- Open access

- Published: 14 May 2015

Strength and Durability Evaluation of Recycled Aggregate Concrete

- Sherif Yehia 1 ,

- Kareem Helal 1 ,

- Anaam Abusharkh 1 ,

- Amani Zaher 1 &

- Hiba Istaitiyeh 1

International Journal of Concrete Structures and Materials volume 9 , pages 219–239 ( 2015 ) Cite this article

52k Accesses

156 Citations

7 Altmetric

Metrics details

This paper discusses the suitability of producing concrete with 100 % recycled aggregate to meet durability and strength requirements for different applications. Aggregate strength, gradation, absorption, specific gravity, shape and texture are some of the physical and mechanical characteristics that contribute to the strength and durability of concrete. In general, the quality of recycled aggregate depends on the loading and exposure conditions of the demolished structures. Therefore, the experimental program was focused on the evaluation of physical and mechanical properties of the recycled aggregate over a period of 6 months. In addition, concrete properties produced with fine and coarse recycled aggregate were evaluated. Several concrete mixes were prepared with 100 % recycled aggregates and the results were compared to that of a control mix. SEM was conducted to examine the microstructure of selected mixes. The results showed that concrete with acceptable strength and durability could be produced if high packing density is achieved.

1 Introduction

Utilizing recycled aggregate is certainly an important step towards sustainable development in the concrete industry and management of construction waste. Recycled aggregate (RA) is a viable alternative to natural aggregate, which helps in the preservation of the environment. One of the critical parameters that affect the use of recycled aggregate is variability of the aggregate properties. Quality of the recycled aggregate is influenced by the quality of materials being collected and delivered to the recycling plants. Therefore, production of recycled aggregate at an acceptable price rate and quality is difficult to achieve due the current limitations on the recycling plants. These issues concern the clients about the stability of production and variability in aggregate properties. The main goal of the current research project is to investigate variability of aggregate properties and their impact on concrete production. Aggregate strength, gradation, absorption, moisture content, specific gravity, shape, and texture are some of the physical and mechanical characteristics that contribute to the strength and durability of concrete. Therefore, it is necessary to evaluate these properties before utilizing the aggregate. In this paper, properties of recycled aggregate from an unknown source collected over a period of 6 months from a recycling plant were evaluated. In addition, properties of concrete produced with 100 % recycled aggregates were investigated.

2 Background

2.1 economical and environmental impact.

The evolution in the construction industry introduces several concerns regarding availability of natural aggregate resources, as they are being rapidly depleted. Recent statistics showed the increasing demand of construction aggregate to reach 48.3 billion metric tons by the year 2015 with the highest consumption being in Asia and Pacific as shown in Fig. 1 (The Freedonia Group 2012 ). This increasing demand is accompanied by an increase of construction waste. For example, construction waste from European Union countries represents about 31 % of the total waste generation per year (Marinkovic et al. 2010 ; Ministry of Natural Resources 2010 ). Similarly, in Hong Kong, the waste production was nearly 20 million tons in the year 2011, which constitutes about 50 % of the global waste generation (Tam and Tam 2007 ; Lu and Tam 2013 ; Ann et al. 2013 ). Disposal in landfills is the common method to manage the construction waste, which creates large deposits of construction and demolition waste sites (Marinkovic et al. 2010 ; Tam and Tam 2007 ; Naik and Moriconi 2005 ). Efforts to limit this practice and to encourage recycling of construction and demolition waste in different construction applications led to utilizing up to 10 % of the recycled aggregate in different construction applications (Marinkovic et al. 2010 ; Ministry of Natural Resources 2010 ; Naik and Moriconi 2005 ; European Aggregate Association 2010 ; Cement, Concrete, and Aggregates 2008 ; Tepordei 1999 ). Therefore, recycling has the potential to reduce the amount of waste materials disposed of in landfills and to preserve natural resources (Sonawane and Pimplikar 2013 ; Llatas 2011 ; Lu and Yuan 2011 ; Braunschweig et al. 2011 ; Marinkovic et al. 2010 ; Gupta 2009 ; Rao et al. 2010 ; Tam 2008 ; Topcu and Guncan 1995 ).

Demand on construction aggregates worldwide (The Freedonia Group 2012 ).

2.2 Properties of Recycled Aggregate Concrete

Durability and other concrete properties are affected by the use of recycled aggregate in concrete mixes. Research efforts to introduce RA into the construction industry and to address their effects on properties could be classified to the following categories:

Policies, cost and benefits: the goals are to standardize the use of RA in concrete, highlight the cost of capital investments and to emphasize environmental and economic benefits. Land protection and preservation of natural resources are the main benefits of utilizing recycled materials in the construction industry (Hansen 1986 ; Kartam et al. 2004 ; FHWA 2004 ; Oikonomou 2005 ; Tam and Tam 2007 ; EU Directive 2008 /98/EC; Ministry of Natural Resources 2010 ; Marinkovic et al. 2010 ; Ann et al. 2013 ; Silva et al. 2014 ; Lu and Tam 2013 ; Bodet 2014 ).

Evaluation of physical and mechanical properties of RA: absorption, aggregate texture (type of crushers, number of crushing stages), aggregate size and gradation, specific gravity, density, mortar content, percentage and type of contamination, aggregate strength and abrasion resistance are the main properties that affect utilizing RA in concrete production. Variation in the RA properties due to loading, different environmental conditions in addition to the crushing process, contamination and impurities such as wood and plastic pieces, affect concrete properties produced using RA. Mortar adhered to RA lead to lower density, high absorption, and high L.A. abrasion loss. In addition, sulphate and alkali contents cause expansive reactions which can be controlled if the maximum sulphate is in the range of 0.8–1.0 % by mass and alkali content below 3.5 kg/m 3 (Tam et al. 2008 ; De Juan and Gutiérrez 2009 ; McNeil and Kang 2013 ; De Brito and Saikia 2013 ; Akbarnezhad et al. 2013 ; Silva et al. 2014 ).

Mix design and proportioning: direct volume replacement, weight replacement and equivalent mortar replacement are some of the approaches that could be followed to design mixtures with RA. In addition, the mixing process can affect overall concrete properties. Both volume replacements and pre-soaking approaches showed improved properties of concrete produced with RA (Tam et al. 2007a , b ; Cabral et al. 2010 ; Fathifazl et al. 2009 ; Knaack and Kurama 2013 ; Wardeh et al. 2014 ).

Evaluation of fresh and hardened concrete made with RA: there are numerous efforts to evaluate fresh and hardened properties of concrete with RA. Optimizations to determine the percent of RA that could be used without affecting the short and long term performance were also investigated. Design equations based on data collected from many publications were also proposed. In general, the use of recycled aggregate led to reduction in all mechanical properties, in addition to influencing the fresh stage properties and concrete durability due to high absorption and porosity (Xiao et al. 2006 ; Yang et al. 2008 ; Kwan et al. 2012 ; Manzi et al. 2013 ; Akbarnezhad et al. 2013 ; Ulloa et al. 2013 ; Xiao et al. 2014 ; McNeil and Kang 2013 ; Silva et al. 2014 ).

Improving durability of RA concrete: concerns about durability and the long-term performance of concrete with RA are hurdles that limit utilization of RA in many applications. Chloride conductivity, oxygen and water permeability, carbonation depth, alkaline aggregate reaction, sulphate resistance, shrinkage and creep performance, abrasion resistance and freeze resistance are some of the parameters that could be used as durability and long-term performance indicators of concrete material. In general, concrete made with RA showed less durability due to high pore volume which led to high permeability and water absorption. High water absorption is due to cement paste adhered on the aggregate surface. However, this can be countered by achieving saturated surface dry (SSD) conditions before mixing. This might not be practical in some cases of mass production. Therefore, aggregate absorption can be accounted for during the mix design stage by adjusting the mixing water that will be absorbed by the recycled aggregate. Surface coating was another approach to control absorption and improve properties (Olorunsogo and Padayachee 2002 ; Zaharieva et al. 2003 ; Levy and Helene 2004 ; Ann et al. 2008 ; Yang et al. 2008 ; Abbas et al. 2009 ; Thomas et al. 2013 ; Lederle and Hiller 2013 ; Fathifazl and Razaqpur 2013 ; Xiao et al. 2014 ; Ryou and Lee 2014 ). In addition, many research efforts showed that the use of supplementary cementitious materials (SCM) as a replacement for cement or addition by weight can improve concrete durability due to improvement of pore structure and reduction of the volume of macro pores. Fly ash (25–35 %), silica fume (10 %) and ground-granulated blast-furnace slag (up to 65 %) are the most commonly SCM which are used to improve concrete strength and durability properties (Berndt 2009 ; Kou and Poon 2012 ; Amorim et al. 2012 ; Eisa 2014 ).

Microstructure, interfacial transition zone (ITZ) and bond characteristics: close inspection of the interfacial transition zone (ITZ) showed porous microstructure which can be attributed to high porosity and high absorption capacity of the recycled aggregate. In addition, possible cracking due to crunching and processing and exposure to several chemicals and depositions of harmful substances on the surface of aggregate can lead to cracks in concrete and reduction in the bond between the cement and aggregate. The mixing process, less w/c ratio and addition of SCM can improve the ITZ and bond characteristics of recycled aggregate concrete (Otsuki et al. 2003 ; Poon et al. 2004 ; Tam et al. 2005 ; Evangelista and Brito 2007 ; Tabsh and Abdelfatah 2009 ; Xiao et al. 2012 a)

Table 1 summarizes some of the findings, limitations and potential challenges in using recycled aggregate in concrete applications.

3 Aggregates Used in the Study

Quality and availability of recycled aggregate are the main factors towards stable use and introduction of recycled aggregate concrete to the construction industry. The crushed stone aggregate used in the study was obtained from a recycling plant which was established and directed towards reducing waste produced from the construction industry to provide an efficient alternative for the reuse of recycled aggregate. The waste is received and processed to produce several products; however, the main product is aggregate. The process involves crushing, separation of metals by a magnet, manual removal of other impurities (plastic, wood, etc..), and classification of aggregate to different grades based on particle size. The facility produces 5 grades that vary from fine aggregate (grade 5) to 63 mm particle size (grade 3). The percentage produced from each grade depends on the materials delivered to the facility; however, grades 1, 2, 4 and 5 represent about 80 % of the plant production that ensure availability of these grades for the use in the construction industry.

4 Experimental Program

The main objectives of the experimental program were to (i) investigate variability of recycled aggregate properties and their impact on concrete production and (ii) evaluate properties of concrete prepared with 100 % recycled aggregate. Therefore, the experimental program was divided into two phases; Phase 1 deals with evaluation of the aggregate properties and Phase 2 focuses on the evaluation of concrete mixtures utilizing 100 % recycled aggregates. Figure 2 summarizes the experimental program and list of physical and mechanical properties included in the investigation. All results were compared to that of a control mix prepared with virgin aggregate (crushed lime stone). In addition, Scanning Electron Microscopy (SEM) was conducted to examine the microstructure of some samples to provide an idea about the bond strength between cement and aggregate and identify potential weak points within the mix.

Summary of the experimental program conducted in the investigation.

4.1 Phase 1: Evaluation of Aggregate Properties

The recycling facility was the source of the recycled aggregate (RA) used in the investigation. Aggregate was collected at different time intervals to evaluate the effect of consistency and variability in the quality on concrete properties. Only four grades were included in the investigation, grade 1 (maximum size of 10 mm), 2 (maximum size of 25 mm), 4 (mixture of course and fine aggregate along with impurities) and 5 (fine sand). Grade 3 was excluded because of the particle size (63 mm). In this phase, several physical and mechanical properties of aggregate that are directly related to concrete properties were evaluated, as shown in Fig. 2 .

4.1.1 Results of Aggregate Evaluation

Results of the physical and mechanical tests conducted on RA showed expected variations from virgin aggregate mainly due to the presence of mortar adhered on the aggregate which is reflected in the high absorption capacity of the aggregate. Figure 3 shows sample of different aggregate grades used in the study. Small percentage of impurities (wood and plastic chips) was found in the aggregate, such impurities are expected due to the recycling process.

Different grades of recycled aggregates produced by the recycling facility.

Sieve analysis Four batches of RA were obtained from the recycling facility between December 2012 and April 2013. All batches went through the same evaluation to investigate any variability in production. Figure 4 shows the sieve analysis results of the RA and virgin aggregate (control) compared to the upper and lower limits specified by (ASTM C33/C33 M 2013a , ASTM C136 2011a ). Although the gradation varies from that of the control and did not meet any ASTM grading requirements, there was a clear similarity in the gradation of the last 3 batches of each grade which indicates a consistent RA production. Additionally, the authors decided to use the RA to produce concrete without any alteration of the gradations already obtained from the plant. The reasons for the decision are to avoid additional costs and to utilize available gradations to achieve acceptable particle distribution.

Sieve analysis of RA and virgin (control) aggregate.

Aggregate crushing value (ACV) provides an indication of the aggregate strength. Aggregate with lower ACV is recommended to ensure that the aggregate will be able to resist applied loads. The test was conducted on coarse aggregate of different grades. The ACV is calculated as the ratio between the weight passing sieve 2.36 and the original weight. Values were in the range of 20–30, as shown in Fig. 5 a.

Evaluation of physical and mechanical properties of RA.

Abrasion resistance is an indication of the aggregates’ toughness. The Los Angeles (LA) test was conducted according to (ASTM C131 2006 ) and the test results are shown in Fig. 5 b. The coarse aggregates in grade 4 had a higher percentage of weight loss, close inspection showed weak aggregate (small-sized aggregate covered with mortar, Fig. 3 d).

Absorption grades 1 and 4 showed high absorption capacity (up to 8 %) while it was in the range of 3 % for grade 2 and 5. These values indicate high porosity which will require special considerations during mixing to achieve workability and to control water demand.

Soundness Soundness test was conducted according to (ASTM C88. 2013b ) using Sodium Sulphate salt. Coarse aggregates from Grades 2 and 4 were sieved to different sizes and the retained on each sieve was exposed to four cycles of soaking in the solution and drying in air. Figure 5 d shows percentage of the weight loss in size 9.5 mm. There was about 20 % weight loss in grade 2; however, the loss in grade 4 was in the range of 20 to 40 %. The reasons for this high loss in volume from exposure to deicing agents are weak strength and high porosity of the recycled aggregate as indicated by high absorption.

4.1.2 Comparison Between Properties of the Virgin Aggregate and RA

Table 2 shows a sample of the results obtained from the physical and mechanical tests of recycled aggregate in December 2012 and April 2013 respectively. The last three batches indicated a similar trend with slight variations in properties, while aggregate gradation and particle sizes were maintained. However, there was an increase in the specific gravity values of Grade 5, which may have resulted from the addition of asphalt to increase its selling value.

Values obtained from the evaluation of the physical and mechanical properties of RA were compared against the values obtained from the same evaluation process conducted on virgin aggregate, as shown in Table 3 . The results showed that RA has higher absorption capacity due to the mortar adhered on the surface, higher abrasion loss, high crushing value, and soundness loss which could be attributed to previous exposure to weathering and loading.

4.2 Phase 2: Evaluation of Concrete Properties Prepared with Different Grade Combinations

In this phase, extensive evaluation was conducted to select the grade combinations as-delivered that could be used in concrete production to meet the target strength and durability requirements for different applications. Compressive strength, splitting tensile strength, flexural strength, and modulus of elasticity tests were performed to determine suitability of these mixes to different applications. Additionally, the rapid chloride penetration tests (RCPT) (Kwan et al. 2012 ) for all mixes and scanning electron microscopy (SEM) scans to examine the micro-structural features for selected samples were conducted to provide information about the long-term durability.

Materials Grades 1, 2, 4, and 5 as fine and coarse aggregates, in addition, type I cement were used in all mixes. No supplementary cementitious materials were used in the mixes; only high range water reducer admixture was used to achieve the target workability.

Control mix the mix proportioning is based on the absolute volume method to produce self-consolidated concrete (SCC). The main reason for selecting a SCC mix that issues related to workability and aggregate gradation could be emphasized with a SCC mix. In addition, if recycled aggregate (RA) could be used to produce SCC; hence, RA could be used for other mixes with target slump. The following volumetric ratios of 14 % cement, 17.6 % water (w/c = 0.4) and 68.4 % aggregate. The aggregate percentage (68.4 %) was divided into 37.6 % coarse aggregate (crushed lime stone) and 30.8 % fine aggregate based on the optimization of packing density of normal weight fine and coarse aggregates used for the control mix. The target cube compressive strength was 50 MPa (7000 psi) and total slump flow was 500 mm (20 in.) spread.

Packed density of RA based on the volumetric ratios, the weight of grade 1, grade 2 and grade 5 were proportioned and collected in a measuring cylinder has a volume of 10 dm 3 (cubic decimeters), which is equivalent to 10 l. This cylinder is used in determining loose and compacted bulk density of aggregates according to ASTM C29/29 M ( 2009 ). The sum of the design volumes of these materials is 68.4 % of the total volume; however, when the dry materials were placed and tamped in three layers, as shown in Fig. 6 a, the materials occupied 68 % of the volume. This indicates that the mix proportioning utilizing grades 1, 2 and 5 leads to a dense matrix, which in turn should reflect on strength and durability performance.

Evaluation of grades 1,2, 5 combined.

Mix proportioning for recycled aggregate concrete the same volumetric ratios of the control mix was adopted for the recycled aggregate, however, since different grades of the recycled aggregate with different particle sizes were available, the following approach was considered in the current study: (i) in case of mixes contain grades 1 and 2, percentage of the coarse aggregate was divided to 50–50 %, (ii) mixes with grades 1, 4, and 5, 37.6 % of grade 4, 15 % of grade 1 and 15.8 % of grade 5 were used. These ratios were verified according to the packed density as discussed before.

Water and moisture adjustment mixing water of different mixes was adjusted during the mix design stage according to the moisture content and percentage absorption of each grade included in a specific mix. In addition, the decision was to use the same quantity of the admixture used for the control mix and monitor the slump/flow for the mixes with recycled aggregate. The concrete mixes had the same water to cement ratio ( w/c ) and cement content.

Several mixes were prepared utilizing four grades, grades 1, 2, 4, and 5 of the recycled aggregate. Mixes were identified according to the grades used in each mix, for example, Mix 1,2,5 indicates that grade 1, grade 2 and grade 5 were used in that mix. Six mixes from the four grades were prepared in addition to the control mix.

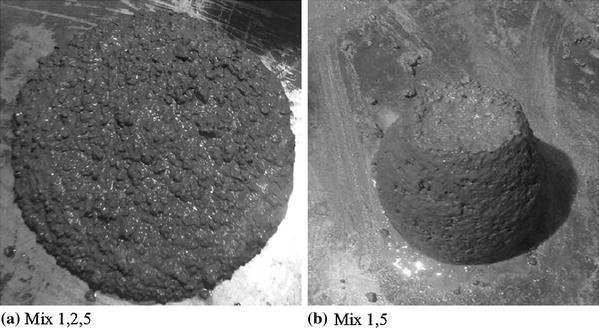

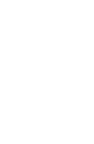

4.2.1 Fresh Stage Evaluation

Table 4 summarizes the results of slump, air content, and unit weight, which were recorded immediately after every mix. All mixes achieved the target flow except Mix 1,5 because of the particle size and distribution. Figure 7 shows slump test for Mixes 1,2,5 and 1,5. Mix 1,4 produced the least unit weight, which could be attributed to the existence of mortar attached to the aggregate as shown in Fig. 3 d. Air content varied between 0.8 and 2.4 % for mixes with recycled aggregate, which indicates variation in aggregate gradation, particle size and distribution.

Fresh stage evaluation—Workability.

4.2.2 Hardened Stage Evaluation: Mechanical and Microstructure Evaluation

Table 4 summarizes the test results of splitting tensile strength and flexural strength for all mixes compared to the compressive strength. Results of split tensile and modulus of rupture from the current study were compared to corresponding equations from BSI EN 1097-2:2010 ( 2010b ) and proposed equations by (Xiao et al. 2006 ). In addition, Table 5 shows typical failure modes of several samples from different mixes.

Compressive strength Cubes (150 mm × 150 mm × 150 mm) were tested for compressive strength according to (ASTM 2011a ) at 3, 7, 14, 21, and 28 days, strength development with time is shown in Fig. 8 . Compressive strength of concrete produced with the recycled aggregate was in the range of 41 to 52 MPa. Mix 4 had the lowest compressive strength. This was expected due to the nature of grade 4, which has poor particle distribution and contains different impurities. Mix 1,4 and Mix 1,2,5 showed similar compressive strength to that of the control. Mix 1,4 consisted of grade 1 (10 mm) as coarse aggregate in addition to grade 4, which has different particle sizes varying from 20 mm and different distribution of fine aggregate. This aggregate gradation provided a dense matrix, which reduces the amount of voids within the mix leading to higher compressive strength. In Mix 1,2,5, grades 1, 2 and 5 provided good distribution of fine and coarse aggregate, which led to higher compressive strength and unit weight similar to that of the control mix. This was also supported by the sieve analysis and packed density as shown in Fig. 6 . On the other hand, Mix 4 had the lowest strength out of all mixes due to the gap-gradation that shows an absence of an appropriate distribution of the coarse aggregate. Most of the aggregate sizes are either 20 mm coarse or fine aggregate. In addition, failure modes were observed during testing as shown in Table 5 . All failure modes were similar to that of the control. Plane of failures did not go through the coarse aggregates, instead the failure was in the mortar or aggregates were pulled out during the flexural tests, as indicated in Table 5 .

Development of compressive strength with time—Phase II.

Splitting tensile strength Splitting tensile tests were conducted according to ASTM C496/C496 M ( 2011b ) to determine indirect tensile strength of concrete. Mix 1,2,5 had the highest splitting tensile strength while Mix 1,5 showed the least splitting tensile strength at 28 days. The test results did not show a clear trend, which might be attributed to the aggregate distribution and particle size. However, values in Table 4 were in the range of 4.6–7.46 % of the cube compressive strength, which is close to the range predicted by Eq. 1 (6–7 %). Split tensile results calculated using Eq. 2 were different from those of the current study and Eq. 1. The predicted values are scattered and not close to the test data.

Flexural strength Third-point loading was applied on simple concrete prisms to determine the flexural strength for all mixes. Mix 1,2,5 and Mix 1,5 showed flexural strength higher or similar to that of the control mix. This could be attributed to the improved mechanical interlocking due to better bond between crushed coarse aggregate and cement paste. This was observed from the failure modes and cracking of aggregate as shown in Table 5 . In addition, results in Table 4 showed that all mixes achieved flexural strength similar or higher than that predicted using Eq. 3. The average ratio of f r / \({{\sqrt{f_{c}^{\prime}}}}\) is 0.85 which is higher than the 0.7 used in Eq. 3; however, it is closer to that proposed by Eq. 4.

Modulus of elasticity Several samples from each mix were tested to evaluate the stress–strain relationship and to calculate the modulus of elasticity values. The modulus of elasticity values were in the range of 25–28 GPa. This variation could be attributed to low aggregate strength and the variation of the volumetric ratio of the course aggregate (some grades have coarse aggregate within their distribution).

Rapid chloride penetration test (RCPT) Ability of concrete to resist chloride ion penetration at 60 voltage direct current (VDC) and 6 h of testing is taken as an indicator of the concrete durability. The results in Coulombs are summarized in Table 4 and categorized according to ASTM C1202 ( 2012b ). All mixes except Mix 1,2,5 had high or close to the upper boundary of moderate permeability which could be attributed to the poor aggregate distribution. On the other hand, Mix 1,2,5 produced similar results to that of the control. The use of two different course aggregate distributions along with the fine aggregate led to a dense mix with less voids and better resistance to the chloride ion penetration.

The SEM scans were conducted on samples of two mixes, which had high and low chloride ion permeability according to the RCPT classifications. Figure 9 a shows a SEM scan for Mix 1,2,5 (low permeability mix), a good bond and no sign of the wall effect at the Interfacial Transition Zone (ITZ) between the cement paste and the recycled aggregate was observed. On the hand, a close inspection to the SEM scans for Mix 1,5 in Fig. 9 b (high permeability mix) shows that a porous layer exists between the aggregate and cement paste, which confirm the formation of the wall effect at ITZ in this mix. This layer, which could be cement hydrates, adhered to the coarse aggregate, in addition to different contaminants and voids contributed to the higher absorption and higher chloride ion permeability in this mix category. In both mixes, micro cracks (not due to sample preparation) were found in the cement paste; this type of cracks usually occur due to shrinkage and difference in modulus of elasticity between the paste and the coarse aggregate particles (Neville 1995 ).

SEM features of concrete with recycled aggregate.

6 Discussion

Results of Phase II evaluations showed that Mix 1,2,5 achieved acceptable compressive, flexural, and splitting tensile strength. In addition, it had the best performance in RCPT which was confirmed with the microstructure evaluation as shown in the SEM scans. The main reason of this performance was achieving high packing density by utilizing different grades. The high packing density provided solution for limitations in particle distribution and aggregate strength. This led to reduction in total pore volume which in turn improved the strength and durability of the mix. This also is in agreement with that reported by (Levy and Helene 2004 ; McNeil and Kang 2013 ). In addition, the absolute volume method used in the current study took into consideration variability in specific gravity of the RA during mix proportioning which led to improved properties. This is also in agreement with the findings by (Knaack and Kurama 2013 ). Examination of the SEM and crack propagation, Fig. 10 , showed that cracks are initiated at the interface between the aggregates and mortar. Figure 10 shows that regardless of the sample shape the cracks started at the pours mortar adhered to the recycled aggregate. This indicates, in this case, a weakness of the old mortar which led to reduced bond between the old and new mortar. Similar behavior was discussed by (Tam et al. 2007a , b ; Xiao et al. 2012 a).

Crack initiation and propagation in RA concrete.

Table 6 provides a summary of the results from several investigations found in the literature compared to that of Mix 1,2,5. The results included in Table 6 are only those of concrete mixes with 100 % RA or from full replacement of coarse aggregate. No results of partial replacement of natural aggregate are included. Although the testing environment, aggregate source, and w/c ratios are different, there is a good agreement in all the mechanical properties. This summary emphasizes that concrete with similar results could be produced with recycled aggregate regardless the source of the aggregate. In addition, the following could be observed from over all the results in Table 6 , (1) RA with high absorption capacity and low specific gravity lead to concrete with less compressive strength compared to target strength; (2) 7 to 15 % reduction in compressive strength compared to target strength when w/cm ratio is maintained in the range of 0.4 to 0.45; (3) flexural and splitting strength varied based on the w/c ratio and aggregate source and (4) reduction of about 10 to 15 % in the modulus of elasticity.

6.1 Recommendations from the Current Study

The following recommendations could be drawn from the study:

For every batch of recycled aggregate:

Particle size and distribution should be evaluated every batch

Absorption capacity, abrasion resistance, and soundness are important properties that need to be evaluated.

Mixture design method based on direct volume replacement and high packing density is the key to achieve strength and durable concrete.

w/c ratio ≤0.4 is preferred to improve strength and durability of concrete with RA

Effect of SCM and high packing density on strength and durability of concrete with RA need to be investigated.

7 Conclusions

The work presented in this paper evaluates the effect of recycled aggregate quality on the properties of concrete. Evaluation of the aggregate physical and mechanical properties showed an acceptable variation in properties when samples were collected and evaluated from unknown source over 6 months. However, limitations in gradation requirements; high absorption and aggregate strength could be resolved during the proportioning stage and by achieving high packing density. Furthermore, concrete produced utilizing different combination of coarse and fine aggregate without alteration in particle size or distribution showed that comparable compressive, flexural, splitting strength, and modulus of elasticity could be achieved. All mixes except Mix 1,2,5 did not show acceptable performance in the RCPT because of the high porosity supported by the examination of the microstructure of the hardened concrete. High concrete porosity and permeability might be attributed to the variability in aggregate gradation and existence of contamination. It is also important to monitor the long-term performance and volume change (creep and shrinkage) to have better assessment of the concrete produced with recycled aggregate.

Abbas, A., Fathifazl, G., Isgor, O. B., Razaqpur, A. G., Fournier, B., & Foo, S. (2009). Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cement & Concrete Composites, 31 (8), 555–563.

Article Google Scholar

Abdelfatah, A., Tabsh, S., & Yehia, S. (2011). Utlilization of recycled coarse aggregate in concrete mixes. Journal of Civil Engineering and Architecture, 5 (6), 562–566.

Google Scholar

Akbarnezhad, A., Ong, K. C. G., Tam, C. T., & Zhang, M. H. (2013). Effects of the parent concrete properties and crushing procedure on the properties of coarse recycled concrete aggregates. Journal of Materials in Civil Engineering, 25 (12), 1795–1802.

Amorim, P., De Brito, J., & Evangelista, L. (2012). Concrete made with coarse concrete aggregate: Influence of curing on durability. ACI Materials Journal, 109 (2), 195.

Ann, K. Y., Moon, H. Y., Kim, Y. B., & Ryou, J. (2008). Durability of recycled aggregate concrete using pozzolanic materials. Waste Management, 28 (6), 993–999.

Ann, T. W., Poon, C. S., Wong, A., Yip, R., & Jaillon, L. (2013). Impact of construction waste disposal charging scheme on work practices at construction sites in Hong Kong. Waste Management, 33 (1), 138–146.

ASTM C131. (2006). Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Angeles machine. West Conshohocken, PA: ASTM International.

ASTM C29/29 M. (2009). Standard test method for bulk density (unit weight) and voids in aggregate. West Conshohocken, PA: ASTM International.

ASTM C78/C78 M-10e1. (2010). Standard test method for flexural strength of concrete (using simple beam with third-point loading). West Conshohocken, PA: ASTM International.

ASTM C136. (2011a). Standard test method for sieve analysis of fine and coarse aggregates ASTM West Conshohocken, PA: ASTM International.

ASTM C496/C496 M. (2011b). Standard test method for splitting tensile strength of cylindrical concrete specimens. West Conshohocken, PA: ASTM International.

ASTM C127. (2012a). Standard test method for density, relative density (specific gravity), and absorption of coarse aggregate. West Conshohocken, PA: ASTM International.

ASTM C1202. (2012b). Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. West Conshohocken, PA: ASTM International.

ASTM C33/C33. M (2013a). Standard specification for concrete aggregates. West Conshohocken, PA: ASTM International.

ASTM C88. (2013b). Standard test method for soundness of aggregates by use of sodium sulfate or magnesium sulfate. West Conshohocken, PA: ASTM International.

Berndt, M. L. (2009). Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Construction and Building Materials, 23 (7), 2606–2613.

Bodet, R. (2014). Review French/European standards and regulations. 08/07/2014 http://navier.enpc.fr/IMG/pdf/Standards_and_regulation_R-BODET.pdf .

Braunschweig, A., Kytzia, S., & Bischof, S. (2011). Recycled concrete: Environmentally beneficial over virgin concrete?, www.lcm2011.org .

BSI EN 12390-6:2009. (2010a). Testing hardened concrete Compressive strength of test specimens. British Standard Institute.

BSI EN 1097-2:2010. (2010b). Tests for mechanical and physical properties of aggregates: Methods for the determination of resistance to fragmentation. London, UK: British Standards Institute.

BSI 812-105.2. (1990). Method for determination of particle size: Elongation index of coarse aggregate. London, UK: British Standard Institute.

Cabral, A. E. B., Schalch, V., Dal Molin, D. C. C., & Ribeiro, J. L. D. (2010). Mechanical properties modeling of recycled aggregate concrete. Construction and Building Materials, 24 (4), 421–430.

Cement, Concrete, and Aggregates (2008). Use of recycled aggregate. Australia: Hong Kong Housing Authority.

Chen, H.-G., & Ying, J.-W. (2011). Analysis of factors influencing durability of recycled aggregate: A review . Paper presented at the electric technology and civil engineering, Lushan.

Chen, Z.-P., Huang, K.-W., Zhang, X.-G., & Xue, J.-Y. (2010). Experimental research on the flexural strength of recycled coarse aggregate concrete . Paper presented at the 2010 international conference on mechanic automation and control engineering (MACE), Wuhan, China.

Corinaldesi, V. (2010). Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Construction and Building Materials, 24 (9), 1616–1620. doi: 10.1016/j.conbuildmat.2010.02.031 .

Corinaldesi, V., & Moriconi, G. (2009). Influence of mineral additions on the performance of 100% recycled aggregate concrete. Construction and Building Materials, 23 (8), 2869–2876.

De Brito, J., & Saikia, N. (2013). Recycled aggregate in concrete: Use of industrial, construction and demolition waste. 445 p., London, UK: Springer.

de Juan, M. S., & Gutiérrez, P. A. (2009). Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Construction and Building Materials, 23 (2), 872–877.

EU. Directive 2008/98/EC of the European Parliament and the Council of 19 November 2008 on waste and repealing certain Directives. European Union.

Domingo-Cabo, A., Lázaro, C., López-Gayarre, F., Serrano-López, M. A., Serna, P., & Castaño-Tabares, J. O. (2009). Creep and shrinkage of recycled aggregate concrete. Construction and Building Materials, 23 (7), 2545–2553.

Eisa, A. (2014). Properties of concrete incorporating recycled post-consumer environmental wastes. International Journal of Concrete Structures and Materials, 8 (3), 251–258.

Etxeberria, M., Vazques, E., Mari, A., & Barra, M. (2007). Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cement and Concrete Research, 37 (5), 735–742.

European Aggregate Association. (2010). Planning policies and permitting procedures to ensure the sustainable supply of aggregates in Europe . Austria: University of Leoben.

Evangelista, L., & Brito, J. D. (2007). Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cement & Concrete Composites, 29 (5), 397–401. doi: 10.1016/j.cemconcomp.2006.12.004 .

Fathifazl, G., & Razaqpur, A. G. (2013). Creep rheological models for recycled aggregate concrete. ACI Materials Journal, 110 (2), 115–126.

Fathifazl , G., Abbas, A., Razaqpur, A. G., Isgor, O. B., Fournier, B., & Foo, S. (2009). New mixture proportioning method for concrete made with coarse recycled concrete aggregate. Journal of Materials in Civil Engineering, 21 (10), 601–611.

Fathifazl, G., Razaqpur, A. G., Isgor, O. B., Abbas, A., Fournier, B., & Foo, S. (2011). Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete aggregate. Cement & Concrete Composites, 33 (10), 1026–1037.

Garg, P., Singh, H., & Walia, B. S. (2013). Optimum Size of Recycled Aggregate. GE - International Journal of Engineering Research . pp. 35–41, ISSN:2321-1717

Gonclaves, A., Esteves, A., & Vieira, M. (2004). Influence of recycled concrete aggregate on concrete durability . Paper presented at the National Laboratory of Civil Engineering, Portugal.

Gupta, Y. P. (2009). Use of recycled aggregate in concrete construction: A need for sustainable environment . Paper presented at the our world in concrete and structures, Singapore.

Hansen, T. C. (1986). Recycled aggregates and recycled aggregate concrete second state-of-the-art report developments 1945–1985. Materials and Structures, 19 (3), 201–246.

Henschen, J., Teramoto, A., & Lange, D. A. (2012, January). Shrinkage and creep performance of recycled aggregate concrete. In 7th RILEM international conference on cracking in pavements (pp. 1333–1340). Springer Netherlands.

Kartam, N., Al-Mutairi, N., Al-Ghusain, I., & Al-Humoud, J. (2004). Environmental management of construction and demolition waste in Kuwait. Waste Management, 24 (10), 1049–1059.

Katz, A. (2003). Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cement and Concrete Research, 33 (5), 703–711.

Knaack, A. M., & Kurama, Y. C. (2013). Design of concrete mixtures with recycled concrete aggregates. ACI Materials Journal, 110 (5), 483–493.

Kou, S. C., & Poon, C. S. (2012). Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Construction and Building Materials, 35 , 69–76.

Kwan, W. H., Ramli, M., Kam, K. J., & Sulieman, M. Z. (2012). Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Construction and Building Materials, 26 (1), 565–573.

Lederle, R. E., & Hiller, J. E. (2013). Reversible shrinkage of concrete made with recycled concrete aggregate and other aggregate types. ACI Materials Journal, 110 (4), 423.

Levy, S. M., & Helene, P. (2004). Durability of recycled aggregates concrete: A safe way to sustainable development. Cement and Concrete Research, 34 (11), 1975–1980.

Limbachiya, M. C., Koulouris, A., Roberts, J. J., & Fried, A. N. (2004). Performance of Recycled Concrete Aggregate . Paper presented at the RILEM international symposium on environmental-conscious materials and systems for sustainable development

Llatas, C. (2011). A model for quantifying construction waste in projects according to the European waste list. Waste Management, 31 (6), 1261–1276.

Lu, W., & Tam, V. W. (2013). Construction waste management policies and their effectiveness in Hong Kong: A longitudinal review. Renewable and Sustainable Energy Reviews, 23 , 214–223.

Lu, W., & Yuan, H. (2011). A framework for understanding waste management studies in construction. Waste Management, 31 (6), 1252–1260.

Malešev, M., Radonjanin, V., & Marinković, S. (2010). Recycled concrete as aggregate for structural concrete production. Sustainability, 2 (5), 1204–1225. doi: 10.3390/su2051204 .

Manzi, S., Mazzotti, C., & Bignozzi, M. C. (2013). Short and long-term behavior of structural concrete with recycled concrete aggregate. Cement & Concrete Composites, 37 , 312–318.

Marinkovic, S., Radonjanin, V., Malesev, M., & Ignjatovic, I. (2010). Comparative environmental assessment of natural and recycled aggregate concrete. Waste Management, Elsevier, 30 (11), 2255–2264.

McNeil, K., & Kang, T. H.-K. (2013). Recycled concrete aggregates: A review. International Journal of Concrete Structures and Materials, 7 (1), 61–69.

Medina, C., Zhu, W., Howind, T., Sanchez de Rojas, M. I., & Frias, M. (2014). Influence of mixed recycled aggregate on the physical-mechanical properties of recycled concrete. Journal of Cleaner Production, 68 (1), 216–225.

Ministry of Natural Resources (2010). State of the aggregate resource in Ontario study. Toronto, Canada: Queen’s Printer for Ontario.

Naik, T. R., & Moriconi, G. (2005) Environmental-friendly durable concrete made with recycled materials for sustainable concrete construction CANMET/ACI international symposium on sustainable development of cement and concrete, Toronto, Canada, October 2005 (pp. 1–13).

Neville, A. M. (1995). Properties of concrete . Harlow, NY: Pearson.

Oikonomou, N. D. (2005). Recycled concrete aggregates. Cement & Concrete Composites, 27 (2), 315–318.

Olorunsogo, F. T., & Padayachee, N. (2002). Performance of recycled aggregate concrete monitored by durability indexes. Cement and Concrete Research, 32 (2), 179–185.

Otsuki, N., Miyazato, S. I., & Yodsudjai, W. (2003). Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. Journal of Materials in Civil Engineering, 15 (5), 443–451.

Padmini, A. K., Ramamurthy, K., & Mathews, M. S. (2009). Influence of parent concrete on the properties of recycled aggregate concrete. Construction and Building Materials, 23 (2), 829–836. doi: 10.1016/j.conbuildmat.2008.03.006 .

Poon, C. S., Shui, Z. H., & Lam, L. (2004). Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Construction and Building Materials, 18 (6), 461–468.

Qasrawi, H., & Marie, I. (2013). Towards better understanding of concrete containing recycled concrete aggregate. Advances in Materials and Science Engineering . doi: 10.1155/2013/636034 .

Rahal, K. (2007). Mechanical properties of concrete with recycled coarse aggregate. Building and Environment, 42 (1), 407–415. doi: 10.1016/j.buildenv.2005.07.033 .

Rao, M. C., Bhattacharyya, S. K., & Barai, S. V. (2010). Recycled aggregate concrete: A sustainable built environment . Paper presented at the ICSBE: International conference on sustainable built environment.

Ryou, J. S., & Lee, Y. S. (2014). Characterization of recycled coarse aggregate (RCA) via a surface coating method. International Journal of Concrete Structures and Materials, 8 (2), 165–172.

Sagoe-Crentsil, K., Brown, T., & Taylor, A. H. (2001). Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cement and Concrete Research, 31 (5), 707–712. doi: 10.1016/S0008-8846(00)00476-2 .

Silva, R. V., De Brito, J., & Dhir, R. K. (2014). Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Construction and Building Materials, 65 , 201–217.

Silva, R. V., de Brito, J., & Dhir, R. K. (2015). Prediction of the shrinkage behavior of recycled aggregate concrete: A review. Construction and Building Materials, 77 , 327–339.

Sim, J., & Park, C. (2011). Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Management, 31 (11), 2352–2360. doi: 10.1016/j.wasman.2011.06.014 .

Sonawane, T. R., & Pimplikar, S. S. (2013). Use of recycled aggregate in concrete. International Journal of Engineering Research and Technology (IJERT), 2 (1), 1–9.

Tabsh, S. W., & Abdelfatah, A. S. (2009). Influence of recycled concrete aggregates on strength properties of concrete. Construction and Building Materials, 23 (2), 1163–1167. doi: 10.1016/j.conbuildmat.2008.06.007 .

Tam, V. W. Y. (2008). Economic comparison of concrete recycling: A case study approach. Elsevier, 52 (5), 821–828.

Tam, V. W., Gao, X. F., & Tam, C. M. (2005). Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cement and Concrete Research, 35 (6), 1195–1203.

Tam, V. W., Gao, X. F., Tam, C. M., & Chan, C. H. (2008). New approach in measuring water absorption of recycled aggregates. Construction and Building Materials, 22 (3), 364–369.

Tam, V. W. Y., & Tam, C. M. (2007). Economic comparison of recycling over-ordered fresh concrete: A case study approach. Resources, Conservation and Recycling, 52 (2), 208–218. doi: 10.1016/j.resconrec.2006.12.005 .

Tam, V. W., Tam, C. M., & Le, K. N. (2007a). Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resources, Conservation and Recycling, 50 (1), 82–101.

Tam, V. W., Tam, C. M., & Wang, Y. (2007b). Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach. Construction and Building Materials, 21 (10), 1928–1939.

Tepordei, V. V. (1999). Natural aggregates—Foundation of America’s future. USGS: Science for a changing world .

The Freedonia Group. (2012). World Construction Aggregates.

Thomas, C., Setien, J., Polanco, J. A., Alaejos, P., & Sanchez de Juan, M. (2013). Durability of recycled concrete aggregate. Construction and Building Materials, 40 , 1054–1065.

Topcu, I. B., & Guncan, N. F. (1995). Using waste concrete as aggregate. Cement and Concrete Research, 25 (7), 1385–1390. doi: 10.1016/0008-8846(95)00131-U .

Transportation Applications of Recycled Concrete Aggregate—FHWA State of the Practice National Review 2004; U.S. Department of Transportation Federal Highway Administration: Washington, DC, 2004; pp. 1–47.

Ulloa, V. A., García-Taengua, E., Pelufo, M. J., Domingo, A., & Serna, P. (2013). New views on effect of recycled aggregates on concrete compressive strength. ACI Materials Journal, 110 (6), 1–10.

Vyas, C. M., & Bhatt, D. R. (2013). Evaluation of modulus of elasticity for recycled coarse aggregate concrete. International Journal of Engineering Science and Innovative Technology, 2 (1), 26.

Wardeh, G., Ghorbel, E., & Gomart, H. (2014). Mix design and properties of recycled aggregate concretes: Applicability of Eurocode 2. International Journal of Concrete Structures and Materials, 9 (1), 1–20.

Xiao, J., Li, W., Sun, Z., & Shah, S. P. (2012a). Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Materials Journal, 109 (4), 451–462.

Xiao, J., Fana, L. Y., & Huang, X. (2012b). An overview of study on recycled aggregate concrete in China (1996–2011). Construction and Building Materials, 31 , 364–383. doi: 10.1016/j.conbuildmat.2011.12.074 .

Xiao, J., Li, L., Tam, V. W., & Li, H. (2014). The state of the art regarding the long-term properties of recycled aggregate concrete. Structural Concrete, 15 (1), 3–12.

Xiao, J. Z., Li, J. B., & Zhang, C. (2006). On relationships between the mechanical properties of recycled aggregate concrete: An overview. Materials and Structures, 39 (6), 655–664.

Yang, K. H., Chung, H. S., & Ashour, A. F. (2008). Influence of type and replacement level of recycled aggregates on concrete properties. ACI Materials Journal, 105 (3), 289–296.

Yehia, S., Khan, S., & Abudayyeh, O. (2008). Evaluation of mechanical properties of recycled aggregate for structural applications. HBRC Journal, 4 (3), 7–16.

Zaharieva, R., Buyle-Bodin, F., Skoczylas, F., & Wirquin E. (2003). Assessment of the surface permeation properties of recycled aggregate concrete. Cement and Concrete Composites, 25 (2), 223–232. doi: 10.1016/S0958-9465(02)00010-0

Download references

Author information

Authors and affiliations.

Department of Civil Engineering, American University of Sharjah, Sharjah, United Arab Emirates

Sherif Yehia, Kareem Helal, Anaam Abusharkh, Amani Zaher & Hiba Istaitiyeh

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Sherif Yehia .

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

Reprints and permissions

About this article

Cite this article.

Yehia, S., Helal, K., Abusharkh, A. et al. Strength and Durability Evaluation of Recycled Aggregate Concrete. International Journal of Concrete Structures and Materials 9 , 219–239 (2015). https://doi.org/10.1007/s40069-015-0100-0

Download citation

Received : 09 October 2014

Accepted : 06 April 2015

Published : 14 May 2015

Issue Date : June 2015

DOI : https://doi.org/10.1007/s40069-015-0100-0

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- recycled aggregate

- concrete properties

- physical properties

- mechanical properties

- Previous Article

- Next Article

Using and optimizing the recycled aggregates in concrete: A review

- Article contents

- Figures & tables

- Supplementary Data

- Peer Review

- Reprints and Permissions

- Cite Icon Cite

- Search Site

Yasir H. Mohammed , Alyaa A. Al-Attar , Firas Kh. Jaber; Using and optimizing the recycled aggregates in concrete: A review. AIP Conf. Proc. 15 December 2023; 2862 (1): 020001. https://doi.org/10.1063/5.0171434

Download citation file:

- Ris (Zotero)

- Reference Manager

Reusing aggregate from building and demolition waste can help protect the ordinary natural aggregate supply, reduce landfill demand, and drive toward a more sustainable environment. This paper examines the recycled history of recycled aggregate and recycled aggregate. A general review of how recycled aggregates were used by previous researchers in recent years and their findings are reviewed in this review paper. In addition, methods for enhancing the mechanical characteristics of recycled aggregate and long-term efficiency such as improving the properties without modifying the recycled aggregate (namely, different concrete mixing designs and the addition of reinforcing fibers) were reviewed. The machine learning model for predicting compressive strength in addition to compressive stress modulus and graphs for recycled aggregate concrete are reviewed, as well as their limitations are discussed. It discusses the research perspectives of recycled aggregate, namely the development of “green” processing methods for recycled aggregate and additional guidance on building a database to predict the strength of recycled aggregate.

Sign in via your Institution

Citing articles via, publish with us - request a quote.

Sign up for alerts

- Online ISSN 1551-7616

- Print ISSN 0094-243X

- For Researchers

- For Librarians

- For Advertisers

- Our Publishing Partners

- Physics Today

- Conference Proceedings

- Special Topics

pubs.aip.org

- Privacy Policy

- Terms of Use

Connect with AIP Publishing

This feature is available to subscribers only.

Sign In or Create an Account

Click through the PLOS taxonomy to find articles in your field.

For more information about PLOS Subject Areas, click here .

Loading metrics

Open Access

Peer-reviewed

Research Article

Compression stress-strain curve of lithium slag recycled fine aggregate concrete

Roles Data curation, Investigation, Software, Writing – original draft

Affiliation Faculty of Civil & Architecture Engineering, East China University of Technology, Nanchang, P.R. China

Roles Conceptualization, Data curation, Funding acquisition, Methodology, Project administration, Resources, Writing – review & editing

Roles Project administration, Validation, Writing – review & editing

* E-mail: [email protected]

Affiliations College of Civil Engineering and Architecture, Wenzhou University, Wenzhou, P.R. China, Key Laboratory of Engineering and Technology for Soft Soil Foundation and Tideland Reclamation of Zhejiang Province, Wenzhou, P.R. China

- Xue-Bin Chen,

- Jiong-Feng Liang,

- Published: April 18, 2024

- https://doi.org/10.1371/journal.pone.0302176

- Reader Comments

As one of the key materials used in the civil engineering industry, concrete has a global annual consumption of approximately 10 billion tons. Cement and fine aggregate are the main raw materials of concrete, and their production causes certain harm to the environment. As one of the countries with the largest production of industrial solid waste, China needs to handle solid waste properly. Researchers have proposed to use them as raw materials for concrete. In this paper, the effects of different lithium slag (LS) contents (0%, 10%, 20%, 40%) and different substitution rates of recycled fine aggregates (RFA) (0%, 10%, 20%, 30%) on the axial compressive strength and stress-strain curve of concrete are discussed. The results show that the axial compressive strength, elastic modulus, and peak strain of concrete can increase first and then decrease when LS is added, and the optimal is reached when the LS content is 20%. With the increase of the substitution rate of RFA, the axial compressive strength and elastic modulus of concrete decrease, but the peak strain increases. The appropriate amount of LS can make up for the mechanical defects caused by the addition of RFA to concrete. Based on the test data, the stress-strain curve relationship of lithium slag recycled fine aggregate concrete is proposed, which has a high degree of agreement compared with the test results, which can provide a reference for practical engineering applications. In this study, LS and RFA are innovatively applied to concrete, which provides a new way for the harmless utilization of solid waste and is of great significance for the control of environmental pollution and resource reuse.

Citation: Chen X-B, Liang J-F, Li W (2024) Compression stress-strain curve of lithium slag recycled fine aggregate concrete. PLoS ONE 19(4): e0302176. https://doi.org/10.1371/journal.pone.0302176

Editor: Kim Hung Mo, University of Malaya, MALAYSIA

Received: November 15, 2023; Accepted: March 27, 2024; Published: April 18, 2024

Copyright: © 2024 Chen et al. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Data Availability: All relevant data are within the paper.

Funding: The authors are grateful to the financial support provided by the Chinese National Natural Science Foundation (No. 52068001), the Project of academic and technological leaders of major disciplines in Jiangxi Province (No.20204BCJL2037), the Natural Science Foundation of Jiangxi Province (No. 20202ACBL214017), the Key R&D Program of Jiangxi Province (No.20212BBG73002), the Key Laboratory for Structural Engineering and Disaster Prevention of Fujian Province (Huaqiao University) (No.SEDPFJ-2020-01) and the research fund of Jiangsu Province key laboratory of Structure Engineering (No.ZD1901). The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Competing interests: The authors have declared that no competing interests exist.

1. Introduction

Concrete is the most common building material in the construction industry and the second largest consumer in the world, with around 10 billion tons of concrete produced worldwide every year and showing an upward trend every year [ 1 ], posing a huge threat to global warming. As an important cementitious material, cement has been widely used in concrete and mortar. As a major cement producer, China’s cement output in 2022 attained 2.13 billion tons, accounting for about 51.17% of the global output, ranking first in the world [ 2 ]. The traditional production of cement is based on the calcination method, which will produce a large amount of CO 2 in the process, which aggravates the completion of China’s "carbon peak" and "carbon neutrality" goals. Human beings will produce a large amount of industrial waste in production and construction, such as fly ash [ 3 ], LS [ 4 ], copper tailings [ 5 ], etc. In addition, according to statistics, the annual consumption of river sand in the world is about 40 billion to 50 billion tons [ 6 ], and river sand alone cannot meet the demand, so there is an urgent need to develop new materials as a substitute for river sand, such as desert sand [ 7 ], coconut shells [ 8 ], recycled fine aggregates [ 9 ], etc. Large amounts of river sand can also pollute water sources and cause problems such as the safety of river embankments. At present, there are a large number of buildings around the world that need to be demolished and waste concrete will be produced in the process. The traditional way of disposing of waste concrete is to landfill or build roads, which not only leads to a large number of waste concrete and is not benignly utilized, but also easily causes problems such as air, soil, and water pollution while occupying land resources. The storage and disposal of this industrial waste, as well as waste concrete, is one of the biggest environmental challenges facing the world today.

In China, with the rapid development of the new energy field, the market demand for lithium batteries is becoming more and more vigorous [ 10 ], and a large amount of lithium slag industrial waste will be generated in the process of producing lithium batteries. According to relevant statistics, about 8–10 tons of LS can be produced for every 1 ton of lithium carbonate produced [ 11 ]. At present, most of the LS is treated by accumulation, landfill, etc., which will not only lead to a waste of land resources but also cause great harm to the surrounding ecological environment [ 12 , 13 ]. Since China is the world’s largest producer of lithium carbonate [ 14 , 15 ], according to China’s industrial development statistics in 2021, the annual output of lithium carbonate will exceed 240,000 tons, mainly distributed in Jiangxi, Xinjiang, and other places [ 16 ]; Therefore, it is necessary to find an effective way to utilize LS to promote the sustainable development of the lithium industry.

The mineral composition of LS is mainly composed of oxides such as silicon, aluminum, and calcium [ 17 , 18 ], which is very similar to the mineral composition of cement. These also makes many researchers use LS as a mineral admixture to partially replace cement, to reduce cement as a necessary binder material in concrete production, thereby reducing construction costs and helping to achieve the goal of carbon neutrality [ 19 – 21 ]. Many scholars have begun to discuss the effects of LS on the properties of concrete from the aspects of the hydration process and microstructure. Zhao et al. [ 22 ] used LS as a mineral admixture to replace cement, and the results showed that it can densify the microstructure of the concrete interface transition zone (ITZ), reduce internal porosity, and improve the aggressiveness of chloride ions and sulfates. Li et al. [ 23 ] also showed that the incorporation of lithium slag can increase the hydration reaction, produce hydrated calcium silicate gel (C-S-H), fill the internal pores, and improve the porosity and macrostructure of concrete. The high SO 3 content in LS limited its high proportion to replace cement [ 24 ], and the addition of LS as a supplementary cementitious composite material would adversely affect the early strength [ 25 ], but Tan et al. [ 26 ] found that the early strength of cement slurry could be improved by wet grinding of LS. Therefore, the use of LS to replace a certain amount of cementing materials can improve the mechanical properties of concrete on the one hand, and provide a new way for the sustainable development of the lithium industry on the other hand.

Today, solid waste is being generated at an exponential rate worldwide. In China, the annual output of construction waste in 2017 was about 2 billion tons [ 27 ], and it is expected that by the end of 2026, the annual output of construction waste will reach 4.0 billion tons [ 28 ]. The study found that every 1 ton of construction waste that was comprehensively utilized can reduce carbon dioxide emissions by about 0.698 tons [ 29 ]. It has been found that shredding construction and demolition waste into RFA for reuse to replace natural fine aggregate to produce new concrete is a very effective way to dispose of construction waste [ 30 , 31 ].

RFA has the defects of high water absorption [ 32 ], sharp and angular particles, and high porosity [ 33 ], which also limits its application in engineering practice. How to use RFA as a building material to produce concrete has attracted the interest of many researchers and scholars. Huang et al. [ 34 ] found that replacing natural fine aggregate with RFA can improve the early strength of concrete, but the later strength is still lower than that of natural fine aggregate concrete. Kirthika et al. [ 35 ] found that the use of RFA can negatively affect the durability performance of concrete. Therefore, to make up for the shortcomings of RFA. Some researchers have tried to reprocess RFA [ 36 – 39 ], use fibers [ 40 ], mineral admixtures [ 33 ], and other methods [ 41 ] to improve the mechanical properties of concrete, and have achieved good results. Gao et al. [ 42 ] found that the incorporation of mineral admixture can reduce the porosity, average pore size, and maximum pore size of recycled aggregate concrete (RAC). Barragan-Ramos et al. [ 43 ] found that the incorporation of RFA into concrete increases its conductivity, but the use of 20% fly ash can mitigate the adverse effects of RFA, thereby increasing resistance to chloride ion penetration. In this study, LS was ground into powder as a mineral admixture to replace cement and added to RFA concrete, to give full play to the advantages of the volcanic ash effect of LS and make up for the defects of RFA.

At present, many scholars have studied the single materials of LS and RFA [ 19 , 20 , 44 , 45 ], but there are relatively few studies on the coupling of the two materials to concrete. Most of the studies focus on the basic mechanical properties of lithium slag recycled coarse aggregate concrete, and there are few studies on the stress-strain curve of lithium slag recycled fine aggregate concrete. In this study, the purpose of this study is to analyze the effects of LS content and RFA substitution rate on the axial compressive strength, peak strain, stress-strain curve shape, and elastic modulus of concrete, and to propose a stress-strain curve model of lithium slag recycled fine aggregate concrete. It is found that the incorporation of an appropriate amount of LS can make up for the mechanical defects caused by the RFA so that the axial compressive strength and elastic modulus of concrete are less different from the benchmark values, which can provide a theoretical basis and reference for the application of RFA in concrete load-bearing structures in the later stage.

2. Experimental program

2.1 materials.

The cement used in this test is M32.5 cement, the physical properties are shown in Table 1 , and the chemical composition is shown in Table 2 . LS was provided by an enterprise in Wanzai County, Jiangxi Province, and the average particle size was 13.21 μm after drying and grinding by a laboratory ball mill for 1 hour, and the cumulative distribution curve of LS and cement particle size is shown in Fig 1 . The specific chemical composition of LS is shown in Table 2 , and the physical properties are shown in Table 3 .

- PPT PowerPoint slide

- PNG larger image

- TIFF original image

https://doi.org/10.1371/journal.pone.0302176.g001

https://doi.org/10.1371/journal.pone.0302176.t001

https://doi.org/10.1371/journal.pone.0302176.t002

https://doi.org/10.1371/journal.pone.0302176.t003

Natural river sand (RS) comes from Jiangxi Nanchang Changxin Cement Building Materials Co., Ltd., with a fineness modulus of 2.74, which belongs to the middle and in the second zone, with good gradation, and the physical properties of river sand are shown in Table 4 . RFA taken from abandoned concrete blocks on broken road surfaces at East China University of Technology, automatically crushed by the crusher and then manually screened with a particle size of less than 4.75 mm, its fineness modulus is 2.18, the flow chart of RFA crushing is shown in Fig 2 , in order to ensure that the surface reaches a saturated and wet state, the RFA used in the test is soaked in water for 24 hours, and its physical properties are shown in Table 4 . SEM plots of RS and RFA are shown in Fig 3 , the particle size sieving curve is shown in Fig 4 .

https://doi.org/10.1371/journal.pone.0302176.g002

(a) RS. (b) RFA.

https://doi.org/10.1371/journal.pone.0302176.g003

https://doi.org/10.1371/journal.pone.0302176.g004

https://doi.org/10.1371/journal.pone.0302176.t004

The coarse aggregate was provided by Jiangxi Nanchang Changxin Cement Building Materials Co., Ltd. In China, the maximum particle size did not exceed 31.5mm. The physical properties of the coarse aggregate are shown in Table 5 , the grading curve is shown in Fig 5 .

https://doi.org/10.1371/journal.pone.0302176.g005

https://doi.org/10.1371/journal.pone.0302176.t005

The water used in this laboratory is the tap water provided by the structural laboratory, which meets the requirements of the concrete mixed water specification JGJ63-2006 through the relevant tests, and the water quality analysis results of the mixing water are shown in Table 6 .

https://doi.org/10.1371/journal.pone.0302176.t006

2.2 Mix proportions

In this paper, the influence of two factors, LS partially replacing cement mass (0, 10%, 20%, 40%) and RFA partial substitution of river sand mass (0, 10, 20%, 30%) on concrete prismatic specimens. A total of 16 groups of different mix ratios were designed, and 48 pieces of 100mm×100mm×300mm non-standard prismatic specimens were made for measuring the axial compressive strength of prism and the stress-strain relationship curve. There is a certain conversion coefficient between the axial compressive strength of standard prism specimens and non-standard prismatic specimens, with a conversion coefficient of 0.95. The design strength of the test concrete is C30, the concrete trial strength is 38.225MPa, and the mix ratio is designed by JGJ55-2011 "Ordinary Concrete Mix Design Regulations", as shown in Table 7 .

https://doi.org/10.1371/journal.pone.0302176.t007

2.3 Preparation of test specimens and testing methods

This test specimen was mixed was a single-horizontal shaft concrete mixer. The feeding sequence of all raw materials was gravel, RS, RFA, cement, and LS, and after 90 seconds of dry mixing, all materials were dry mixed evenly, then slowly added water to the mixer, and let the concrete mixer continue to mix for 1 minute to ensure that all the materials were mixed together, and the water was evenly mixed. The test specimen should be treated with an air pump 24 hours after pouring and forming, and then placed in the water tank for 28 days of curing, then taken out and dried naturally for testing. The test used a YAW-3000 microcomputer-controlled electro-hydraulic servo-pressured testing machine, and the maximum capacity of the pressure machine was 3000 kN. During the axial compressive strength and stress-strain test of the prism, the displacement control loading mode was adopted for control, and the loading rate was set at 0.3mm/min. During the test, the computer automatically collects the load and vertical deformation data of the concrete test block.

3. Results and discussion

3.1 axial compressive strength.

Fig 6 shows the typical failure mode of the axial compression of the prism of lithium slag recycled fine aggregate concrete. From the point of view of the whole failure process, when the specimen started to be loaded, there was no crack on its surface. The cracks began to develop downwards. At this time, the cracks were wider and quickly penetrated the entire test specimen. At the same time, many small cracks gradually appeared around the surface of the test specimen, followed by a violent sound, and the load value dropped rapidly. The test specimen failure occurred due to loss of bearing capacity and eventually became a cone-shaped failure, which was manifested as an obvious brittle failure. The axial compressive failure process of the lithium slag recycled fine aggregate concrete group and the benchmark concrete group was very similar. But with the increase of the replacement rate of RFA, the failure process was slightly shorter than that of no RFA, and during the failure process, the debris produced by the specimen increased. From the perspective of the internal structure of concrete failure, when the LS content is less than 20%, the failure surface is basically a fracture between the coarse and fine aggregates. When the LS content exceeds 20%, the failure surface is basically the fracture phenomenon caused by the insufficient adhesion between the coarse and fine aggregates and the cementitious material.

https://doi.org/10.1371/journal.pone.0302176.g006

It can be seen from Fig 7 that with the increase of LS content, the axial compressive strength of lithium slag recycled fine aggregate concrete first increases and then decreases, and its peak value is when the LS content is 20%, This is similar to the results of Qin et al [ 46 ]. The axial compressive strength of the LS content is even lower than that of the control group’s concrete axial compressive strength. The reason can be attributed to the fact that the incorporation of an appropriate amount of LS can refine the cement pores, while the excess LS cannot produce enough hydrated calcium silicate gel to fill the concrete pores, resulting in the enlargement of concrete pores [ 11 , 13 , 20 ]. When only the influence of the substitution rate of RFA on the axial compressive strength of concrete is considered, with the increase of the substitution rate of RFA, the axial compressive strength of RFA concrete shows a downward trend, and the more the dosage, the more obvious the downward trend [ 47 , 48 ], because the RFA will produce more microcracks when it is crushed, and its composition contains fine powder, mud and harmful substances, etc., which hinder the cementation of cement and aggregate, and cannot effectively fill the gap between the coarse aggregate, resulting in the reduction of concrete compactness and the increase of porosity [ 49 , 50 ]. When the two materials act together in the concrete, the appropriate amount of LS will make up for the defects caused by the RFA, such as the axial compressive strength of LS10-RFA10, LS20-RFA10 and LS20-RFA20 is higher than that of the reference group, because the chemical composition of LS contains a large amount of SiO 2 , Al 2 O 3 and CaO, etc. These chemicals can have a secondary hydration reaction with the hydration product Ca(OH) 2 in cement. A hydrated calcium silicate gel (C-S-H) with a certain strength is generated, which can be filled in the microcracks produced by the crushing of concrete pores and RFA, resulting in a decrease in porosity, and its axial compressive strength is higher than that of the non-mixed LS group.

(a) LS. (b) RFA.

https://doi.org/10.1371/journal.pone.0302176.g007

3.2 Elastic modulus

The elastic modulus E C of concrete is defined as the ratio of compressive strain to stress under unidirectional compression, and the secant modulus from the initial point to the 0.4f cp point in the rising section of the stress-strain curve is generally taken as the E C value. Fig 8 shows the result value of the elastic modulus of lithium slag recycled fine aggregate concrete. Compared with the axial compressive strength results of the prism, it is found that the elastic modulus value is very similar to the axial compressive strength value of the prism. With the increase of LS content, the elastic modulus of concrete increases first and then decreases, and when the LS content is 20%, its elastic modulus reaches the optimum [ 46 , 51 ]. With the increase of the RFA substitution rate, its elastic modulus decreases with the increase of the RFA substitution rate [ 52 – 54 ]. Compared with RFA0, RFA10, RFA20 and RFA30 decreased by 15.61%, 33.17% and 49.23% compared with RFA0 when the LS content was 0%. When the LS content was 10%, it decreased by 4.68%, 27.21% and 35.95%. When the LS content was 20%, it decreased by 9.37%, 22.92%, and 34.60%. When the LS content was 40%, it decreased by 18.22%, 41.63%, and 63.19%. The cause analysis is consistent with the analysis of the cause of the axial compressive strength of the lithium slag recycled fine aggregate concrete prism, and will not elaborate too much here.

https://doi.org/10.1371/journal.pone.0302176.g008

3.3 Stress-strain relationship

The stress-strain relationship curve between LS content and concrete is shown in Fig 9 . The stress-strain curves of concrete show similar rules regardless of the substitution rate of RFA, which are composed of rising and descending sections. The analysis of Fig 9 shows that the curve of the ascending section shows great differences when different RFA is applied. With the increase of the substitution rate of RFA, the curve slope will be more gentle, which also indicates that its elastic modulus is decreasing. In the descending section of the stress-strain curve, there is also a certain difference when the RFA is regenerated with different substitution rates, and the curve changes in the descending section are steep at first and then gradually tends to be flat when the substitution rate of the RFA increases. This is because the RFA itself has many cracks and high porosity defects, the higher the substitution rate, the more it shows the characteristics of crushing, which makes the curve rise section perform steeper, with the increase of the load, some of the RFA is completely crushed, filled in the concrete void, so that the curve in the descending section is more gentle.

(a) Sample with 0% LS content. (b) Sample with 10% LS content. (c) Sample with 20% LS content. (d) Sample with 40% LS content.

https://doi.org/10.1371/journal.pone.0302176.g009