We will reply to your message within an hour.

About Shafts

Thread-mount idler rotary shafts.

Easy Gear Selection Pages

- Helical Gears

- Bevel Gears

- Miter Gears

- Internal Gears

- Screw Gears

- Selecting gears

- Stock gears

- Gear Catalog

- Gear Drawing

- Gear Knowledge

- Plastic Gears

- Bevel Gearbox

- Other Products

- Gear Nomenclature

What is an idler gear?

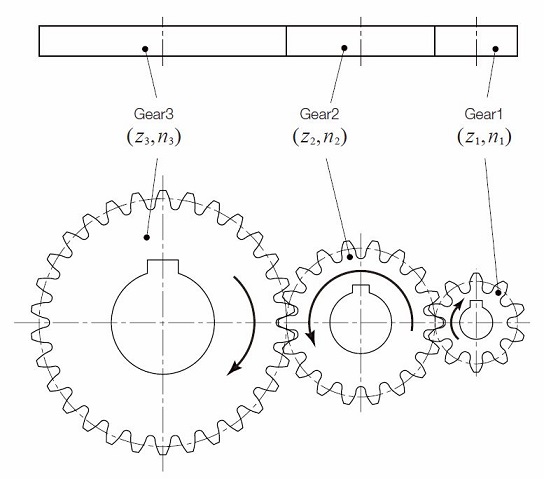

An idler gear in a gear train is defined as the gear placed between the input and output shafts (between the drive gear and the driven gear ). For example, it is used to change the rotational direction of the output shaft, or to fill a large gap between the input and output shafts without affecting the speed ratio. In the example shown below, Gear2 becomes the idler gear without changing the speed ratio .

It should be noted that the speed ratio of this single stage gear mechanism is as follows. Speed ratio i = z 2 /z 1 × z 3 /z 2 = z 3 /z 1

Kohara Gear Industry Co.,Ltd.

13-17 Nakacho Kawaguchi-shi Saitama-ken, 332-0022, Japan TEL : +81 48 254 1744 FAX : +81 48 254 1765

Copyright© 2021 Kohara Gear Industry Co.,Ltd. All Rights Reserved.

- Remember me Not recommended on shared computers

Forgot your password?

- IH Construction Equipment

TD9 Idler Wheel

By Timkar June 7, 2006 in IH Construction Equipment

- Start new topic

Recommended Posts

I have just broken the tracks and peeled them back to check the front idlers. There seems to be a lot of slop. When I can cut the rusty bolts off of the shaft clamp so that I can remove the guides I'll see what I am up against. I am hoping it is just the bushings and not the shafts on both idler wheels. I can't find the info in the manual telling me what size the bushings are and what they are made of.(suspect bronze or brass) Any info would be appreciated.

Thanks...Tim

Link to comment

Share on other sites.

You might find they are steel backed, copper-bronze split bushings depending on the age. I don`t know of a source for this particular style. Vancouver would be a start??

For most bearings and bushings, I go to Kaman Industrial Technologies. the closest branch is at 2508 Kenworth Rd. Naniamo (250) 758-3255 You will have to be able to give them accurate mesurements.

Thanks guys..When I can get these guides removed I'll try and figure out the size (using guide as the outer and shaft pin as the inner) and go up to KAMAN in Nanaimo. I have dealt with them for other types of things before...Thanks again...Tim

Hi Tim Generally on those things everything gets worn. They should have had steel backed bronze bushings in there. Kaman just brought us some new bushing stock that looks pretty heavy duty, it's cast iron with round graphite inserts formed into it radially, it would probably work great for those idlers, the shaft could be turned down so it's round & straight again, they usually wear like an apple core letting the wheel tip sideways. Regards, Russell

unscrupless_modifer

Been laying off to fix the same on my TD-9 for a longgggg time. Please post pictures. Maybe that will get me to move on this job.

I'll get some pics tomorrow..It's pouring rain here, but I did manage to get the rusty bolts broken off and the idlers apart. The idler pin is actually not bad and measures 3.115 inches O.D.all the way around. The inside of the bushings are at 3.135 so that's 20 thou of play, which isn't as bad as I thought. I'm not sure what the original measurements would have been and can't seem to find them. Just wondering if it's worth going any further or should I just put it back together and pump them full of grease...(they were really dry)

This is the TD9 I have without a motor (but decent undercarriage), so I am just trying to ensure everything is in order before removing motor from the other TD9 which runs well but has a worn out undercarriage...Tracks are coming off a little too often on this one nowadays, but it still likes to work.

Pics so far of Idler removal and clean up....

According to my chassis book (ISS-1032B), here is what it says...

Front idler shaft diameter = 3.124 - 3.125

Front idler bore diameter = 3.290 - 3.292

Front idler bushing ID = 3.126 - 3.128

According to my chassis book (ISS-1032B), here is what it says... Front idler shaft diameter = 3.124 - 3.125 Front idler bore diameter = 3.290 - 3.292 Front idler bushing ID = 3.126 - 3.128 Thanks...that's what I needed to know...2 to 4 thou guess it's time for new oversize bushings

- 4 months later...

OK, now I need to do one of my front idler bushings as well. Track is split, Idler is out etc. How in the world do you get the old felt oil seal out to get to the snap ring underneath? The old one is bad, so I don't care what I do to it to get it out, but man, it's in there! Is there an easy way?

OK, now I need to do one of my front idler bushings as well. Track is split, Idler is out etc. How in the world do you get the old felt oil seal out to get to the snap ring underneath? The old one is bad, so I don't care what I do to it to get it out, but man, it's in there! Is there an easy way? Thanks! TD9-91

Mine just basically fell out when I took the idler apart. I haven't had a chance to get any further on mine as I have been trying to get the TD14 fixed up . It runs great but I only have one brake and one steering clutch working .(both on the same side) I also just bought a modified 1938 T20 (FE loader and rear blade) with a blown motor that i've got to get home one of these days. I've just finished rebuilding a trailer to haul it, so hopefully within the next couple of weeks I can go and get it.

Sorry I couldn't help.......Tim

If it is a felt in a metal retainer there is a lip seal behind it, sometimes the retainer is 2 piece. An option is to use a cape chisel and collapse the retainer.

- 2 years later...

Good post wish mine looked this good did you find busshings

This topic is now archived and is closed to further replies.

- Existing user? Sign In

- Red Power Magazine

- Online Users

- All Activity

- My Activity Streams

- Unread Content

- Content I Started

- Leaderboard

- Create New...

IMAGES

VIDEO

COMMENTS

What would the overall length of the shaft be if made to the upper limit Unit 14 Dimensions and Tolerances 103 -02 0 - -19 2 2 CKD BY: APPR BY: JCC LMS MATERIAL: BRS Pev. DATE DWN BY: 5/28/17 TAK SCALE DESCRIPTION DATE BY FULL STANDARD TOLERANCES UNLESS OTHERWISE SPECIFIED PART NAME: IDLER SHAFT +1/54 2 PLC, DECIMAL 1.01 METSON ANGULAR ...

Draw the idler shaft support. Step 2 of 2. The line C-C is . Back to top. Corresponding textbook. Basic Blueprint Reading and Sketching | 9th Edition. ISBN-13: 9781435483781 ISBN: 1435483782 Authors: Thomas P Olivo, C Thomas Olivo Rent | Buy. Alternate ISBN: 9781133010838, 9781285530284.

For permission to use material from the text or product, contact us by Tel. (800) 730-2214 Fax (800) 730-2215 www.thomsonrights.com. Elementary blueprint reading for machinists / David L. Taylor.—5th ed. p.cm. ISBN 1-4018-6256-X. 1.

Follow along as I Linebore a rear idler wheel shaft on a D-9 Dozer. There arent too many videos on lineboring so hopefully this does it some justice. Enjoy.

Assignment D-5: Axle Shaft; Unit 11. One-View Drawings. One-View Drawings; Assignment D-6: Spacer Shim; Unit 12. Auxiliary Views. Sketch S-8: Angle Bracket; ... Assignment D-9: Idler Shaft; Unit 15. Decimal Dimensions and Tolerances. Decimal Dimensions; Decimal Tolerances; Point-to-Point Dimensions;

IDLER PULLEY LESSON. It is a variation of a drafting assignment form an old Mechanical drawing book. The objectives of this lesson are visualization, interpretation of drawings, planning and sequencing. This lesson is designed to test the student's ability to read and interpreting a set of drawings and to reproduce these drawings in a CAD ...

Wikipedia

Largest Manufacturing Technology Community on the Web. Search Forum Discussions; Search Entire Site; REGISTER FREE; Search forums; Manufacturing Today; General - Archive; Building

D) Output shaft 6) 7) The ring gear on the differential is driven by the pinion gear on the _____. A) Main shaft B) Input shaft C) Idler shaft D) None of these 7) 8) Torque steer can be caused by _____. A) Unequal CV joint angles B) Unequal length of the shafts C) The tendency for the longer drive shaft to twist D) All of the above 8) 2

Thread-Mount Idler Rotary Shafts. Thread these shafts into a tapped hole to support idler sprockets and pulleys in tensioning applications. They have a retaining-ring groove, retaining ring, and spacers to position your component and hold it in place. For technical drawings and 3-D models, click on a part number.

To manufacturers have switched to using 1045 shafting forcorrectly size the pulley shaft, the first step is to make sure that it is properly sized for the pulley. First, the shaft must be sized as in Eq. (2). Then, with this ini-tial size, the size factor, kb = (D)-0.19, can be calculated. Sf (for use in Eq. (1)) is then calculated from ka, kb ...

Specific guidelines and recommendations are given below. 13.1 Inside/Outside Inside idlers are generally preferred over backside idlers from a belt fatigue standpoint. Both are commonly used with good success. Inside idlers should be pulleys, but can be flat, if the O.D. is equivalent to the pitch diameter of a 40-groove pulley. Backside idlers ...

An idler gear is used tofacilitate the smooth transmission of motion between gears and ensure that. Figure 1: Electric motor, idler gear, bearings, and machine shafts. Problem Statement. gears required to have 1 6, 3 2, and 2 4 teeth with a diametral pitch of 8. An idler gear is used to. in the desired direction without changing the speed ...

D 9 With grooves and chain sprockets i only 9 9 Shaft cap Standard S 9 Regreasable S 9 Shaft Standard i 9 9 D 9 Cross-drilled thread i + D 9 9 External seal Galvanised labyrinth i 9 Labyrinth i 9 Labyrinth with FPM i 9 Deflection seal in PTFE (for IP69k) D 9 Note: For cross-drilled and threaded shaft dimensions refer to the dimensional drawings ...

Hey guys, rebuilding a TD9-91 series D350 motor, the idler gear shaft has a location dowel however there are two holes to locate the shaft, each 180 degrees from each other. Does it matter which hole you use? I have tried both and each align the gear fine. Reason I ask is I saw on YouTube a video of a guy resorting a MD with similar engine ...

An idler gear in a gear train is defined as the gear placed between the input and output shafts (between the drive gear and the driven gear ). For example, it is used to change the rotational direction of the output shaft, or to fill a large gap between the input and output shafts without affecting the speed ratio. In the example shown below ...

Assignment 1. 9(2) PART 1 BLUEPRINT READING. 11(1) Section 1 Lines. 12(14) The Alphabet of Lines and Object Lines. 12(3) Blueprint 2: Pressure Pad. 14(1) Assignment BP-2. ... Idler Shaft Support. 146(1) Assignment BP-26A. 147(1) Blueprint 26B: Pump System Mount. 148(1) Assignment BP-26B. 149(1) Half Sections, Partial Sections, and Full Section ...

Is the end shaft SYMM? Is the end shaft SYMM? AI Homework Help. Expert Help. Study Resources. Log in Join. ... ASSIGNMENT A-UNIT 8. Exercise 1. Exercise 2. Exercise 3. Exercise 4. Exercise 5. Exercise 6. Exercise 7. Exercise 8. ... The main job of the idler arm is to __. a - support the left side of the center link b -... Automotive Technology ...

Study with Quizlet and memorize flashcards containing terms like Gear Drive Components, Idler Gear, Determining Torque and Speed and more. ... multiple shaft drives. 8 terms. acidlogic. Preview. Air Medical Safety and Crashes. 41 terms. quizlette51206429. Preview. Spur Gear Drives. 27 terms. Jesus_Cordova1. Preview. AASA Know Questions Pt1.

The idler pin is actually not bad and measures 3.115 inches O.D.all the way around. The inside of the bushings are at 3.135 so that's 20 thou of play, which isn't as bad as I thought. I'm not sure what the original measurements would have been and can't seem to find them.

1. The name of the part is AXLE SHAFT. 2. The date is 3/14/17. 3. The overall length = 7.12 inch. View the full answer. Step 2. Unlock.

In a multiple gear drive system an idler gear is used mainly to __________. change direction of rotation. The concepts that are used to calculate speed and torque of multi-gear drives can also be applied to compound gears with one minor change. the gear ratio of any gears mounted on the same shaft must be combined and included in the calculation.