Logistics and Supply Chain Case Studies

Review our case studies to see how we’ve helped major corporations turn logistical ideas into a reality., leading beverage distributor, penske logistics helps beverage distributor rapidly establish new warehousing operations.

When this distributor had to expand its operation quickly to counter a competitor, they turned to Penske to deploy a customized solution.

Baby2Baby Donation Transportation

Coordination and planning lead to successful transport of $3 million clothing donation.

Penske Logistics worked with Baby2Baby, a nonprofit that provides basic essentials to impoverished children, and Old Navy to transport $3M of clothing donations.

Luxury Product Manufacturer

Penske logistics reduces inventory shrinkage, improves overall inventory management.

A leading producer of fine luxury products required a partner who could improve their warehouse and distribution operations and reduce the theft.

Poultry Supplier

Transporting food items requires extra care and expertise.

Poultry producers, navigate a complex array of supply and delivery challenges to ensure their food arrives fresh, wholesome, and on-time.

Building Products Manufacturer

Customized fleet technology solution.

A leading building products manufacturer sought to streamline its supply chain operations and expand its fleet while improving visibility through the implementation of fleet management technology.

National Wholesale Distributor

A national wholesale distributor case study.

A national wholesale distributor of heating and air conditioning supplies was struggling to manage its complex supply chain and maintain high levels of customer service, which is a top priority.

Looping Process Ensures Continuous Production

Penske collaborated with Novelis to create a closed-loop recycling network that moves finished aluminum coils and transports scrap for new production.

A Global Manufacturer

Optimizing activities in the distribution center.

Penske worked with this global manufacturer to optimize its inventory routing and mode selection and to improve visibility to its supply chain.

Quick Service Restaurant

Food and beverage in-store delivery and warehousing.

Penske helped this restaurant chain get its supply chain fundamentals in place with the right logistics tools, truck driver training and warehousing solutions.

Tier 1 Automotive Component Supplier

Managing the inbound supply chain.

Penske helped this supplier minimize supply chain disruptions by designing a network that optimized mode selection, routing and analysis.

- Supply Chain Management

- Lead Logistics Provider

- Consulting Services

- Network Design

- Dedicated Contract Carriage

- Shared Dedicated Transportation

- Freight Management

- ClearChain ® Control

- Transportation Services

- Transportation Management Solutions

- Truckload Shipping Services

- Warehousing and Distribution

- Warehouse Design

- Warehouse Operations

- Multi-Client Warehousing

- Freight Brokerage

- Freight Forwarding

- Become a Carrier for Penske

Contact Penske Logistics about our services.

- Noatum Group

- Get to know us

- Our Leadership

- Recognition and awards

- Our history

- Certifications

- Maritime Containers

- Air Containers

- Conversion Tables

- Dangerous goods labels

- Goods tariff code

Freight Management

- Contract Logistics / Warehouse & Distribution

- Customs services

- International Supply Chain Management

- Project cargo logistics

- Reefer Logistics

Automotive & Aerospace

Chemical industry, construction.

- Consumer Electronics

- Industrial Manufacturing

Oil and Gas

- Pharma & Healthcare

Renewable Energy

Case studies.

- Location & Contact

- Maritime containers

- Air containers

- Get a quote

Home / Case Studies

Case Study – Air transport services for mining industry

Our client needed to transport a total of 8 cable reels of 23 tons each from Shanghai. The challenge was to make the shipment in the shortest possible time with reasonable costs.

Case Study – Air Charter for Healthcare

The start of the Covid-19 vaccination campaign was imminent and our client needed regular shipments of syringes from China, where the factory was located, to Peru so they could ensure the vaccination campaign ran smoothly.

Case study – Air charter for the mining sector

Our client needed to urgently ship two conveyor belts from Santiago de Chile to Lima. These conveyor belts are used to move the mineral extracted from the mine into the storage area. Due to their size and weight, more than 60 tonnes, it was necessary to study in detail what would be the best transport solution to deliver in the shortest possible time.

Case Study – Automotive logistics

To create a cost saving solutions with enhanced service levels, whilst maintaining existing structures and warehouse facilities.

Case Study – Retail logistics: LG Harris

When understanding the LG Harris supply chain requirements, Noatum Logistics quickly identified that their buying terms were CIF (cost, insurance, freight) across the majority of their supply base. This prevented shipment visibility for LG Harris until the goods arrived into port. Accounting for over 1,000 TEU per annum was a major headache. The supply chain model was completely reactive with little or no reporting or key-performance-indicator (KPI) management. This created high demurrage charges, inbound-inventory and stock-control challenges at the LG Harris distribution centre (DC) located in the Midlands (UK).

Case Study – Personal care logistics

The customer felt its supply chain was working fine. No pain, no need to change! However, having worked with Noatum Logistics in the past, and experienced improved operations, the new leader was willing to let us review the company’s pricing and route information on outbound shipments to the United States, Japan, Taiwan, Malaysia and Australia.

Case Study – Outdoor retailer logistics

The retailer faced major challenges with days-in-inventory and capacity at its distribution center (DC). Days-in-inventory time continued to increase over the prior five years The single distribution center experienced overly high storage levels, delays with unloading railcars and shipping containers, and an overall worsening in port-to-DC transit times (hovering around 40 days).

Case Study – Oil & Gas industry

With each unit weighing approximately 32,000 pounds, the company faced high shipping costs for the pumping units sourced from China.

Case Study – Oil and Gas logistics

The customer suspected they were being overcharged for shipping. They were not using freight forwarders, instead allowing manufacturers to arrange for the ocean-freight shipping of the oilfield equipment from China to Canada. Cargo was shipped using fixed load plans with no optimization for larger batches.

Case Study – Mining logistics

An initial assignment was for the movement of Autoclave and Flash Vessel pieces from their manufacturing plant, located 30 miles inland from the Shanghai port, to the mining project 90 miles east of Lima, Peru. The equipment pieces were over size and over weight, requiring special loading/unloading procedures; ocean, rail and ground transportation; and infrastructure modifications.

Case Study – High Tech logistics

With a significant segment of the semiconductor wafer foundry base moving to Asia, our customer decided to relocate operations closer to their end user. Our customer opened an equipment integration facility in Singapore near their customer who provides wafer fabrication equipment. Unfortunately, this move created an increase in real estate and labor costs, thus denying our customer the warehouse space to stage components for assembly and integration.

Case Study – Pharma&Healthcare logistics

Sourcing product from Korea, the customer initially used Noatum Logistics to assist with international freight forwarding and the custom clearance process for shipments to the U.S. As the customer grew their customer base and product offering, it was apparent their outsourced warehouse solution in the U.S. could not keep up with their needs. The end customers’ orders frequently required special packing, rush deliveries, and special project handling, straining the customer’s inventory management practices.

Case Study – Fashion industry logistics: Gant

Capitalise on the retail expertise and capabilities of Noatum Logistics, including our robust warehouse management technologies and local capacity. The benefits of greater inventory visibility and control would cascade into other supply chain functions including transportation, warehousing, distribution and customer service.

Case Study – Consumer Electronics logistics

A leading manufacturer of cell phone accessories was in a crisis. Issues with an overseas partner completely shut down their supply chain. They needed a new logistics services provider to quickly step in and get shipments moving. The manufacturer also recognized the need to rethink its supply chain to gain better control over vendors, reduce costs and achieve more efficient handling of orders.

Case Study – Apparel retailer logistics

A retail client of Noatum Logistics for international freight forwarding services sought additional assistance for improving control over its global supply chain. The client recognized that greater visibility to purchase orders and shipments would lead to better purchasing, transportation and distribution decisions.

Case Study – Industrial Manufacturing logistics

Our customer is a leading multinational manufacturer of automobiles and agricultural machinery. The company entered the U.S. market in 2000; since 2002, Noatum Logistics has handled the company’s customs brokerage at Noatum Logistics’ Houston branch.

Case Study – Fashion industry logistics

Founded in 1920, New Era Cap Company is an American headwear company headquartered in Buffalo, New York. Best known for being the official on-field cap for Major League Baseball, the official sideline cap for the National Football League, and the official on-court cap for the National Basketball Association.

Case Study – High tech firm

The customer, a global provider of secure IP/Ethernet switching solutions, sources products from South China and Taiwan for sales in the United States. They identified cost containment objectives and wanted to improve the overall performance of their supply chain.

Logistics Services

- Freight management

Logistics Solutions

Key industries.

- Automotive Logistics

- Chemicals Logistics

- Construction Logistics

- Fashion Logistics

- Food Logistics

- Furniture Logistics

- Mining Logistics

- Oil and Gas Logistics

- Retail Logistics

- Renewable Energy Logistics

- Case studies

Noatum Logistics is a company of Noatum group

Reach out: [email protected] Whistleblowing: Online portal

© Copyright 2024. All Rights Reserved.

- Livro de reclamaçoes

- Privacy Policy

- Legal warning

- Cookies Policy

- All our business are subject to Noatum Logistics USA LLC Terms & Conditions

Select your country

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

It’s Time to Rethink Your Global Logistics

- Willy C. Shih

- Adrien Foucault

The pandemic has overloaded companies’ usual shipping networks.

The initial supply and demand shocks caused by the pandemic were followed by an import surge as suppliers tried to replenish inventories, which threw normal transportation operations into turmoil. In the United States, this has included a lack of freight-handling capacity at Los Angeles and Long Beach ports, overloaded U.S. intermodal rail networks, and a lack of containers. But alternatives to established logistics networks exist. It’s time for companies to take advantage of them.

Over the last three decades, companies have established wide-ranging global supply chains that have taken advantage of steadily improving scale economies in global logistics. Efficient and reliable ocean and air cargo have linked low-cost manufacturing hubs across Asia with major markets in the United States and Europe. Much of this global sourcing was driven by the cost savings reaped through labor arbitrage, cost savings that were so dramatic that it more than covered the expense associated with moving products across vast distances to markets, or the extra cost of carrying inventory in long pipelines.

- Willy C. Shih is a Baker Foundation Professor of Management Practice at Harvard Business School.

- Adrien Foucault is an MBA student at Harvard Business School and has worked at maritime transport company CMA CGM.

Partner Center

- Browse All Articles

- Newsletter Sign-Up

Logistics →

- 25 Apr 2023

How SHEIN and Temu Conquered Fast Fashion—and Forged a New Business Model

The platforms SHEIN and Temu match consumer demand and factory output, bringing Chinese production to the rest of the world. The companies have remade fast fashion, but their pioneering approach has the potential to go far beyond retail, says John Deighton.

- 18 Oct 2022

- Cold Call Podcast

Chewy.com’s Make-or-Break Logistics Dilemma

In late 2013, Ryan Cohen, cofounder and then-CEO of online pet products retailer Chewy.com, was facing a decision that could determine his company’s future. Should he stay with a third-party logistics provider (3PL) for all of Chewy.com’s e-commerce fulfillment or take that function in house? Cohen was convinced that achieving scale would be essential to making the business work and he worried that the company’s current 3PL may not be able to scale with Chewy.com’s projected growth or maintain the company’s performance standards for service quality and fulfillment. But neither he nor his cofounders had any experience managing logistics, and the company’s board members were pressuring him to leave order fulfillment to the 3PL. They worried that any changes could destabilize the existing 3PL relationship and endanger the viability of the fast-growing business. What should Cohen do? Senior Lecturer Jeffrey Rayport discusses the options in his case, “Chewy.com (A).”

- 12 Jul 2022

Can the Foodservice Distribution Industry Recover from the Pandemic?

At the height of the pandemic in 2020, US Foods struggled, as restaurant and school closures reduced demand for foodservice distribution. The situation improved after the return of indoor dining and in-person learning, but an industry-wide shortage of truck drivers and warehouse staff hampered the foodservice distributor’s post-pandemic recovery. That left CEO Pietro Satriano to determine the best strategy to attract and retain essential workers, even as he was tasked with expanding the wholesale grocery store chain (CHEF’STORE) that US Foods launched during the pandemic lockdown. Harvard Business School Professor David E. Bell explores how post-pandemic supply chain challenges continue to affect the foodservice distribution industry in his case, “US Foods: Driving Post-Pandemic Success?”

- 05 Jul 2022

- What Do You Think?

Have We Seen the Peak of Just-in-Time Inventory Management?

Toyota and other companies have harnessed just-in-time inventory management to cut logistics costs and boost service. That is, until COVID-19 roiled global supply chains. Will we ever get back to the days of tighter inventory control? asks James Heskett. Open for comment; 0 Comments.

- 19 Oct 2021

- Research & Ideas

Fed Up Workers and Supply Woes: What's Next for Dollar Stores?

Willy Shih discusses how higher costs, shipping delays, and worker shortages are putting the dollar store business model to the test ahead of the critical holiday shopping season. Open for comment; 0 Comments.

- 26 Mar 2014

How Electronic Patient Records Can Slow Doctor Productivity

Electronic health records are sweeping through the medical field, but some doctors report a disturbing side effect. Instead of becoming more efficient, some practices are becoming less so. Robert Huckman's research explains why. Open for comment; 0 Comments.

- 11 Nov 2013

- Working Paper Summaries

Increased Speed Equals Increased Wait: The Impact of a Reduction in Emergency Department Ultrasound Order Processing Time

This study of ultrasound test orders in hospital emergency departments (EDs) shows that, paradoxically, increasing capacity in a service setting may not alleviate congestion, and can actually increase it due to increased resource use. Specifically, the study finds that reducing the time it takes to order an ultrasound counter intuitively increases patient throughput time as a result of increased ultrasound use without a corresponding increase in quality of care. Furthermore, the authors show that in the complex, interconnected system or hospitals, changes in resource capacity affects not only the patients who receive the additional resources, but also other patients who share the resource, in this case, radiology. These results highlight how demand can be influenced by capacity due to behavioral responses to changes in resource availability, and that this change in demand has far reaching effects on multiple types of patients. Interestingly, the increased ultrasound ordering capacity was achieved by removing what appeared to be a "wasteful" step in the process. However, the results suggest that the step may not have been wasteful as it reduced inefficient ultrasound orders. In healthcare, these results are very important as they provide an explanation for some of the ever-increasing costs: reducing congestion through increased capacity results in even more congestion due to higher resource use. Overall, the study suggests an operations-based solution of increasing the cost/difficulty of ordering discretionary but sometimes low-efficacy treatments to address the rise in healthcare spending. Therefore, to improve hospital performance it could be optimal to put into place "inefficiencies" to become more efficient. Key concepts include: A process improvement can inadvertently cause an increase in demand for a service as well as associated shared resources, which results in congestion, counter intuitively decreasing overall system performance. While individual patients and physicians may benefit from the reduced processing time, there can be unintended consequences for overall system performance. Closed for comment; 0 Comments.

- 25 Jan 2013

Why a Harvard Finance Instructor Went to the Kumbh Mela

Every 12 years, millions of Hindu pilgrims travel to the Indian city of Allahabad for the Kumbh Mela, the largest public gathering in the world. In this first-person account, Senior Lecturer John Macomber shares his first impressions and explains what he's doing there. Closed for comment; 0 Comments.

- 07 Aug 2012

Off and Running: Professors Comment on Olympics

The most difficult challenge at The Olympics is the behind-the-scenes efforts to actually get them up and running. Is it worth it? HBS professors Stephen A. Greyser, John D. Macomber, and John T. Gourville offer insights into the business behind the games. Open for comment; 0 Comments.

- 19 Oct 2010

The Impact of Supply Learning on Customer Demand: Model and Estimation Methodology

"Supply learning" is the process by which customers predict a company's ability to fulfill product orders in the future using information about how well the company fulfilled orders in the past. A new paper investigates how and whether a customer's assumptions about future supplier performance will affect the likelihood that the customer will order from that supplier in the future. Research, based on data from apparel manufacturer Hugo Boss, was conducted by Nathan Craig and Ananth Raman of Harvard Business School, and Nicole DeHoratius of the University of Portland. Key concepts include: Two key measures of supplier performance include "consistency", which is the likelihood that a company will continue to keep items in stock and meet demand, and "recovery", which is the likelihood that a company will deliver on time in spite of past stock-outs. Improvements in consistency and recovery are associated with increases in orders from retail customers. Increasing the level of service may lead to an increase in orders, even when the service level is already nearly perfect. Closed for comment; 0 Comments.

- 19 Jul 2010

How Mercadona Fixes Retail’s ’Last 10 Yards’ Problem

Spanish supermarket chain Mercadona offers aggressive pricing, yet high-touch customer service and above-average employee wages. What's its secret? The operations between loading dock and the customer's hands, says HBS professor Zeynep Ton. Key concepts include: The last 10 yards of the supply chain lies between the store's loading dock and the customer's hands. Poor operational decisions create unnecessary complications that lead to quality problems and lower labor productivity and, in general, make life hard for retail employees. Adopting Mercadona's approach requires a long-term view and a leader with a strong backbone. Closed for comment; 0 Comments.

- 12 Jul 2010

Rocket Science Retailing: A Practical Guide

How can retailers make the most of cutting-edge developments and emerging technologies? Book excerpt plus Q&A with HBS professor Ananth Raman, coauthor with Wharton professor Marshall Fisher of The New Science of Retailing: How Analytics Are Transforming the Supply Chain and Improving Performance. Key concepts include: Retailers can better identify and exploit hidden opportunities in the data they generate. Integrating new analytics within retail organizations is not easy. Raman outlines the typical barriers and a path to overcome them. Incentives must be aligned within organizations and in the supply chain. The first step is to identify the behavior you want to induce. To attract and retain the best employees, successful retailers empower them in specific ways. Closed for comment; 0 Comments.

- 05 Jul 2006

The Motion Picture Industry: Critical Issues in Practice, Current Research & New Research Directions

This paper reviews research and trends in three key areas of movie making: production, distribution, and exhibition. In the production process, the authors recommend risk management and portfolio management for studios, and explore talent compensation issues. Distribution trends show that box-office performance will increasingly depend on a small number of blockbusters, advertising spending will rise (but will cross different types of media), and the timing of releases (and DVDs) will become a bigger issue. As for exhibiting movies, trends show that more sophisticated exhibitors will emerge, contractual changes between distributor and exhibitors will change, and strategies for tickets prices may be reevaluated. Key concepts include: Business tools such as quantitative and qualitative research and market research should be applied to the decision-making process at earlier stages of development. Technological developments will continue to have unknown effects on every stage of the movie-making value chain (production, distribution, exhibition, consumption). Closed for comment; 0 Comments.

- 20 Dec 2004

How an Order Views Your Company

HBS Professors Benson Shapiro and Kash Rangan bring us up to date on their pioneering research that helped ignite today’s intense focus on the customer. The key? Know your order cycle management. Closed for comment; 0 Comments.

- 15 Apr 2002

In the Virtual Dressing Room Returns Are A Real Problem

That little red number looked smashing onscreen, but the puce caftan the delivery guy brought is just one more casualty of the online shopping battle. HBS professor Jan Hammond researches what the textile and apparel industries can do to curtail returns. Closed for comment; 0 Comments.

- 26 Nov 2001

How Toyota Turns Workers Into Problem Solvers

Toyota's reputation for sustaining high product quality is legendary. But the company's methods are not secret. So why can't other carmakers match Toyota's track record? HBS professor Steven Spear says it's all about problem solving. Closed for comment; 0 Comments.

- 19 Nov 2001

Wrapping Your Alliances In a World Wide Web

HBS professor Andrew McAfee researches how the Internet affects manufacturing and productivity and how business can team up to get the most out of technology. Closed for comment; 0 Comments.

- 22 Jan 2001

Control Your Inventory in a World of Lean Retailing

"Manufacturers of consumer goods are in the hot seat these days," the authors of this Harvard Business Review article remind readers. But there is no need to surrender to escalating costs of inventories. In this excerpt, they describe one new way to help lower inventory costs. Closed for comment; 0 Comments.

- 12 Oct 1999

Decoding the DNA of the Toyota Production System

How can one production operation be both rigidly scripted and enormously flexible? In this summary of an article from the Harvard Business Review, HBS Professors H. Kent Bowen and Steven Spear disclose the secret to Toyota's production success. The company's operations can be seen as a continuous series of controlled experiments: whenever Toyota defines a specification, it is establishing a hypothesis that is then tested through action. The workers, who have internalized this scientific-method approach, are stimulated to respond to problems as they appear; using data from the strictly defined experiment, they are able to adapt fluidly to changing circumstances. Closed for comment; 0 Comments.

Rapid Response: Inside the Retailing Revolution

A simple bar code scan at your local department store today launches a whirlwind of action: data is transmitted about the color, the size, and the style of the item to forecasters and production planners; distributors and suppliers are informed of the demand and the possible need to restock. All in the blink of an electronic eye. It wasn’t always this way, though. HBS Professor Janice Hammond has focused her recent research on the transformation of the apparel and textile industries from the classic, limited model to the new lean inventories and flexible manufacturing capabilities. Closed for comment; 0 Comments.

Case Studies in Carbon-Efficient Logistics

Logistics is a leading source of carbon. Nearly 6 percent of the greenhouse gases generated by humans come from the flow of products to consumers. Reducing these emissions takes more than setting goals; it requires clear, measurable initiatives that hit sustainability targets while delivering lower costs and higher service levels.

Sponsored by Environmental Defense Fund (EDF), Dr. Edgar E Blanco Research Director of the Carbon-Efficient Supply Chains Research Project at the MIT Center for Transportation & Logistics, worked alongside three US companies to help them quantify the carbon footprint of some of their logistics initiatives. The goal was to document the projects, and illustrate to other companies that it is possible to reduce cost and become more environmentally friendly.

In this case study we present two Ocean Spray initiatives – distribution network redesign and intermodal shift from road to rail – that in combination led to a 20% reduction in transportation CO2 emissions, while achieving comparable cost savings across the transportation network.

Shifting to Rail – A Collaborative Approach

Ocean Spray, CSX (the rail operator), and fruit shipping companies partnered in order to enable Ocean Spray to ship more products intermodally from its New Jersey distribution center to the company's Florida facility. Prior to the collaboration, these boxcars were returning empty to the Florida region. Shipments that shifted to intermodal generated 65% less emissions while saving over 40% of transportation costs.

Distribution Network Redesign

Ocean Spray added new manufacturing and distribution capabilities in Florida to support the company’s growing customer base. To fully and effectively utilize these additions, Ocean Spray conducted a national network re-design project to determine which customers will receive product from the new location. Ocean Spray projected that over 17% of the total shipments will be served from the new facility.

Read the full Ocean Spray case study here .

In this case study, we analyzed the inbound shipping operations of Caterpillar’s North American large mining truck facility to determine – based on weight, packaging, routing, and scheduling – opportunities to streamline shipping protocols, and thus reduce carbon emissions associated with the supply chain. When combined, the streamlined shipping and packaging efforts could reduce Caterpillar’s overall carbon emissions by 340-730 tonnes of CO2 per year.

Switching Shipment Packaging from Steel to Light-Weight Plastic

At present, Caterpillar uses steel containers to transport parts. Caterpillar has been working for the past four years to phase out these steel containers and replace them with plastic containers, which weigh considerably less.

Analyzing Inbound Shipments to Identify Potential Consolidation

To construct the very large vehicles used in the mining industry, parts are shipped from all over the globe for assembly at Caterpillar’s manufacturing facility in Decatur, Illinois. We analyzed historical shipment data to identify areas where shipments could be consolidated to save fuel and reduce vehicle CO2 emissions. More specifically, we analyzed:

Read the full Caterpillar case study here .

Boise Inc. has launched two initiatives to improve its logistics operations and environmental performance. The Carload Direct Initiative is shifting product transport to rail, and the Three-Tier Pallet Initiative is increasing railcar utilization. Both initiatives have resulted in a combined 62-72% reduction in the company’s CO2 emissions, as well as cost savings on those shipments.

Reducing CO2 Emissions Through Carload Direct

Traditionally, manufacturers use trucks, or a mix of trucks and rail, to transport their products to customers. As trucks produce greater emissions than trains, a logical way to reduce emissions is to minimize the use of trucks and maximize the use of rail. Boise coordinated with its customers to promote rail transport so that product could be sent directly from the manufacturing plant to the customer’s warehouse. The transition from using a mix of truck and rail to exclusively rail eliminated more than 2,600 tons of C02; the equivalent of saving over 264,000 gallons of fuel consumed by road vehicles.

Optimizing Railcar Utilization with Three-Tier Pallets

Prior to this project, railcars were loaded two pallets high, leaving a space from the top of the second pallet to the roof of the railcar, thus under-utilizing the full capacity of the railcar. Boise redesigned its pallets and loading structure by creating a half-pallet, which allowed the company to rethink pallet stacking and maximize shipping capacities for its loads. These redesigns maximized carloads by reducing the number of shipments required to deliver product. Using just 930 railcars in 2011 reduced the company’s C02 emissions by 190 tons, which is equal to the C02 emissions from 21,637 gallons of fuel consumed by road vehicles.

Read the full Boise case study here .

Hear directly from Dr. Edgar Blanco, from MIT CTL, joined by EDF’s Jason Mathers, Ross Corthell from Boise, Kristine Young from Ocean Spray, and Zena Onstott from Caterpillar as they share their insights from these case studies on this webinar .

To find out more about the case studies, contact Dr. Edgar E. Blanco , Research Director, Carbon Efficient Supply Chains Research Project, MIT CTL, and co-founder of the LEAP consortium.

The Carbon Efficient Supply Chains Research Project is addressing three challenges: how to measure the carbon footprint of a supply chain, developing strategies for reducing supply chain carbon emissions, and communicating carbon footprints to consumers and stakeholders. Further information is available here .

The Leaders in Environmental Assessment and Performance (LEAP) consortium is a vehicle for organizations to leverage MIT’s knowledge and resources as well as the lessons learned from corporate environmental efforts. LEAP is a joint initiative between MIT CTL and the MIT Material Systems Laboratory. Further information is available here .

- Country initiatives

- Country pages

- Case study: Going digital in the logistics and transportation sector

Digital transformation as a response to economic downturn

Background:.

A logistics and transportation business offers a range of logistic services from domestic road transport to the warehousing of goods. The business initially started operations in customs clearance, but over the years its services have expanded into logistics forwarding through good business relationships and partnerships with clients and suppliers. The business has become one of the key market players and is an example of a modern, fast growing business.

Due to poor market conditions and overall economic downturn, the business was looking for new ways to manage its clients’ supply chains and logistics departments to improve efficiency reduce costs and mitigate any risks.

The business’s goal was to provide integrated business solutions through innovation and digital transformation. It wanted to integrate digital technology into its business models to enter new markets, improve market intelligence and deliver higher value to customers. It wanted to establish a fully-digital business model via a digital app and meet customer demand by utilising the logistics capacity of other businesses rather than owning its own logistics assets.

The solution:

The business underwent a digital transformation leading to where they are today, employing around 200 people without needing to actually own any physical logistics assets. Even though transitioning to the non-asset business model required high initial costs, it allowed the business to reduce amortisation and inventory costs, saving the business money in the long term.

It tracked all shipments with digital technology and acted as a middleman in matching logistics capacity to customer demand. By establishing operations this way, the business was able to provide the same level of service as much bigger players in the market. As a small business, it benefited from an agile approach, making digitalising the entire business model and then adopting it easier.

A non-asset-based logistics business finds its market in providing expertise within supply chains and negotiating better commercial terms with the parties – it is connecting clients with distribution companies that deliver, store and manage their products and materials. The high flexibility of such supply chain models allows it to identify the best approach to meet the demands of industry and to respond to clients’ needs on a case-by-case basis.

The new strategy included a mission of providing innovative integrated logistics services, emphasising efficiency and dedication to customers as well as a vision of creating a sustainable model to take a leading position on the regional market. As part of the strategy, the business also aimed to invest in its employees and in technology.

The business conducted a skills assessment to make sure its workforce was able to implement its strategy. This helped it to identify a skills gap and to prepare a workforce plan to develop its current workforce and recruit people with the necessary skills to support the business transformation. The business managed to establish a balanced workforce of young and energetic people and experts with proven knowledge and experience.

In hiring employees the business focused on young people without significant previous work experience and trained them through its internship programme. During their studies, they got to know the business and gained some practical knowledge and experience. Many stayed with the business after the internship programme ended. The fact that the employees were already adapted to and comfortable with the business’s working environment and culture benefited both the business and its employees.

When it comes to digitalisation , the business has turned to providing its clients with transportation management system software, compatible with logistics platforms such as EDI, SKYTRAK and WMS. This helps clients to procure distribution services in an efficient and timely manner. It has also invested in the education of its employees and in an integrated information system that allows quicker flow of information within the business.

- Case Studies

the link of the current page has been copied

The website uses Cookies. Please confirm if you agree or disagree with it?

If yes, please click on the relevant country below:

The EBRD has conducted a series of legal and practical country guidance workshops to build business resilience.

For more details click on the relevant country below.

Market (Europe - English)

- United States

Top Searches

- Real Time Visibility

Case Studies

Freight sourcing.

Sonepar plugs into a new era of freight matching with Transporeon Freight Procurement

How Transporeon is helping Limagrain Europe achieve its field of dreams

Transporeon improving Amica’s logistics processes

Pirelli: Managing Complexity in Freight Procurement

Benetton Group: Comparability of offers and transparency

AB InBev brews up double-digit spot freight savings with Transporeon Autonomous Procurement

RPM Logistics Deploys Autonomous Truckload Procurement

ZF Friedrichshafen: Easy handling of complex logistics tenders

Transport Execution

Ritex Logistics' journey to operational excellence with Transport Assignment solutions

Transporeon solutions help Essity reach 1bn people every day

Barilla Group achieves 99% carrier allocation success

Duracell: Managing Parcel, FTL and LTL shipments on one Transportation Management Platform

Acerinox: Globalization with a single tool

How we helped DHL to innovate at a crucial time

Facil chooses Transport Operations to streamline transportation flows

How Pfeifer is putting logistics efficiency at the root of their business

Flowing with success: Acqua Vera

Girteka Logistics: Developing relationships between business partners

H.Essers: Finding price-competitive capacity and speeding up the average time to carrier acceptance with Freight Matching

Barilla: Digitalization is the secret ingredient that keeps your pasta fresh

Perfect transport partners with the Transporeon Transportation Management Platform

How Burgo Group digitises its logistics

How K+S achieves efficient end-to-end processes and carrier connectivity with Transporeon and Visibility Hub

Dock & Yard Management

ArcelorMittal Hamburg: Improving time management and streamlining processes in logistics

Metro Logistics: Digitisation ensures transparency in the incoming goods department

How GEBA Trans is improving its customer service offering with Transporeon’s Visibility Hub

How Nestlé is using Transporeon Visibility Hub to manage supply chain disruptions

Saint Gobain Isover: Rapidly scalable visibility solution with high levels of automation

Sustainability

IKEA Supply Chain Operations & Girteka Logistics: You can’t manage what you can’t measure

Schneider Electric: Unlocking greater visibility into the market

Freight Audit & Payment

Top 50 Fortune 500 FMCG company saves big with Freight Audit solution

Interested in our solutions?

Get in touch with us to learn more!

Our solutions for your transport and logistic needs

Visibility Hub

- Reduce check calls and automate processes.

- Increase performance and customer satisfaction.

- Reduce wait and dwell times with more accurate ETAs.

- Increase your on-time performance and avoid penalties

- Reduce CO2 emissions and empty mileage.

Freight Audit and Payment Hub

- Pre-fill and validate fields from the Transporeon platform.

- Easily transfer documents to ERP systems via the interface.

- All relevant parties maintain access to the latest versions of all documents.

- Get automatic reminders and notifications for requirements documents.

- Instantaneous and traceable digital transmission of all documents.

Transport Execution Hub

Attachment Services

- Pre-fill and validate fields from the Transporeon platform

- Easily transfer documents to ERP systems via the interface

- All relevant parties maintain access to the latest versions of all documents

- Get automatic reminders and notifications for requirements documents

- Instantaneous and traceable digital transmission of all documents

Freight Sourcing Hub

Autonomous Procurement

- Automates procurement using data and behavioural science.

- Analyses how carriers make pricing decisions.

- Achieves requested capacity at lower freight rates for road transports.

- Fully automated process of predicting, framing offers, and concluding assignments.

- Entirely carrier specific and automated process.

Best Carrier

- Access the spot market more easily.

- Cut transaction costs by up to 19%.

- React quickly to market fluctuations.

- Improve process efficiency with better integrations.

- Cloud-based system provides real-time transparency.

Sustainability Hub

Carbon Visibility

- Precise measuring & reporting on logistics emission.

- Across entire supply chain and all transport modes.

- Based on the highest market standards covering the total emissions (Well-to-Wheel).

- Enables operations to move to Net Zero logistics.

Carrier Premium Account

- Apply for suitable calls for bids with one click and win new customers.

- Make your business known on the platform and in the service provider database.

- Clear distribution of competencies and tasks between Head Office and Branch Office.

- Optimize internal processes through additional functions and reports.

Dock & Yard Management Hub

Digital Transport Documents

- Paperless management of the consignment note through all involved parties

- Easy usage due to conveniently comment and signing of the eCMR on a mobile device

- Provide the eCMR in real time via Transporeon platform plus additional communication channels

Platform Capabilities

ERP Interfaces

- Integrate the Transporeon platform into your ERP system using the ERP interfaces.

- Stay within your ERP system while using the full-service power of the integrated Transporeon platform.

Event Management

- Track transports from collection to end-point delivery with digital event management.

- Events can be defined and provided to customer needs.

- View actual delivery status and trigger subsequent processes.

- Reliable information about time of arrival for all parties.

- Enable proactive reactions or automated platform based mitigation tasks.

Extended Yard Management powered by Peripass

- Reduce manual efforts by digitising the registration process.

- Save on reception costs and reduce waiting times.

- Keep an overview of your site and how capacity is used.

- Shorten lead times, increase volumes and reduce waiting costs by 85%.

- Get a real-time overview of all trucks, containers, trailers etc on site.

- Centralise and digitise the operations of shunters, forklift and truck drivers and security personnel on site.

Freight Audit & Payment Hub

Freight Audit

- Full visibility of process, data and carrier performance.

- Logistics should no longer deal with invoicing.

- Underbilling is reported.

- Receives alerts about rejection/approval.

- Cost allocation of freight audit costs are automated.

Freight Matching

- Maximize profitability and productivity by equipping your teams to utilize available capacity opportunities within your trusted network, faster.

- Enable your carriers to realize their full potential by matching with the loads that are right for them.

- Manage your carrier relationships with more transparency from increased number of data points.

- Stay in control of your shipments and provide end-to-end visibility to your customers, and eradicate check calls.

- Reduce manual effort, and increase accuracy with full digitalization.

Freight Procurement

- Smart purchasing strategy.

- Achieve optimum freight rates.

- Reduce administrative effort and costs.

- Find suitable partners worldwide.

- Audit-proof the tendering process.

Procurement Advisory

- Save up to 19% on freight costs.

- Save 30% on administrative effort with e-sourcing.

- Use only quality-approved data for tender processes and RFQ events.

- Ensure 100% compliance with tendering processes.

Freight Settlement

- Save time by resolving billing issues before the invoice is sent.

- Simplified control of individual invoice items.

- All settlement transactions are displayed in their entirety to provide complete transparency.

- Company-wide and standardized coordination process.

- Can be also used as stand-alone-solution also compatible with other products.

Insights Hub

Market Insights

- Monitor the contractually agreed rates between shippers, logistic service providers, and the spot market.

- Use important "indirect" indicators to illustrate the capacity situation on any given lane or market.

- Define the lanes and metrics that you want to monitor.

- Get a clear overview of the biggest market changes and top movers.

Strategic Benchmarking

- Persistent freight cost savings with up to 8% with our state of art benchmarking approach.

- Get the most comprehensive overview of all markets and for all modes.

- Profit from insights into latest market developments & forecasts.

- Get a deeper understanding of rate developments & costs drivers.

- Receive regular information with market overviews, developments, cost drivers.

No-Touch Order

- Automated shipment execution processes.

- Fewer empty runs.

- Cut process costs by up to 30%.

Rate Management

- All freight rates and freight contracts in one centralized database.

- Rate query engine factors in multiple currencies, surcharges and total chargeable cost per available carrier.

- Optimization of inquiry processes and better usage of internal resources.

- Fully integrated process of assigning transports and management of rates in an organization.

- Centralized interfaces and import/export functions.

Real Time Workflow

- Less labor-intensive solution due to electronic workflows and paperless management of transport documents.

- Integration of drivers into the digital workflow.

- Immediate updates about status changes and shipping stages of the goods to be delivered.

- Photographic documentation of transport damage and proof of cargo safety.

Real-Time Yard Management

- Improve overall visibility and ability to predict changes.

- Combine yard, transport, and warehouse management.

- Automate arrivals, check-ins, and call-offs.

- Avoid costs and fees caused by idle and inefficient processes.

- Monitor, measure, and improve KPIs.

Time Slot Management for Retail

- Increase handling capacity by up to 20%

- Reduce driver wait times by up to 40%

- Shorten loading times by up to 60 minutes

- Audit and legal security

- Completely documented processes

- The SAP Add Ons integrates all Transporeon functionalities without a need for interfaces or middleware into the SAP ERP system.

- Benefit from the Transporeon UX within your standard SAP system.

Market Intelligence & Benchmarking

Supply Chain Advisory

- Know-How from more than 1,700 supply chain projects and 25+ years of experience

- Gain full global network transparency

- Achieve cost savings through supply chain optimization

- Support for all phases, from conception to implementation into your supply chain

- Deep knowledge of all modes of transport

- Specialized Benchmarks with proven Market Intelligence methodology

MBA Knowledge Base

Business • Management • Technology

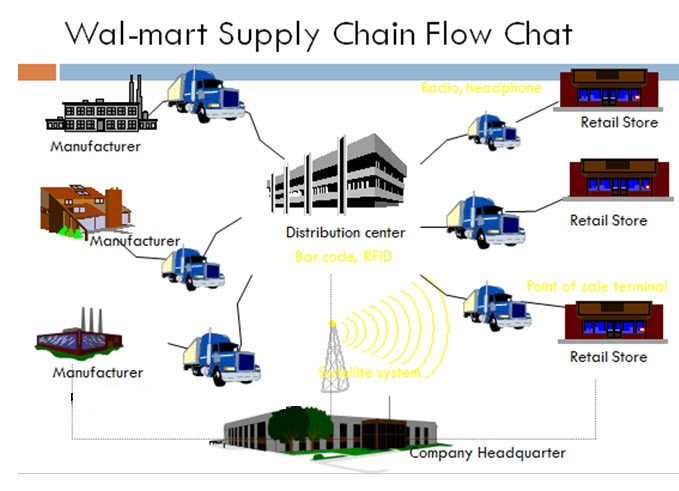

Home » Management Case Studies » Case Study: Wal-Mart’s Distribution and Logistics System

Case Study: Wal-Mart’s Distribution and Logistics System

As the world’s largest retailer with net sales of almost $419 billion for the fiscal year 2011, Wal-Mart is considered a “best-in-class” company for its supply chain management practices . These practices are a key competitive advantage that have enabled Wal-Mart to achieve leadership in the retail industry through a focus on increasing operational efficiency and on customer needs. Wal-Mart’s corporate website calls “logistics” and “distribution” the heart of its operation, one that keeps millions of products moving to customers every day of the year.

Wal-Mart’s highly-automated distribution centers, which operate 24 hours a day and are served by Wal-Mart’s truck fleet, are the foundation of its growth strategy and supply network. In the United States alone, the company has more than 40 regional distribution centers for import flow and more than 140 distribution centers for domestic flow. When entering a new geographic arena, the company first determines if the area will be able to contain enough stores to support a distribution center. Each distribution center supports between 75 to 100 retail stores within a 250-mile area. Once a center is built, stores are gradually built around it to saturate the area and the distribution network is realigned to maximize efficiencies through a process termed “reoptimization”. The result is a “trickle-down” effect: trucks do not have to travel as far to retail stores to make deliveries, shorter distances reduce transportation costs and lead time, and shorter lead time means holding less safety inventory. If shortages do occur, replenishment can be made more quickly because stores receive daily deliveries from distribution centers.

An important feature of Wal-Mart’s logistics infrastructure was its fast and responsive transportation system. The distribution centers were serviced by more than 3,500 company owned trucks. These dedicated truck fleets allowed the company to ship goods from the distribution centers to the stores within two days and replenish the store shelves twice a week. The truck fleet was the visible link between the stores and distribution centers. Wal-Mart believed that it needed drivers who were committed and dedicated to customer service. The company hired only experienced drivers who had driven more than 300,000 accident-free miles, with no major traffic violation.

Wal-Mart truck drivers generally moved the merchandise-loaded trailers from Wal-Mart distribution centers to the retail stores serviced by each distribution center. These retail stores were considered as customers by the distribution centers. The drivers had to report their hours of service to a coordinator daily. The coordinator scheduled all dispatches depending on the available driving time and the estimated time for travel between the distribution centers and the retail stores. The coordinator informed the driver of his dispatches, either on the driver’s arrival at the distribution center or on his return to the distribution center from the retail store. The driver was usually expected to take a loaded truck trailer from the distribution center to the retail store and return back with an empty trailer. He had to dispatch a loaded truck trailer at the retail store and spend the night there. A driver had to bring the trailer at the dock of a store only at its scheduled unloading time, no matter when he arrived at the store. The drivers delivered the trailers in the afternoon and evening hours and they would be unloaded at the store at nights. There was a gap of two hours between unloading of each trailer. For instance, if a store received three trailers, the first one would be unloaded at midnight (12 AM), the second one would be unloaded at 2 AM and the third one at 4 AM. Although, the trailers were left unattended, they were secured by the drivers, until the store personnel took charge of them at night. Wal-Mart received more trailers than they had docks, due to their large volume of business.

Because Wal-Mart’s fast, responsive transportation operations are such a major part of the company’s successful logistics system, great care is taken in the hiring, training, supervising, and assigning of drivers’ schedules and job responsibilities. From the onset of his retailing career, Wal-Mart founder Sam Walton recognized the importance of hiring experienced people and of building loyalty not only in his customers but also in his employees. The company hires only experienced drivers who have driven more than 300,000 accident-free miles and whom it believes will be committed to customer service. Its retail stores are considered important “customers” of the distribution centers. As stated in the “Private Fleet Driver Handbook” that each driver is given a copy of, drivers are expected to be “polite” and “kind” when dealing with store personnel and others. In addition to containing a driver’s code of conduct, the Private Fleet Driver Handbook gives instructions and rules for following pre-planned travel routes and schedules, the responsible unloading of a truck trailer at a retail store, and the safe-guarding of Wal-Mart’s property. For example, although drivers deliver loaded trailers in the afternoon and evening hours, a trailer can be brought to the store’s docks only at its scheduled unloading time. Because unloading is done at two-hour intervals during the night, a driver is expected to spend the night, returning to the distribution center at a pre-scheduled time with an empty trailer. Coordinators closely monitor the detailed records of each driver’s activities for adherence to rules. Violations are dealt with according to handbook procedures, which include employee education to prevent future occurrences of incorrect actions. By effectively managing every aspect of its transportation operations and treating its drivers fairly, Wal-Mart gets results that are unrivaled in the logistics arena. This philosophy parallels the successful coaching style of New York Giant’s football coach Tom Coughlin who believes that rules are more than just discipline. Rules are a key to consistency, which leads to preparedness, which then leads to proper execution.

To make its distribution process more efficient, Wal-Mart also made use of a logistics technique known as ‘cross-docking.’ In this system, the finished goods were directly picked up from the manufacturing plant of a supplier, sorted out and then directly supplied to the customers. The system reduced the handling and storage of finished goods, virtually eliminating the role of the distribution centers and stores. There were five types of cross-docking.

- Opportunistic Cross docking – In this method of cross docking, the exact information about where the necessary good should be shipped and from where it should be procured and exact quantity which will be sent was necessary. This method of cross docking has allowed the company to ship directly the goods, necessary retail clients, not storing them in warehouse bins or shelves. Opportunistic cross docking could also be used when the warehouse software of management installed by the retailer, has set ready it, that the specific product was ready to moving and could be moved immediately.

- Flow-through Cross docking – In this type of cross docking, there was a constant inflow and outflow of the goods from the distribution center. This type of cross docking was mostly suitable for the perishable goods which had very short interval of time, or the goods which were difficult to be kept in warehouses. This cross docking system was mainly accompanied by supermarkets and other retail discount stores, especially for perishable items.

- Distributor Cross docking – In this type of cross docking, the manufacturer has delivered the goods to directly to retailer. No intermediaries have been involved in this process. It has allowed the retailer to save a major portion of the expenses in the form of storage. As the retailer should not support the distribution center for storage various kinds of the goods, he has helped it to save warehouse costs. The lead time for the delivery of goods from the manufacturer to the consumer was also drastically reduced. However, this method had some disadvantages too. Expenses of transportation both for the manufacturer and for the retailer tended to increase during time when the goods have been required to be transported to different locations several times. Besides, the transportation system should be very fast. Otherwise, the purpose of cross docking has been lost. The transportation system should be also highly responsive and to take the responsibility for delays in delivery of the goods. The retailer was at a greater risk. He has lost that advantage to sharing risks with the manufacturer. This type of cross docking was suitable only for those retailers who had the big distributive network and could be used in situations when goods had to be delivered in a short span of time.

- Manufacturing Cross docking – In Manufacturing cross docking, these cross docking facilities served the factories and acted as temporary and “mini warehouses.” Whenever a manufacturing company required some parts or materials for manufacturing a particular product, it was delivered by the supplier in small lots within a very short span of time, just when it was needed. This helped reduce the transportation and warehouse costs substantially.

- Pre-Allocated Cross Docking – Pre-allocated cross docking is very much like the usual cross-docking, except that in this type of cross docking, the goods are already packed and labeled by the manufacturer and it is ready for shipment to the distribution center from where it is sent to the store. The goods can be delivered by the distribution center directly to the store without opening the pack of the manufacturer and re-packing the goods. The store can then deliver the goods directly to the consumer without any further repacking. Goods received by the distribution center or the store are directly sent into the outbound shipping truck, to be delivered to the consumer, without altering the package of the good. Cross docking requires very close co-ordination and co-operation of the manufacturers, warehouse personnel and the stores personnel. Goods can be easily and quickly delivered only when accurate information is available readily. The information can be managed with the help of Electronic Data Interchange (EDI) and other general sales information.

In cross docking, requisitions received for different goods from a store were converted into purchase or procurement orders. These purchase orders were then forwarded to the manufacturers who conveyed their ability or inability to supply the goods within a particular period of time. In cases where the manufacturer agreed to supply the required goods within the specified time, the goods were directly forwarded to a place called the staging area. The goods were packed here according to the orders received from different stores and then directly sent to the respective customers. To gain maximum out of cross-docking, Wal-Mart had to make fundamental changes in its approach to managerial control . Traditionally, decisions about merchandising, pricing and promotions had been highly centralized and were generally taken at the corporate level. The crossdocking system, however, changed this practice. The system shifted the focus from “supply chain” to the “demand chain,” which meant that instead of the retailer ‘pushing’ products into the system; customers could ‘pull’ products, when and where they needed. This approach placed a premium on frequent, informal cooperation among stores, distribution centers and suppliers with far less centralized control than earlier.

Besides, if the supplier knows also, that for the company it will be incredibly difficult to make proper adjustments to guarantee smooth transition to the different supplier, then they will be less inclined to lower their price as much. It is not, how existing suppliers deal with Wal-Mart; when they see that Wal-Mart has found the supplier who will give them lower price, current suppliers lower their prices accordingly. They know that logistical system of the Wal-Mart can address with transition easily, and consequently they do not receive additional leverage, as it will not be difficult or expensive for Wal-Mart to choose other supplier.

Another reason that Wal-Mart’s prices are so competitive is because they buy in such large quantities that transportation from one end of the supply chain to another is not as expensive for additional units. This aspect of the logistical system does not come from skill or expertise it simply comes from the sheer size of the company, but this is still a factor. On the other hand, the Wal-Mart buys so many supplies from different places throughout the world, that they have the luxury of using bigger trucks and using less fuel to go back and forth. Also if by chance they have to use shipping services to transport material from one location to another, Wal-Mart will give them so much business that they will get huge discounts.

On the whole, the logistical system that Wal-Mart uses is so effective because it is so flexible. This is why Wal-Mart is able to offer things much cheaper than other companies can.

About Wal-mart Stores

Wal-Mart Stores, Inc. is the largest retailer in the world, the world’s second-largest company and the nation’s largest nongovernmental employer. Wal-Mart Stores, Inc. operates retail stores in various retailing formats in all 50 states in the United States. The Company’s mass merchandising operations serve its customers primarily through the operation of three segments. The Wal-Mart Stores segment includes its discount stores, Supercenters, and Neighborhood Markets in the United States. The Sam’s club segment includes the warehouse membership clubs in the United States. The Company’s subsidiary, McLane Company, Inc. provides products and distribution services to retail industry and institutional foodservice customers. Wal-Mart serves customers and members more than 200 million times per week at more than 8,416 retail units under 53 different banners in 15 countries. With fiscal year 2010 sales of $405 billion, Wal-Mart employs more than 2.1 million associates worldwide. Nearly 75% of its stores are in the United States (“Wal-Mart International Operations”, 2004), but Wal-Mart is expanding internationally. The Group is engaged in the operations of retail stores located in all 50 states of the United States, Argentina, Brazil, Canada, Japan, Puerto Rico and the United Kingdom, Central America, Chile, Mexico,India and China.

Related Posts:

- Case Study: Why Woolworths Failed as a Business?

- Case Study of Cisco: Transformation of Entire Supply Chain into an Extended Enterprise System

- Case Study of Zara: Sustainability in Fast Fashion Industry

- Case Study: Tesco's US Grocery Market Entry

- Case Study: Supply Chain Management of Walmart

- Zara's Lean Operation: Source of Competitive Advantage

- Case Study: Wal-Marts Competitive Advantage

- Case Study: McDonalds Marketing Strategies

- Case Study: Why Walmart Failed in Germany?

- Case Study: Business Strategy Analysis of Wal-Mart

One thought on “ Case Study: Wal-Mart’s Distribution and Logistics System ”

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Logistics and transportation cases

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Aerospace, Defense, & Government

- Aftermarket

- Automotive & Manufacturing

- Consumer Goods

- Healthcare & Pharmaceuticals

- Logistics Service Providers

- Parcel Carriers

- Restaurant & Food Service

- Retail & Grocery

- Business Model

- Digital Supply Chain Network™

- Supply Chain Control Towers

- Digital Transformation

- Sales & Operations Planning (S&OP)

- Business Continuity & Risk Management

- Sustainability

- TMS Solution

- Transportation Planning & Optimization

- Transportation Execution & Management

- WMS Solution

- Global Logistics Gateway

- Dock Door Scheduling

- Yard Management

- Global Trade Management

- Financial Reconciliation

- Outbound Fulfillment

- Demand Management

- Forecasting

- Demand Sensing

- Order Management

- Vendor Managed Inventory

- Multi-Tier Replenishment

- Multi-Tier Inventory Management

- Demand-Driven Deployment

- Integrated Inbound Supply

- Procure-to-Pay

- Production Planning & Scheduling

- Demand Translation

- Supplier Order Management

- Best Practice Templates

- B2B Infrastructure

- Federated Network

- Master Data Management

- Business Internet Services

- Social Apps

- Wi-Fi Enablement

- NEO Intelligent Agents

- ONE Blockchain

- ONE Chain of Custody

- For Developers

- SDK for the NEO Platform

- Developer Learning Center

- Microservices & Module Store

- Current Partners

- Consulting Partner

- Application (ISV) Partner

- Affiliate Partner

- Resource Library

- Published Articles

- Press Releases

- Supply Chain Videos

- Corporate Blog

- ONE Community Forum

- Conferences

- Company Leadership

- REQUEST A DEMO

ALBERTSONS’ SAFEWAY CENTRALIZES AND STREAMLINES TRANSPORTATION MANAGEMENT ACROSS MANUFACTURING AND RETAIL

A retail logistics and transportation management case study.

Albertsons is one of North America’s largest food retailers, with over 2,200 stores located mostly in the western, midwestern, and mid-Atlantic regions of the US, as well as western Canada. It also operates regional supermarket companies, including Safeway, The Vons Companies (primarily in Southern California), Dominick’s Finer Foods (Chicago), Carr-Gottstein Foods (Alaska’s largest retailer), Genuardi’s Family Markets (eastern US), and Randall’s Food Markets (Texas). It also owns e-retailer GroceryWorks.com. Outside of the US, Albertsons owns 49% of Casa Ley, which operates about 135 food and variety stores in western Mexico.

Key Facts About Albertsons Safeway

- 2nd largest food and drug retailers in the U.S.

- Annual Sales $57.5 billion

- 2,205 stores

- Stores in 33 states

- Nearly 265,000 employees

Challenges Retail Logistics and Transportation Management

One Network’s journey with Albertson’s began with Safeway in 2002. In an effort to streamline supply chain, Albertsons’ Safeway went through a centralization of their Transportation activities. The centralization increased the number of loads to be tendered and managed by Safeway’s Corporate Traffic department, located in Phoenix, AZ, approximately 300%-375% based on seasonality (from 300-400/week to 900-1900 week). Constrained by a manual process that required the Corporate Traffic department to make telephone calls to carriers and update an internally built MS Access application to provide track and trace functionality. In addition, meetings with the Produce department were required to provide visibility of load status at the beginning of each day.

How the Intelligent Logistics Management Solution Helped

Ultimately the process resulted in:

- A centralized transportation process, however a de-centralized scheduling process resulting in five dedicated schedulers (one for each warehouse) across each of Albertsons’ 16 facilities.

- Increased transportation and produce costs, due to increased stops and ‘Street Buying’

- Reduced delivery performance, due to a lack of visibility and notification of lead time and transportation issues potentially reducing retail sales due to out of stock conditions

- Increased labor costs due to manual process required to gain full supply chain visibility

Business Goals for the Logistics & Transportation Management Solution

Safeway approached One Network to provide a solution to:

- Substantially improve and automate the transportation processes defined above.

- Centralize transportation activities including carrier selection, tendering and contract management.

- Improve visibility and communication (between Buyers, Transportation, Carriers, and Service Vendors) of order status, and improved delivery performance.

- Centralize appointment scheduling to remove schedulers at each warehouse

Highlights of the Retail Transportation Case Study

- 2nd largest food and drug retailer in the United States

- Deployed One Network Transportation and Appointment Scheduling solutions in less than 3 months

- Centralized transportation and appointment scheduling processes

- Delivered a single systemic platform across Manufacturing and Retail Transportation Operations

- Reduced scheduling overhead by 90%

One Network’s Logistics Management Solution Selected

Safeway selected One Network’s Intelligent Logistics solution , utilized One Network’s Logistics Network, which was already used by approximately 25% of the Grocery Industry. Within the Intelligent Logistics solution Safeway activated the Transportation Management and Appointment Scheduling solutions.

Albertsons’ Safeway Transportation Network

- Approximate Annual Appointments: 533,463

- Approximate Annual Tenders: 81,328

- Core Carriers: 319

- Number of Carriers Scheduling On-Line: 1604

- Number of Users: 176 Users

“One Network has successfully allowed Safeway to streamline and centralize our transportation and appointment scheduling functions. We have benefited by reducing labor costs, improving our supply chain predictability and visibility, and reducing overall transportation costs.” – VP Transportation, Safeway

Logistics & Transportation Management Solution – The Results

Within 78 days from contractual signature, Safeway had rolled out an automated solution across their entire business providing corporate-wide purchase order visibility, online carrier selection and tendering, and in-route shipment visibility from their manufacturers to their distribution centers.

Additionally Safeway centralized the storage and maintenance of contracts, which resulted in dramatic increase in compliance worth a large six figure bottom line improvement. Prior to One Network, Safeway’s Corporate Transportation, established carrier contract guidelines, which were in turn utilized by each transportation specialist when they negotiated rates with their carrier-base. With Corporate Transportation having little measurement and monitoring capabilities, transportation specialist quickly strayed from the corporate contract policies established.

The result was a varying range of Safeway and carrier agreements that did not comply with Corporate Traffic guidelines costing Safeway Corporate Traffic hundreds of thousands of dollars per year.

Finally, Safeway deployed One Network’s Appointment Scheduling solution and centralized their appointment scheduling activities across all their warehouses.

Benefits of the Logistics & Transportation Management Solution

- Delivered a single systemic platform across Safeway’s Manufacturing and Retail Transportation Operations

- 90% reduction in scheduling overhead resulting in $2.35 M in annual cost savings

- 85.38% of appointments scheduled by Safeway vendors and/or carriers

- 100% of transportation and scheduling relevant data captured systemically in a central database repository for analysis and long-term planning. Examples of data captured include load tenders, freight costs, vendor scheduling compliance, and on-time deliveries.

- Vendor delivery date versus requested delivery date compliance

- Carrier turnaround time at Distribution Centers

- Number of orders re-scheduled

- On-time delivery

- Previously procurement phone calls were required to transportation and vendors, in order to identify if delivered freight was scheduled to arrive on time.

Due to the rapid return on investment and significant improvements that Albertson’s have seen with the Safeway project, they will be rolling One Network’s solution out to the whole company.

About One Network Enterprises

One Network offers a unique approach to supply chain management and other multi-party problems. One Network’s cloud platform, the Real Time Value Network , eliminates the traditional divide between planning and execution and enables visibility and data flow across the entire supply network of trading partners – in real time.

Additionally, One Network offers PaaS solutions and developers tools that enable organizations to design, build, and run multi-party applications that solve problems unrelated to their supply chains.

Leading organizations from around the world from nearly every industry have joined One Network, helping to transform industries including CPG, Healthcare, Automotive, Retail, Logistics, and Public Sector and Defense. Headquartered in Dallas, One Network also has offices in China, Europe, and India.

1.866.302.1936 (toll free) CALL

[email protected] EMAIL

Click here to REQUEST A DEMO

Click here to JOIN THE NETWORK

Sign up for our Newsletter

Check your inbox or spam folder to confirm your subscription.

Logistics and Transportation Cases

OUR CLIENTS

Our large clients play leading roles in various sectors of the European economy.

The management within all of these corporations understand what they want and need. Their experience means they appreciate high-quality services and expect a certain level of expertise in shipping and logistics. This means that they are selective in their choice of logistics companies for strategic partnership.

THE OPPORTUNITY

To obtain freight logistics solutions that raise the standards of efficiency and cover all the needs within this area.

WELL PACK offers its own vehicle fleet and has developed a robust network of warehouses throughout Europe.

We cooperate with companies that produce reusable plastic boxes. WELL PACK transports their RPCs to washing and back on a regular basis, easily managing high volumes. We transport plastic boxes for their customers, and provide pallet exchange for them, with transport customer service available 24/7. It is possible to track the shipments at any point of transportation. New technologies are continuously developed as one of the main goals is to automate the working processes as much as possible. WELL PACK is always optimizing routes, transport costs, and logistics solutions.

Transportation and logistics is a crucial element for many businesses. For example, food logistics and e-commerce logistics are in high demand today, as the COVID-19 pandemic has drastically changed buyers’ preferences. To satisfy this demand, WELL PACK utilizes its vehicle fleet that consists of various types of transport means in different sizes, weight limits, and designed purpose:

- small trucks

- boxes/fridges, etc.

WELL PACK perfectly suits the concept of “freight forwarding companies near me,” as it is represented in 14 European countries and is able to cover long distances quickly. Our “logistics locations” include the Czech Republic, Austria, Germany, United Kingdom, Poland, Romania, Greece, France, Serbia, Ireland and Hungary.

The routes are made with the highest possible accuracy to minimize the travel time, reduce fuel consumption, and lower overall costs. The goods can be delivered to the destination point directly or via the transit point, but always on time. This is not limited to only European destinations. WELL PACK aims to meet all the requirements of its customers, and offers a range of additional and related services, including express transportation, storage, packaging, and more.

WELL PACK’s main objective is reached when new clients become long term customers because of our effective transportation and logistics solutions. Coordination and successful planning lead to maximum efficiency of the supply chain. Thanks to large volumes, the company is able to offer lower prices.

Do you have any questions?

You needn’t care about the details with a well-tuned supply chain. WELL PACK will do this for you offering the best logistics solutions that fit your specific business needs and will boost your growth.

Country Czech Republic Germany Austria Hungary Poland Greece Romania Russia