize any risk associated with tampering their brand reputation. Carter’s 10C model suggests brand reputation can be associated with control of the process, clean (has a legal license) and culture.

3. Helps in stimulating the cost factor: There are various cost factors associated with hiring the suppliers. A huge sum of money is invested by organizations while finalizing on their suppliers. By having a systematic evaluation form the organizations can understand the overall ability of their vendors to fulfill the organization’s expectations and requirements. Associating with Carter’s 10C, the cost factor is in tandem with cost and monetary competency.

Thinking of evaluating the service of your suppliers? Here’s QuestionPro’s free supplier service evaluation form template.

After being chosen as a vendor/supplier by a company, it is important for a vendor/supplier to communicate with his customer as well. From a vendor’s perspective, he has to make sure he takes care of the above points in order to stay ahead of his competition and make his client a loyal customer. In order to do so, he needs to identify the requirements of a customer and what are the factors that can strengthen the vendor-customer relationship. In such a case, the vendor can carry out a small survey with his clients, which will enable him to improve in certain areas after understanding the customer’s expectations.

Top 3 free supplier evaluation forms and survey templates:

- Supplier or vendor satisfaction template

- Supplier or vendor security evaluation template

- Supplier or vendor service evaluation template

MORE LIKE THIS

NPS Survey Platform: Types, Tips, 11 Best Platforms & Tools

Apr 26, 2024

User Journey vs User Flow: Differences and Similarities

Best 7 Gap Analysis Tools to Empower Your Business

Apr 25, 2024

12 Best Employee Survey Tools for Organizational Excellence

Other categories.

- Academic Research

- Artificial Intelligence

- Assessments

- Brand Awareness

- Case Studies

- Communities

- Consumer Insights

- Customer effort score

- Customer Engagement

- Customer Experience

- Customer Loyalty

- Customer Research

- Customer Satisfaction

- Employee Benefits

- Employee Engagement

- Employee Retention

- Friday Five

- General Data Protection Regulation

- Insights Hub

- Life@QuestionPro

- Market Research

- Mobile diaries

- Mobile Surveys

- New Features

- Online Communities

- Question Types

- Questionnaire

- QuestionPro Products

- Release Notes

- Research Tools and Apps

- Revenue at Risk

- Survey Templates

- Training Tips

- Uncategorized

- Video Learning Series

- What’s Coming Up

- Workforce Intelligence

Vendor Assessment and Evaluation Simplified

By Diana Ramos | June 18, 2020 (updated March 23, 2024)

- Share on Facebook

- Share on LinkedIn

Link copied

Which vendors should become your long-term business partners? Using a framework and the right tools to make the selection process easier, Dr. Ray Carter offers expertise and best practices to help you become a vendor assessment pro.

Included on this page, you’ll find a vendor assessment criteria checklist , a vendor assessment framework , tips for strong vendor assessment , a guide to the vendor evaluation process , and a list of disaster and pandemic readiness questions .

What Is Vendor Assessment?

Vendor assessment is an evaluation and approval process that businesses can use to determine if prospective vendors and suppliers can meet their organizational standards and obligations once under contract. The end goal is to secure a low-risk, best-in-class vendor and supplier portfolio.

Vendors and suppliers both furnish services or goods, but there is a distinction: The term vendor applies to business-to-business (B2B) and business-to-consumer (B2C) sales relationships, while supplier applies only to B2B relationships.

Benefits of Vendor Assessment

Although the vendor assessment process can be challenging, the benefits include finding low-risk sources for high-quality goods and services, as well as the development of mutually beneficial, long-term business relationships.

Dr. Ray Carter is Director of DPSS Consultants (Developing People Serving the Supply Chain), creator of the 10C Model of Supplier Evaluation, and author of five vendor management and supply chain books, including Practical Procurement . Carter points to the COVID-19 pandemic as a prime example of the need for systematic vendor and supplier assessment that enables organizations to weather any storm in the business environment.

“What the COVID-19 emergency illustrates,” Carter says, “is the importance of engaging suppliers with sufficient resources and access to working capital to continue to operate, gear up if necessary to meet demand, and survive crises.” Assessing vendor and supplier crisis management plans is one of the aspects of risk mitigation you should consider during your vetting process. “Future crises driven by foreseeable factors — global warming, wild animal and nature conservation, human interactions, and political unrest — are almost inevitable. Therefore, exploring the quality and robustness of vendor and supplier contingency plans is crucial.”

Dr. Carter advises caution when selecting business partners for goods and services. “Deficient evaluation constructs begin with poorly defined specifications, which then feeds into the procurement process and award criteria and the selection of suppliers that lack the necessary expertise or resources,” Carter explains. “Post-award, this leads to a perfect storm: a fractious relationship characterized by ‘blame game’ disputes and, often, operational failure. A reliable process and careful vetting helps avoid that risk — and many others.”

Additional benefits of vendor assessment include the following:

- Lower Regulatory Compliance Risk: Confirm compliance with the laws, regulations, and standards that apply to your business. If your vendor is in another country or you sell to another country, check those countries’ legal requirements, too. For example, if you do business in the European Union, the General Data Protection Regulation (GDPR) applies.

- Scope of Service and Contract Compliance: Conduct a legal review of contract terms, nondisclosure agreements (NDAs), or partnership agreements to ensure that you’ve set favorable conditions and mitigated any risks.

- Decrease Security and Cyber Risk: The threat of cyber risk grows as we increasingly move our work to the cloud. Therefore, it’s crucial to protect all your customer and company data. Your selection process should focus on assessing a third-party vendor or supplier to store your data. First, identify and evaluate the type of data that vendors and suppliers may need to access, and decide whether they need to access all, some, or none of it to do their work. It’s crucial to ensure the vendor takes the proper measures to encrypt and protect your data. Once you identify potential partners, have them complete a questionnaire that thoroughly covers security management system details.

Get more risk mitigation information, tools, and templates in the “ Definitive Guide to Vendor Risk Management .”

See how Smartsheet can help you be more effective

Watch the demo to see how you can more effectively manage your team, projects, and processes with real-time work management in Smartsheet.

Watch a free demo

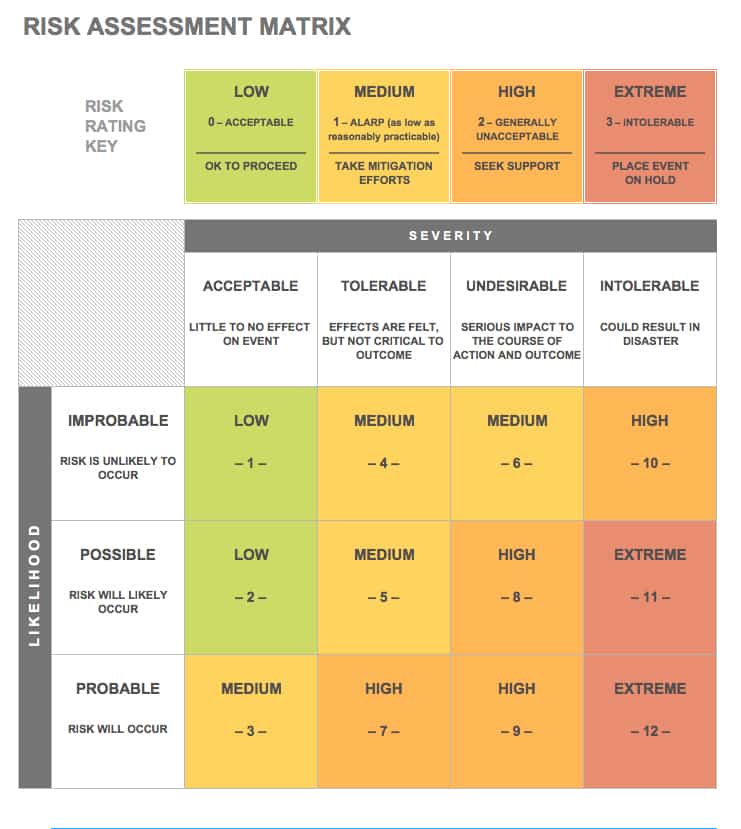

Risk Assessment Matrix Template

Understand your organization’s tolerance for specific risks — this is an important factor when deciding which companies to contract companies for goods and services. This matrix captures the risk assessment information your company needs to review, estimate, and prioritize using rankings of generally acceptable (GA), as low as reasonably possible (ALARTP), and generally unacceptable (GU). Using this template, you can list each risk and determine their likelihood and rate the severity, all on a single color-coded chart.

Download the Risk Assessment Matrix Template

Excel | Word | PDF | Smartsheet

Find more useful tips and templates at “ Free Vendor Risk Assessment Templates ."

- Identify Top Vendors: Based on a considered combination of your essential vendor selection criteria and risk assessment, you’ll find vendors with the reputation, skills, and knowledge to solve your business challenges.

- Reduce Costs: While cost shouldn’t be the ultimate deciding factor, you will likely save by comparing top-notch vendors and the competitive environment by avoiding financial issues around poor service and delivery. Plus, once you establish your relationship, vendors may offer future opportunities to reduce costs through volume or continuity discounts further.

- Increase Efficiency: The ability of a business to act fast and move quickly depends on the smooth flow of your supply chain. With ongoing monitoring, you’ll notice when inefficiencies occur and be able to rectify them in partnership with your vendor or supplier before it’s too late.

- Strengthen Relationships: Proper vendor management, which fosters communication, collaboration, and loyalty, bolsters your brand and supports mutually beneficial working relationships that serve everyone in the long run and improve your reputation.

- Improve Your Business: Proper vetting will help you engage top-notice vendors and enable you to provide higher-quality and more competitively priced goods or services. This results in serving your customers far better — as you improve decision-making and effectiveness, expect an upswing in customer loyalty and sales.

By performing extensive due diligence before you engage a vendor or supplier, you can save time and money, as well as support trust and your company's reputation. Base that due diligence on criteria that make sense for you and your organization. For example, if data and personal information security is of utmost importance because you are a healthcare company bound by HIPAA security rules, that criteria may override cost or efficiency concerns.

Supplier and Vendor Assessment Framework

A vendor or supplier assessment framework supports an organized approach to vet and rank potential vendors. The framework is based on a set of standard criteria to determine prospective vendors’ suitability and any risks they may pose to your company.

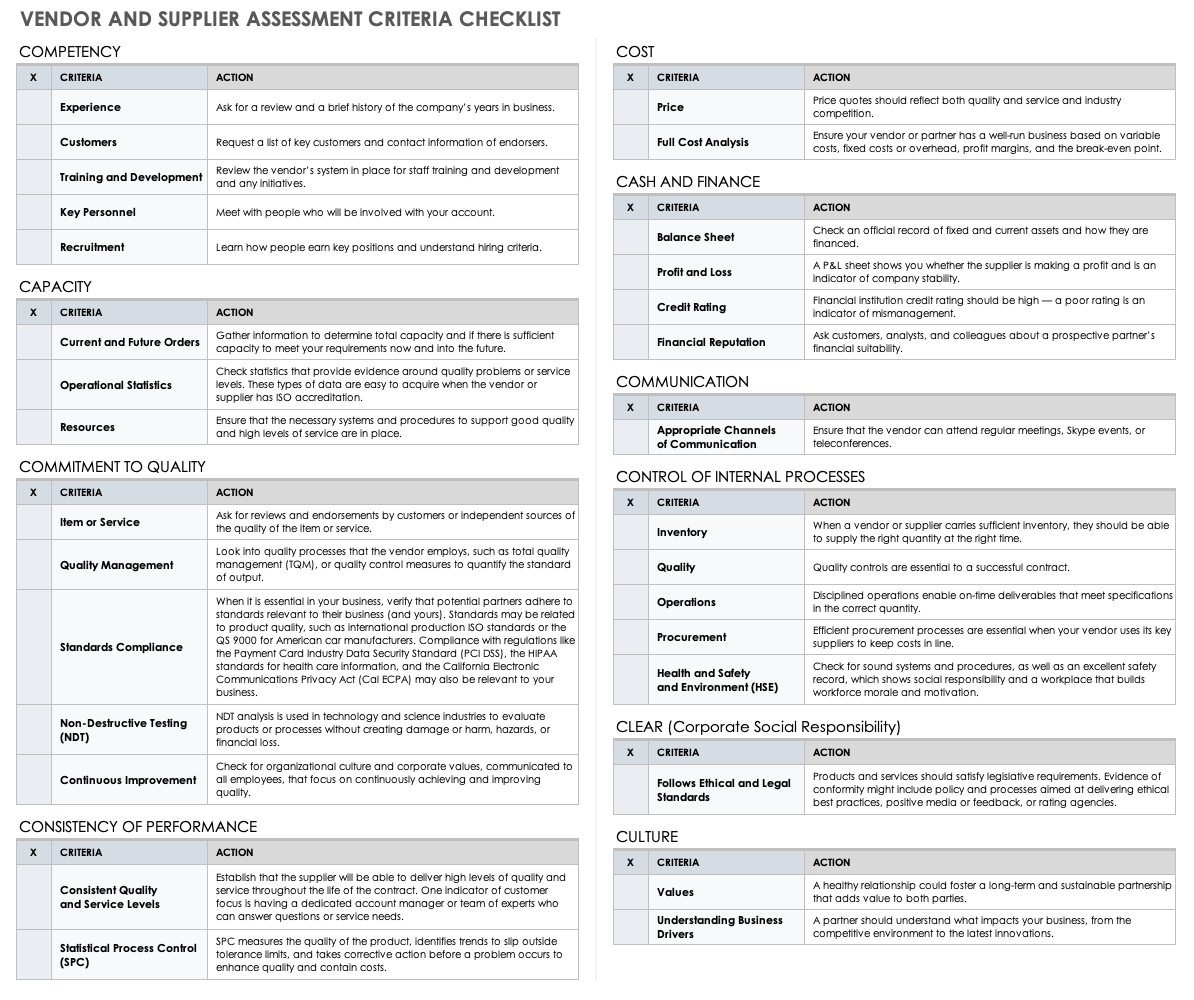

You can use an assessment framework to determine the best vendor or supplier based not only on price, but also on a full spectrum of concerns that Dr. Carter of DPSS Consultants delineates in his 10C Model of Supplier Evaluation.

Dr. Carter created his model because he saw that poor supplier selection causes business breakdowns. “I developed my framework to provide a simple and systematic process of investigating, analyzing, and verifying the resources and capabilities of potential suppliers (the extent of which is dependent upon the risk and value of the contract) leading to the appointment of an effective and sustainable source.”

Vendor and supplier assessment occurs most often within purchasing departments. It also forms part of the pre-qualification step within the purchasing area, although it usually includes the participation and input of other departments and stakeholders.

The 10C Model of Supplier Evaluation allows sufficient space for you to fill in the blanks with criteria in each category that applies to your specific business, business model, and goods and services needs.

- Competency: Ask vendors to provide evidence of proven quality with other customers, and review their training and development procedures, qualification records, essential personnel background and abilities, and recruitment methods.

- Capacity: Look into prospective partners’ current and forecasted orders and customers, along with how that impacts the ability to meet your current and projected requirements. Ask for operational statistics around quality- or service-level challenges, which should be readily available if the supplier is ISO 9000 accredited. To learn more about this accreditation read “ The Ultimate Guide to ISO 9000 .”

- Commitment to Quality: Review the policies and procedures the company uses on an ongoing basis to monitor and manage quality and adherence to industry standards, such as ISO 9000 and HIPAA.

- Consistency of Performance: Ensure that your future partner will be able to deliver consistently high levels of quality and service throughout the life of the contract. For example, look for a vendor that assigns an account manager as a single point of contact dedicated to quality control and oversight; this indicates the vendor’s commitment to high performance.

- Cost: Review whether the product or service can be delivered at a reasonable price and keep your vendor or supplier in business.

- Cash and Finance: Of course, you want to work with a financially stable entity. Request the most recent fixed and current asset lists, profit and loss (P&L) statements, and credit rating documentation.

- Communication: Ensure that your vendor or supplier will set up and manage (or conform to your existing) communications channels, whether in person with your account manager and other key personnel, via virtual meetings, or with collaboration software.

- Control of Internal Processes: Ask for evidence of how the company manages inventory, quality control operations procurement, marketing, distribution and health, and safety.

- Clear (Corporate Social Responsibility): Vendor and supplier services and products should conform to legal and environmental standards and requirements.

- Culture: Determine if you and your potential partner share values and working philosophies before you enter into a contract. A similar outlook makes for smoother work relationships and helps you establish long-term partnerships.

Vendor Assessment Criteria

Vendor assessment criteria should support your company mission, ethics, and business goals in the areas of technical competence and quality, cost and financial integrity, ability to communicate, social responsibility, and cultural commitments.

Assessing vendors and suppliers also involves reviewing the criteria that matter most to your company goals and your larger industry. For example, if a business looks for a packaging company, the most significant concerns might involve graphics and structural design and rely on a review of custom versus standard options and shipping durability. Use the following checklist, based on the 10C Model of Supplier Evaluation, to gather your criteria on vendors and suppliers, and then use it as a “go or no go” tool to assess prospective or current business partners.

Vendor and Supplier Assessment Criteria Checklist

Download Vendor and Supplier Assessment Criteria Checklist

You can apply these criteria to potential partners, as well as use them to evaluate and rate current partners. Paring down partnerships is not a bad idea: according to research conducted in 2020 by The Hackett Group, companies average 3,000 suppliers per $1 billion in spend. While you may not spend $1 billion a year with your vendors and suppliers, if you don’t have strict control over your business partners or which companies have access to your data, you’re taking a risk from a financial and security standpoint.

How to Evaluate a Vendor

When evaluating vendors and suppliers, you’ll need to make both quantitative and qualitative assessments to ensure a purchasing process that works for your organization. It's a good idea to track metrics on an ongoing basis to confirm contracts are still beneficial.

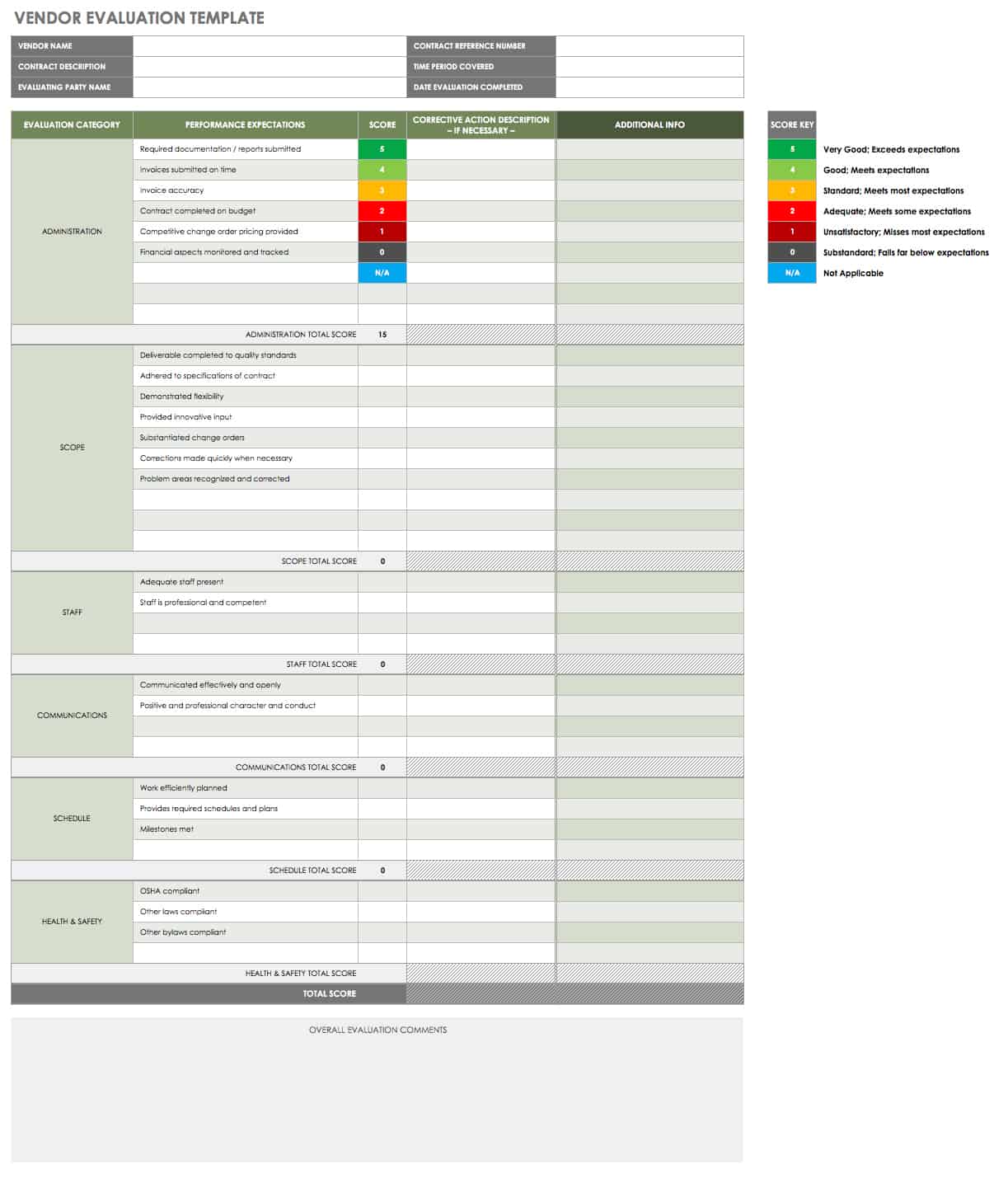

Vendor Evaluation Template

This third-party vendor assessment template includes areas to note corrective actions and observations, but you can also adjust it to reflect your company criteria. Additionally, the template includes a scoring system that makes it easy to rank individual vendors and suppliers, and you can use the aggregated scores to make comparisons. By compiling this information in one place, you can combine written descriptions with ease.

Download Vendor Evaluation Template

Excel | Word

If you need more templates to manage your supply chain process, take a look at “ 13 Free Vendor Templates .”

Different Methods of Vendor Evaluation

There is no single vendor evaluation method that covers every circumstance. To evaluate vendors, take into consideration your business and the vendor classification, as well as whether the vendor is a prospect or already under contract, and if you're conducting a post-award review.

Following is a list of common methods that you may use to conduct your vendor evaluation:

- Commercial: When considering the commercial side of any potential vendor or supplier, keep in mind their reputation, market dominance, market and advertising presence, awards, ability to deliver promptly, and existing clients.

- Technical: A technical evaluation is centered on standards for compliance, innovation, technical equipment, and scientific capabilities.

- Records: In this type of vendor evaluation, you collect data from public sources, such as financial records, industry news items, and award notices.

- Before-the-Fact: In this type of evaluation, the evaluator plans and starts gathering data from public data sources and vendor or supplier endorsement or reviews early in the history of the project. Replies to RFIs and RFPs with substantiating documents should provide many of the necessary answers, too.

- After-the-Fact: For this evaluation, review a first engagement or shipment and assess performance and process. Ask critical stakeholders about successes, failures, and operations. Responses provide data for decisions, future planning, and discussions after an event is complete.

By performing these vendor analysis methods based on criteria and data, you will have support in making evidence-based decisions. Remember that in today’s competitive business environment, you shouldn’t simply be solving for cost — the price for poor quality or delivery can be too high in the end.

Vendor Performance Evaluation

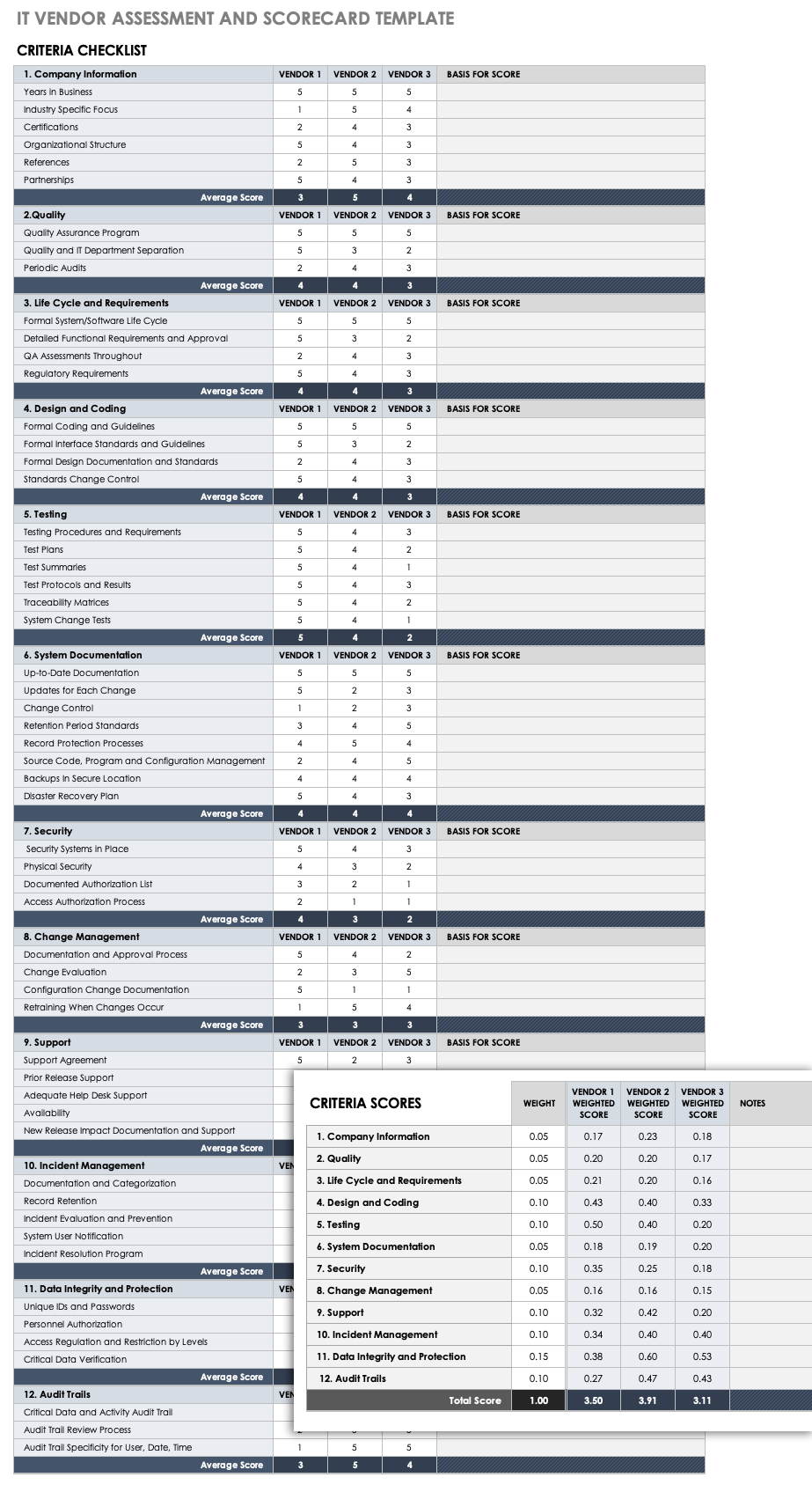

Vendor performance evaluation requires three elements: a vendor roster based on value to your organization; a system to track performance against metrics and service level agreement; and the utilization of a strategic ranking system.

1. Organize Your Roster: You can use the description of the goods or services a vendor supplies or rank them by their usefulness to the organization, then incorporate colors, numbers, letters, or words to categorize them in charts or spreadsheets. You can think about vendors by their value to the organization and how much you invest in their engagement to assign relative value by size, capability, or dollar amounts.

Use this scorecard as a selection or ongoing rating system template for your vendor roster. Once you've gathered your data and compiled it into the spreadsheet, you can use the roster to compare current vendors or to evaluate a single supplier. Easily edit the criteria checklist to match your business needs.

Download Vendor Assessment and Scorecard Template - Excel

To learn more about vendor management scorecards, refer to “ The Ultimate to Vendor Scorecards .”

2. Establish Tracking and Performance: Pick an auditor or a small team that can promote or demote a vendor or highlight distinctive evaluations. Track vendor and supplier value on an ongoing basis, or take a survey based on trigger metrics that have raised concerns like quality issues, delivery delays, or damaged products.

Surveys can be helpful and provide a way to get input from purchasing or other personnel who may be closer to the situation than a manager. Set guidelines for employee feedback: Make sure they are fact-based and not just opinions. Answers to survey questions can be on a simple value scale from one to five. Survey categories and questions might include the following:

- Performance: Did the supplier perform according to specifications?

- Delivery: Were deliveries on time?

- Invoicing: How did the final price compare to the budget?

- Customer Service: How well does the vendor respond to questions or solve problems?

- Knowledge: How knowledgeable is the vendor about your company?

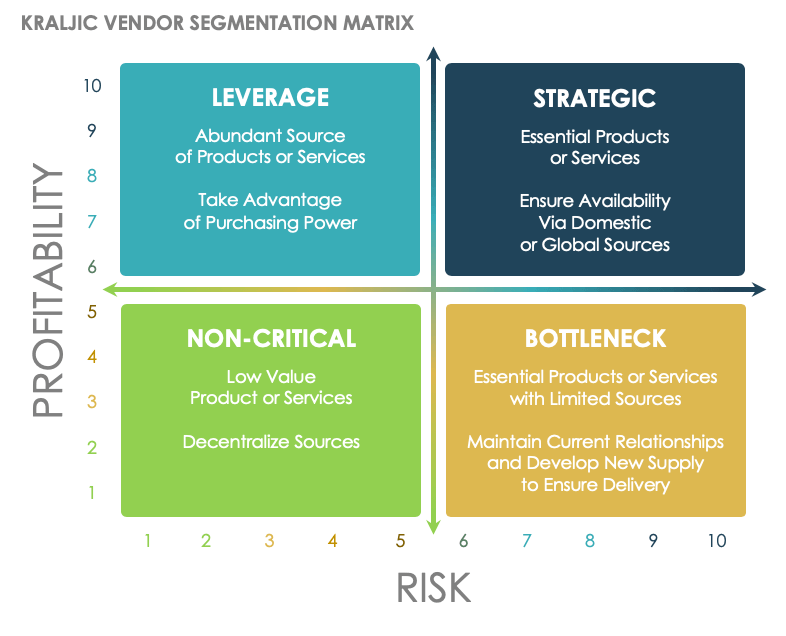

3. Maintain a Strategic Vendor Evaluation System: Apply what you know about vendor and supplier performance to segment vendors strategically. The Kraljic Matrix is a vendor evaluation method used to apportion goods or services by dividing them into four quadrants or classes, based on the risk or complexity of market supply and the value of the purchased item based on the impact to your company’s profitability. The matrix allows your company to define the most advantageous purchasing strategies and avoid bottlenecks that prevent you from meeting your product or service delivery goals.

Kraljic Vendor Segmentation Matrix Template

Use this template to maximize supply stability, lower costs, and shift procurement from a transaction to a strategic activity. In the Kraljic model, supply risk rises when there are few suppliers; when availability could be affected by natural disasters, pandemics, or government instability; or when delivery logistics are challenging. Profit impact is high when the item adds sizable value to the organization's productivity or impacts quality.

The template prompts you to classify services and products you purchase as strategic, leverage , bottleneck, or non-critical , according to the supply risk and profit potential of each. Doing so helps you determine which vendors make the most sense based on business objectives.

Download Kraljic Vendor Segmentation Matrix Template

Perform ongoing vendor reviews to yield red flags when vendors don't meet expectations. The process should be easy if you have proper documentation and ongoing oversight. When problems occur, alert the vendor right away. You and the vendor should have contingency plans for potential workarounds when issues arise. If it looks like there's no remedy and the situation isn't an anomaly, you may need to end the partnership. If you terminate a relationship, be sure to have a post-mortem with your team and vendor.

Tips to Improve the Vendor Assessment Process

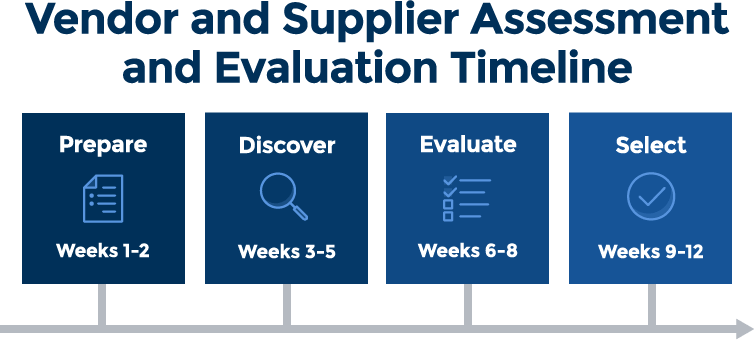

The vendor assessment process centers on clarity and a time-based, four-phase approach: prepare (lay the groundwork); discover (perform due diligence); evaluate (perform a vendor comparison); and select (make decisions and sign contracts). Below are two key best practices to keep in mind when assessing vendors:

- Assign Responsibility: Decide who in your company is responsible for the assessment. It’s often an employee in the purchasing department, but for high-dollar or complex situations, you may hire an outside business analyst. The consultant takes over some of the time-consuming aspects of the process, including research, writing the request for proposal (RFP), and performing an in-depth financial analysis that may not be available in house.

- Set Up a Timeframe: Without a timeframe and process, getting to the final selection and hiring process can take up to a year. A good rule of thumb is to allow a maximum of three months to complete the process.

Vendor and Supplier Selection Process and Timeline

1. Prepare: This is the state when you define your basic requirements and create request-for-information (RFI) and request-for-proposal (RFP) packages. RFIs and RFPs provide a standard against which to evaluate potential vendors. They provide a detailed explanation of what you want and why, and you can use them to solicit bids and identify the best partner in developing the product. An RFI or RFP is a competitive process in which several companies may submit proposals. If you’re new to the RFI and RFP process, read “ Write a Winning Request for Proposal and Conquer the Process in Your Company .”

2. Discover: Research vendors and suppliers, and distribute RFIs and RFPs to companies that meet your criteria.

3. Evaluate: Evaluate RFI and RFP responses. Select the top vendors, compare their qualifications, and review with stakeholders, legal, and business analysts.

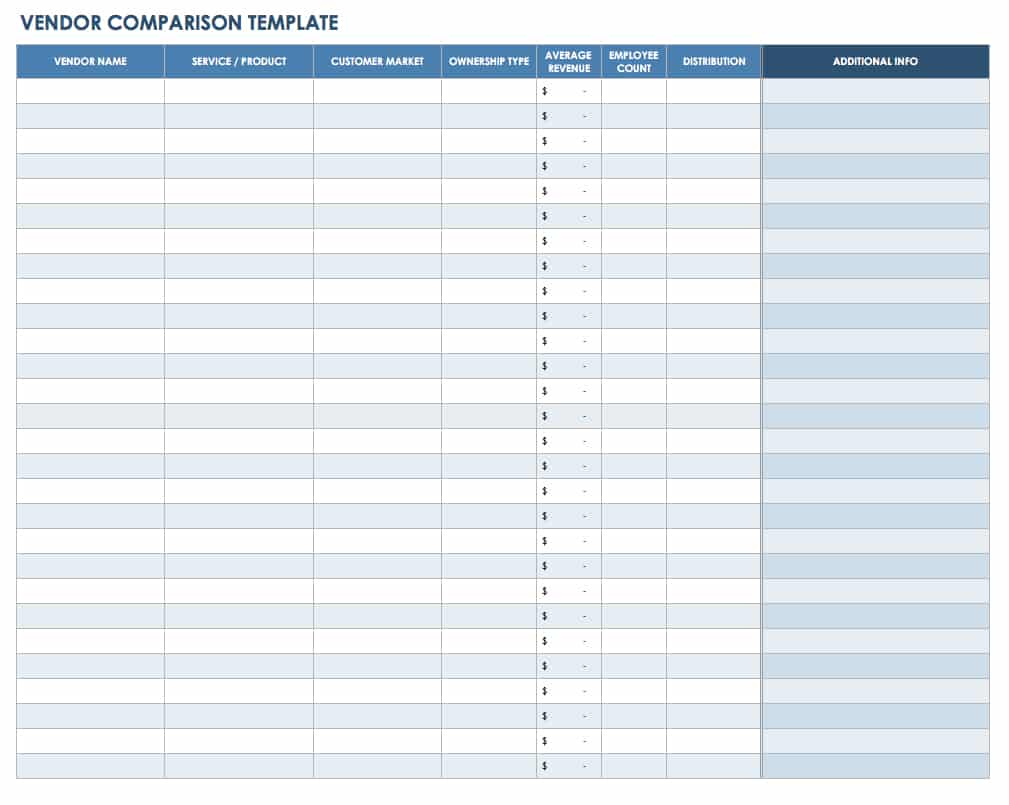

After you’ve received RFIs or RFPs from potential vendors or suppliers, use this spreadsheet to quickly compare them based on criteria or business attributes in your screening documents. This template provides a simple way to compile statistics and background information to aid in your selection process.

Download Vendor Comparison Template

Excel | PDF

4. Select: Based on criteria you set, choose and meet with the top two potential vendors. Have the purchasing lead or key decision-makers make a final selection. Prepare contracts, set up accounts, and prepare for onboarding.

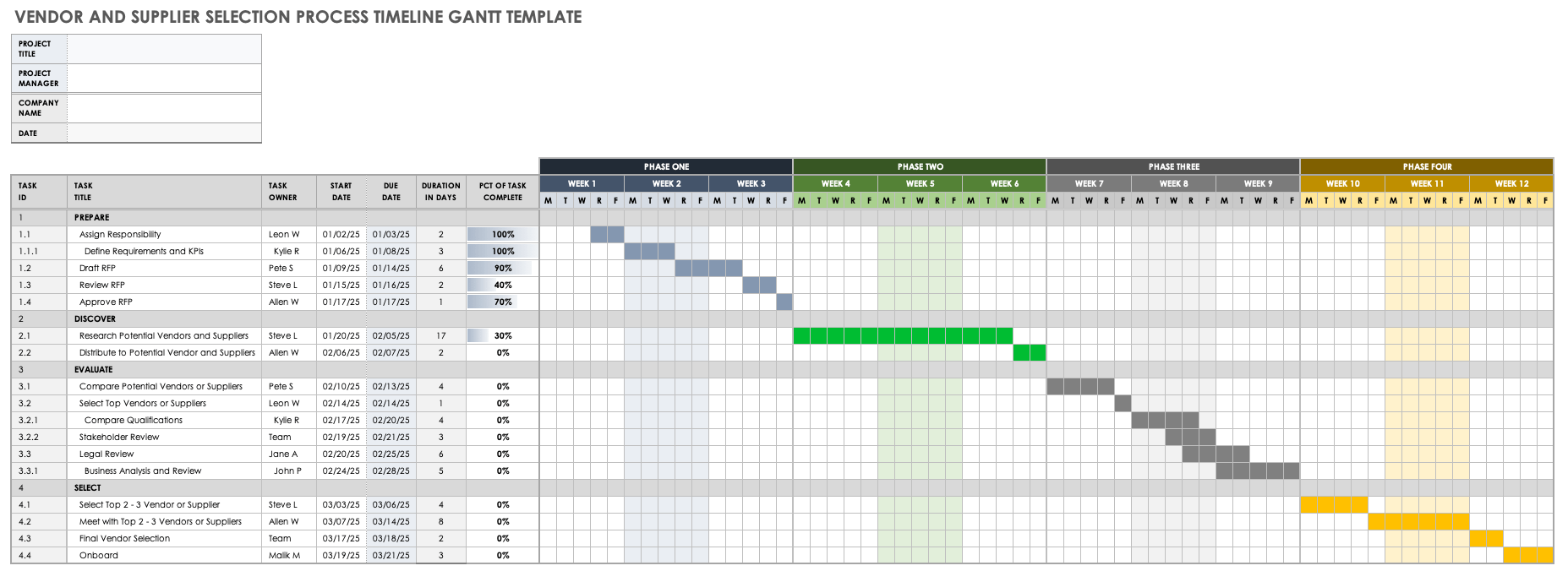

Vendor and Supplier Selection Process and Timeline Gantt Template

This Gantt template provides all team members with a simple way to organize and track the vendor and selection process, as well as ensure that you’re sticking to deadlines. To begin your selection process, input the task data — organized here into the Prepare, Discover, Evaluate, and Select phases — along with who owns the task, as well as start and end dates, to generate a high-level visual overview. Customize and add more steps as your organization requires them.

Download the Vendor and Supplier Selection Process and Timeline Gantt Template

Excel | Smartsheet

- Verify Information by Quality: When you evaluate vendors and suppliers, obtain the best possible information. “A key aspect of the 10C Model is the need to assess the quality and validity of the information submitted by potential partner companies,” advises Dr. Carter. “The model defines verified and high-quality evidence as complete, verified by a third party, current and comprehensive. Medium-quality evidence is almost complete, offers some verification, some observation, and a contribution of desk research and limited observation. L ow-quality evidence relies on records and desk research, is incomplete, and has limited verification. You can use these scores in the overall evaluation of the contractor or supplier,” says Dr. Carter.

- Establish Key Performance Indicators (KPIs): KPIs are business metrics deployed to evaluate the performance of specific factors and strategic goals that are crucial to company success. You can use KPIs in vendor evaluation to help vet their performance. Find out more about developing your own KPIs and how to organize them with “ All About KPI Dashboards .”

- Consider a Common Playbook: If you’re working with other vendors on a large project, Dr. Carter says a common pre-qualification process makes sense. “The principal contractors working on HS2 (UK’s £100M proposed high-speed rail link) have collaborated to create a common pre-qualification system that will cut costs and streamline tenders for subcontractors,” he explains. “Bidders who want to work with four of the main contractors on the HS2 scheme will go through an identical pre-qualification process, thus reducing duplication and the constant reworking of submission information to meet the varied formats of the customer.”

- Emphasize Communications: Give and take to improve relationships and deliverables. Be clear with vendors early in any process or project about expectations, deadlines, and critical information without overwhelming them. Personalize communication and respond promptly to concerns.

- Make a Site Visit: Conduct a site visit to verify that information submitted in writing or through conversation reflects reality. An in-person inspection reveals how the supplier conducts business, as well as their capacity to meet your criteria.

- Onboard: Once you’ve gone through such an exacting process, you’ll want to maintain good relationships with your vendors. A proven way to start on the right foot and ensure a smooth interaction is with a transparent process to bring your new suppliers online. Learn onboarding best practices with “How to Streamline Supplier and Vendor Onboarding: Best Practices, Process Flows, and Checklists .”

Leverage Cloud-Based Software: Use cloud-based software to simplify compliance, reduce risk, and help organize and speed vendor assessments.

Disaster and Pandemic Readiness

Assessing vendors should include questions about disaster and pandemic preparedness. The COVID-19 pandemic has underscored the need to assess vendors’ ability to deliver the services and products you need to maintain critical operations under emergency conditions.

Diversity of customer, supplier, and third-party providers across geographies will help avoid single points of failure and decrease your organization's exposure to local outages, as well as geopolitical and pandemic events.

Here are some disaster and pandemic readiness questions to ask of present and potential vendors:

Build Powerful, Automated Business Processes and Workflows with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Discover why over 90% of Fortune 100 companies trust Smartsheet to get work done.

Supplier Evaluation — Everything a Procurement Professional Should

What is supplier evaluation, the importance of supplier evaluation, the benefits of conducting an evaluation of suppliers, supplier performance evaluation checklist, frequently asked questions.

- Supplier evaluation is an instrument used to measure the effectiveness and suitability of suppliers to your company.

- A regular supplier evaluation has many benefits, including your supplier’s improvement in performance.

- Supplier evaluation also helps companies choose and select the best partners.

1. Enhance the visibility of the supplier’s performance

2. mitigate risks, 3. improve supplier performance, 4. align customer and business practices, 1. establish performance indicators.

- Price – The organization can create a win-win situation with vendors who are able and willing to lower their prices. By lowering their prices, the organization would want to deal with them often.

- Cost – This can either be monetary or non-monetary when dealing with suppliers. It includes peripheral costs that are associated with movement, packaging, delivery, and disposal

- Quantity – The organization can also consider the comparison between quantities ordered and received. Sometimes, the vendor will send a notice to confirm and explain anomalies in the delivery.

- Quality – The organization must inspect the delivered goods to check any visible product defects, rejections, and returns.

- Service – This includes indicators such as the response time of resolving issues and client satisfaction engagement.

- Delivery – This indicator focuses on the timeliness of the order process and the pre-delivery waiting period.

- Payment terms – A fast payment method and terms are preferable to organizations than a slow payment process.

- Financial health – Suppliers that have good financial health can provide for the needs of an organization much better.

- Compliance – You need to know how compliant your suppliers are in terms of their taxes, contracts, and procedures.

2. Classify suppliers

3. centralize the data, 4. collaborate with suppliers for feedback, 5. create an actionable plan, why is it needed, what are the indicators that the organization must include in its evaluation, about the author.

Call Us (877) 968-7147

Most popular blog categories

- Payroll Tips

- Accounting Tips

- Accountant Professional Tips

Increase Efficiency With a Routine Supplier Evaluation

As a business owner, you likely evaluate your employees’ performance from time to time. But, your employees aren’t the only ones you should be assessing. If you have suppliers you go to for inventory and materials, you need to evaluate their performance, too. To learn more about supplier evaluation and how to evaluate a supplier, read on.

Supplier evaluation process 101

Suppliers and vendors can make or break your company’s success. With good suppliers and vendors, you can streamline business operations, lower risks, and eliminate unnecessary expenses. Not to mention, conducting regular evaluations can help you spot problems and create a more prosperous partnership.

While evaluating your suppliers, consider the following:

- Performance

- Production capacity

So, what all should a supplier assessment include? Before you can start evaluating suppliers, you need to have a game plan. To get started learning how to evaluate suppliers, follow these six steps.

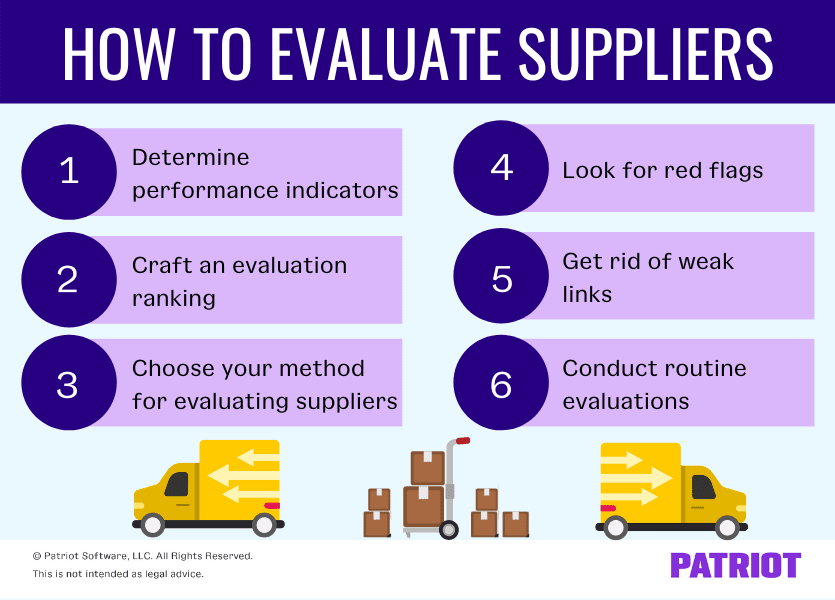

1. Determine performance indicators

To evaluate your suppliers’ performance, you need to determine what you’re going to be rating them on. The metrics you use can vary depending on your type of business and the suppliers you have.

Here are a few examples of performance indicators for vendors:

- On-time performance percentage

- Delivery track record

- Price competitiveness

- Defect rate

- Purchase order and invoice accuracy

- Vendor availability

Again, your performance indicators may vary depending on your business and the supplier. Narrow down what indicators your business will look at when it evaluates suppliers.

2. Craft an evaluation ranking

If your business has a lot of suppliers, it may be easier to evaluate them if you break them down by classification.

For example, you may want to classify suppliers into various categories, such as Level 1, Level 2, and Level 3. The categories allow you to evaluate suppliers using different surveys or methods.

Typically, companies use this step to classify suppliers based on how critical they are to the business.

3. Choose your method for evaluating suppliers

There are a number of supplier evaluation methods to choose from. You may want to use:

- Evaluation forms

- System metrics

Regardless of which method you choose, it’s always good to get feedback from your team. With forms and surveys, you can have employees answer questions about suppliers and vendors and receive honest feedback.

In conjunction with employee feedback, you may also want to gather metrics (e.g., number of products you had to return) to back up claims, especially if the supplier needs to make improvements.

You may want to meet as a team to discuss supplier performance. Or, you may designate a person or small group to go over the feedback and metrics.

4. Look for red flags

There’s nothing worse than dealing with a supplier who performs poorly and doesn’t meet expectations. When going through your evaluations, be on the lookout for supplier red flags. Red flags can include:

- Poor quality products

- Bad business-supplier relationships

- Overpriced products or services

- Poor communication

If you notice some red flags, don’t jump the gun and dissolve the partnership right away. Instead, offer constructive feedback. Discuss your concerns with suppliers who are giving you warning signs. Talk through your problems and use your data to back up your feedback. Consider giving them a warning first before jumping to more drastic actions (e.g., firing your supplier).

5. Get rid of weak links, if necessary

Sometimes, an issue (especially a repetitive one) with a supplier may be the final straw. And in some cases, it may be best to cut ties with an unreliable and underperforming supplier.

If you have discussed performance problems with a supplier and they have not improved, it may be time to end your business relationship with them.

If you have decided to let go of a supplier or vendor, let them know as soon as possible. Communicate with your supplier why you want to cut ties and let them know you would like to end the business relationship.

6. Conduct routine evaluations

Of course, your supplier evaluations shouldn’t occur just once in a blue moon. You should conduct assessments on a regular basis to ensure your business is getting good quality products, minimizing operating costs, and streamlining production timelines.

Conduct routine evaluations regularly, like once a month, quarter, or year. Make sure to inform your team and suppliers about your business’s evaluation schedule so they can prepare.

Need a way to record transactions, like payments made to suppliers and vendors? Give Patriot’s affordable and easy-to-use accounting software a go. With Patriot’s online accounting, you can streamline your books and get back to business. Try it for free today!

This is not intended as legal advice; for more information, please click here.

Stay up to date on the latest accounting tips and training

You may also be interested in:

Need help with accounting? Easy peasy.

Business owners love Patriot’s accounting software.

But don’t just take our word…

Explore the Demo! Start My Free Trial

Relax—run payroll in just 3 easy steps!

Get up and running with free payroll setup, and enjoy free expert support. Try our payroll software in a free, no-obligation 30-day trial.

Relax—pay employees in just 3 steps with Patriot Payroll!

Business owners love Patriot’s award-winning payroll software.

Watch Video Demo!

Watch Video Demo

5 key criteria for evaluating your suppliers

In any supplier evaluation , whether of a new or existing supplier, it’s important to measure the company’s production capacity, performance, risks, quality and environmental impact . However, evaluating these factors on their own will get you nowhere if you don’t have an organized approach to evaluation and a broader framework to make the evaluation information work for you.In this article, we’ll review some of the most crucial factors in conducting supplier evaluations, as well as how to ensure successful evaluations. First, however, we’ll look at why supplier evaluations are important , and how to set up a broader supplier evaluation system to ensure you can get the most out of your evaluation data.

- 1 Why conduct a supplier evaluation?

- 2 Setting up a supplier evaluation system

- 3.1 Production capacity

- 3.2 Quality

- 3.3 Performance

- 3.5 Environmental impact

- 4 How to ensure a successful supplier evaluation

- 5 Visit your supplier’s website

- 6 The benefits of supplier evaluations

Why conduct a supplier evaluation?

A strong supply chain is the backbone of a successful business . Whatever your industry, close working relationships with your suppliers will enable you to streamline production lead times, minimize operating costs and guarantee the quality of your products.Most companies regularly evaluate the performance of their suppliers in search of inefficiencies or growth opportunities to consolidate the supply chain and strengthen supplier relationships . By examining a supplier’s capabilities, technological resources, delivery strategies and general business practices, you can ensure that your partners share your priorities, and can then adjust their operations in the interests of your company’s competitiveness. By doing so, you can significantly reduce your own risks , improve visibility at every stage of operations, and create greater value for your products and services .

Setting up a supplier evaluation system

Evaluating supplier performance should be an integral part of your company’s procurement activities , not a procedure reserved for reviewing new suppliers . A robust supplier evaluation system will regularly assess suppliers, using categories and rankings within those categories to determine procurement strengths and weaknesses.Even for companies that are limited only in the number of suppliers they can use, evaluations help to distinguish which suppliers are to be preferred , as well as identifying areas of potential risk .

The ultimate aim of the system is to monitor the consistency of supplier performance in a way that is integrated with the purchasing process.Supplier performance should include key performance indicators (KPIs) and clear metrics focused on business priorities, including alert measures to show when a supplier is not meeting standards. Buyers should evaluate suppliers every time they call on them, with deadlines for sending feedback after a purchase. Feedback should also be reviewed regularly by the person or group responsible for ranking suppliers. It can be easier to implement software when buyers rate supplier performance , as the final scores can be used to easily rank companies.

These ratings and indicators don’t have to exist only internally, either. It’s important to agree them with your suppliers so that they are aware of expectations and can provide feedback on them. The inclusion of a system for recognizing and rewarding improvement can also help to clarify expectations of them, and motivate them to improve . Common mistakes in supplier evaluation systems include inconsistent use of KPIs and agreed metrics , failure to give suppliers regular feedback on their performance, ignoring supplier feedback in discussions and setting metrics, and the use of confusing metrics and KPIs.

What should be assessed in a supplier evaluation?

Supplier evaluation is largely data-driven. It must therefore be a carefully structured process, focused on quantifiable performance indicators such as delivery times, production costs and stock levels . A standardized set of supplier evaluation criteria provides a necessary frame of reference with which you can assess a supplier’s capabilities and compare them to those of its competitors.However, before evaluating a current or potential supplier, the company needs to set clear expectations for the relationship between them. From the outset, you need to state your objectives clearly , so that the supplier fully understands the obligations involved, and can adjust its operations accordingly if necessary.While the evaluation of a supplier can be based on a number of factors, there are several elements that every company needs to take into account, whatever the industry concerned. Some of these factors include

Production capacity

All supplier evaluations must address the supplier’s capabilities and limitations . A supplier who can’t adapt production to your production cycles won’t do well.

Although it can be difficult to quantify product quality , it should always be a central element in supplier evaluation . ISO 9001 certification remains the industry standard in this area, indicating that the supplier excels in management responsibility, resource management, product realization and measurement, analysis and improvement.

Performance

Your company should ask as many questions as necessary to determine whether a supplier can perform your typical functions . Previous experience with similar companies, relevant recent projects and possible advances on current products or processes are all valid topics for discussion.

Every company invariably faces certain risks, but suppliers should strive to minimize them throughout the supply chain. Examining performance measures such as overall delays, average response time and corrective actions can help you develop a reliable quantitative assessment of the risks posed by a particular supplier .

Environmental impact

Sustainable development is an essential element of a company’s success, for both financial and ethical reasons. The assessment should cover the supplier’s waste management strategies, waste minimization practices and materials procurement procedures , as well as its energy efficiency efforts and protocols for handling hazardous materials .

How to ensure a successful supplier evaluation

While many companies can easily identify the criteria required for supplier evaluation , it can be difficult to follow the practices necessary to ensure its success . The following guidelines can help your company stay focused throughout your evaluation .Establish a timetable . By clearly defining the necessary tasks and setting deadlines for them, you ensure that everyone understands their responsibilities and will strive to complete them correctly and promptly. Provide your suppliers with a concise but detailed questionnaire at the start of the process. The questionnaire should ask for both factual and subjective answers , should solicit only the necessary information, and should not contain questions that the respondent cannot answer .

Visit your supplier’s website

A personal visit to your supplier’s site can confirm the data obtained from the questionnaire, while offering insight into intangible aspects of the supplier’s business, such as workplace culture. It’s also an opportunity to examine the supplier’s quality control strategies, the current state of equipment and the technical skills of the workforce. Make sure the right staff members are involved in the assessment. If you need to evaluate the performance of a Tier 1 supplier , for example, the CFO should probably be involved, as well as purchasing department managers. Be courteous to your supplier . A strong working relationship with your supplier can only improve productivity . Don’t hesitate to congratulate the best-performing suppliers and give them a warning and advice so that they can try to solve the problem before you end your partnership.

The benefits of supplier evaluations

Supplier evaluation criteria are a valuable tool for your company . By carrying them out regularly, your company can better understand its operations, proactively identify opportunities for growth , reduce risk, streamline lead times , eliminate unnecessary expenditure and improve the performance of your suppliers . These competitive advantages cannot be overstated, and while supplier evaluation must, of course, be comprehensive, it need not be difficult . By following the right protocols within a broader framework, it can be a straightforward process for companies and suppliers alike, enabling both to better understand each other’s strengths and weaknesses , and encouraging them to work together to build a stronger, more prosperous partnership .

Want to learn more about our procurement management software Weproc? Contact us or request your free 15-minutes demo below!

Weproc is a SaaS software specialized in digitizing the procurement process of companies. From purchase requests to supplier invoicing, through the validation process, Weproc is designed to simplify the purchase management of SMEs and mid-sized companies by centralizing all purchase-related activities.

One thought on “ 5 key criteria for evaluating your suppliers ”

This is a topic that is close to my heart… Thank you! Where are your contact details though?

Also visit my webpage – jim’s formal wear trenton

Leave a Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

You may also like

Making supplier invoice management a strategic axis.

Suppliers play a significant role in purchasing management and in the operation of companies in general. It is therefore important to consolidate […]

Electronic supplier invoicing: accessible to all?

Today, thanks to developments in the world of technology, the digitisation of incoming business invoices is tending to become the norm. But […]

How to successfully onboard suppliers?

The management of supplier onboarding is a key element in ensuring a company’s market positioning. It not only helps to maintain solid […]

Recevez chaque mois nos meilleurs articles ! En bonus, nous vous mettons à disposition nos nouveaux modèles de documents en avant première.

Alors, pas mal non ?

- SaaS Solution Weproc

- Free Ressources

- Discover our tool

Plastic 3D Printing Service

Fused Deposition Modeling

HP Multi Jet Fusion

Selective Laser Sintering

Stereolithography

Production Photopolymers

Nexa3D LSPc

Direct Metal Laser Sintering

Metal Binder Jetting

Vapor Smoothing 3D Prints

CNC Machining

CNC Milling

CNC Turning

Wire EDM Machining

Medical CNC

CNC Routing

Sheet Metal Fabrication

Sheet Cutting

Laser Cutting

Waterjet Cutting

Plasma Cutting

Tube Bending

Laser Tube Cutting

Laser Engraving

Custom Die Cutting

Plastic Injection Molding

Quick-Turn Molding

Prototype Molding

Bridge Molding

Production Molding

Overmolding

Insert Molding

Urethane and Silicone Casting

Plastic Extrusion

HDPE Injection Molding

Injection Molded Surface Finishes

Custom Plastic Fabrication

Micro Molding

Metal Injection Molding

Die Casting

Metal Stamping

Metal Extrusion

Custom Hydroforming

Assembly Services

Rapid Prototyping

High-Volume Production

Precision Grinding

Surface Grinding

Powder Coating

Aerospace and Defense

Consumer Products

Design Agencies

Electronics and Semiconductors

Hardware Startups

Medical and Dental

Supply Chain and Purchasing

All Technical Guides

Design Guides

eBooks Library

3D Printing Articles

Injection Molding Articles

Machining Articles

Sheet Cutting Articles

Xometry Production Guide

CAD Add-ins

Manufacturing Standards

Standard Sheet Thicknesses

Standard Tube and Pipe Sizes

Standard Threads

Standard Inserts

ITAR and Certifications

Case Studies

Supplier Community

Release Notes

Call: +1-800-983-1959

Email: [email protected]

Discover Xometry Teamspace

Meet An Account Rep

eProcurement Integrations

Bulk Upload for Production Quotes

Onboard Xometry As Your Vendor

How to Use the Xometry Instant Quoting Engine®

Test Drive Xometry

Tool Library and Tool Detail Pages

Part Revisions & Same-Suppliers for Repeat Orders

Xometry's Privacy and Security

Xometry’s Quality Assurance

Xometry’s Supplier Network

Xometry's Machine Learning

5 Key Factors to Consider When Conducting a Supplier Evaluation

In this guide, we’ll be going over some of the most crucial factors in conducting supplier evaluations, as well as how to ensure evaluations are successful.

In any supplier evaluation, whether for a new or current vendor, it’s important to gauge the company’s production capacity, performance, risk, quality, and environmental impact. However, gauging these factors by itself will get you nowhere without an organized approach to the evaluation and a larger framework to make the assessment information work for you.

In this guide, we’ll be going over some of the most crucial factors in conducting supplier evaluations, as well as how to ensure evaluations are successful. First, however, we’ll be diving into why supplier assessments are important and how to set up a larger vendor evaluation system to ensure you can get the fullest benefit from your evaluation data.

.css-2xf3ee{font-size:0.6em;margin-left:-2em;position:absolute;color:#22445F;} .css-14nvrlq{display:inline-block;line-height:1;height:1em;background-color:currentColor;-webkit-mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;-webkit-mask:url(https://assets.xometry.com/fontawesome-pro/v6/svgs/light/link.svg) no-repeat center/contain content-box;aspect-ratio:640/512;vertical-align:-15%;}.css-14nvrlq:before{content:"";} Why Conduct a Supplier Assessment?

A strong supply chain is the backbone of a successful business. Regardless of your industry, close working relationships with your suppliers will streamline production timelines, minimize operating costs, and guarantee the quality of your products.

Most companies regularly evaluate their suppliers’ performance in search of inefficiencies or possibilities for further growth to buttress the supply chain and reinforce relationships with suppliers. These supplier evaluations are holistic assessments grounded in verifiable quantitative metrics and meaningful qualitative observations.

By examining a supplier’s capacities, technological resources, delivery strategies, and general business practices, you can ensure that your partners share your priorities, and can then adjust their operations to your company’s competitive benefit. In the process, you can significantly reduce your own risks, improve visibility at every stage of operations, and create greater value for your products and services.

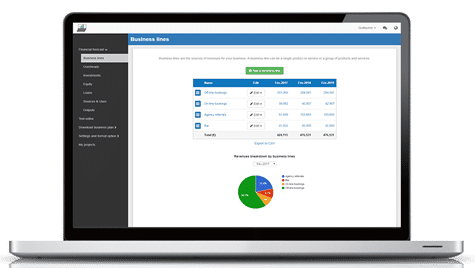

Putting a Vendor Evaluation System in Place

Vendor performance should include clear KPIs and metrics slated toward company priorities, including red flag metrics to show when a supplier fails to meet standards. Procurers should rate suppliers each time they are used, with deadlines for when they submit the feedback after a purchase. The feedback should also be reviewed regularly by the person or group classifying vendors. It can be easier to adopt a number evaluation system when procurers rate supplier performance, as the final scores can be used to easily rank companies.

These ratings and indicators shouldn’t just exist internally either. It’s important to agree on them with your vendors so that they’re aware of expectations and can provide feedback about them. Including a system of recognition and reward for improvements can also help to clarify expectations for them and motivate improvements. Common mistakes in vendor evaluation systems include inconsistent use of agreed-upon KPIs and metrics, not giving regular feedback to suppliers on their performance, ignoring supplier feedback in discussions and determining metrics, and using confusing metrics and KPIs.

What to Assess in a Supplier Evaluation

Vendor evaluation is largely founded on data. Therefore, this should be a carefully structured process, centered on quantifiable performance indicators such as delivery times, production costs, and inventory levels. A standardized set of supplier evaluation criteria provides a necessary frame of reference with which you can assess a supplier’s abilities and compare it with those of competitors.

Before evaluating a current or potential supplier, however, a company must set clear expectations for the relationship between them. At the outset, you should clearly articulate your goals so that the supplier fully understands the obligations involved and can adjust operations accordingly if needed.

While supplier evaluation can be based on a number of factors, there are several considerations that every company should address, regardless of the specific industry. Some of these elements include:

- Production Capacity All supplier evaluations should thoroughly appraise the supplier’s abilities and limitations. A supplier that cannot scale production in response to your production cycles will not fare well in any review.

- Quality While it can be difficult to quantify the quality of a product, this should always be a central component of a supplier evaluation. ISO BS/EN ISO 9001:2000 certification remains the industry standard here, which indicates that the supplier excels in management responsibility, resource management, product realization, and measurement, analysis, and improvement.

- Performance Your company should ask as many questions as needed to determine whether a supplier can handle your typical functions. Previous experiences with similar companies, relevant recent projects, and possible advances on current products or processes are all valid subjects for discussion.

- Risk Every business invariably confronts some risks, but its suppliers should actively work to minimize them throughout the supply chain. Reviewing performance metrics such as overall delays, average response time, and corrective actions can help you develop a reliable quantitative assessment of the risks posed by a particular supplier.

- Environmental Impact Sustainability is an essential element of a successful business for both financial and ethical reasons. An evaluation should cover a supplier’s waste management strategies, waste reduction practices, and material procurement procedures, as well as efforts to achieve energy efficiency and any protocols employed when handling harmful materials.

How to Ensure a Successful Supplier Evaluation

While many companies can easily identify the criteria needed for a supplier evaluation, it can be a challenge to follow the practices needed to guarantee its success. The following guidelines can help your company retain its focus throughout your evaluation.

- Outline a schedule. Clearly defining needed tasks and establishing deadlines for them ensures that everybody understands their responsibilities and will work to complete them correctly and promptly.

- Provide your suppliers with a concise yet detailed questionnaire at the beginning of the process. The questionnaire should request both factual and subjective responses, should only solicit necessary information, and should not contain any questions that the respondent cannot answer.

- Visit your supplier’s facilities. A personal visit to your supplier can confirm the data gained from the questionnaire while offering insights into intangible aspects of the supplier’s operations, such as workplace culture. This also offers an opportunity to review the supplier’s quality control strategies, the current state of equipment, and the workforce’s technical competence.

- Ensure that the right staff members are participating in the evaluation. If you need to evaluate the performance of a Level 1 supplier, for example, the chief financial or revenue officer should probably be involved, as well as senior members of the procurement department.

- Be courteous to your supplier . A strong working relationship with your supplier can only heighten productivity. Don’t hesitate to congratulate strong performers, and provide less successful suppliers with a warning and some guidance so that they can attempt to resolve the issue before you end your partnership.

The Value of Smart Supplier Evaluations

Supplier evaluations serve as an invaluable tool for your business. By conducting them regularly, your company can gain greater insight into operations, proactively identify opportunities for growth, lower risks, streamline production timelines, eliminate unnecessary expenses, and bolster the performance of your suppliers. These competitive benefits cannot be overstated.

Although it should, of course, be comprehensive, supplier evaluation doesn’t need to be difficult. By following the appropriate protocols within a larger framework, it can be a simple process for companies and suppliers alike, allowing both to better understand their strengths and shortcomings, and encouraging both to work together to build a stronger, more prosperous partnership.

How to Evaluate Suppliers: 6 Questions to Consider

Good supplier evaluation is not a game of chance. You need to have the right processes in place. Using a formal assessment can help you better understand your suppliers, their scope of business and their performance.

For this blog post, we spoke with Doug Keeley, senior product marketing manager at Ivalua, to get his insights on supplier evaluation. Read on for answers to six common questions about evaluating suppliers.

What Is Supplier Evaluation?

At its most basic level, supplier evaluation is a formal assessment to measure and monitor your relationship with a supplier, or to pre-qualify a potential supplier. Buyers commonly request information to initiate the process of assessing whether a supplier is a good fit for their business.

The criteria for supplier evaluation and selection generally cover technical, financial, commercial and other requirements, because competition on price is not the only criteria. For example, manufacturers often also want to understand the following about their suppliers:

- Capacity: manufacturing capacity, ability to fulfill un-forecasted increases/decreases

- Cost control: minimized controllable indirect costs (freight, inventory, handling and tariffs)

- Quality: goods and services, defect rate and incident repeat rate

- Performance: certifications and documentation, responsiveness and participation

“Companies also look at what kind of risks the supplier may present to the supply chain,” said Keeley. He adds that corporations customize their supplier evaluation process and requirements based on the needs of their industry, region, standards or logistics, among others. It’s important to note that it’s unlikely that a single supplier evaluation survey covers all possible facets for all products across all industries and markets.

Why Is Supplier Evaluation Important?

Most enterprises use a formal supplier evaluation and qualification process when selecting suppliers, as well as for maintaining long-term partnerships. “If you don’t know how to evaluate your suppliers, it is very hard to understand who you are working with nor what potential risks they may introduce to your supply chain,” said Keeley.

Once you’ve completed your supplier assessment, you want to be able to use the data you’ve collected to make better and more timely decisions that maximize value across the supply chain. You also need to update the evaluation frequently enough so that your supplier strategy includes any changes in their business.

And the true value of supplier selection and evaluation shows up in supplier development, in other words, when supporting them to develop new capability or competency.

“Every company, every manufacturer should be investing in supplier development processes and strategies to build supply chain resilience,” Keeley emphasized. “This is especially true today, when enterprises are dealing with very significant crises that are incredibly disruptive.” So, supplier evaluation and development help develop mutually beneficial relationships with your suppliers.

How Do You Select a Supplier?